| Pages:

1

2

3

4

5

6

..

8 |

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

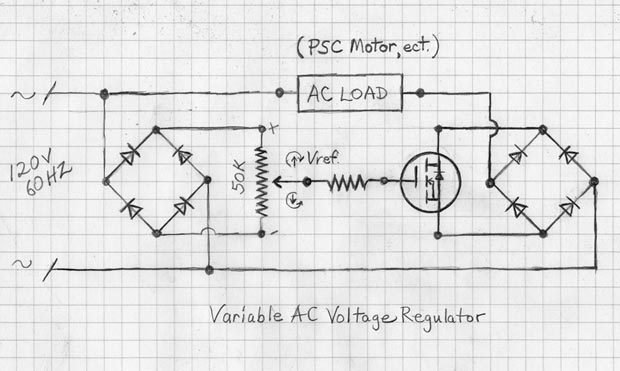

A question for the circuit gurus , please take a look

at the attached file and tell me if the modernized

and hexfet adapted " emitter follower " I have

drawn in the schematic will work as I am thinking it will .

On rare occasion I have been reading and have

encountered the term " electronic rheostat " used

in various ways for no specific circuit which of course

is never illustrated either . But what I have supposed

is that such a device would work similarly as do the

resistance wire rheostats , limiting current by their

IR heat loss , and voltage drop across the semiconductor

when it is operating in the active region .

Anyway , there are uses for these simpler circuits where the noisy waveforms and ripple generated by PWM and other switching type power supplies is

unacceptable .

I have been thinking about possible ways of speed / power controlling permanent split capacitor asynchronous AC motors

such as 1/10 horsepower and less , using off the shelf standard motors , and not the more expensive inverter duty

motors as are required for PWM variable frequency drives .

The simple circuit I have been contemplating could work

well open loop and it could also very easily have the feedback loop closed with some modification and added components . Anyway it looks to me like

the basic circuit should work , but I haven't tried it yet .

Take a look and tell me what you think .

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

Likely the mosfet will blow when the gate goes negative with respect to the source.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by IrC

Likely the mosfet will blow when the gate goes negative with respect to the source. |

I don't see how that would happen since the source has to follow the gate , the same as does the emitter have to follow the base in an NPN emitter

follower . The source will

be at the same voltage as the gate which is Vref.

The idea is that a greatly current amplified Vref. appear on

the right hand side of the AC load , with the rest of the voltage above Vref . being dropped across the mosfet being

forced to act as a power resistor .

Hmmmm , please analyze and elaborate .

Please talk me through it by the half cycle ,

because I don't see it looking straight at it

Edit : see attachment for the mosfet modus operandi

[Edited on 2-2-2006 by Rosco Bodine]

Attachment: mosfet used as source follower.pdf (93kB)

This file has been downloaded 1084 times

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by IrC

Likely the mosfet will blow when the gate goes negative with respect to the source. |

For a few hours I have been studying the proposed circuit

and I still don't see the problem . However should you prove to be correct because of something I'm not seeing in terms of direct or parasitic paths

, I have been thinking about how to remedy the problem of the barbecued mosfet so that volunteer mosfet number two has a happier time of it .

What I am thinking is to self-bias the mosfet from a local

supply derived from its own DC rails across the power bridge rectifier , using an optocoupler to control the gate , and using

Vref. to drive the transmitter side of the optocoupler . The ultimate voltage would probably be 6 volts less across the AC load , but the mosfet

would be bulletproofed . I am thinking a 400 volt rated mosfet minimum , 500 volts even better , for the same reason as the 370 volt capacitor rating

if you have a PSC motor as the load , the peak to peak doubling of voltage that can happen because of the capacitor .

Edit : I have been retracing the paths using different colored highlighters for the two halves of the cycle , and now I see the problem . It

wouldn't hurt the mosfet , but neither would the circuit provide fullwave regulation . When the bottom AC rail is negative going the mosfet can't

function as a source follower but would be in saturation at any of the higher Vref. settings . The result would a baseline shift for the AC through

the load with regulation only upwards from 50% and an asymmetrical output to the load . So ....back to the drawing board

I can do better and I will sketch this hopefully better idea

and post it here .

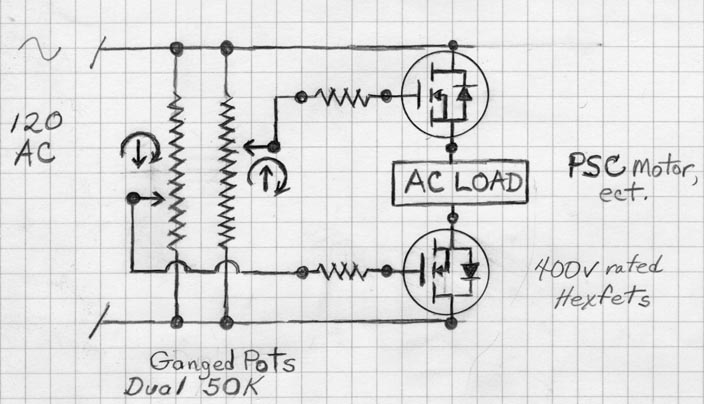

The alternative idea which probably has a better chance of working , involves a ganged pot directly between the AC rails with each separate Vref.

from the wipers driving the gates of two separate N channel mosfets each having their drain connected to the respective AC rail and the source of each

mosfet connected to opposite ends of the AC load . The mosfets operate sequentially as source followers during the half cycles when their drain is

positive , with the return diode in the non-conducting mosfet completing the path through the load to the rail which is negative on that half cycle .

The ganged pots are connected between the AC rails in the way that the wiper of each moves towards rail voltage of the respective mosfet whose gate

is supplied increasing Vref. as the pot is turned clockwise . This should provide a balanced circuit with a symmetrical AC output and no baseline

shift and using fewer parts than the other idea , as well as dividing the heat dissipation between two mosfets when the voltage is set for lower

levels . I have never seen this circuit I have in mind , but it seems so simple

it would have to work .....I hope

[Edited on 3-2-2006 by Rosco Bodine]

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

At the very least, toss on a protection resistor and 12V zener diode, yeesh!

Tim

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

See my edit above , I found the problem and

thought of a better circuit at about the same time

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

Having the gate more negative than the source is not a problem - its a trick often used to provide noise immunity to a mosfet thats supposed to be

off.

The problem is the likelyhood of exceeding the gate/source breakdown voltage - which will fry your fet instantly.

The other issue is heat - you're running the fet linear, with potentially larfe current and large voltage across it. The poor thing could end up

trying to dump 50W or more.

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Here's the simpler circuit that I am thinking

would be sure to work . Any criticisms or

comments or suggestions are welcome .

With regards to the breakdown voltage ,

I thought it was customary practice that

the manufacturers put zener protection

on the gates . I have seen the zener on

manufacturers data sheets , and sometimes

the return diode is a zener too , something

would have to be a higher rated zener than

the max allowable drain to source voltage .

One thing which would probably not hurt is

to parallel an external return diode across the

mosfet to split the heat dissipation from the

internal diode which occurs on each half cycle .

Yeah running any semiconductors in that

active region where they are in fact semiconducting

and acting as resistors is going to produce a whole

lot of heat , so big old heatsinks would be a good idea ,

even a fan cooled CPU heatsink would probably

be a good solution for this circuit when operating

at medium output voltages where the mosfets are

dumping as much heat as the motor .

[Edited on 3-2-2006 by Rosco Bodine]

|

|

|

densest

Hazard to Others

Posts: 359

Registered: 1-10-2005

Location: in the lehr

Member Is Offline

Mood: slowly warming to strain point

|

|

I've got a couple of questions:

Wouldn't an autotransformer (Variac (tm)) work a lot better?

Is there a specific reason to take an analog-ish mosfet approach?

Comments:

It will probably self-destruct releasing the magic smoke inside the transistors.

Sam Goldwasser and his friends have published the circuits inside of commercial

dimmers, motor controls, etc. See sci.electronics.repair.

Each application (motor control, etc.) mentioned in the thread probably

requires a different circuit design and approach if active devices are used.

What follows is a random rant about the subtleties of power circuits.

The FET manufacturers have extensive application notes and sample circuits to copy.

They're not simple - they can't be and still work reliably. Many of the

sample circuits include a sample PCB layout which can be copied as well.

This saves enormous grief.

If the intent is to make a low electrical noise attenuator for line power,

a transformer or autotransformer is the best power/cost for an amateur.

If you happen to have (for example) Crown (tm) power amplifier and a signal generator,

you can make clean sine waves. This costs more $$ unless you have the equipment already.

The third way (more exotic) is to get Texas Instruments' pulse density modulation

power amplifier modules and wire them up (carefully), using a correctly sized reconstruction

filter on the output.

Using today's power MOSFETs as analog devices is treacherous.

They oscillate, overheat, and generally are rebellious unless you've studied a lot of electronics.

They are not designed to be used "partly on" and they are not characterized for that.

In any case attaching the gate to a pot connected to the power line is

a recipe for much smoke. At least connect series resistors and parallel zeners

to make sure that the gate never exceeds + or - 15 volts with respect to the source.

Even instantaneous spikes will kill the FET. The built in zener diodes (if present) have

extremely limited power handling capability. Be sure that the zener diode power

limits are never exceeded.

There's a further problem here:

most power FETs can work well into high megahertz frequencies, and the parasitic

inductances and capacitances of the leads & nearby components frequently cause

oscillations which can destroy the FET quickly. The gate must be driven from a low

impedance (usually in the 1-100 ohm range) to prevent oscillation. This usually requires

an active circuit to drive the gate.

If anyone makes it this far and wants to know more, I'll deliver more prime bull.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

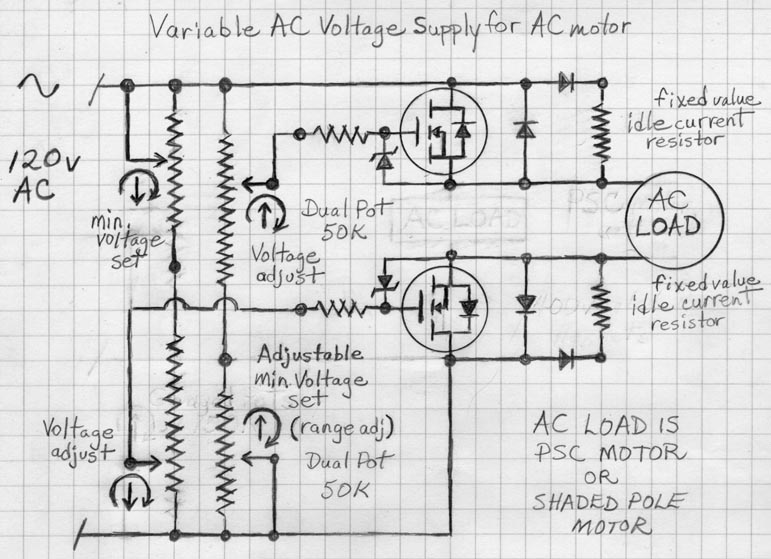

@densest

Look at the attached file showing the evolution of the

circuit design which I have been contemplating , and

consider why certain advantages are provided over

a variac , such as being able to set a minimum voltage

where the adjustment begins to effect adding power to the motor . The use of control circuitry also provides locations

where logic input is possible to be applied to make the circuit behave differently in response to sensed conditions .

For example when the circuit is first powered up , the existing

voltage setting could optionally be over-ridden by external signal specifying some selected number of complete cycles of full voltage to the motor to

provide extra starting torque ,

and when the counted number of full voltage cycles has

completed , the circuit resumes operation at its setpoint voltage just after the motor breakaway into rotation .

What I am looking at is simple ways of improving the performance particularly of off the shelf 1/10 hp and less permanent split capacitor AC motors ,

using something

better for the task than triac based sine wave choppers .

The trapezoidal waveform from the circuit I have attached

is more nearly zero crossing with its waveform being continuous to less than 2 volts of zero on each half cycle

before dropout . This should be a very quiet circuit in

terms of any unwanted harmonic effects or spikes .

IGBT's could be used as easily as MOSFET's .

Edit : I may have the left side of the range adjustment pot

drawn wrong , and moving the wrong direction .

I just drew this and am looking at it . I think

its coil probably needs to be above ......yeah I'll have to redraw it and repost the corrected schematic . I have made

some changes and really should redraw the entire schematic

in a better layout . Long day .

I'm too tired to redraw the whole thing so forgive the smudges from my erasures and corrections . Here's the

corrected schematic for where I am now .

[Edited on 4-2-2006 by Rosco Bodine]

|

|

|

densest

Hazard to Others

Posts: 359

Registered: 1-10-2005

Location: in the lehr

Member Is Offline

Mood: slowly warming to strain point

|

|

@balanced_world: for temperature control (resistive heater) a triac driven by an asymmetrical diac (to prevent "snap on") is cheap, effective, and

simple. If you need electrical quiet, use a cycle skipping zero crossing triac chopper which only delivers full cycles to the load. Thermal inertia

takes care of temperature fluctuations.

@rosco: (please excuse typos - a cat is holding one hand hostage)

Sorry if I'm pedantic about this. I've been studying motor drives and power transmission recently. I'm assuming that your intended applications are

not for large scale production, so scrounging good equipment on EBay, etc., can cut your costs a lot.

Your motor control application is reasonable. Is this intended for existing motors or new ones? What's the intended speed range (i.e. if 100 is

"full speed", do you want 1-300 or 5-120?) Do you want constant torque, constant power, or ?? over the speed range? Remember that as speed decreases

you must increase torque (magnet strength) to maintain power, and electromagnets fry if you saturate the steel.

For old motors or existing ones: remember stiction at startup or low RPM. At low voltages, the power and torque of AC motors is pretty low. Some of

the chopper drives, ridiculously simple as they are, do provide more power as the load increases even at low speeds. If your goal is to control the

rotor speed, you must have load feedback.

For a new design: consider a three phase motor. It inherently is easier to drive at full power or torque over a wide speed range. Rather than

changing the voltage alone, changing the frequency as well gives you a more control. The capacitor phase shift in a 1PH motor doesn't like a wide

frequency range. It's inherently simpler (no startup circuits, no cap to blow up...) Some new washing machines use IGBT choppers to drive a 3PH motor

for all the washer functions with only a belt connecting the tub and the motor. No more transmissions to break.

If you derate them (like using a 1HP motor at 1/3 HP), "motor drive rating" doesn't matter very much. Saves a lot of money.

For a new design: consider a permanent magnet DC motor if you need high torque at low speed.

In any case, IGBTs and FETs are much happier used in a H-bridge configuration when driving an inductive load.

I'm looking forward to seeing your design.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

@densest

For reasons of economy and simplicity and practicality

for the application , the alternatives you suggest are

not valid . I want to control a single phase 120 Volt

60 cycle off the shelf permanent split capacitor motor

of 1/10 horsepower or less , using most desirably the

inherent abilty of a quadratic load to self regulate

the speed of the motor , without the use of closed loop

digital speed regulation . If the power and motor is

well matched to the load , particulaly a dual quadratic

load on a dual shaft motor where say 20% to 30% of

the motors torque is diverted into a parasitic quadratic

load like a squirrel cage cooling fan or a hysteresis disc ,

or even static field of DC injection into the stator itself ,

an asynchronous motor being driven under these conditions

will self speed regulate acceptably well at a fixed supply voltage . If the workload decreases on the motor , its

speed increase is limited by the parasitic load increase ,

and vice versa . And the response is instantaneous in

such a self-regulation scheme where feedback is an inherent

property of a quadratic load being exploited as a parasitic

load . I hope that made sense . This regulation effect

should occur best in the speed range from about 120 rpm to 1200 rpm for a four pole PSC motor where the torque speed

slope is linear . The shaft horsepower output should still be more than double at the same wattage for a PSC motor run

in such a scheme as is gotten from a shaded pole motor ,

and the speed regulation better , as well as the starting torque and entire low speed range torque .

I really can't understand the fascination of people with variable frequency drives for asynhronous motors which will never be run up to synchronous

speed where the effciency

would be realized . And for a 75 watt motor the hardware investment is hardly worth consideration in the same sense as would be understandable for a

75Kw motor in a factory .

|

|

|

Lambda

National Hazard

Posts: 566

Registered: 15-4-2005

Location: Netherlands

Member Is Offline

Mood: Euforic Online

|

|

Zero crossing firing and cycle skipping

@Densest,

I would like to know what you think about using a "cycle skipping zero crossing Triac chopper" in a Power Supply.

Transformer Specs.(Philips): 24 Volts and 40 Amps.

This is not the usual 1000 Watt Magnetron type Transformer kind of garbage. At least 4 Magnetron type Transformers would fit this Core, and the leads

are about 8 mm diameter and made of solid Copper wire connected to M10 Brass studs. At 40 Amps, this "Monster" stays ice cold which makes me believe

that 40 Amps is a rather conservative rating from the guy who sold it to me.

I would like to keep the "Bridge-Caps" voltage about 5 Volts (or even less) above the regulating Transistors output Voltage, to give them regulation

space.

By using Triacs in the primary leads and firing them in the Sin Cycle, not only "bumps" the transformer, but also produces lots of Harmonics and heat

in the Core. The Transformer efficiency drops drastically.

"Zero crossing firing and cycle skipping" seems to be a very elegant solution. I have 10, 25, 50 and 100 Amp zero crossing Solid-State relays from

"Crouzet" and "Gunther" etc.. They are internally Optic-Coupled, and only need 3-32 Volts to trigger them and can switch 24-280 Volts AC. Even if they

are fired during a Sin Cycle, they still take the first zero crossing.

[Edited on 4-2-2006 by Lambda]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Lambda ,

Be careful with cycle skipping or people

will say the real truth is that you are

performing burst modulation

Page 10 on the attached file may interest you .

[Edited on 4-2-2006 by Rosco Bodine]

Attachment: Triac Inductive Load Control Circuits.pdf (92kB)

This file has been downloaded 920 times

|

|

|

bio2

Hazard to Others

Posts: 447

Registered: 15-1-2005

Member Is Offline

Mood: No Mood

|

|

@ rosco

The circuit you have in mind controlling a series

connected AC load using the DC side of a bridge rectifier

does work but has many limitations such as non linear operation and not of much use except between 80-120 volt. The simplicity can't be beat except

perhaps by a triac like the inductive rated "quadracs" made up to 40A

800V by Teccor.

This may well be adequate for your application and can be simply implemented using a duty cycle modulated transistor on the DC side. This circuit

puts a lot of noise on the AC line if that matters.

Motorola had patented a circuit like this years ago but it never recieved much attention or use. The unit I built some years ago for a 3phase 20A 480V

application used

a PWM duty cycle controlled bipolar transistor on each phase and worked well enough.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

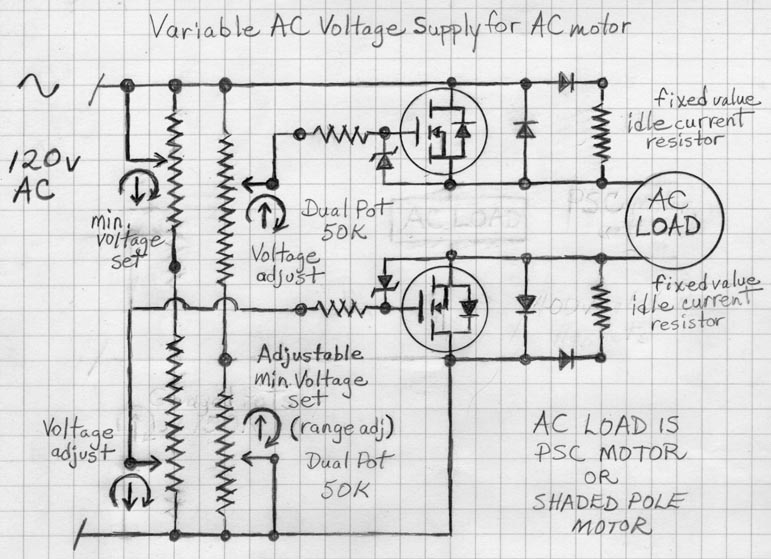

The latest corrected revision of the mosfet circuit I am

considering is first attached at the end of my fourth

post above counting this post as one . Please take a

look . I think this particular circuit will work fine and

can be matched to the characteristic of a particular motor

in a particular application by using different value

power resistors for the fixed idle current value to the

motor , to supply just sufficient power that the motor

will barely turn , windmilling under light load . The value for these fixed resistors will have to be selected by first doing a rheostat test with

the motor and 4 diodes ( two in series forward biased paralleled with two more in series reverse biased ) and measuring the resistance value needed

for setting the idle current . These power resistors will divert much of the heat dissipation from the mosfets when the adjustable voltage is at

minimum , reducing the heatsinking requirement . The redundant return diode I have added externally across the mosfet drain to source will also halve

the return diode dissipation which would otherwise be there in the mosfet . The added zeners are likely to be 15 volt and are redundant gate

protection . Candidate mosfets are Hitachi 2SK1837 , overkill for sure , but the overkill translates to ruggedness at little extra cost above using a

minimal device for the mission critical component and having a failure

later from too little transient immunity .

I think I will reattach the schematic file here since I am further describing the circuit here in more detail and it

may be lost in the posts above departure to other related

circuits .

There is an idea which I have wondered if it has ever been

explored by the industry regarding the possible use of

many CdS photoresistor elements paralleled as regions

to form a " power photoresistor based optocoupler " ,

a " power vactrol " if you are familiar with the signal level

vactrol optocoupler by Perkin Elmer . Such devices are

high voltage AC photoresistors which might be arrayed

in sufficient number in parallel , deposited directly on a

heatsinkable substrate and driven by high output LEDS ,

to form a high current capable full wave line voltage AC controller , driven by TTL voltage levels , and passing

the AC power with the waveform completely unchanged

except in terms of controlling its voltage . Has anyone

heard of such a device ?

Anyway the revised mosfet circuit from the earlier discussion

is reattached here . I will likely prototype and test this

particular revision attached below since it seems workable in visualization of how it should work . Now if only Murphy's Law will not discover what I

may have missed , it should be all right

I am going out on a limb here , but there is always the possibility when anyone is drawing a schematic for a

dedicated circuit for a niche application , that what they

design is entirely novel , since if they could find the circuit

already published in an application note as a commonly known circuit , then there would be no need to invent it

themselves in the first place . So it is just possible that

what I have done is propose an entirely new circuit in

one of those necessity is the mother of invention scenarios ,

and the fact it is a simple circuit in no way rules that out .

So if anybody should run across this circuit already published somewhere , please let me know since it also likely that often these sort of things

turn out to be that in the lands where no wheel was to be found , it was reinvented by one genius after another who are all cousins of mine

[Edited on 4-2-2006 by Rosco Bodine]

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Erm... *ANY*!!! *AC* motor will really highly NOT appeciate a "light dimmer" approach. This will ONLY work on universal type motors (the kind that

you can use a dimmer switch on anyway).

Other than that, the circuit ought to work as shown, not counting the blown junctions of course (I hope you have a good way to dissipate all that

wasted power).

Tim

[Edited on 2-4-2006 by 12AX7]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by 12AX7

Erm... *ANY*!!! *AC* motor will really highly NOT appeciate a "light dimmer" approach. This will ONLY work on universal type motors (the kind that

you can use a dimmer switch on anyway). |

Hmmm , there are dimmers of the sort we all know ,

and then there are other different circuits having different waveforms , like what I am illustrating , and indeed this should work for PSC and shaded

pole motors better than

triac based wave choppers or series rheostat circuits which

are often used even though their behavior is counterintuitive

in that the inherent feedback to motor current increase under loading goes in the wrong direction , reenforcing the

speed decrease towards a stall . And then there's the buzzing created by switching harmonics of triac circuits which

cause stator hum and insulation breakdown over time .

What I propose should address those deficiencies and that

is the motivation .

| Quote: |

Other than that, the circuit ought to work as shown, not counting the blown junctions of course (I hope you have a good way to dissipate all that

wasted power).

Tim

|

Exactly where do you expect blown junctions and why ?

And who cares about dumping heat and " wasted power " from smoothly controlling a sub-fractional horsepower motor

when you don't get something for nothing in this case ,

and the wasted heat amounts to about what is dumped

from your computers CPU heatsink right now .....that's

wasted power too , but very necessary to get done

what business is at hand . All in all the waste is less than

what is dumped by the average desk lamp , and that waste

goes away completely as the voltage setting is raised to

maximum . The heat dumping only occurs at the lower

voltage settings .

When it comes to the matter of active closed loop speed regulation , there is a method which is fairly simple to implement to provide for fine control

of the speed when

there is not a great variation of the load , perhaps in the range of plus or minus 10% . The method involves eddy

current braking being applied as a parasitic load to a motor

to increase its slip and reduce its stable rpms at a given voltage . If you have two iron core inductors with their

airgaps widened sufficiently that the opposite edges of an aluminum disk on the motor shaft is travelling through the airgaps during rotation , the

magnetic field through the gap induces eddy currents in the disc and produces a torque loading on the motor which varies quadratically with rpms or

with the strength of the field which may be varied by the current through the electromagnets . There is some inherent

speed regulation present with this sort of parasitic load ,

and the effect can be increased by active control of the current through the electromagnets , which can decrease or

increase the torque load on the motor which varies its

slip speed and rpms accordingly , even if the voltage to the motor is held constant . This is similar to the scenario where

a car with an automatic transmission is stopped on a steep uphill grade and a little throttle is applied sufficient for the car

to roll uphill , but a little pressure on the brake pedal holds

the vehicle in position ......yes power is being " wasted " but

for very good reasons which the situation requires , a balancing of forces which allows the vehicle to only roll forward when the traffic light

changes and pressure on the brake is released , with no chance of rolling backwards and

smashing the grille of the police car stopped behind

Now that's regulation !

[Edited on 4-2-2006 by Rosco Bodine]

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

| Quote: | Originally posted by Rosco Bodine

or series rheostat circuits which are often used even though their behavior is counterintuitive

in that the inherent feedback to motor current increase under loading goes in the wrong direction , reenforcing the

speed decrease towards a stall. |

Yeah, you can reduce the RPM of an AC motor by reducing voltage, thus limiting power by the DC resistance of the winding and running it on the stall

slope (relatively constant torque), but that's a really shitty way to do it.

| Quote: | And then there's the buzzing created by switching harmonics of triac circuits which

cause stator hum and insulation breakdown over time .

What I propose should address those deficiencies and that

is the motivation. |

Proper snubbing can prevent this, although in general triac control of any inductive load is irresponsible anyway.

| Quote: | | Quote: |

Other than that, the circuit ought to work as shown, not counting the blown junctions of course (I hope you have a good way to dissipate all that

wasted power).

|

Exactly where do you expect blown junctions and why ? |

*Points at schematic* That transistor, and that transistor.

| Quote: | | And who cares about dumping heat and " wasted power " |

Well, I suppose you wouldn't understand what engineering is about, so it's a bit of a lost cause on you anyway...

| Quote: | | from smoothly controlling a sub-fractional horsepower motor |

It might be rated for 0.6A at 120V. At half voltage (assuming a resistive response), that's 0.3A at 60V = 18W in each (9W per transistor). That can

be easily dissipated, but using this on any heavier motor will quickly cost you.

Oh, and don't forget short circuit protection. Transistors don't appreciate 160V peak at 50A. (Don't say it won't happen, if it can it will. A fuse

is NOT fast enough to protect silicon!)

| Quote: | When it comes to the matter of active closed loop speed regulation , there is a method which is fairly simple to implement to provide for fine control

of the speed when

there is not a great variation of the load , perhaps in the range of plus or minus 10% . The method involves eddy

current braking being applied as a parasitic load to a motor

to increase its slip and reduce its stable rpms at a given voltage. |

Holy crap, I suppose you also run your heating and air conditioning at the same time, too?!

If you're going to do *breaking* in the first place, skip the whole voltage control and use the low torque output of the motor itself... it'll waste

less power, too! (All shaded pole motors are rated as "impedance protected".)

| Quote: | If you have two iron core inductors with their

airgaps widened sufficiently that the opposite edges of an aluminum disk on the motor shaft is travelling through the airgaps during rotation , the

magnetic field through the gap induces eddy currents in the disc and produces a torque loading on the motor which varies quadratically with rpms or

with the strength of the field which may be varied by the current through the electromagnets. |

Ahem.. force (torque) is proportional to RPM linearly, not squared. Since *power* is force times rate, the power varies as a squared law.

| Quote: | There is some inherent

speed regulation present with this sort of parasitic load ,

and the effect can be increased by active control of the current through the electromagnets |

I wonder, do you also keep your car's gas pedal floored and control your speed down the road with the brakes?

Tim

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Taken to extremes of absurdity , any rationale

including engineering principles which have validity

in a qualified sense and limited application can

be made into a farce , which is what you are doing .

The small rotor mass and momentum of small motors

involves different considerations for how to do things

best , than is directly applicable to much larger motors .

You are a purist when it comes to engineering .

I am a pragmatist , get the job done with what

works best within economic reason , but not

necessarily the cheapest or dumbest POS

that can be made .

If mosfets were never intended nor designed to be

run in DC linear mode , then why in the hell do the

manufacturers data sheets specify their performance

operating in exactly that fashion as one of their

parameters ? They will not fry so long as they are

operated within limits .

And short circuit protection is optional but can be added .

Voltage sensing across a low value resistor in series with the load can be used like a meter shunt as an input to a comparator , and a reference for

current limit set on the other input , with the comparator output used to drive optocouplers clamping the gates to their rails at below their minimum

on voltages . But with your vast knowledge of engineering , I'm sure I don't need to explain this to you .

I know how to drive , and can power brake even a

manual transmission vehicle on a hill by using my right heel on the brake pedal and the toes of the same foot on the gas while the left foot eases out

the clutch ....

but I have never found this useful while simply cruising

down the road .

What you were saying about eddy current braking being used entirely for speed control is indeed possible but it

is generally done by letting the motor run at full speed

and using an eddy current clutch to couple to the load ,

they may call it a hysteresis clutch in some circles . It

works like a fan clutch on an automobile radiator , and they

may even make some of those using an eddy current clutch ,

but most of them are miniature hydraulic torque converters

which are thermostatically engaged or disengaged or

throttled in between by a little spiral pilot valve operated

by a bimetal coil which responds to the temperature of the airflow from the radiator .

With regards to quadratic loads , the torque requirement appears as the speed squared , and the power requirement

as the speed cubed . Somehow we aren't on the same page . And the linear slope for the torque speed characteristic is the shallow slope upwards

from locked rotor

to about 75% of synchronous speed of 1800 for a 4 pole motor , 1260 rpm or so . The steep part of the slope is from

about 95% of synchronous back down to about 80% , not

much of a speed range for adjustment where the motor is

working in the range of its maximum output . So the

low and gradual slope is exactly where speed must be

controlled if the purpose for such a speed control is the

drive for a magnetic stirrer , which is what I am doing .

Does my strategy now make more sense ?

[Edited on 5-2-2006 by Rosco Bodine]

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

| Quote: | Originally posted by Rosco Bodine

If mosfets were never intended nor designed to be

run in DC linear mode , then why in the hell do the

manufacturers data sheets specify their performance

operating in exactly that fashion as one of their

parameters ? They will not fry so long as they are

operated within limits .

|

I don't like wasting power. Linear region means volts times amps. You can certainly make a wonderful amplifier using the full linear region, but if

you tack on a PWM and integrator, you can go from 33% to 95% efficiency in one fell swoop! Class D has plenty of volts and amps, but not together, so

there's very little waste.

FYI: because of the favorable characteristics, many FETs are only rated for pulse or switching applications. That doesn't mean they won't work in the

linear range, it just means they weren't intended for it. This isn't new: vacuum tubes designed for TV sweep or radar pulse applications have few

linear operating points listed.

Tim

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Hey I don't like wasting power either , but there

is a time for practicality versus pure power utilization

economy , and for a small motor it isn't worth the expense and grief of hardware complexity to save a few watts

when they can be more easily just dumped as the cost of doing business in the particular application . With light

motors , cogging and hunting oscillations are inevitable

using pure brute force digital closed loop speed control

at low speeds . So it is far better to try to match the

motor to the task , and exploit every inherent speed regulation method which can be used , before ever getting

to the point of using closed loop feedback for fine control .

The idea is that the thing should run pretty stable ,

and perhaps stable enough , even without any feedback

from digital controllers . Well designed equipment where

the components are well matched can do the job very well

open loop , and many times that is exactly the way equipment of the old days was made , mechanically governed like steam engine throttles , before any

digital

circuitry was ever invented . Some of these scenarios

are really quite ingenious and work very well . There is

a trap involved in getting overly technical on a simple device where it isn't necessary if there is a simpler and

possibly better way , even if it does waste half the power

of a 75 watt device at its least efficent point of operation .

For the price of 37 Watts I'll take simplicity and reliability

and economy any day .

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Bah... Dig out a switchmode power supply chip, a pair of MOSFETs, rig a ferrite transformer (all of ten minutes winding one) with DC restorer for

gate drive, rectify the line voltage then chop it, add a filter and you've got a PWM class D amplifier, 95% efficient or better, and if you generate

your own drive signal you can get any frequency, amplitude or waveform you want.

For something this small, pffbt... but anything over a half horsepower, this is how it's done.

Tim

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

For those really critical range hood ventilator fan

speed settings when only the best will do ......

make this little gem the powerhandler and the manufacturer

will throw in the dedicated workstation with user friendly

interface for free

http://www.ballantinelabs.com/bli1620a.htm

Then again , when it's a five dollar motor ......

there just has to be an easier way

Actually my first thought on this project was to open up

an inexpensive uninterruptable power supply and

see if it would be possible to easily adjust the voltage

output from the inverter .

The output would already be well filtered sinewave

so it would simply be a matter of being able to adjust the output voltage . The input side is already there for keeping the battery charged , but of

course the battery isn't needed for the use to which the UPS power stage would be adapted .

[Edited on 5-2-2006 by Rosco Bodine]

|

|

|

densest

Hazard to Others

Posts: 359

Registered: 1-10-2005

Location: in the lehr

Member Is Offline

Mood: slowly warming to strain point

|

|

Modern circuit design has gone away from analog power circuits for a number of reasons, like size, weight, cost, and reliability. Choppers are widely

used to drive motors because they are very simple and do a "reasonable" job for low cost.

There's a "simple" way to make sine waves digitally at reasonably arbitrary voltages from a fixed supply. It uses sneaky math to work, but the

circuit is simple. More or less.

Get a microcontroller with one digital output and several digital inputs or one analog input. If the inputs are all digital, this requires log(2) of

the number of discrete voltage steps. The microcontroller should be capable of switching the output at (say) 256X the desired output frequency while

sampling the inputs at (say) 10x per second. For this application jitter is not too important.

Compute the Fourier transform of the desired waveforms, which for sine outputs is a single nonzero value. Compute the reverse Fourier transform at

the desired sample rate and quantize to 1 bit using a good random number generator for dither. Burn tables into the microcontroller

for the desired amplitudes. Program the microcontroller to output the table values (1 or 0) depending on the control inputs.

Connect the output of the micro to a high-voltage mosfet high/low driver pair. Invert the output and connect it to another driver pair. Make an "H"

bridge of mosfets - the output is the crossbar. If desired, compute a 3 or 4 section passive LC Bessel filter for the output of the bridge. At least

put an L -> C for 12dB/octave at 2X output frequency or so and some snubbers (choose your favorite).

There are a couple of options for the input (AC line).

1) Brute force: Get the DC buss from a bridge rectifier and cap. Ripple doesn't matter much. Output voltage is proportional to input voltage.

2) Sneaky: Sync the micro to the input line zero crossings and apply a sine function as a correction to the quantization during table generation.

Rectify the line with a bridge rectifier. No filter cap needed at all. Output voltage is proportional to input AC voltage. This is the closest I think

practical to a "just step down the input" circuit.

3) Drive the DC buss from an off-the-shelf PFC circuit. You get regulation and universal input for free.

Total parts count: 20-40, with most in the PFC version. All but the power components (4/5 FETs, diodes, inductor(s), filter caps) could be tiny little

things on a tiny little PCB.

None of this addresses the problem of speed control. Dissipative speed control is possible but inelegant. Monitoring the reverse EMF of the motor is

pretty easy given this approach, but it would add another (say) 10 parts and some microcontroller inputs. Response times could be < 5 output cycles

or so.

Efficiency should be > 80%, RFI should be easily controllable, response quick, and cost < $30 for parts. If you want cheaper use a universal

motor and an SCR.

Possibilities: for lower speeds changing the output frequency to a lower value would allow the motor to run closer to its synchronous frequency and

therefore run cooler. That approach would require input version (3) since the output would no longer be synchronous with the power line. Of course

this approach is limited because the motor phase shift capacitor becomes less effective with lower frequency excitation.

A three-phase version would always run the motor at its synchronous frequency, but it is probably impractical for < 200W motors unless you have a

cheap supply of synchros, which would work beautifully.

|

|

|

| Pages:

1

2

3

4

5

6

..

8 |