| Pages:

1

..

54

55

56

57

58

..

66 |

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Sublimatus  | I don't think that's right. In my last run I didn't add the t-butanol until after the white smoke had been generated and escaped from the

apparatus between 90 and 130 C.

Next time I try this I'm going to include a cold trap to try to condense the smoke and see what it is. |

Huh, that's really strange. I would have bet money on it being the alcohol. If you can collect some I'm very interested in what it is. Sounds like you

used a number of different oils so it's probably not from any particular solvent, either. Weird...

|

|

|

Sublimatus

Hazard to Others

Posts: 108

Registered: 8-6-2011

Member Is Offline

Mood: No Mood

|

|

I also thought it was the alcohol, up until that last run where I forgot to add it before heating things up.

I'm preparing another run now. I've set up a trap at the end of the apparatus that I'm going to cool with a methanol/dry ice mixture to try to

capture whatever that gas or aerosol is. It's most definitely overkill, using such a strong coolant, but I figured I'd just bring out the big guns

right away, rather than screwing around.

__________________________________________________

Edit:

Disappointingly, the smoke was not generated violently enough to even make it to the trap. It filled the head space in the roundbottom quite densely,

but after a minute or so disappeared (without passing up through the condenser).

It seems clear that at least part of the smoke isn't the alcohol. If it was water, I think it would simply reflux under the condenser without

dissipating, though I suppose it could be consumed in some reaction in the flask.

I'll have to run this again later with the same conditions as my fifth experiment to get the violent generation of smoke. This time I ran the

magnesium through a coffee grinder, and smashed the potassium hydroxide pellets under oil in a mortar in pestle. Why this made the smoke generation

less violent, rather than more, I don't understand.

I'll report my failure or success in a few hours.

[Edited on 6/19/2013 by Sublimatus]

|

|

|

hyfalcon

International Hazard

Posts: 1003

Registered: 29-3-2012

Member Is Offline

Mood: No Mood

|

|

I'm looking for a nickel crucible. I'm thinking about running a batch of KOH through a cycle of 800C for about 4-5hrs then see if that helps things

along somewhat.

|

|

|

MyNameIsUnnecessarilyLong

Hazard to Self

Posts: 71

Registered: 12-7-2010

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by hyfalcon  | I've got less then an hour of reflux left. It isn't looking too good at the present. Air is definitely not enough cooling. I stacked two condensers

and a fractionating column together to keep things under reflux. I don't know if we are starting out dry enough for this to work right or not. How

hard is it to dry your KOH out somewhat before starting? I used 500ml of a water thin paraffin based lamp oil. MSDS says that it boils at 220 C. I

added 61.9 g of KOH to a 1000ml 2-necked flask along with 10.5g of 200-325 mesh pyro grade Mg along with 10.5g of Mg chips and then 10.5g of Mg

turnings. I had the normal H2 emission at the expected temperatures. If I did anything wrong in retrospect, I think I used too much t-butanol. I

tried something different to to t-butanol. I added 3ml at the start and mixed another 7ml in some extra lamp fuel and added to a sep funnel that I

had on the second neck. After I started hard reflux and start dripping the extra t-butanol in on a timed release. I'll report back when the reflux

is done and things have cooled and I can check for fines.

|

62g KOH/31g Mg (just chips), and water-thin paraffin oil is exactly what I used in my reaction. Except I used about .4mL more t-butyl than you did and

added it all before heating.

The only difference seems to be the amount of stirring. I swirled my flask approximately every 15 minutes and broke up the hard oxide chunks with a

skewer. Try doing that next time.

I also didn't dehydrate my KOH. Just crushed it from flake purchased from DudaDiesel off ebay.

[Edited on 6-20-2013 by MyNameIsUnnecessarilyLong]

|

|

|

hyfalcon

International Hazard

Posts: 1003

Registered: 29-3-2012

Member Is Offline

Mood: No Mood

|

|

How do you break up the chunks of oxide and keep oxygen out of the system?

|

|

|

MyNameIsUnnecessarilyLong

Hazard to Self

Posts: 71

Registered: 12-7-2010

Member Is Offline

Mood: No Mood

|

|

I didn't. I just opened up a joint and had at it with the skewer. It took me less than a minute to get most of it broken up into 1CM chunks or so.

After closing it up, I purged the system with more butane.

|

|

|

Sublimatus

Hazard to Others

Posts: 108

Registered: 8-6-2011

Member Is Offline

Mood: No Mood

|

|

As I understand it, that could be a very bad idea, depending on the solvent being used.

220 C is at or in excess of the autoignition temperature of kerosene, depending on the grade. The introduction of oxygen from outside the apparatus

could start a spontaneous fire. It would probably be a spectacular disaster, given <strike>then</strike> that the solvent would burn,

potentially followed by the finely ground magnesium.

The autoignition temperature for mineral spirits is a bit higher, and I imagine it should be even higher for mineral oil. In any case, be careful.

The reaction I started yesterday seems to have failed to produce potassium. One thing I've come to realize is that quite a bit of magnesium is left

after stopping the reaction. I'm not sure if this is due to passivation (the magnesium is coated in something black), or insufficient temperature

(the kerosene maxes out at 184 C reflux). I may go back to trying mineral oil, since 220+ C can be achieved, and I'm using different potassium

hydroxide and magnesium than I used the one time I attempted this reaction with mineral oil.

[Edited on 6/20/2013 by Sublimatus]

|

|

|

hyfalcon

International Hazard

Posts: 1003

Registered: 29-3-2012

Member Is Offline

Mood: No Mood

|

|

I've had some etching in my 1000ml 2 neck using this solvent. Make me think things where kind of "wet".

|

|

|

MyNameIsUnnecessarilyLong

Hazard to Self

Posts: 71

Registered: 12-7-2010

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Sublimatus  | As I understand it, that could be a very bad idea, depending on the solvent being used.

220 C is at or in excess of the autoignition temperature of kerosene, depending on the grade. The introduction of oxygen from outside the apparatus

could start a spontaneous fire. It would probably be a spectacular disaster, given <strike>then</strike> that the solvent would burn,

potentially followed by the finely ground magnesium.

The autoignition temperature for mineral spirits is a bit higher, and I imagine it should be even higher for mineral oil. In any case, be careful.

|

I did let it cool a bit to the point where it was no longer boiling before I opened it.

I'm running the same reaction again right now (62.7g KOH/33g Mg/10.4mL t-butyl) with the same solvent used in my last run. My IR thermometer gives an

average reading of 252F when it's at full boil. White smoke became vigorous at a mere 130F, then it completely halted for about a minute and quickly

picked up once again at 180F. This intermittent production of smoke continued at least 5 more times. Can anyone speculate why this would occur in

periods instead of as one continuous production?

EDIT: The medium has turned quite cloudy and white gel is building up just above the meniscus. Temperature of the solution now reads 280-293F, while

the glass portion above the liquid fluctuates between 215-245F

+2.5 hours later: solution now looking pretty clear with no apparent gel, and oxide is settled out on top of shiny magnesium. I carefully cracked the

oxide with a skewer to expose the unreacted magnesium and am now swirling the flask every 15 minutes. Temp now averages at about 330F.

+2 hours after breaking the oxide ^ and swirling every 30 mins, solution has gradually progressed from light gray to dark gray, and a few .5mm - 1mm

balls of potassium can be seen when the flask is swirled. Temp is still at 330F

So, looks like it's perfectly OK to reuse solvent from previous (completed) reactions. I noticed my condenser with RT coolant still wasn't able to

condense whatever was distilling off early on. Next time I'll try either chilled coolant or a longer column.

17g of magnesium was prepared on a lathe last night over the span of about an hour, the other 15g was left over from about 4 days ago. Both times I

just captured the chips into an empty container in open air as they were coming off; no oil was used to prevent oxidation. The 62g KOH was crushed in

about 5 minutes then put into a small bottle and covered with cling wrap. I stored the Mg this way too, and both the KOH and Mg were allowed to sit

overnight like this before being put into the reaction.

[Edited on 6-21-2013 by MyNameIsUnnecessarilyLong]

|

|

|

Sublimatus

Hazard to Others

Posts: 108

Registered: 8-6-2011

Member Is Offline

Mood: No Mood

|

|

Yes, that sounds fine. My apologies if what I wrote came across condescendingly.

I just wanted to mention the possibility. Now and in the future there may be readers who aren't familiar with flash and autoignition points. I think

it would be better to read about it in a thread where it's relevant, rather than becoming aware of them the hard way.

|

|

|

MyNameIsUnnecessarilyLong

Hazard to Self

Posts: 71

Registered: 12-7-2010

Member Is Offline

Mood: No Mood

|

|

This is the size of the magnesium I used: http://i.imgur.com/ZaYEaGP.jpg

Reaction just after the white smoke ceased: http://i.imgur.com/Lp16lCQ.jpg

Reaction once it became cloudy and a gel precipitate appeared: http://i.imgur.com/D0tFV8U.jpg

Reaction after about 2 hours. Practically no swirling was really done up to this point. Unreacted magnesium lies in bottom of the flask and it's at

this point that I punctured and broke up the hard formations with a skewer and began periodically swirling the flask every 25-30mins: http://i.imgur.com/nJx9tJB.jpg

Reaction apprx 2 hours after breaking the aggregate and periodic swirling. Potassium balls are buried in and obscured by dark sediment but a few were

seen when the flask was tilted: http://i.imgur.com/SS55Edy.jpg

Finally, swirling was stopped for about an hour, dark grey suspension settled out, and the solvent became crystal clear: http://i.imgur.com/KSD8RNz.jpg

A few clips of the vapor stage:

(2nd eruption @ 3:10 mark) http://www.youtube.com/watch?v=gfEGPTO3tZU

http://www.youtube.com/watch?v=8zRoUqoxJxE

Clip of the rxn when solution became like jelly: http://www.youtube.com/watch?v=gZ-1USwUEwI

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

What can I say, MNUL?

In my case, when reaction proceeds, the appearance of the reagent mix evolves like this:

1) KOH flakes start breaking down (presumed loss of water)

2) Solvent starts clouding over (presumed formation of fine MgO)

3) Bottom sludge starts darkening

4) All being well globules of K start slowly appearing from about 1 1/2 to 2 h

In most cases the MgO seems to re-agglomerate.

Have you checked for hydrogen emission?

|

|

|

Pyrocystis Lunula

Harmless

Posts: 2

Registered: 18-6-2013

Member Is Offline

Mood: No Mood

|

|

Success!

Update on my last unsuccessful trial: despite trying to activate the magnesium with iodine and prolonged heating (6 hour minimum) on 2 separate days,

the oxidized magnesium powder did not produce any signs of magnesium. But on to my success!

A 99.95% pure magnesium block was used as my base source. I spent a day trying to figure out how to break it down into powder and turnings. What I

ended up doing was wiping it with an oiled paper towel to prevent any extra oxidation, then took a hack saw to a corner. Oiling the saw kept the dust

that came off in one place and this was collected. I also tried using a steel chisel and hammer to break off small chunks and ended up with irregular

mm sized pieces from that. Finally, I used a drill attachment on a dremel tool because my drill has decided to not work. The turnings felt flaky and

were slightly duller than the other samples, but were used nonetheless. All of this only amounted to 0.8g of shiny, fresh magnesium so I went with a

small scale approach.

The mixed sample of powder, coarse chunks, and turnings were put in a 25 ml flask and 1.6g KOH flakes from the same source as my previous runs were

added. This was put under 25ml of the same hypoallergenic baby oil and 0.4ml of t-butanol was pipetted in. A leibig condenser was attached to the

flask with a rubber stopper and air cooling was run through it. The hot plate was set on high and within a few minutes vigorous bubbling began, The

bubbling was much more vigorous than when the oxidized powder was used. Over the next hours, the magnesium turnings sticking above the KOH and powder

melt slowly darkened to black. The oil remained clear every time I checked in on it. I didn't look at the time when I started and checking now, easily

5 hours later if not longer, I see a shiny blob poking out from the sediment. It does not look like any magnesium or bubbles and doesn't break apart

on swirling so I am confidently stating I was successful, despite sloppy attention to procedure.

So some notes on my efforts so far:

Paraffin wax, as noted further up the thread, is NOT worth using. It was an enormous pain as other members said it would be. Go to your local grocery

or general store and get some baby oil, it works well.

Comparing the original magnesium powder used to the shiny, fresh sample made from the block it is very clear the old powder was heavily oxidized. Dark

grey, oxidized magnesium is once again showing to prevent the reaction from producing potassium. Trying to activate the heavily oxidized magnesium

with a tiny amount of iodine was unsuccessful.

Small scale was successful, no word on yield yet however. When the flask cools, I will try to get an estimate. "One-pot" approach also shown to work

at this scale, not sure if relevant.

It sure is satisfying to see that shiny blob resting in the flask after so many failed attempts. Don't give up those who haven't yet had success! Once

I figure out a better way to process my magnesium block to usable quantities, I'll be scaling this reaction slowly upwards.

|

|

|

MyNameIsUnnecessarilyLong

Hazard to Self

Posts: 71

Registered: 12-7-2010

Member Is Offline

Mood: No Mood

|

|

What diameter was the ball?

|

|

|

hyfalcon

International Hazard

Posts: 1003

Registered: 29-3-2012

Member Is Offline

Mood: No Mood

|

|

I'm about to try ball milling my Mg under some lamp oil. It will make a holy mess, but I should be able to have maximum activation without worrying

out oxidation on the Mg. Just to be on the safe side I'm going to do this remotely and outside.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

'Well done' to Pyrocystis Lunula. Good idea to downscale!

Re. Mg, I must really try my much finer and positively glistening Mg and compare it to my coarser and fairly dull looking reagent grade Mg. I'm still

not convinced Mg is the only source of failure (in those cases where experimenters are seemingly doing everything right).

|

|

|

BobD1001

Hazard to Others

Posts: 182

Registered: 29-3-2013

Member Is Offline

Mood: No Mood

|

|

Well I'm currently on my fifth attempt at this synthesis. All my attempts so far have been faliures to produce elemental K.

Attempts one and two utilized the following reagents:

-Lamplight Medallion lamp oil (about water thin) from Walmart

-Attempts 4 and 5 utilized Ultra Pure Clear Paraffin Oil

-Duda Diesel Potassium Hydroxide

-T-Butyl alcohol from an eBay seller (stated 99.7% purity)

-Fresh magnesium metal turnings from a 15lb AM50A alloy ingot. Approximately 93-95% percent purity with the majority of the remainder being Aluminum.

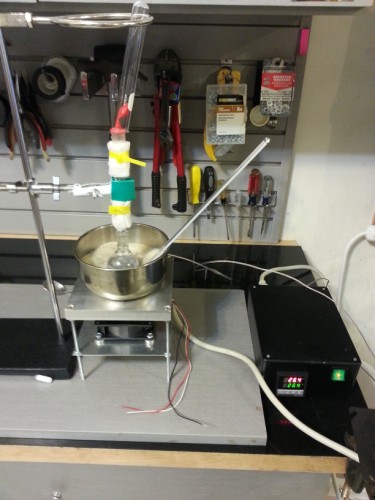

Here is a visual of my setup that I am using:

It consists of a 50ml boiling flask connected to a vigreux column wrapped in paper towels dampened with water/ipa to provide evaporative cooling. No

solvent or t-butyl alcohol seems to escape the vigreux column. There is the a balloon affixed atop the column with small holes poked in it to prevent

air from entering the apparatus as well as adding the t-butyl. Also a test tube is used to catch any hydrogen evolved from the reaction.

My reagents are added as follows: 5g KOH, 2g Mg, 30ml solvent, and .8ml t-Butyl.

I have run into the hydrogen production that everyone seems to mention, as well as this strange phenomenon where my solvent begins to 'harden' above

the meniscus of the solvent in my reaction vessel (a 50ml boiling flask)

Attempts 4 and 5 utilized a new solvent, the Ultra Pure Clear paraffin oil which is said to be excellent for this reaction.

Currently my 5th attempt at this synthesis has been running for 5 hours at the time of writing this, with no signs of potassium production. Each run

my magnesium turnings seem to darken significantly, to the point of being black, but are never reduced to this sand everyone mentions. My other

attempts were terminated after 4 hours, however this 5th run will go for 8 hours to see if my time scale is too brief. My other runs also all utilized

the one-pot method, whereas this time i have been incrementally adding the t-butyl.

I wonder if this could be impurities in the magnesium (notably the ~4-5% aluminum in this alloy) that could be passivating the turnings. Does anyone

have input as to purity of the Mg used?

Here is a picture from the beginning of the current (5th) experiment:

Also of note, I am using my homebuild PID controlled hotplate, which turned out to be a great success, but I am keeping the temp of the plate at

approx 260*C on this current run. The sand bath may be slightly cooler than the plate itself, however, previous runs were done at higher temps,

however it caused my solvent to gel after a while. Attempt 3 even reached 350*C hotplate temp for an hour, but no change in reaction occurred aside

from gelling of the solvent.

Does anyone have some input as to my potential issue here? I am thinking purity of Mg, but could it be the t-Butyl from eBay? (the melting.freezing

point matches literature and the smell matches the camphor like odor that is cited online)

I would like to attempt this with t-Amyl alcohol if anyone would be generous enough to share a small amount of which I can reimburse you for as I

cannot find it in reasonable prices for small quantities online. Or potentially a more pure source of Mg, which I'll purchase right away if the forum

recommends.

[Edited on 25-6-2013 by BobD1001]

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Hmm, aluminum is a good point: that alloy even burns slowly, in my experience, tending to make clumpy brain-like mounds of metal, oxide and nitride

rather than simply burning with the familiar intense white flame. It still works fine for thermite reactions, but so does aluminum.

Any guesses what could be added to destabilize the aluminum (metal, oxide or hydroxide) and potentially prove the culprit and fix the reaction at the

same time?

Tim

|

|

|

MyNameIsUnnecessarilyLong

Hazard to Self

Posts: 71

Registered: 12-7-2010

Member Is Offline

Mood: No Mood

|

|

I'm using the same KOH and T-butyl vender (DudaDiesel/billythec) and Lamplight solvent as you, so it must be your magnesium or the particle size. My

rxn runs at about 170°C but your higher temps shouldn't matter. Maybe purge the air out with propane/butane before heating? Did you stir things up

after the gel formed?

With large magnesium turnings, you might need to add more to compensate for the lower surface area

[Edited on 6-25-2013 by MyNameIsUnnecessarilyLong]

|

|

|

BobD1001

Hazard to Others

Posts: 182

Registered: 29-3-2013

Member Is Offline

Mood: No Mood

|

|

MNIUL,

I have tried agitating the reaction vessel by both swirling, and stirring with a glass stir rod to break up KOH/Mg clumps. My t-Butyl is from a

different seller on eBay, selling it for use as a fragrance carrier, but I believe it is truly t-Butyl due to its matching of cited freezing/melting

temps and smell. I just ordered an ingot of 99.9% pure mg from gallium source, so as soon as it arrives, hopefully there will be some potassium made!

|

|

|

MyNameIsUnnecessarilyLong

Hazard to Self

Posts: 71

Registered: 12-7-2010

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by BobD1001  | MNIUL,

I have tried agitating the reaction vessel by both swirling, and stirring with a glass stir rod to break up KOH/Mg clumps. My t-Butyl is from a

different seller on eBay, selling it for use as a fragrance carrier, but I believe it is truly t-Butyl due to its matching of cited freezing/melting

temps and smell. I just ordered an ingot of 99.9% pure mg from gallium source, so as soon as it arrives, hopefully there will be some potassium made!

|

T-butyl from islandscentsability? I bought from him too, and his stuff is actually what I used in my first run, which was successful. And I used

billythec's in my second run which was also fine.

Can you post a picture with scale of the size of magnesium turnings you're using?

|

|

|

BobD1001

Hazard to Others

Posts: 182

Registered: 29-3-2013

Member Is Offline

Mood: No Mood

|

|

MNIUL,

Here's a picture of my magnesium turnings alongside a zinc brass penny. The turnings are only perhaps a thousandth of an inch thick, and easily turn

to powdery fragments between my fingers. There is also quite a bit of fines along with the turnings, which are of a very fine particle size.

Hopefully the pure Mg i just ordered will do the trick. And have you noticed this reaction taking its toll in your reaction flask? My has been etched

pretty badly, but it still very serviceable.

|

|

|

MyNameIsUnnecessarilyLong

Hazard to Self

Posts: 71

Registered: 12-7-2010

Member Is Offline

Mood: No Mood

|

|

If your chips aren't being reduced to sand, perhaps it's because they're too large. The first failed rxn of mine was with drill turnings from a mg

firestarter block that looked something like that. At the time I just figured it was the quality that was the problem. I'm tempted to retry

firestarter Mg with a finer grade

This reaction will make your flasks ugly but it probably won't render them unsafe to use for heating purposes. My RBF got heavily pitted the first

time doing this because I poured the KOH in first and neglected to stir things, so the KOH pieces sat in the same place for hours. Now, I put

magnesium down first in the flask then lay the KOH on top. Once the water is liberated from the rxn the KOH will no longer etch things as much and you

can stir it and let it rest wherever.

|

|

|

BobD1001

Hazard to Others

Posts: 182

Registered: 29-3-2013

Member Is Offline

Mood: No Mood

|

|

Can anyone direct me to a source for t-Amyl alcohol, I'm spinning my wheels trying to find this stuff in a small quantity ~50ml or so.

If not, would anyone be willing to provide a small quantity to me? I would compensate you for your costs and shipping.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by BobD1001  | Can anyone direct me to a source for t-Amyl alcohol, I'm spinning my wheels trying to find this stuff in a small quantity ~50ml or so.

If not, would anyone be willing to provide a small quantity to me? I would compensate you for your costs and shipping.

|

Where are you?

|

|

|

| Pages:

1

..

54

55

56

57

58

..

66 |