| Pages:

1

..

3

4

5

6

7

8 |

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Or heck, if you're taking 60Hz alone, you can just PWM that with a source-to-source MOSFET deal (making a fast, bidirectional switch). The PWM can be

open loop, just 0 to 100% adjustable, or can have feedback for speed control or whatever. Mind the circuit will have to be referenced to ground, so

isolation would be a good idea.

An RFI filter, snubber and integrator filter cover the hash in or out.

Tim

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

The inexpensive standard 60 Hz PSC motors most

have Class B insulation and don't have the ruggedness

to long survive in a variable frequency drive or being driven

by a noisy waveform . When they hum to any great extent ,

they are being damaged by magnetostriction and that is what is being heard as the audio signature of the effect .

So for my purposes I am going to stay with 60 Hz , that is simply a given , and vary the voltage , letting the inherent

power feedback of a PSC motor driving an external quadratic load provide *some* stability to the speed , augmenting that power feedback from the

driven load with additional inherent power feedback from a quadratic load which is an ever present parasitic load perhaps amounting to 20% of the

total output realizable from the motor . I am definitely going to use this approach of passive closed loop regulation before

going further to any active closed loop regulation by digital

tachometer and error signal processing which effects active modulation of the power to the motor . Using passive feedback is as easy as putting a

quadratic load on a motor ,

whereupon the speed response of the motor is immediately very different from a completely unloaded motor with a bare shaft sitting in a test cradle

spinning away freely and driving nothing .

Consider the following scenario as in illustration of my idea for passive closed loop inherent speed regulation. A squirrel cage blower wheel is a

quadratic load which can be varied simply by opening up or closing off the intake airflow

to increase or decrease the loading the wheel places on the

driving motor . Suppose you have a blower wheel whose

inside diameter is just a fraction of an inch larger than the case diameter of a double shaft motor which is top mounted vertically with its lower end

hanging in free air . And you invert the blower wheel on the lower shaft so that the motor

body slips inside the blower wheel for half the length of the motor . Now most of the intake area for the wheel has been obstructed by the motor body

so the wheel has been greatly unloaded as compared with its normal free air loading , and

as a bonus some very effective cooling airflow has been added to the motor , even at low speed operation because

the wheel has to pull nearly all its airflow through the openings in the endshields of the motor . The effect of this

parasitic quadratic load on the motor may be further augmented very easily by attaching small permanent magnets on opposite sides of the endshield

which is

within the blower wheel , so that the disc which is the backing plate for the wheel is affected by eddy current loads

induced by the influence of the static fields from the permanent magnets . The intensity of this eddy current braking could be adjusted simply by

raising or lowering

the mounting position of the wheel on the lower shaft ,

to increase or decrease the air gap between the rotating disc and the magnets on the endshield of the motor .

By this scheme there is provided both low speed cooling for the motor and an adjustable quadratic load which conveys

inherent speed regulation to the motor at a given voltage .

Has the term " elegant " come up somewhere in this

discussion ?

Now what were some folks saying about " engineering " ......

Hmmmmm ?

Rosco breathes on fingernails and buffs them against his collar

Need a bigger chair about now , something more

befitting an intellect of such stature

What say you , fellow gentlemen and scholars

Is this good or is this good ?

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Sounds noisy.

Tim

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by 12AX7

Sounds noisy.

Tim |

Oh contrare .

It is a Beckett wheel # F120-42S precision balanced

for 6400 rpm duty , but I'll never run it past 1200 rpm

and it is dead silent and vibration free .

http://www.beckettair.com/fergas-wheels/Fergas-Single-specs....

The clearance between the motor case and the inside tips

of the turbine blades is about 5 mm which is plenty .

A fat O-ring glued to the motor case could even close that gap nearly completely if necessary .

An even closer clearance could be gotten with a # F115-42S

but I have the slightly larger wheel already on hand .

BTW ,

I'm a rambling wreck from Georgia Tech ........

And ........

And .....

How does the rest of that song go ?

I'm A Rambling Wreck

I'm a Ramblin' Wreck from Georgia Tech and a hell of an engineer,

A helluva, helluva, helluva, helluva, hell of an engineer.

Like all the jolly good fellows, I drink my whiskey clear.

I'm a Ramblin' Wreck from Georgia Tech and a hell of an engineer.

Oh, if I had a daughter, sir, I'd dress her in White and Gold,

And put her on the campus, to cheer the brave and bold.

But if I had a son, sir, I'll tell you what he'd do.

He would yell, "To Hell with Georgia," like his daddy used to do.

Oh! I wish I had a barrel of rum and sugar three thousand pounds,

A college bell to put it in and a clapper to stir it round.

I'd drink to all good fellows who come from far and near.

I'm a ramblin', gamblin', hell of an engineer.

[Edited on 5-2-2006 by Rosco Bodine]

|

|

|

densest

Hazard to Others

Posts: 359

Registered: 1-10-2005

Location: in the lehr

Member Is Offline

Mood: slowly warming to strain point

|

|

| Quote: | Originally posted by Rosco Bodine

The inexpensive standard 60 Hz PSC motors most

have Class B insulation and don't have the ruggedness

to long survive in a variable frequency drive or being driven

by a noisy waveform . When they hum to any great extent ,

they are being damaged by magnetostriction and that is what is being heard as the audio signature of the effect .

So for my purposes I am going to stay with 60 Hz , that is simply a given ,

|

The PDM scheme I mentioned puts the first significant harmonic out 64x60 = 4KHz. Run the circuit at 1024x and you're past 16KHz. The reconstruction

filter removes those signals leaving a clean sine wave.

This is a specialized version of what happens inside a CD player.

| Quote: | and vary the voltage to use this approach of passive closed loop regulation before

going further to any active closed loop regulation by digital

tachometer and error signal processing which effects active modulation of the power to the motor .

|

The PDM scheme is open loop. Just input a request for a particular output voltage.

| Quote: |

Using passive feedback is as easy as putting a quadratic load on a motor ,

whereupon the speed response of the motor is immediately very different from a completely unloaded motor with a bare shaft sitting in a test cradle

spinning away freely and driving nothing .

Consider the following scenario as in illustration of my idea for passive closed loop inherent speed regulation. A squirrel cage blower wheel is a

quadratic load which can be varied simply by opening up or closing off the intake airflow

to increase or decrease the loading the wheel places on the

driving motor . Suppose you have a blower wheel...

|

...stuff deleted...

This is a mechanical shunt regulator with corresponding weaknesses and strengths.

This would be interesting if you were aiming for one speed only. By sizing the lossy element correctly and setting the no-load speed correctly with

respect to the torque/speed curve of the motor and the expected load range, you could have a reasonably efficient, quiet, and reliable scheme. At low

speeds < optimum, the load element is ineffective. At high speeds > optimum, the load element consumes all available power.

| Quote: | Has the term " elegant " come up somewhere in this

discussion ?

Now what were some folks saying about " engineering " ......

Hmmmmm ?

Rosco breathes on fingernails and buffs them against his collar

Need a bigger chair about now , something more

befitting an intellect of such stature

What say you , fellow gentlemen and scholars

Is this good or is this good ? |

If this were a computer or electronics group/board you'd find the view from your position nailed upside-down on the dartboard very enthralling

My chemistry knowledge is mostly 40 years out-of-date and I humbly acknowledge the work many people here put into research. For things with wires, I

give PhDs headaches because I'm right more often than they are.

[Edited on 5-2-2006 by densest]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by densest

The PDM scheme I mentioned puts the first significant harmonic out 64x60 = 4KHz. Run the circuit at 1024x and you're past 16KHz. The reconstruction

filter removes those signals leaving a clean sine wave.

This is a specialized version of what happens inside a CD player. The PDM scheme is open loop. Just input a request for a particular output voltage.

|

Can you please provide a schematic or reference ?

(snipped desription of the parasitic quadratic loading scheme)

| Quote: |

This is a mechanical shunt regulator with corresponding weaknesses and strengths. |

Shunt regulators do work don't they ?

| Quote: |

This would be interesting if you were aiming for one speed only. By sizing the lossy element correctly and setting the no-load speed correctly with

respect to the torque/speed curve of the motor and the expected load range, you could have a reasonably efficient, quiet, and reliable scheme. At low

speeds < optimum, the load element is ineffective. At high speeds > optimum, the load element consumes all available power.

|

You are making this more complicated than it is . There isn't any "no load speed" on this eddy current braked system .

There is eddy current parasitic load present from the first movement of the conductor in the field and the load increases exponentially with velocity

. The regulating effect of the quadratic loading is present across the entire speed range , not just at one selected speed . There are actually two

additional quadratic loads on the motor at the driven element end . You see the drive magnet assembly sits beneath a plate of aluminum which is the

hotplate above and there is an even more substantial eddy current load produced there in that plate by the stronger field of the main drive magnet ,

augmented even more when an especially large stirbar intensifies the field through the aluminum plate . Also the load characteristic of the liquid

being stirred is a quadratic load . So the entire loading of the motor is quadratic in nature . The nature of such loads

is that a slight decrease in speed causes a disproportionately

larger decrease in the power required to maintain the lower

speed , while a slight increase in speed requires a disproportionately greater increase in power , so the speed

of the system tends to be self-regulating . This works in harmony with the voltage / current / rpm characteristic of

a PSC motor running from a fixed voltage to give inherent

speed regulation with surprising stability if there is sufficent

amount of the quadratic load to emulate the effect of a

" mechanical governor " on the motor . Another advantage

of this sort of soft coupled speed regulation is that there are no sudden speed changes which would shear the magnetic coupling between the driven

element ( the stirbar ) , and the driving magnet below .

| Quote: |

If this were a computer or electronics group/board you'd find the view from your position nailed upside-down on the dartboard very enthralling  |

If you chillun don't respect your elders , then how can

you ever get beyond just being apprentices

I'm a hardware hacker from way back .

| Quote: |

For things with wires, I give PhDs headaches because I'm right more often than they are.

[Edited on 5-2-2006 by densest] |

I am intrigued by the regulated AC power supply you have described , and if the schematic gives me a headache I'll

probably stick with the components I already have in transit

for the prototype . There is a lot of the KISS philosophy applied to whatever I do , and I know there are other ways

maybe better ways in terms of absolutes . But I also know

it is possible to overdesign something simple and make something more difficult than it has to be . So I am trying to keep this as simple as possible

without really compromising

function which is desired to be only very damn good .......

not perfect

[Edited on 6-2-2006 by Rosco Bodine]

|

|

|

densest

Hazard to Others

Posts: 359

Registered: 1-10-2005

Location: in the lehr

Member Is Offline

Mood: slowly warming to strain point

|

|

OK. Is this correct: You're making a speed-regulated stirrer? You've chosen the motor?

I'll try to get a schematic together for a PDM (pulse density modulation) noise shaping driver and/or a set of references to manufacturers' ap notes.

PFC front ends with very good efficiency are available from www.st.com, www.irf.com, www.ti.com, www.onsemi.com, etc. The biggest problem is selecting the correct inductor, for which all the app notes give formulas. At 100W or less, that

problem is pretty easy. Several of the manufacturers give schematics with values and sample PCBs.

The output stage is simple so I should be able to draw it fairly quickly - it's one microcontroller (perhaps with external table memory), two half-H

drivers (see the above suspects for data sheets and samples), four FETs (for your application, IRF840s are probably overkill and very easily available

at $1 or so), one inverter (or using an inverting-input bridge driver), snubbers (there's a certain amount of black magic here - that's why I specify

overkill FETs), and optional output L-C-R filtering. If you specify the motor at (say) 200% of your anticipated load, the temperature rise without

filtering will be very tolerable.

Re: shunt regulator comments: A shunt regulator works, no problem. All the problems are second order. If the motor's coils and laminations were

lossless, then your scheme would work as well as possible. Shunt regulators go out of regulation beyond a point determined by the compliance of the

regulating element. You're depending on the fan being truly 4th order over the full RPM range. That's a big assumption without numbers to back it up.

Since the motor windings, bearings, laminations, etc., are not lossless, there is an optimum RPM/load combination for each motor design. The motor

manufacturer (if honest) attempts to set the motor's characteristics such that the nominal operating point is also the optimal operating point. At any

other operating point the motor will get hotter. Most motors have a fairly narrow optimum range. Going from 60 to 50 Hz, for instance, a 16% change,

usually means a significant derating unless the motor is made for that service. If I want a motor to run over a wide speed range for which it wasn't

designed using a chopper without filtering I usually specify at least a 300% over-rating, which seems to work well with a low failure rate. Even with

sine wave drive it's advisable to have either a small duty cycle or 200+% over-rating for a variable speed motor application with a general-purpose

motor.

In your 4th-order-regulated scenario, the motor will always be running at the maximum dissipation possible for its current RPM. This is half of what

the engineers are screaming about. The motor temp will be high and this kills the windings much more than chopper voltage stresses. The temp also

kills the bearings.

Chopper evil harmonics can easily be attenuated with L or LCR networks which are widely available. Look for "AC motor drive reactors". They're not

cheap at 500+W, but under 100 they can be made with off-the-shelf parts. A two-pole (series L to parallel R-C series pair) lossy output filter will

give you 20dB/decade with no back talk. The PDM scheme with an RLC filter would put the harmonics 40+ dB down - no heating/breakdown problems at all.

Second, the dissipative controller will be running at elevated temps, which double (or worse) the failure rate for every 10C. Have you spec'ed your

heat sinks and/or fans for possible air blockages? Have you put overheating sensors in if necessary? Have you put one on the motor or is it already

thermally protected? If the motor stops, do you have alarm sensors - I'd hate to be doing a nitration when my stirrer conks out!

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

I already have the Mosfets , Hitachi 2SK1837 @ a buck apiece . Yeah I already have the motor too and locked rotor at full voltage is about 0.7 Amp .

The motor is indeed being run at max. 60% of rated , but off-label use on what would be the " stall slope " which would be correct naming for that

operating region if it were a linear load being driven , But of course for a quadratic load there is no actual " stall slope " the load just finds a

speed where there is a balance of the load with the power output available , and there it runs at equilibrium until some system load or power

parameter changes .

You can do a little experiment to see the effect quite easily . Take a PSC motor with no load and increase the voltage from zero until the breakaway

into rotation , and leave the voltage set where it is , and watch the motor increase in speed nearly all the way to maximum . Backing off the voltage

to slow it down it will simply stall ....no speed control at all . Now put a naked blower wheel on the shaft and repeat the test and you will be

amazed what a little quadratic load does for introducing speed regulation . When you think about what you are observing , then the point of all I

have been saying will

become clear . Also enlightening is putting an ammeter

in the motor lead and watching what happens at various speeds , and the power / speed response which is

associated with limiting the intake air to the wheel .

Bringing a magnet near it increases the effect .

There is a huge misunderstanding if anyone has the idea

that any effort is being made to run the motor at any

sort of " optimum efficiency or output " , absolutely not because that would be running the motor at ~95% of the synchronous speed , and that is not

the purpose at all , and entirely beyond the scope of the application .

The purpose is to operate an off the shelf motor with

usable power and control in a way that it was never actually designed to work , but have it do the job well

enough to do useful work anyway , by having addressed those parameters which require special attention for the peculiar operating conditions being

forced into effect .

After all the losses from the entirely necessary but

nevertheless parasitic load elements in the drive ,

there is likely only about a third of the motors output

actually being delivered at the stirbar , which still amounts to about three times more the actual power of something like a 12" Cimarec 2 stirrer

from Thermolyne ,

at a similar power consumption . The ultimate speed

will be a couple hundred rpm higher also and the low end torque more than triple . They are using shaded pole

4 pole 1/125 hp motors with a 250 Ohm 50 W rheostat ,

and these are the " heavy duty " stirrers of those sort available . The newer stuff from Corning even their top of the line models are complete trash

so far as the drives

in them goes , toys right from the box with little C-frame

motors all digitized to try to perform an act they can never do , which is to work properly on anything you may want to do on a 10" plate . The base

drive for my prototype 10" plate is a 1/25 hp 4 pole PSC motor , with rare earth sintered magnequench drive structure , something with backbone , a

real instrument .....not an inadequate toy .

For the dissipation of heat I am looking at under 15 watts

maximum for each transistor which will be on back to back

extruded heatsinks sitting in the exhaust draft from the blower wheel ...... so they should be cool runners .

Dittos for the motor which has automatic thermal protection , but it will never be needed , because even

at a windmilling crawl of 120 rpm , the wheel will pull

plenty of cooling for the motor and for the Mosfets .

As for stalling the motor , no worries there . The decoupling torque for the largest allowable stirbar is just less than the stall torque for the

motor so the coupling field shears first ......cute huh ?

I was considering supporting the lower endshaft on a magnetic support bearing like a gyro or high end turntable . But the rotor floats anyway because

of

the stator field centering and the direction of the coupling field of the main drive magnet providing lift

also .

[Edited on 6-2-2006 by Rosco Bodine]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

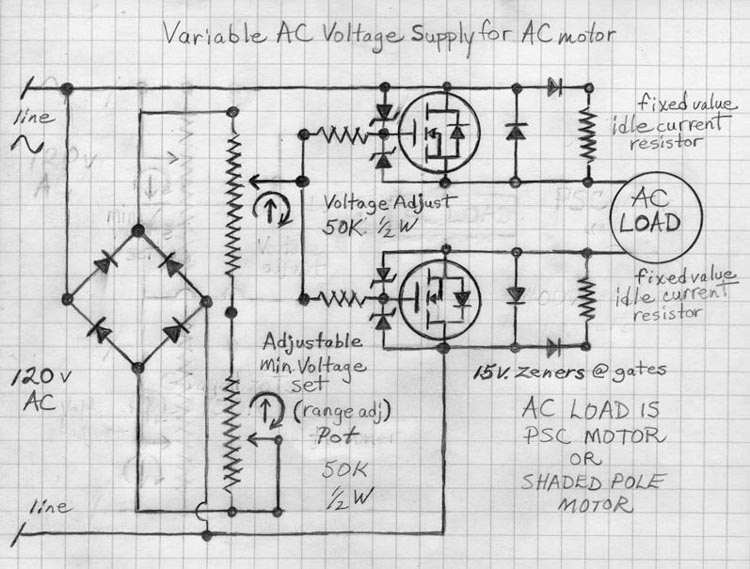

Here is another revision to my circuit attached ,

which does away with the dual pots . There will

likely be further revision to isolate the high voltage

mosfet gate driver circuit from the control pot ,

and use regular TTL level through an optocoupler ,

perhaps using a vactrol type optocoupler as I mentioned

in describing earlier thoughts here about this project .

It just mades for a safer panel to have low level on a

control pot , and avoid line level signal if there is any

way to manage that , which can likely be arranged

with a few more components .......might as well

do the job right and supply a TTL level input capability

which will be useful for other things too . That's what's next

if anyone wonders where I'm going with this .

Anyway , please take alook at this revision and holler if any

defect is spotted .

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Ermmm, why did you draw two zeners? What happens when supply voltage exceeds Vf and line voltage appears on the gate? Either smoke, or you get a

maximum voltage drop of whatever the zener is...

Speaking of diodes, you even draw the MOSFETs explicitly with intrinsic body diodes -- what are the external diodes for? Most MOSFETs have reasonably

rated body diodes.

In case the AC load is disconnected, there should be a "fixed value idle current resistor" in that place, too.

The FWB trick looks like it will work.

BTW, your drawing is nice and neat and square. Although arc wire crossings and really really long resistors went out of style in the 1960s.

Tim

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

Mm. Delete the zeners between gate and drain.

It occurs to me that a simpler method exists if you only want a few discrete speed steps - wire an appropriate size light bulb in series with your

motor. With two switches and two light bulbs you can have 4 speed settings. Add another switch and bulb and you get eight...

Simple, cheap and robust.

There's nothing wrong with long resistors and arc crossovers - it makes for a really readable schematic. Putting 4 wires into a join dot is a no-no,

though. Three max, for clarity, just in case the 'dot' disappears in printing.

[Edited on 7-2-2006 by Twospoons]

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by 12AX7

Ermmm, why did you draw two zeners? |

I haven't fully settled it in my mind what may the potential of turn-off / turn-on transients with the motor capacitor in the circuit simply being

switched by an external toggle switch at

any particular out of sync point with regards to the

zero crossing . I may never have it settled in my mind

what all the different transients are that are possible ,

and don't want to be surprised by what I hadn't discerned

in advance , so the zeners are just insurance against

the assorted unforeseen perils . Back to back zeners are an old trick for gate protection against transients , static electricity discharges included

. After eliminating the dual pots and tying the gates together there is another very foreseeable necessity for adding zeners , I explain a few

lines below .

| Quote: |

What happens when supply voltage exceeds Vf and line voltage appears on the gate? Either smoke, or you get a maximum voltage drop of whatever the

zener is... |

I'm not source following you there  .....Vf where ? .....Vf where ?

| Quote: |

Speaking of diodes, you even draw the MOSFETs explicitly with intrinsic body diodes -- what are the external diodes for? Most MOSFETs have reasonably

rated body diodes. |

They are redundant .

| Quote: |

In case the AC load is disconnected, there should be a "fixed value idle current resistor" in that place, too. |

No disconnection of the AC load is contemplated , it's all one dedicated system on the same power line hard wired together ......but I am not

following where you say I need another resistor or why .

| Quote: |

The FWB trick looks like it will work. |

Yes , I think so too . I thought about it before but had some concerns about the gate of the non-conducting Mosfet being

highly reverse biased with regards to its drain , but the zeners keep the reverse biasing felt by the gate during its

off period half-cycle , within safe limits . Without the zeners

both mosfets would be destroyed on the first power cycle .

It could even be legitimate for this reason to use 'em in parallel pairs since they are absolutely critical . If a zener blows , so does the mosfet ,

absolutely guaranteed .

The dual pot circuit was immune to that so it's sort of

a " judgement call " which way to go , and since the dual pots could complicate other things to be added later ,

I decided to make the change to the simpler biasing .

It eliminates the need for matched pots and that precision

where no twins seem to be identical like they should , just due to manufacturing tolerances .

| Quote: |

BTW, your drawing is nice and neat and square. Although arc wire crossings and really really long resistors went out of style in the 1960s.  |

I actually like to see and draw the overpassing conductors

with the semicircle , because it shows the layering of the

flyover , ( or under ) conductors so that if you are visualizing

tilting a " panel " of the circuit , imaginary connecting wires

are kept from imaginary snags on other conductors and components  It helps

visualizing the hookup points and conductor paths for the board especially when the circuit is It helps

visualizing the hookup points and conductor paths for the board especially when the circuit is

not printed , but manually wired on perf board .

[Edited on 7-2-2006 by Rosco Bodine]

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

| Quote: | Originally posted by Rosco Bodine

Back to back zeners are an old trick for gate protection against transients , static electricity discharges included . |

Yes, but what you have drawn is not 'back-to-back' zeners! To do that you need to put your two back to back zeners in series between the gate and

source.

What you have drawn is a FET circuit that will always be on, as any positve (wrt source) voltage on the drain will bias the gate on by forward

conduction through the top zener.

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

densest

Hazard to Others

Posts: 359

Registered: 1-10-2005

Location: in the lehr

Member Is Offline

Mood: slowly warming to strain point

|

|

Please don't take offense, but it really sounds like Mr. R. B. has already chosen a solution before fully characterizing the application. This is far

too easy to do - I've done it many times.

IMnsHO, a DC PM motor is a better choice for a stirrer application. They have good torque down to 0 RPM and are simple to drive even with a very

simple chopper. See the mini-lathe newsgroup/mailing list for the cheep-cheep-cheep drive circuit which uses the reverse EMF feedback for constant

speed. I could send you the PCB and motor ("1/2 HP" giggle) from a Chinese-made Harbor Freight lathe which would stir molasses in mid-Winter if your

magnet is strong enough. The low end speed is adjustable down to about 50 RPM. DC gearmotors are available for $10-30 surplus with top speeds in the

200-400 RPM range. This would put the low end RPM at maybe 5 or so.

That aside, if you want low part count, a plain old rheostat equivalent using a set of power resistors and a 10-position switch is probably available

for $10 or so (surplus) with a power rating within your requirements. Add a fan and your total parts count is:

switch - 10 ON and 1 OFF position

10 power resistors

motor

fan

This would be much more robust than FETs and would generate no electrical noise. I'd advise against a plain rheostat unless you're sure that the power

rating is sufficient at the lowest resistance values.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

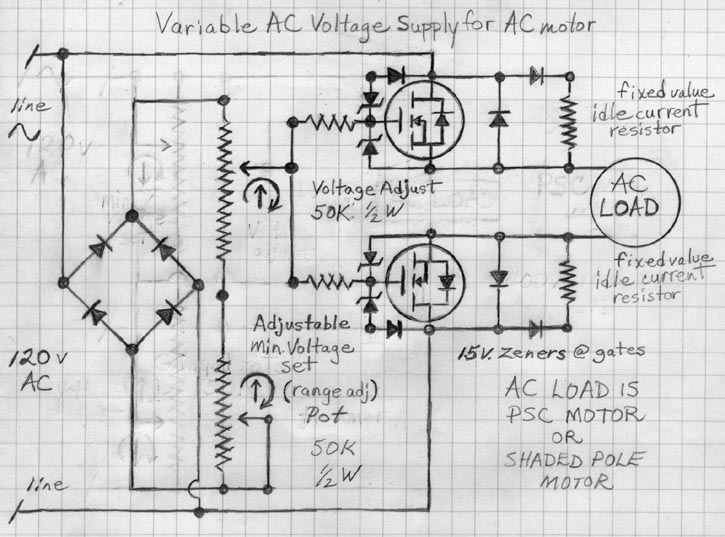

@ Twospoons

Thanks for catching that .

You are absolutely right and I am looking at it ,

because I sure as hell missed it completely or

thought it " back to back " and didn't draw it .

What I need there is an ordinary diode back to back in series with that Zener . I will correct the drawing .

@densest

I know DC gives the best performance . There is nothing

experimental about that approach , and what I am about

here is sort of like star trek , you know going where no

one has gone before , giving the lowly PSC motor made

cheaply by the gazillions something different to do where

it is better than the shaded pole motors used already in

the application . As for the rheostat , I have several of them

and its been there , done that , and know the limitations .

I'm on the right track I think and if not , well then the

experimental prototype will be a learning experience .

@ Twospoons

The attached revision of the schematic shows the corrected

diode protection for the gates . Thanks again for spotting the missing diodes .

@ 12AX7

I take it that both you and Twospoons were seeing the same

missing blocking diode there and that is what you were meaning about Vf appearing at the gate ? Thanks for hollering .....I got it , fixed it too

[Edited on 7-2-2006 by Rosco Bodine]

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Erm, why did you add *another* pair of diodes?

As shown, the zener gate-drain diodes act by limiting G-D voltage to 0.7V, but there is a plain diode present, presumably with PIV > 200V, so this

possible clamping action is essentially removed. For the plain diode to be forward-biased, the zener will be reversed, i.e., in the zener region.

For this to become active, the drain must be (zener rating) + 0.7 volts lower than the gate, which can never happen in normal conduction. At (or

after) zero crossing, however, the drain falls to about 0.7V below the source, which clamps it by the diodes. If the gate zeners are equal, then the

gate voltage will be clamped to the zener voltage plus a diode drop -- the extra diode drop is either the source-drain diode or the gate-drain diode.

Look. I don't care if you have a diode fetish, or something: it'll work with no extra parts if you:

Remove all diodes except the source-gate zeners, and the FWB

Remove the "fixed value idle current resistors" and, if you do want an idle load on the MOSFETs, place a resistor in parallel with the motor

(redundant, since the motor is ""permanent""). If your intention was to give the motor an idle current, then why the adjustable minimum?

*Looks up datasheet*

Holy shit, what do you need a FET that big for? I'll give you $10 (plus shipping) for six of those if they are indeed 2SK1837s.

Yeesh, and they already have gate zeners too! External zeners can clamp the gate to safer, saner values, though.

Tim

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

LOL , I'm dying here because I know seeing a MOSFET

upside down from its usual orientation as a " switching "

device is like trying to ride a bicycle backwards . I am having the same problem with the visualization , like

holding a rifle on the shoulder aimed at a target behind the back and aiming by lining up the sights with a shaving mirror held at arms length . You

have to think it through like

looking through a telescope without a terrestrial inverter ,

because everything tries to move the " wrong way " as you

are visualizing it with a mind conditioned to the opposite

configuration

| Quote: | Originally posted by 12AX7

Erm, why did you add *another* pair of diodes? |

Because I saw what you were meaning to point out ,

even though you described its actual location flipped

180 degrees from where the defect was

This " source follower " configuration makes me crosseyed too

| Quote: |

As shown, the zener gate-drain diodes act by limiting G-D voltage to 0.7V, but there is a plain diode present, presumably with PIV > 200V, so this

possible clamping action is essentially removed. |

No way is the clamping action removed , but is made

into a unidirectional breakover diode , allowing zener conduction to occur but blocking normal forward conduction

coming back the other way , which it would without the added normal diode as a blocking diode .

| Quote: |

For the plain diode to be forward-biased, the zener will be reversed, i.e., in the zener region. For this to become active, the drain must be (zener

rating) + 0.7 volts lower than the gate, which can never happen in normal conduction. |

Correct , but the MOSFET is not in normal conduction when the clamp is needed , the MOSFET is off , and a negative

bias voltage is being applied to the gate trying to turn it

" more off " , which is where the problem arises requiring

the clamping by the zener . If the zener wasn't there then

the negative bias ( gate to source ) would exceed the -30

volts maximum , destroying the Mosfet . Therefore the

zener has to be there .

| Quote: |

At (or after) zero crossing, however, the drain falls to about 0.7V below the source, which clamps it by the diodes. If the gate zeners are equal,

then the gate voltage will be clamped to the zener voltage plus a diode drop -- the extra diode drop is either the source-drain diode or the

gate-drain diode. |

That's the idea , but since that Mosfet is off , the idea is not

for it to be allowed to be conduction biased , but to be kept

within safe gate signal parameters while it is in the off condition during its idle half cycle .

| Quote: |

Look. I don't care if you have a diode fetish, or something: |

LOL ...I do love my damn diodes don't I !

But there's nothing like a cathode rejuvenator on

a cold winter night  If the girls are squeamish If the girls are squeamish

when you ask them to Thevinize it , you sometimes

have to settle for a quick Kirchoff

Just the way it is ......I think , unless I am looking at it

crosseyed again .......which is not any surprise if true .

I am having to reteach my eyes on this one . I even thought

about just drawing the damn thing as an NPN emitter follower to relieve

the " diode fatigue " and see a familiar

power device in a well known configuration . Then translate

it later for Mr. Mosfet in source follower mode .

| Quote: |

with no extra parts if you:

Remove all diodes except the source-gate zeners, and the FWB |

Nope gotta keep 'em there for good reason . Study it some more and you'll see it .

| Quote: |

Remove the "fixed value idle current resistors" and, if you do want an idle load on the MOSFETs, place a resistor in parallel with the motor

(redundant, since the motor is ""permanent""). If your intention was to give the motor an idle current, then why the adjustable minimum?

|

The idle current resistors are to windmill the motor without

heating the mosfets at idle . The adjustable minimum is so that the full range of the main voltage adjust has affect on the motor speed , and you

don't have to turn the knob

halfway before the motor responds .

| Quote: |

*Looks up datasheet*

Holy shit, what do you need a FET that big for? I'll give you $10 (plus shipping) for six of those if they are indeed 2SK1837s.

Yeesh, and they already have gate zeners too! External zeners can clamp the gate to safer, saner values, though.

Tim |

They are pretty aren't they ? Watch out now ,

or people will think you have the hots for a MOSFET

Isolated oversized cases too , long beautiful legs

all the way up to her ass ....sweet

70 Nm + or - 10 Nm mounting torque , and the cases

are flat both sides so they can be sandwiched between

two heatsinks if you like .

Maybe google 'em or check eBay , there's a few around .

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Meh, TO-247 isn't very sexy, it has sharp masculine corners if anything. A pair of TO-3's side-by-side would be more interesting.

But anyway.

The single source-gate zener diode is forward biased if the gate is less than the source, keeping the gate above -0.7V. Likewise it is reverse-biased

(zener clamp), limiting gate to below say, 12V, for a 12V zener. Considering the transconductance, you could easily get away with a 6V zener. This

and this alone is sufficient and there is no need for any more diodes.

The 2SK1837 is more than stocky enough to withstand reverse current, so external reverse diodes are not necessary. Diodes are not required for the

"idle current" resistors, which themselves are not necessary either (when the output is turned down, current is low, so dissipation is low -- for a

resistive load, maximum dissipation takes place at *half* voltage output!).

Study it more and you'll see it.

Tim

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by 12AX7

Meh, TO-247 isn't very sexy, it has sharp masculine corners if anything. A pair of TO-3's side-by-side would be more interesting.

But anyway.

The single source-gate zener diode is forward biased if the gate is less than the source, keeping the gate above -0.7V. Likewise it is reverse-biased

(zener clamp), limiting gate to below say, 12V, for a 12V zener. Considering the transconductance, you could easily get away with a 6V zener. This

and this alone is sufficient and there is no need for any more diodes.

The 2SK1837 is more than stocky enough to withstand reverse current, so external reverse diodes are not necessary. Diodes are not required for the

"idle current" resistors, which themselves are not necessary either (when the output is turned down, current is low, so dissipation is low -- for a

resistive load, maximum dissipation takes place at *half* voltage output!).

Study it more and you'll see it.

Tim |

The idle voltage for the motor is about 30-35% of line so I figured just let some power resistors take the heat and spare the mosfets .

Isn't it the overvoltage that does the damage to high impedance inputs , even if the current is miniscule ?

Similar story to puncturing the dielectric in a capacitor ?

About the diode protection , there was another reason

I wanted to add this , and that is the unknown effect of capacitances that are going to be present both from the Mosfets and in the photoresistor I

intend to add next .

There is also the matter of transients which are possible

from manually switching the load in part of a cycle , as will

occur during power up or powerdown . I didn't want to

power up the circuit and have it work beautifully until the first time it turned off , being stone dead thereafter .

There is also the matter phase shift thrown in to muddy things further , since the load is reactive . So some of the

considerations are hypothetical conditions which may or may not ever appear . It is better to err on the side of caution

and cover the possibilities , than to just cover the expected ,

and later get burned by the anomaly . The diodes are cheap insurance .

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Yeah, that's why you use zeners that conduct at 0.7V forward and rated voltage when reversed. You get a sweet spot of +Vz to -0.7V on the gate, NO

MORE. Impulses are clipped by the zener and series resistor.

I was going to say don't worry about capacitance since 60Hz is damn slow, but since you've settled for these boatanchor sized FETs, it might be worth

adding a speed-up cap across the series resistor. Possibly, one with series resistance, so it speeds up the gate signal only so much.

Don't worry about transients, a transistor like that will handle what... half a joule or more, avalanche? Besides, diodes don't protect against

avalanche so your diodes won't do anything in that regard.

If you want you can add a (300 or 400V rated) TVS across the motor and/or supply line.

Tim

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Bear with me here for a minute as I truly am trying to

better understand this concern you have over the single zener across the gate to source becoming forward biased . I can't quite see any way that

would occur

except in one scenario where the Voltage adjust is

set much lower than the idle voltage of the motor

being supplied by the power resistor , and adding

a blocking diode could stop that if that was a problem .

But I don't see how this scenario would effect any

response from the Mosfet , because the drop across

the diode would prevent the gate from being forward biased into conduction . I'm not sure what exactly

is the minimum gate to source threshold voltage differential for the Mosfet to conduct in the source follower mode , but for sure it is some some

positive value which the source voltage tries to rise to meet . And in this scenario the gate is already at least .7 volt lower than whatever voltage

there would be on the source , so the mosfet is not in conduction . The gate would have to be at some higher voltage than the source for the Mosfet

to be in conduction . Anybody know what the typical gate to source drop would be

for a source follower ? It could be several volts ,

I'm not sure . But I'll guarantee it is a positive value ,

not -.7 .

I suppose I could add a blocking diode there too , just to make it a moot point and the zener would still serve its

intended purpose as an overvoltage clamp . It would make for a nice and symmetrical clipping filter on the gate .

As I am looking at this sort of gate protection having a four diode clipping filter for a mosfet gate it actually makes the gate pretty well

bulletproof , so I wonder why this isn't simply integrated on the mosfet when they manufacture them . It would not interfere with the normal

operation of the mosfet but would give it gate protection way beyond what it has with one zener from gate to source , or none at all as some of them

are made .

[Edited on 8-2-2006 by Rosco Bodine]

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

| Quote: | Originally posted by Rosco Bodine

Bear with me here for a minute as I truly am trying to

better understand this concern you have over the single zener across the gate to source becoming forward biased . I can't quite see any way that

would occur

except in one scenario where the Voltage adjust is

set much lower than the idle voltage of the motor

being supplied by the power resistor |

Indeed, with the FWB, the gate voltage can only ever be positive with respect to S.

| Quote: | and adding

a blocking diode could stop that if that was a problem . |

Er so why add another diode to circumvent a protection scheme that may or may not be necessary?

| Quote: | But I don't see how this scenario would effect any

response from the Mosfet , because the drop across

the diode would prevent the gate from being forward biased into conduction . |

What!? Alright do you understand inequalities? I'll spell it out this way: -0.7 < Vg < Vz, where -0.7 is the voltage when gate is NEGATIVE

with respect to source, Vg is the gate voltage, and Vz is the zener diode rating.

G-S voltage is free to be anywhere INBETWEEN, including the linear range required. It is NOT, however, allowed to EXCEED Vz, or to get any

appreciable negative bias.

| Quote: | | Anybody know what the typical gate to source drop would be for a source follower ? |

Err, it's in the datasheet. You *have* looked at the datasheet...right?

Tim

[Edited on 2-8-2006 by 12AX7]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

I looked at the data sheet and a dozen others

before choosing this particular MOSFET . I assumed

the +2 to +3 volt threshold above source would hold

true whether the load was top driven from the source

lead above as in a source follower circuit , or if the load

was top tied to a supply rail and switched from below

by the drain lead through the Mosfet in the usual switch mode where the source is on the negative rail .

The turnon voltage is the same value turnon voltage no matter where the mosfet is located in series with the load .

So the source can only rise to within 2 to 3 volts lower

than the gate voltage applied to the mosfet acting as a source follower . If the potential on the source tries

to rise higher , the Mosfet is no longer " saturated "

as a switch , but becomes semiconducting and operates

" active region " or " linear " as a voltage controlled variable resistor to regulate the voltage on the source at the 2 to 3 volts below the voltage

at the gate .

I don't see how an external zener of higher voltage than that 2 to 3 volts would interfere at all with that normal

excursion of the source voltage which derives from the internal mosfet components providing the source following effect . It's like you are saying

the source can rise no higher than the drop across the zener when it is in zener conduction , and applying that to a scenario where the zener is not

in zener conduction , and where it wouldn't matter in either case anyway . All the source will do is rise to within 2 to 3 volts less than the

voltage on the gate , where it stays , regardless of a zener which

has dropped out of zener conduction way before the

source voltage has risen that near to the gate voltage .

It seems you are looking at the diodes as providing some

sort of active biasing which is either simply not there or I don't recognize it yet . All the single zener from gate to source does is limit the

gate from going over 15 volts

with respect to the source , when a third of that would be more than enougn to saturate the Mosfet , so all the single zener does is clamp any excess

voltage which might appear as a transient on the gate . And if the single zener was in normal forward conduction , it is supplied from the source

whose potential cannot be

higher by the 2 to 3 volts plus the .7 volt drop across

the diode , for the Mosfet as it were to " self - bias "

its own gate from what voltage is on the source .

Any forward biasing of the mosfet gate is going to have to

be routed from the rails on the drain side of that Mosfet .

What you were saying above about not needing the reverse

current protection on gate to drain versus my assertion earlier that the mosfet would be destroyed by the same reverse voltage as is stated for gate

to source ..... I admit that I am uncertain of this and you could be correct . The manufacturer doesn't specify any limitation for the gate to drain

as they do for gate to source and here I assumed that because N channel Mosfets are unipolar devices having a single carrier channel from source to

drain , that the relative

vulnerability of either end of that channel to overvoltage

would be the same . I have read somewhere that N channel

mosfets have a somewhat ambiguous " polarity " with regards to the matter of drain and source , and will happily

pass AC under certain conditions , and I'm not even certain that is true , but adding these things together it just made sense to me that the gate to

source allowable voltages likely

applied equally to the gate to drain . Not knowing for sure ,

I choose to add the diodes which shouldn't hurt a thing if

they aren't needed , but will protect the Mosfet if they

should be needed . When I draw the final circuit I will

have the diode protection on both the gate to drain and the gate to source , for my own peace of mind . It may be sort

of like seatbelts and airbags , or it may be like two seatbelts

when one would do . But either way , the thing is covered .

If anybody else wants to omit the clipping filters they are welcome , but I am putting them in the one I build just to be sure

[Edited on 8-2-2006 by Rosco Bodine]

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

| Quote: | Originally posted by Rosco Bodine

I looked at the data sheet and a dozen others

before choosing this particular MOSFET . I assumed

the +2 to +3 volt threshold above source would hold

true whether the load was top driven from the source

lead above as in a source follower circuit , or if the load

was top tied to a supply rail and switched from below

by the drain lead through the Mosfet in the usual switch mode where the source is on the negative rail .

The turnon voltage is the same value turnon voltage no matter where the mosfet is located in series with the load . |

Ya. Did you look at the range? Several volts variation. It MIGHT be 2V, or hell, it could be 4V. Even a 5V G-S zener would probably suffice.

| Quote: | | I don't see how an external zener of higher voltage than that 2 to 3 volts would interfere at all with that normal |

...Gate voltage?

Wait, I guess you weren't going to say that:

| Quote: | | excursion of the source voltage |

Nevermind...

| Quote: | | It seems you are looking at the diodes as providing some sort of active biasing |

Steeeerike two...

| Quote: | | All the single zener from gate to source does is limit the gate from going over 15 volts with respect to the source, when a third of that would be

more than enougn to saturate the Mosfet, so all the single zener does is clamp any excess voltage which might appear as a transient on the gate.

|

DING DING DING, HOME RUN!

| Quote: | | And if the single zener was in normal forward conduction, it is supplied from the source whose potential cannot be higher by the 2 to 3 volts

|

Wrong channel there, it's enhancement mode, which means the gate is always positive. If the gate is negative (source positive), the voltage is

clamped by the zener forward-conducting (because the arrow points towards the gate..).

| Quote: | | Any forward biasing of the mosfet gate is going to have to be routed from the rails on the drain side of that Mosfet. |

IGNORE THE DRAIN. The drain is BAD. The drain carries ONE HUNDRED TWENTY VOLTS. The gate wants no more than TWENTY.

| Quote: | | The manufacturer doesn't specify any limitation for the gate to drain as they do for gate to source and here I assumed that because N channel Mosfets

are unipolar devices having a single carrier channel from source to drain , that the relative vulnerability of either end of that channel to

overvoltage would be the same. |

*Cough*. MOSFETs aren't JFETs.

I don't know exactly what it is they do, besides the substrate diode, that prevents them from being bidirectional devices, but the fact remains, all

medium and high voltage power MOS manufactured today has a Vds rating much higher than any Vgs rating. The gate is to stay near the source, end of

discussion!!

Tim

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

The peak voltage is actually 170 for 120 rms line voltage ,

so that peak is what can actually be appearing at an unfiltered / unlimited gate input .......and I really doubt

that sort of voltage should be left unlimited , unless

the manufacturer specifically rates a device for that

sort of unsual signal level .

120 volts rms isn't " bad " if that is the power rating of the given device and that is what you are working with out

of necessity . You just have to design a circuit to

account for the conditions encountered in the application .

But it would solve a lot of design problems for control

circuits if the whole world was powered by nothing over

12 volts .

The circuit of the latest revision posted will probably work fine as shown even with line voltage across the ends of the control pot , the same as

would be occurring with

numerous " light dimmer " types of devices using triacs .

So this circuit might get code approval as is and be fine

for fully manual operation . I would still make the input filters identical on gate to source as they are shown for

gate to drain in any actual build .

Adding TTL level control inputs is possible but really should be done using a small transformer and regulated supply for the logic stages , as would

be the conventional

method .

I ran across a very neat optical isolator of a different sort

and its application note shows some interesting AC

applications , so I am attaching the file for the unusual

optoisolator . This device could be very useful in the

biasing of Mosfets .

Look on page 5 of the application note at the AC Switch .

I'm wondering how well this particular circuit would

work in linear operation and if it could simplify what I have been doing differently with the circuit I have been designing ,

by already having TTL level input capability .

I'm getting the same problems with file attachments not downloading properly as was going on the other day , and I think it is the hosting service .

So if there is trouble , just try it again later .

[Edited on 8-2-2006 by Rosco Bodine]

Attachment: AN-1017 photo voltaic isolator PVI device.pdf (176kB)

This file has been downloaded 952 times

|

|

|

| Pages:

1

..

3

4

5

6

7

8 |

|