| Pages:

1

..

3

4

5 |

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

To be honest, I don't know about sodium ethoxide formation. I'm just here for the anhydrous ethanol. I hope that someone more savvier will have

something to say about it.

I stirred the ethanol overnight with strong overhead with 10% w/w MgSO4/CaSO4 mix, filtered. ABV meter showed 95%, which matches with the input so

zero difference. Dissolved impurities affecting SG cannot be excluded, so this measurement is mis-leading, as it should have been distilled

first.

Then I added 5% w/w NaOH and distilled. The boiler turned dark brown after adding NaOH and heating, and it might have something to do with MEK and

other stuff, or then not.

The distillate came over at 77C. This has likely to do with the thermometer accuracy and barometric pressure, because anything below 78 shows 77. The

thermometer is not calibrated, but shows consistent results with other thermometers.

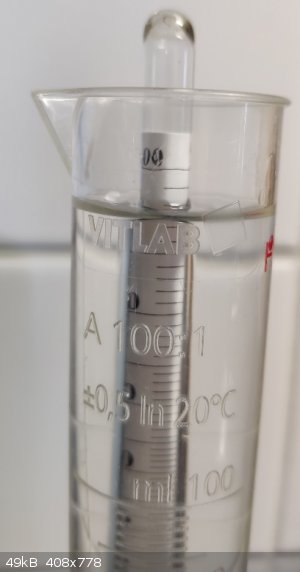

The ABV meter shows 98%, picture attached.

The SG measures 0.787 for 100mL sample. The scale is not calibrated, but shows consistent results with two other scales. This would indicate on the

other hand that it is closer to anhydrous than ABV. To be honest, I have no idea about the accuracy of the ABV meter, but it likely is not very

precise device.

After all the trouble, getting anhydrous EtOH from otc fluid seems to need three distillations: one to extract the volatiles from oils and crap,

second with NaOH to condense the ketones and volatile crap from ethanol and to bring up the ABV, and then using mol sieves to extract the rest of the

water. Needs some work, but I would save time by scaling this process up and do a big batch, like 10 or 20 liters at one run to have a good stock of

anhydrous ethanol. The low price of 2€/L warrants this, as all the alternatives containing more pure ethanol cost as much as 7 times more what I

looked around, and they are still only made from azeotropic ethanol with added denaturing agents, so only the first strip distillation phase could be

left off. The strip run can be done with high speed with no attention to fractions, as all the non-volatiles have very high BP and will not come over,

and the traces will be eaten by NaOH anyway. Adding NaOH directly to the raw fluid works also, but much more is needed, as the additives form as much

as over 10% of the total volume and will consume all NaOH that reacts with any of them.

[Edited on 21-3-2021 by Fyndium]

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Weigh before and after. Everyone tells me they don't (well let's just stop right there) see damage with NaOH or phosphoric acid and I do with both

cheap glass and Pyrex. It can't be good.

Doesn't everyone have buckets of sodium now?

Are there reactions where the directions normally call for ethanolic Na and the usual drying precautions, but still work OK with ethanolic NaOH?

You want dry ethanol, heat garden lime to 85% of the theoretical loss of weight. You want alkoxide, make or buy sodium and use damn dry alcohol.

|

|

|

| Pages:

1

..

3

4

5 |

|