| Pages:

1

..

50

51

52

53

54

..

68 |

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by dangerous amateur  |

| Quote: |

through 7 meters rg6 coax. |

How do you do these tests, did you bury the setup?

7m is extremely short, must be pretty load. How about shrapnel protection? |

No burying theres a sacrificial end on the rg6 which gets destroyed, I am behind a dirt pile and the caseings all plastic plus im already going

deaf

Nux

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

That is a very nice result, 3.6D in penetration!

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Thanks hennig .

Am I right in saying that I should be able to get 7+ cone diameters of penetration (120mm) if everything was perfect with my shaped charge ?

Nuxy

[Edited on 13-9-2015 by nux vomica]

|

|

|

greenlight

National Hazard

Posts: 763

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

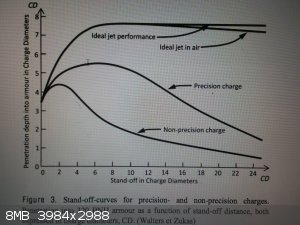

I found a graph in pdf on shaped charge calculation models that may be able to help answer your question. It graphs non-precision charge vs a

precision made charge and then ideal jet performance at the top which would be very hard to explain.

For a non-precision charge it peaks at about 4.5 CD at about 2.5 CD so it seems your standoff was perfect.

Only question is what constitutes a precision made charge because most of the charges on SM are quite precision designed already so where is the line?

I don't know if you could make 7 CD penetration as that is quite high on the table but I couldn't answer until I found out what has to be done to go

from a non-precision charge to a precision one according to the graph

So I've kind of given a question for a question

[Edited on 13-9-2015 by greenlight]

[Edited on 13-9-2015 by greenlight]

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

That 7x cd penetration was a bit pie in the sky greenlight 4.5 sounds more reasonable to me now, I might bump the charge up to 15 grams and see what

difference that makes.

Precision vs. non precision bit of a hard one that maybe there talking about improvised charges vs. military manufactured charges.

thanks Greenlight. nux

|

|

|

greenlight

National Hazard

Posts: 763

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Yes, I think they are talking about military manufactured charges when they say precision.

If enough time is put into putting the charge together and crafting the liner using special equipment, you could come up with something meeting the

"precision" requirements at home surely.

Nux, your liners are perfectly symmetrical and spun on a lathe (proper equipment) if I am correct, they should be above the scale of a non-precision

liner. Maybe more penetration is possible

I wonder if they are made in somewhat the same way in a factory that are designing liners for military use?

I agree with NP, I think you could enhance the penetration depth by using a more powerful explosive.

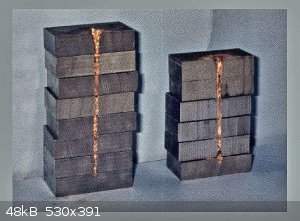

I attached a picture from a page comparing HMX and the new explosive CL-20 in shaped charges and co-crystallization of the two.

CL-20 is on the left and HMX on the right.

It does not state how thick the steel plates are but that is quite a lot of penetration especially considering that the page says that both charges

only had 30 grams of explosive in them!

This also shows that more powerful explosive does help with penetration in CSC's (9100m/s for HMX and 9660m/s for CL-20). The extra 550 m/s gives a

increase of 40% penetration power assuming that the charges had the same confining geometry/liner dimensions.

Differences in heat of explosion, brisance, etc between the two explosives could also increase/decrease penetration I am guessing.

[Edited on 13-9-2015 by greenlight]

[Edited on 13-9-2015 by greenlight]

|

|

|

gnitseretni

Hazard to Others

Posts: 283

Registered: 5-1-2007

Location: Colombia

Member Is Offline

Mood: No Mood

|

|

Nice work Nux! But you sure are making me miss the days when I made shaped charges. Lol!

Based on the graph Greenlight posted... since your cones are very symmetrical, I think you could increase penetration if you increased your standoff.

By increasing standoff you'll stretch the jet and reduce its diameter which should result in deeper penetration.

|

|

|

Joeychemist

Hazard to Others

Posts: 275

Registered: 16-9-2004

Location: Canada

Member Is Offline

Mood: Sedated

|

|

The Precision Linear Shaped Charge (PLSC) design concept basically involves the independent fabrication and assembly of the liner/wedge, the

tamper/confinement, and explosive. The liner is the most important part of a linear shaped charge (LSC) and should be fabricated by a more quality

controlled, precise process than the tamper material. Also, this concept allows the liner material to be different from the tamper material. The

explosive can be loaded between the liner and tamper as the last step in the assembly process rather than the first step as in conventional LSC

designs. PLSC designs have been shown to produce increased jet penetrations in given targets, more reproducible jet penetration, and more efficient

explosive cross-section geometries using a minimum amount of explosive.

PLSC are mainly used in rocket stage separation, parachute system release, flight termination, severance of thick metallic barriers and system flight

abort or disablement. Most of the LSC components for these systems require precise and reproducible jet penetration using the minimum explosive and

component weights.

Some of the disadvantages of conventional LSC designs are as follows: Non-symmetrical cross-section geometries, Nonuniform explosive density (neither

within a plane at a given distance or along the length), Non-optimized explosive and sheath cross-section geometries, Non-reproducible jet

penetrations in target materials, etc...

This is true to an extent but not the only variable... I would also suggest adding more tamping.... The explosive charge to liner mass ratio can be

designed to optimize the transfer of energy from the detonation wave through the liner to the high-velocity jet and the explosive charge to tamper

mass ratio can be designed to optimize the tamper material and thickness too.

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

@Greenlight,

The plates must be 3cm because 30g shaped charge CL-20 is able to pierce through 21 cm iron steel armor (7*3 cm = 21 cm)

[Edited on 13-9-2015 by PHILOU Zrealone]

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by gnitseretni  | Nice work Nux! But you sure are making me miss the days when I made shaped charges. Lol!

Based on the graph Greenlight posted... since your cones are very symmetrical, I think you could increase penetration if you increased your standoff.

By increasing standoff you'll stretch the jet and reduce its diameter which should result in deeper penetration. |

Thanks gnitseretn, its a pity you cant still dabble in them

I am thinking of making the top cone radius larger as I can just get a 1.5 mm rod through the bottom of the hole and think that might enlarge the

hole dia.

With a larger diameter jet and more standoff hopefully I can get some more penertration out of my setup.

Nuxy

[Edited on 13-9-2015 by nux vomica]

|

|

|

ecos

Hazard to Others

Posts: 464

Registered: 6-3-2014

Member Is Offline

Mood: Learning !

|

|

Quote: Originally posted by greenlight  | I went through the document optimized conical shaped charges and photographed a couple of tables that may have answers to some of the problems that

have been arising with the CSC's. The document studys cone angle/diameter, standoff, explosive height/width, liner material/thickness, and explosive

type and tamper.

The first table is different cone angle's and standoff's and their effects.

The second is jet penetration effects from varying explosive height.

The third is a diagram of the final results from all test's incorporated into making a perfect conical shaped charge.

[Edited on 23-8-2015 by greenlight]

[Edited on 23-8-2015 by greenlight]

It seems I was wrong and Ecos was right and the optimum cone angle is 45 degrees with 60 degrees still being effective but any more angle and the

penetration starts to drop off.

So the optimum CSC configuration seems to be:

Cone apex angle 45 Degrees

Liner thickness 0.01 CD (1% cone diameter)

Explosive height 1.5 -2 CD

Explosive width 1-1.4 D

Optimum standoff 2-6 CD

[Edited on 23-8-2015 by greenlight]

[Edited on 23-8-2015 by greenlight] |

according to the tables and the graph of greenlight , the stand-off distance should be around 6 CD.

the angle should be also a good factor. I think the above experiments used 60 degree cones. if it was 45 degree you can reach 1 CD increase in

penetration.

VoD of the EM is an important factor but CL-20 is not easy to be synthesized.

most of the successful setups on internet used (PETN+NG) or plastic ETN.

I found (PETN+NG) gave much better penetration.

Good luck

[Edited on 14-9-2015 by ecos]

|

|

|

greenlight

National Hazard

Posts: 763

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

The graph says that the optimum standoff for a non precision charge peaks at about 2-3 CD.

For a precision charge, optimum standoff appears to be between 4 and 6 CD like ecos said, maybe even up to 8 CD

The only question is because Nux uses proper equipment to form his liners, where does his charge fit on the graph? Precision or non- prescision?

Its probably down to guess work but we will know what category his are in by the penetration of his next CSC test.

[Edited on 14-9-2015 by greenlight]

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by greenlight  | The graph says that the optimum standoff for a non precision charge peaks at about 2-3 CD.

For a precision charge, optimum standoff appears to be between 4 and 6 CD like ecos said, maybe even up to 8 CD

The only question is because Nux uses proper equipment to form his liners, where does his charge fit on the graph? Precision or non- prescision?

Its probably down to guess work but we will know what category his are in by the penetration of his next CSC test.

|

Dont put any pressure on me will you greenlight. Hahaha

[Edited on 14-9-2015 by nux vomica]

|

|

|

gnitseretni

Hazard to Others

Posts: 283

Registered: 5-1-2007

Location: Colombia

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by nux vomica  | Quote: Originally posted by gnitseretni  | Nice work Nux! But you sure are making me miss the days when I made shaped charges. Lol!

Based on the graph Greenlight posted... since your cones are very symmetrical, I think you could increase penetration if you increased your standoff.

By increasing standoff you'll stretch the jet and reduce its diameter which should result in deeper penetration. |

Thanks gnitseretn, its a pity you cant still dabble in them

I am thinking of making the top cone radius larger as I can just get a 1.5 mm rod through the bottom of the hole and think that might enlarge the

hole dia.

With a larger diameter jet and more standoff hopefully I can get some more penertration out of my setup.

Nuxy

[Edited on 13-9-2015 by nux vomica] |

The only way to increase the diameter of the hole while keeping penetration the same is by increasing the whole charge. Liner, amount of explosive,

everything. You don't wanna do that. You can get a slightly bigger hole by decreasing liner angle but you'll sacrifice penetration, which you also

don't wanna do.

The size of the hole is fine. Focus on penetration not the size of the hole.

|

|

|

greenlight

National Hazard

Posts: 763

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

No pressure Nux

Like knitseretni said, keep charge specs the same and see how much penetration can be obtained from it.

|

|

|

greenlight

National Hazard

Posts: 763

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

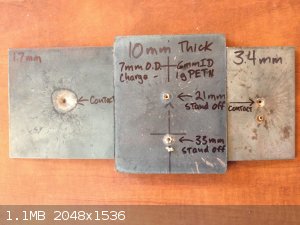

Had a break from trying to catch the EFP slug and decided to try a small scale EFP for a change.

This time diameter of charge was only 18 mm and explosive height was 1.5x liner diameter.

Liner was 1.79g in weight, 0.9mm thick and had a depth of curvature of 3mm.

Charge weight was 9 grams 79/5/16 PETN/RDX/plasticizer/binder.

Target was 6mm steel and standoff was 35 cm.

Result is a nice through and through with a hole diameter of 11mm. I think that it could go through 10 mm which I will eventually attempt as well.

[Edited on 16-9-2015 by greenlight]

[Edited on 16-9-2015 by greenlight]

|

|

|

greenlight

National Hazard

Posts: 763

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

More pictures with scale.

[Edited on 16-9-2015 by greenlight]

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

This began as an experiment on improvised reinforced blasting cap design.

Capsule is made of a 6mm bullet jacket on primary end, pressed inside of a 7mm jacket on output end. Epoxy is applied to exterior of 6mm tube, and a

miniature tubeing cutter is used to swage a locking groove on overlapped area after assembly-

Primary is 350mg of 80:20 Mercury fulminate:Potassium chlorate. A commercial electric match embedded in epoxy putty is used to fire the device.

Base charge is 500mg well pressed & plasticized PETN under 500mg of hand pressed pure PETN.

After a couple of contact tests on steel plates, a couple more shots were tried with 3 and 5 X OD stand offs. The holes in 10mm steel target are at

least 5mm deep- There is still some of the "carrot" down in the hole I could not remove, will section plate and measure full depth later. The output

end seems to behave more as an EFP than a SC- Wide angle of the cavity liner was a fortuitous accident, not my original design intent! Output end

profile of 7mm Copper capsule is spun into it with a 120 degree center punch chucked into a drill press, inspired by Copper smithing disclosed here by

Laboratory of Liptakov-

[Edited on 16-9-2015 by Bert]

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Nice result greenlight looks good.

Bert are you drawing the jackets or are they commercial, nice result as well though .

[Edited on 16-9-2015 by nux vomica]

|

|

|

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

I was wondering if anybody knows why the inside of the holes made by a CSC appear to be lined gold? Is there some kind of alloying of copper with the

steel targets? You note this effect on many of the penetration pics here and I'm curious to know if anybody knows

|

|

|

greenlight

National Hazard

Posts: 763

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

I think it is something to do with when you get new copper pipe it has a nice colour which fades from oxidization in air.

Also, when you cut copper the new cut face is always much brighter in colour.

I think the colour is from the new surface of copper that has been coated on the hole during penetration which oxidizes back to the dull colour after

exposure to air. I think the high temperature and stress energy applied to the copper may contribute to the more golden appearance.

I have noticed the nice gold colour fades to dull brown/orange after a couple of days which supports this.

|

|

|

Joeychemist

Hazard to Others

Posts: 275

Registered: 16-9-2004

Location: Canada

Member Is Offline

Mood: Sedated

|

|

Right, copper is attacked by O2 and CO2 and atmospheric moisture.

2 Cu (s) + O2+ H2O (g) + CO2 = Cu(OH)2 + CuCO3 (s)

This is not a one step process. The copper first oxidizes forming cupric oxide (copper I oxide) . The water and carbon dioxide form carbonic acid

(H2CO3), then the copper I oxide and carbonic acid react forming copper hydroxide and copper carbonate.

The jet from a shaped charge moves at different speeds and that’s why it will stretch. As it stretches it will break up into particles. Also, at the

apex of the cone, which forms the very front of the jet, does not have time to be fully accelerated before it forms its part of the jet. This results

in its small part of jet being projected at a lower velocity than jet formed later behind it. As a result, the initial parts of the jet coalesce to

form a pronounced wider tip portion. As the jet forces through a target, the high pressure and fluid-like behavior of the jet along with the

stretching and break-up of the jet causes the copper to “coat” the inside of target and expose the clean copper that I too really wish was gold.

[Edited on 17-9-2015 by Joeychemist]

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

The 6mm jackets are as provided by Corbin. Only modification is to drill bottom 7/64" and de burr hole for Ematch wire exit point.

The 7mm jackets started out life as .308 x 1.25" long "versatile bench rest" jackets. They have been run through a swage down die intended to make

.284 bullet jackets , are now about 1.4" long. A friend who makes his own jacketed bullets via swaging did this step for me, I'll ask for pictures of

the equipment involved.

I will post additional pictures of the conversion process when I have time-

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Thanks bert I am working on swageing aluminum det capsules at the moment and was wondering if you were starting from flat stock or preformed cups.

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

20 mm shaped charge second try.

Well I had a success and a fail with the second 20mm csc I have a cool looking carrot sticking out of plate no 2, and my tack welds failed so the

plate stack broke apart before I got full penetration.

The charge was exactly the same as charge no 1 but I used 3x standoff and had 100mm of tacked plates on top of the 32mm plate, i still got 79mm

penetration but as I said it looks like the stresses were to much for my tacks so the jet broke the stack apart and it stop penetrating after the 79mm

mark.

Looks like I will need to weld the plates better for the next test nuxy.

[Edited on 18-9-2015 by nux vomica]

|

|

|

| Pages:

1

..

50

51

52

53

54

..

68 |