| Pages:

1

..

41

42

43

44

45

..

68 |

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Nice, the dapping block looks like it does a good job of making hemispherical liners.

I received mine yesterday and am eager to try it out and compare it to the hammer made liner.

I too had a problem where the liner broke up a bit and didn't make a perfectly round hole. I am trying to decide whether to use 1.2mm thick copper

sheet this time instead of the usual 1mm, but I would like the specs to be the same as last time so I can accurately compare the results.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Yeah, the dapping block works like a dream, good suggestion you had there. I am not getting slug elongation so I think a stronger casing may be in

order, especially with these small charges. I hesitate to use things like steel, but it can be done safely. Of course the depth of the dish relative

to its diameter has a lot to do with determining the length and diameter of the projectile. The penetration of the projectile is directly proportional

to the kinetic energy of the projectile and proportional to the cross sectional area for a given mass and velocity therefore given the same projectile

mass and velocity the penetration should be about double for a projectile with half the cross sectional area. Blunt projectiles have their purpose,

but if maximum penetration is desired a longer more narrow projectile is what should be aimed for.

The optimum thickness for the liner depends on the charge diameter among other things.

[Edited on 19-6-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Had a first test with the dapping block today using a 1mm thick copper liner with a curve indent of 5mm.

The same 30 gram PETN charge was pressed behind the liner with a wooden dowel in a thick-walled cardboard tube. Standoff was 120 cm from 1/4 inch

steel plate and the EFP lined up with a laser pointer again.

After intitiation, it was found that the intended effect on the target had not been achieved. Unlike the last time with charge of same specs, there

was not a full penetration. It was so close as can be seen in the picture there is a crack running halfway round the other side of the plate where

the slug hit as the chunk of steel has nearly been removed by the impact. I think this failure was due to the fact that it was getting dark which

made it harder to set up lining up was rushed a bit so the EFP wasn't 100% straight in line with the plate. The plate was slightly offset from the

EFP line of fire and in the picture you can see the slug penetrated more on the side it came into contact with first. If the plate was in line I

think it would have been a through and through. I think that hitting on a slight angle would also reduce power of the slug.

[Edited on 26-6-2015 by greenlight]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

That is a lot of PETN for the effect obtained, I assume you pressed it well. I think both of our EFP tests would greatly benefit from much stronger

casings.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

It is quite disappointing, i pressed it as hard as I could by hand with a wooden dowel, I think the main problem was the fact that the target plate

was off centre so it hit at a slight angle.

I think you are right a stronger case would make a big difference, do you think PVC pipe or go all the way to a metal casing.

[Edited on 26-6-2015 by greenlight]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

At that diameter pressing by hand is not going to get the density very high at all. Loading density is proportional to the applied pressure. You are

limited to the amount of pressure you can apply by hand and pressure is force per unit area or force over area. As the area gets larger the pressure

goes down for a given force. You need mechanical advantage of some sort. That is one of the reasons I like putty/plastic explosives so much, the

density is always near maximum and it is extremely easy to load. Pure explosives without inerts added are of course more powerful, if

they are loaded properly.

Regarding casing material, a detonation is different of course, but looking at the pressure ratings of these materials should give us something to

work with.

http://www.engineeringtoolbox.com/pvc-cpvc-pipes-pressures-d...

http://www.engineeringtoolbox.com/stainless-steel-pipes-pres...

There are lots of other pages too for other pipe materials. Engineering toolbox is a very useful resource!

[Edited on 26-6-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

I will try pressing in my vice next time if it will open wide enough to take casing and a small piece of dowel, otherwise i will have to look for a

bench top mechanical press of some sort to get the higher densities needed or of course start using plastic.

Those pipe pressure ratings look very interesting and obviously take a lot more pressure to burst than cardboard so should make the EFP more

effective; if I can find some 30mm PVC I will definitely include it as the casing in the next test with a higher density as well to check the

difference and move on to metal later.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

The inertia/mass of the casing could be the most important variable. The density of steel is so much higher than PVC.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

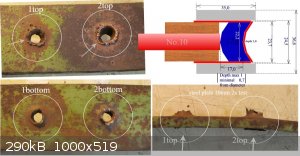

Another test was conducted with an EFP using a copper liner formed with a dapping block:

The liner was a 1mm thick 30 mm diameter copper disc with a curve indent of 5mm like the last test.

This time casing with a higher pressure rating was chosen which was a 30 mm PVC pipe instead of cardboard tube. The charge was 33 grams of PETN which

was loaded with a vice press to achieve a higher density.

Target was the usual slightly over 1/4 inch thick steel plate and the standoff was 120cm sighted with a laser pointer.

This time a full penetration was observed and only a small amount of liner breakup as can be seen on the top right of the entry hole . .

The initial liner weight was 5.70 grams and final slug which was recovered from tree behind target weighed 4.85 grams.

[Edited on 1-7-2015 by greenlight]

[Edited on 1-7-2015 by greenlight]

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Saw this on youtube https://www.youtube.com/watch?v=G0ZOPFiuOL8&feature=play... probably everyone has seen it, but in case not everyone has its pretty interesting

setup, pretty low teck to make.

cheers nuxy

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

That is an interesting video. One of the things I noticed most was how weak the casing was, it was only fairly thin plastic.

I took a snapshot from the video and took a few measurements on my computer screen, then used known quantities to determine the approximate actual

dimensions.

From computer screen:

Liner thickness ~ 1mm

Casing inside diameter ~ 37mm

Casing length (holding charge) ~ 38mm

Given charge mass = 30g

Assume C4 explosive, so density = 1.57g/cc

Given steel target thickness = 10mm

V = pi/4 * D^2 * L

L ~= D so let L = D

V = pi/4 * D^3 also V = 30g / 1.57g/cc = 19.11cc

so actual D ~ 29mm

Liner actual thickness ca. 29mm / 38mm * 1mm = 0.76mm

Liner thickness is 0.76mm / 38mm * 100% = 2% of liner diameter

Penetration = 10mm or 10mm / 29mm = 0.34D

Making accurate measurements from the computer screen was difficult, but even if the inaccuracies resulted in a 50% increase in actual liner thickness

relative to actual liner diameter that would still only bring the liner thickness to 3% of liner diameter. Also, I have never handled C4, but from the

descriptions I have read the plastic explosive in the video seemed almost too soft and mouldable for C4.

Notice how he states in the video that the charge was effective anywhere up to 60 disc diameters from the target. I would have thought that they would

be effective, though maybe not as effective, at much greater distances.

Interesting video, I would like to try a 2 or 3% of diameter liner thickness for my next test using a plastic casing.

[Edited on 3-7-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Im not sure what the explosive is but the boxes on the left of the table are shrike exploders http://www.mondial-defence.com/ProductDetails.aspx?ProductID... from mondial defence systems so it could be pe4 or semtex if they buy there

plastic explosive there as well.

The tube looks like acrylic tube the main uk supplyer has 44mm o/d by 34mm I/d http://www.clearplasticsupplies.co.uk/acrylic_tube_clear.htm that looks close to what our chip buttie loving fellow was using. cheers nuxy.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Even if the dimensions I gave are incorrect proportionately they should still be approximately correct so the liner thickness should still be fairly

close to 2% (at most 3%) of the liner diameter. Yeah, it would make sense that the explosive used was Semtex not C4, P4 is very close to C4 from what

I understand (only slightly different formulation). If it is in fact a type of Semtex the density would likely be somewhere between 1.43 and 1.5g/cc.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

I have seen that video before and alway wondered what his standoff was because he never says, I don't know how you worked that out but well done.

This ideo is what gave me the idea to use 30 gram HE for the charge.

Does anyone know if the empty section of plastic tube he has in front of the copper liner does anything to enhance slug formation or accuracy. It

looks almost like his EFP had a small barrel.

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by greenlight  | I have seen that video before and alway wondered what his standoff was because he never says, I don't know how you worked that out but well done.

This ideo is what gave me the idea to use 30 gram HE for the charge.

Does anyone know if the empty section of plastic tube he has in front of the copper liner does anything to enhance slug formation or accuracy. It

looks almost like his EFP had a small barrel. |

Judging from the lenght of the "barrel" I guess it serves as a standoff guide when using the same diameter cone liner in the plastic tube for a

regular shaped charge effect. For an EFP application I do not hink it has any relevance...

Exact science is a figment of imagination.......

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1387

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

efp

Packaging has almost no influence on the formation liner. It is important to observe the depth charges. Depth greater than 1x average results in

tearing the liner. Less than 0.7 reduces the average power EFP. Very important is the accuracy and the same density EM. With a diameter of 30 mm does

not affect either 2 mm steel for packaging. 5 mm yes. Plastic and paper packaging has no effect. Production accuracy. That's the main thing. This

examples, liner thick 1mm. Liptakov

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

One of the things I noticed was that a shallow dish would hold together well, even if a lot of high velocity explosive was used, but at the same time

the projectile tended to be short and blunt/wide. It would seem that every time one variable is changed other variables have to be changed as well to

get optimum results. The idea that one liner thickness or liner curve depth will suit every type and quantity of explosive and EFP charge diameter is

likely not very realistic. All the variables seem interrelated, much more so than with Munroe effect shaped charges. I find EFPs finicky, but then

maybe I just don't have them figured out yet.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1387

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Of course, I agree. In other words: Build a good symmetrical projectile only one explosion (without tools and products) is very difficult. Copper cake

must hold shape, they must fly single piece of copper. For devices SC, copper can disperse on the liquid metal, and it still works pretty well.

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

I found a length of 25 mm alloy rod I had forgotten in my shed so I copied the risi rp4 ebw ssf casing today used my standard ebw head but I think I

might change it to have a initiator like the original so I can use plasticised etn as the main charge, its almost to good to destroy  . cheers nuxy. . cheers nuxy.

[Edited on 3-7-2015 by nux vomica]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Looks good! You certainly know your way around a lathe and other fabrication shop tools.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Its not part of my trade, one of my old jobs the forman there was a toolmaker by trade but he was a lazy Austrian shit and I ended up learning how

to use a lathe and mill so I could get my jobs done, I suppose I should thank him now

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I ran out of plastic explosive a few days ago and made some more. For the last while I have been using 80/10/10, ETN/ polybutene/mineral oil, but this

composition is quite oily, falls apart fairly easily and is 20% inert material. I decided to try with only polybutene and ETN, 87% ETN and 13%

polybutene was used. The polybutene was smeared out in a thin layer over a previously warmed glass cutting board and then the fine crystalline ETN was

worked in with a glass rolling pin. The composition was repeatedly gathered up with a rubber spatula and rolled out until it was well incorporated and

dense (this was easier when oil was used). This composition holds together well, much better than the previous composition, is not oily or excessively

sticky and contains only 13% inert material. I compared it to "Play-Doh" brand children's modelling compound and it is much stiffer, but still fairly

easy to mould. It could be softened by adding a bit of mineral or silicon oil if desired.

Attached is an image of about 79g of the composition (what I have left after doing a little testing).

[Edited on 3-7-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1387

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

plastification

That's weird. So much plasticizer? I use 4% of the PIB (from vulcanizing tape). In heptane solution of 10%. Thus 9.2 g EM + 4 g of 10% solution (0.4 g

PIB) + 0,4g 5W40 oil. Plasticity is perfect. For all powder EM. The heptane was evaporated. 10 g plasticization takes 5-10 minutes. Under fan warm

air. Very quickly process. Same as in video example Liptex: https://www.youtube.com/watch?v=B6QfTOLH0Gk

or Chedditex. Dr. Liptakov

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

That plastic looks really nice Hennig, how large were the ETN crystals that you used?

Do you think that PETN could be substituted for the ETN in this plastic explosive formulation you have made?

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

The PIB or PB are binders, the plasticizer or softener would be the oil or sebacate, etc. Even C-4 normally has around 10-12% inerts, from what I have

read, and it is apparently not as soft and easily mouldable as plastic explosives like Semtex which have a much higher inerts content. The polybutene

I am using is likely lower molecular weight than is ideal for this purpose which has to be taken into consideration as well. The fact that the PB can

be incorporated fairly easily without the use of a solvent tells a lot I think. Very nice videos by the way!

Thanks, yeah it is really nice to handle, it is bound together really well, is easily mouldable and it is not oily and sticky (almost nothing gets

transferred to the hands when handling it). The ETN was high purity and the crystals were not very large since they were formed from fairly rapid

cooling of a solution in methanol. It would likely be at least a little different with PETN but it should still work more or less the same.

[Edited on 3-7-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

| Pages:

1

..

41

42

43

44

45

..

68 |