| Pages:

1

2

3

4 |

pjig

Hazard to Others

Posts: 169

Registered: 25-5-2010

Member Is Offline

Mood: always learning

|

|

Not to beat a dead horse , but the original patent claimed a matrix that would react with the oxidizer to form a self curing / vulcanizing castable

solid. Is there any success’s with that mix? (W/o) the horse shit and gravy misleading variations.

It’s a novel idea (priming mix out of otc materials. )

I understand that the base mix your describing is the functional one. And from the looks of it if heat cast , should perform close to the patents

claims(6-7k)vod.

I guess circling back to the original claims, the lack of “heat casting” is the attractive thing. A self curing cast material via chemical

reaction or dehydration causing a cross-link to increase density.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1395

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

This color as original manufacture concentration contents 91% H2O (very important for dissolving NaClO4) + catalyseurs + fuel, which replace partially

guar gum and compounds, which increase sensitivity. It was examined in video:

https://www.youtube.com/watch?v=tBLVo-u-XGM

Dry pigment + AP is burning basically without residuum...

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

EF2000

Hazard to Others

Posts: 153

Registered: 10-5-2023

Location: The Steppes

Member Is Offline

Mood: Taste testing the Tonka fuel

|

|

Also, if les gendarmes come to visit you, you can always say that it's dried acrylic paint, absolutely honestly.

Wroom wroom

"The practice of pouring yourself alcohol from a rocket fuel tank is to be strongly condemned encouraged"

-R-1 User's Guide

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1395

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Quote: Originally posted by EF2000  | | Also, if les gendarmes come to visit you, you can always say that it's dried acrylic paint, absolutely honestly. |

Of course, for entire years I only have colors of different densities and shades in stock. Nothing else......

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

pjig

Hazard to Others

Posts: 169

Registered: 25-5-2010

Member Is Offline

Mood: always learning

|

|

I see in the video the use of Ap as the oxidizer. But your text above is saying naclo4( probably answering previous messages) but different from the

original cast mix. Are these salts interchangeable with same weights ? (Greenolite) you claim in a prior text not using the AP for the cast mix…

just clarifying…making sure I understand correctly

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1395

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

.....pjig.....in 0:25 - 0:30 is used NaClO4. Video is only demonstration of properties of dry color pigment.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

pjig

Hazard to Others

Posts: 169

Registered: 25-5-2010

Member Is Offline

Mood: always learning

|

|

Ok Ty for the info. Curious if any acrylic paint will work for this function, or does it need to be the fluorescent type you showed in previous text.

I found some cheap acrylic I wonder if it is usable through this formulation.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1395

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Tested was only fluorescent type. Green, red, orange, yellow, blue. This types works.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

pjig

Hazard to Others

Posts: 169

Registered: 25-5-2010

Member Is Offline

Mood: always learning

|

|

So the paints function was a binder , fuel , and a colorant? If acrylic is the fuel , and another paint similar had approximately same h2o content,

theoretically it could be interchangeable .

|

|

|

pjig

Hazard to Others

Posts: 169

Registered: 25-5-2010

Member Is Offline

Mood: always learning

|

|

Forgive my pressing the matter….. I just am bugged by the “self vulcanizing composition “ . It is a incredibly simple but complex matrix

chemical reaction that haunts my creative mind. I know it is a patent nightmare, misleading info. Etc but I’d like to find the gold at the end of

the rainbow….. myth or not …. There has to be some simple cross linking science to back this up . A matrix that self vulcanizes to a solid

detonatable material . Nitrate activated matrix that solidifies chemically to a primer capable material. Forgive my obsession…. It just irritates

me can’t break down this patent

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1395

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Paints content by important order: Water, senzitizer, binder, colorant. Activated matrix by nitrate for primary use is theory of future.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Mush

National Hazard

Posts: 633

Registered: 27-12-2008

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by jpsmith123  | Thanks for that interesting patent regarding methylamine perchlorate.

BTW, it seems the commercial sodium perchlorate explosive is called "Dynoseis".

According to the MSDS, the proportions are as follows:

Sodium Perchlorate (CAS 7601-89-0) 66 to 72%

Diethylene Glycol (CAS 111-46-6) 22 to 27%

I couldn't find any published performance specifications (at least in any Dyno Nobel literature) , but I did find some data from another company that

supposedly tested it.

Density: 1.78 c/cc

Det. Velocity: 22,000 ft/sec

Det. Pressure: 200 Kbar

Gas Volume: 23.2 moles/kg |

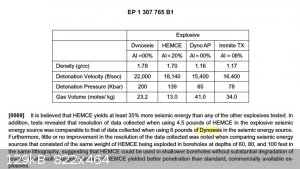

This is the reference:

High energy explosive for seismic methods

EP1307765B1

Note above patent mentions different composition .

Thirty-two sets of test explosions were done. Each set consisted of four test explosions, one test explosion with each of four different explosives.

One of the four explosives used was a high energy melt cast explosive (HEMCE) in accordance with the present invention. The HEMCE consisted of

20 wt% aluminum particulate (average particle size about 20 microns) and 80 wt% of a first explosive material that comprised 30 wt% diethylene glycol

and 70 wt% ammonium perchlorate. Other explosives tested included: Dynoseis (commercially available from Dyno Nobel), Dyno AP (commercially

available from Dyno Nobel), and Iremite TX (commercially available from Dyno Nobel). Dynoseis and Dyno AP are explosives currently used in explosive

seismic energy sources for petroleum and gas exploration. Dynoseis comprises 30 wt% diethylene glycol and 70 wt% ammonium

perchlorate, but it does not comprise any oxidizable metal material. Dyno AP comprises ammonium perchlorate. Iremite TX is an emulsion

explosive that has not been used in petroleum and gas exploration. It is an aluminum nitrate-based trenching explosive typically used in mining, and

comprises about 8 wt% aluminum.

Dynoseis:30 wt% diethylene glycol and 70 wt% ammonium perchlorate

Detonation Velocity :6705 m/s

HEMCE: 20 wt% aluminum , 80 wt% of a first explosive material that comprised 30 wt% diethylene glycol and 70 wt% ammonium perchlorate

DV:5529 m/s

Dyno AP(according to its msds ,it does not containe ammonium perchlorate, patent stated otherwise):

Ammonium Nitrate 6484-52-2 60-80%

Sodium Nitrate 7631-99-4 10-18%

Aluminum 7429-90-5 0-15 %

Mineral Oil 64742-35-4 0-3 %

DV:4693 m/s , Unconfined @ 32 mm (1 1/4 in) diameter

IREMITE® TX. : no info found , phased out product or renamed

There is a need for improved seismic methods and geophysical survey systems that rely on explosive compo-sitions that convert a higher percentage of

the potential energy in the explosive composition into seismic energy. There is also a need for improved methods and systems that efficiently generate

low frequency seismic waves when needed.

Furthermore, it would be advantageous to be able to use shallower boreholes and less explosive to achieve the necessary level of data resolution for

geophysical survey. US3496040 discloses a blasting composition comprising about 16-25 weight percent water, 42-55 weight percent ammonium nitrate,

10-20 weight percent aluminium particles, about 2-10 weight percent hexamethylenetetramine and sufficient water- soluble thickening agent to stabilise

the composition against settling of solids. Not more than 2 percent of the aluminium particles are smaller than 50 mesh (US standard) size (ie, 297

^m).

[Edited on 9-3-2024 by Mush]

|

|

|

pjig

Hazard to Others

Posts: 169

Registered: 25-5-2010

Member Is Offline

Mood: always learning

|

|

That vod seems very high for the AP perchlorate /glycol 70-30 mix.

In same ball park as the Sodium perchlorate mix… (non aluminized)

Just curious if it is #8 sensitive or requires a big booster to push it …

Thank you for sharing that patent .

I’m assuming starting perchlorate is finely ground and dry to start with for proper weights , but may not be completely necessary,having a margin

for water in the mix and particulate size of said perchlorate. (-200mesh or industry standard)

|

|

|

| Pages:

1

2

3

4 |