| Pages:

1

2

3

4

5

6

7 |

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

Thanks for the info, I do not plan on building a large furnace anyway, I just need something to melt small ammounts of powdered antimony, to

consolidate it into any other form, and likely for melting other metals as well. However, for such a small use, it would be a shame to have to buy so

much wire from resistancewire.com, anyone have a source for smaller ammounts?

http://www.used-line.com/c4452597s1424-Ohmite_VT8.htm

This is the one I found, it just needs a new cord(I found it without one). 150$ piece of working equipment for free...wow...

|

|

|

neutrino

International Hazard

Posts: 1583

Registered: 20-8-2004

Location: USA

Member Is Offline

Mood: oscillating

|

|

Have you tried eBay for smaller amounts?

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

Recently I replaced the element and all the bricks in my 117 Vac HB64 kiln, ordering the parts from Olympic. I decided to build a tube furnace around

my 1 inch quartz tubing using the old bricks and crafting them into the shapes I needed. For the element, the cheapest way I found was to just buy a

second replacement element for the original kiln, as it was only 25 dollars. If I were you, this is the way to go, since all needed calculations

concerning resistance and current are already done for the element to run a long time without burnout. The URL is http://www.kilns-kilns.com/ . The element comes with new Kanthal pins and 2 crimp terminals, all you need is a controller. I bought a replacement

infinity controller as that was also only 25 dollars. Worked out great. For items like variacs Fair Radio Sales in Lima, Ohio is a good place to look.

You might consider replacing the copper/graphite brush in your variac, the local place that rebuilds starters and alternators is perfect if you bring

your old one and just do a little machine work to get dimensions correct. While I already have 1KVA and 5 KVA variacs, I found the infinity controller

was vastly superior (and much lighter and smaller!).

|

|

|

Mr. Wizard

International Hazard

Posts: 1042

Registered: 30-3-2003

Member Is Offline

Mood: No Mood

|

|

Thanks for the suggestion to use the copper/graphite brushes from an alternator repair kit. I could have used the brushes from an old starter too, as

they are big and easy to work on, and have the advantage of having a heavier braided copper leads already attached. That's what I did to fix it.

It's a big old boat anchor, awaiting a suitable project.

|

|

|

Magius

Harmless

Posts: 20

Registered: 9-6-2004

Location: Green Bay

Member Is Offline

Mood: Constrianed

|

|

| Quote: | Originally posted by IrC

Recently I replaced the element and all the bricks in my 117 Vac HB64 kiln, ordering the parts from Olympic. I decided to build a tube furnace around

my 1 inch quartz tubing using the old bricks and crafting them into the shapes I needed. For the element, the cheapest way I found was to just buy a

second replacement element for the original kiln, as it was only 25 dollars. If I were you, this is the way to go, since all needed calculations

concerning resistance and current are already done for the element to run a long time without burnout. The URL is http://www.kilns-kilns.com/ . The element comes with new Kanthal pins and 2 crimp terminals, all you need is a controller. I bought a replacement

infinity controller as that was also only 25 dollars. Worked out great. For items like variacs Fair Radio Sales in Lima, Ohio is a good place to look.

You might consider replacing the copper/graphite brush in your variac, the local place that rebuilds starters and alternators is perfect if you bring

your old one and just do a little machine work to get dimensions correct. While I already have 1KVA and 5 KVA variacs, I found the infinity controller

was vastly superior (and much lighter and smaller!). |

Whoa whoa, what?! Surely it can't be that easy.

IrC, are you saying that you built a fully functional furnace (Abit with 1" quartz tubing as the crucible) for 50$ using only the infinity controller

to vary the current and the purchased heating element? Care to enlighten us (with pictures if you have the time) on your particular set up? Does the

heating elemtent come in a preset design/cut length to fit with the powersupply from the infinity controler? Does the controller let you vary the amps

and thus heat out put? I suppose it must, kilns arn't always fired at max temperature...

That just seems too easy. Perhaps I'm missing something?

On another note, I have been doing alot of reading on furnaces, and came across the idea of a reverbatory furnace from Here

This looks nifty, especially if its electric instead of propane fuled. The main advantage I see is not having to deal with a cruicible, while a

disadvantage is that brass/bronze/zinc could never be cast as the Zinc Oxide fumes would probably damage/destroy the heating element. It could be

built easily enough, is usefully for casting ingots, and with an little inginuity, could probably have a base with a jack in it to help pour just like

a cruicible would. See this picture for a rough idea of what I'm talking about

Wait for it...

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

Since the U2U reply does not work right with my browser it is easier to answer here, plus then others gain from any information given. I really don't

like to answer questions like this in a U2U since it does not help the board. So my reply:

Quote the U2U from Magius

"IrC, I posted in the Electric Furnace thread a while back, care to reply? I also have some more questions on your post. The infinity controller you

mentioned, does it look something like this? (http://cgi.ebay.com/Paragon-PCB-1-Power-Control-Infinite-Swi...) And if it does, doesnt that look an aweful lot like this? (http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&item=75723...) For 25$'s though, I'll probably just buy it from the site you mentioned. Now as

for wires, do you know the specifications for resistance, heat expansion, max temp ect? You said that all the calculations were already done for you,

but I must be missing something, becuase some of the kilns require 2+ heating elements to work, how does the kiln pull 2x electricity to get up to the

same temperature? Which leads me to my next question: How hot can the bricks get before they break down?

On this site ( http://www.baileypottery.com/) it lists some of its bricks as having a max temp of 3000F(1650ish C) but the site is unclear as to how much they

cost(5.50 a brick?!)"

---------------------------------------------------------------------

I imagine the controller is the same, just minus the box and wiring, etc.. I do not know the specs on the heating element, as far as I know they don't

state it at Olympic. It was just a replacement element for a 117 Vac kiln, so therefore they had cut the length correctly for the HB64, the kiln I was

talking about. It draws around 15 amps, and the controller is the replacement unit for this model. On the controller question, it is just the

controller by itself for $25, as it goes into the box on the side of the kiln. A kiln using two elements is likely wired for 240 Vac using two 117 Vac

single elements. Don't ask me why 117 and 240, it is just the terms used, where 117 is the so called "national average" of voltage for the power grid

in the U.S. (I know this as I asked a lineman about it once), likewise when it comes to the secondary voltage of a pole transformer the term 240 is

the most often one used.

I am sure around the country the line varies from 110 (rural) to 122 (city) so the confusion as to 220 or 240, etc., but I digress.

Around 2,000 F is the highest safe temperature before the element gets wasted, but I have learned that two things affect this more than other factors.

One is when the wire is installed to correctly stretch the coils so there in not an area where the loops get too close together (this was the point in

my kiln where the element burned in two). Also, the speed at which operating temperature is reached is critical, no more than 100 degrees F per hour

increase will give you long life, VS going from say 500 degrees F to 1800 degrees F in under 60 minutes. This factor is also the same for the bricks

as far as cracking and failure of the refractory goes. If you are impatient and zoom your kiln up to 2,000 degrees F in a real hurry expect to see

catastrophic failures quite often in many areas. Likewise opening your kiln door and letting cold air rush in is a death blow to both the elements and

the refractory.

As to the question "some kilns require 2+ heating elements to work, how does the kiln pull 2x electricity to get up to the same temperature?", You

need more heat source for a kiln with a larger interior size, and the factor of pulling twice the current to get up to temperature only applies to the

area heated. At least in terms of normal kiln design that is, or in other words you could build a kiln with two elements spaced closer together but I

think failures would be an issue, as well as power efficiency. It looks to me like the going method is to have one channel per brick for the elements

to go through. So a kiln two bricks high would have two rows of element(s). This could be one long one or two shorter ones in series, or whatever

variation depending upon kiln size and voltage. Really this is all about amps since kiln manufacturers are usually thinking of the average home power

source, VS some custom setup in a factory or whatever.

The number of elements to get up to temperature is not important from the viewpoint of your question about twice the electricity, etc., as the

elements are cycled on and off. By this I mean two elements for the same internal area likely would be on only half as much. Maybe this is a good idea

for a fast rise in temperature while still keeping long element life but I assume the refractory failure rate would limit these things anyway. As to

the infinity controller obviously you will burn it up if you overload it (amperage wise), it is common sense to properly consider each and every

little point in your overall kiln design.

When you are designing a kiln first you need to know the maximum temperature to choose the right refractory. If I wanted a 2,500 F kiln it makes sense

to find a 3,000 F brick. Then size inside. I would want no more than two and a half inches of distance between heating elements, so if I was using 3

inch brick stacked two high then a single channel down the center of each one would be great. Now overall area. How many inches of total length is

needed for the elements to go all the way around inside, for each row. What is the resistance per foot for the elements I will use? What is the

amperage I wish to have as a maximum limit for my wall outlet? If you say 20 amps at 117 Vac then I would say redesign the kiln for 240 Vac and use 10

amps. Easier on the house wiring so to speak. Under no circumstance would I want a design which needed some form of ballasting. Every kilowatt hour

being used is going to go into heating bricks in any kiln I design.

This may mandate choosing a different heating element to go the same distance around the inside while staying within design parameters such as

amperage draw, and how many amps can the controller handle, and so forth. Consideration should be given to the temperatures expected and what can the

elements handle, and in my case how well do they withstand chemical fumes is important. I just love bringing a big dish of Lanthanum Carbonate up to

2,000 degrees F for two hours and pulling out the dish with this little bitty pile of Lanthanum Oxide. Call me weird but this is more fun than buying

the oxide. Ok, so being real I found a deal on the carbonate and could not find any decent source for the oxide. To be honest until I repaired my

first kiln, and then designed my first kiln, I had no idea what a really complex engineering challenge the whole thing is to have something that will

do all I need combined with extremely long life and absolute safety. Those guys at Olympic must really be on the ball in the engineering department, I

have been very impressed with my little kiln since the day I bought it. Of course the base is the only original part left and I even redesigned that

to give more bottom support. In all fairness to them I don't think they had mad science in mind. I like to get from room temperature to two grand in

two hours, while baking a dish full of chemicals. Who knew?

Of course my life was made much better when a member here introduced me to the concept of ITC-100 for the bricks and ITC-213 for the heating elements!

I used to get burned if I touched the top of the kiln while it was up to 2,000 F. After coating ITC-100 on the inside, now I can actually hold my hand

on top a few seconds without discomfort. I can only guess how much more thermally efficient this is, also the elements are cycling on only a third as

much as they used to. ITC-213 coated on the heating elements protects from burnout as well as protecting them from chemical fumes inside the kiln. The

first time you fire a kiln up you should go through a conditioning process to drive every iota of moisture from the refractory. Rather than write a

novel I would add there are many good sources online for such information.

|

|

|

hinz

Hazard to Others

Posts: 200

Registered: 29-10-2004

Member Is Offline

Mood: No Mood

|

|

I've just finished my own furnace

Here is the link for the pictures.

http://www.picturetrail.com/gallery/view?p=999&gid=88977...

As you can see, It's made of an welded steel frame with heat resistant stones inside. The heating wire is wrapped around some ceramic sticks to give

stability to the heating wires at high temperature. The ceramic sticks are holded by cramps made of Kanthal wire which are jamed into the heat

resistant stone. The isolation is mineral wool.

At the beginning I heated the oven with 220V. At 220V the furnace had 220V*2 coils*6A=2600W which wasn't enough. It only went up to appr. 700°C. So I

hoped that the fuse would hold and connected the furnace at 380V. Surprisingly the fuse hold 380V*2*10,5A=8200W and the furnace went up to 1150°C

after only 5 minutes.

I don't know yet why the fuse hold it, because 380V are 3phases and I had to connect one phase to both two coils and one coil pulls 10,5A but my fuse

is only rated for 16A.

Now I need to build a temperature controller and then I'll try to reduct some phosphate to white phosphorous ( big scale of course)

All the temperatures I measured with an IR radiation thermometer.

[Edited on 20-12-2005 by hinz]

|

|

|

Mr. Wizard

International Hazard

Posts: 1042

Registered: 30-3-2003

Member Is Offline

Mood: No Mood

|

|

Hinz, I worry about a furnace with a wood outside cover. After a few hours of heating the temperature on the outside of the insulation will rise, and

anything over 100C will lead to slow charring of the wood. I know it will take a while, but that heat has to go somewhere. You should IMO, put some

sort of non combustible cover such as sheet metal or a metal can. The inside temperature will be determined by how much heat is being put into the

furnace compared to how much leaks out through the insulation. One other thing I would change is to reduce the resistance of the heating elements by

wiring it in parallel.

Instead of L1~~~~~~~~~~~~~~~~~~~~L2 where L1 is one side of the 220 mains and L2 the other; I would try L1~~~~~~~~~~L2~~~~~~~~~~L1 where the L1

connections are connected. This will lower the resistance of the elements and allow you to get by without using the higher voltages and 3 phase, but

that is only a matter of choice. It will allow more amperage without the higher more dangerous voltages.

Watch that wood.

|

|

|

NJF

Harmless

Posts: 11

Registered: 23-12-2005

Location: England.

Member Is Offline

Mood: No Mood

|

|

Have any of you guys with furnaces had a serious go at making phosphorus yet? I recently inherited an electric kiln which I think should be hot enough

(pics in the phosphorus production thread in the general section), although I haven't powered it up yet. I'm just wondering what happened if anyone

did, and whether or not their houses are still intact?

Formerly \"Nick F.\"

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

Yay, I got an old waffle iron out of the trash today with about 1m(when coiled) of around .4mm resistance wire. As soon as I can get the refractory

ingredients I will be able to make my micro-furnace.

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

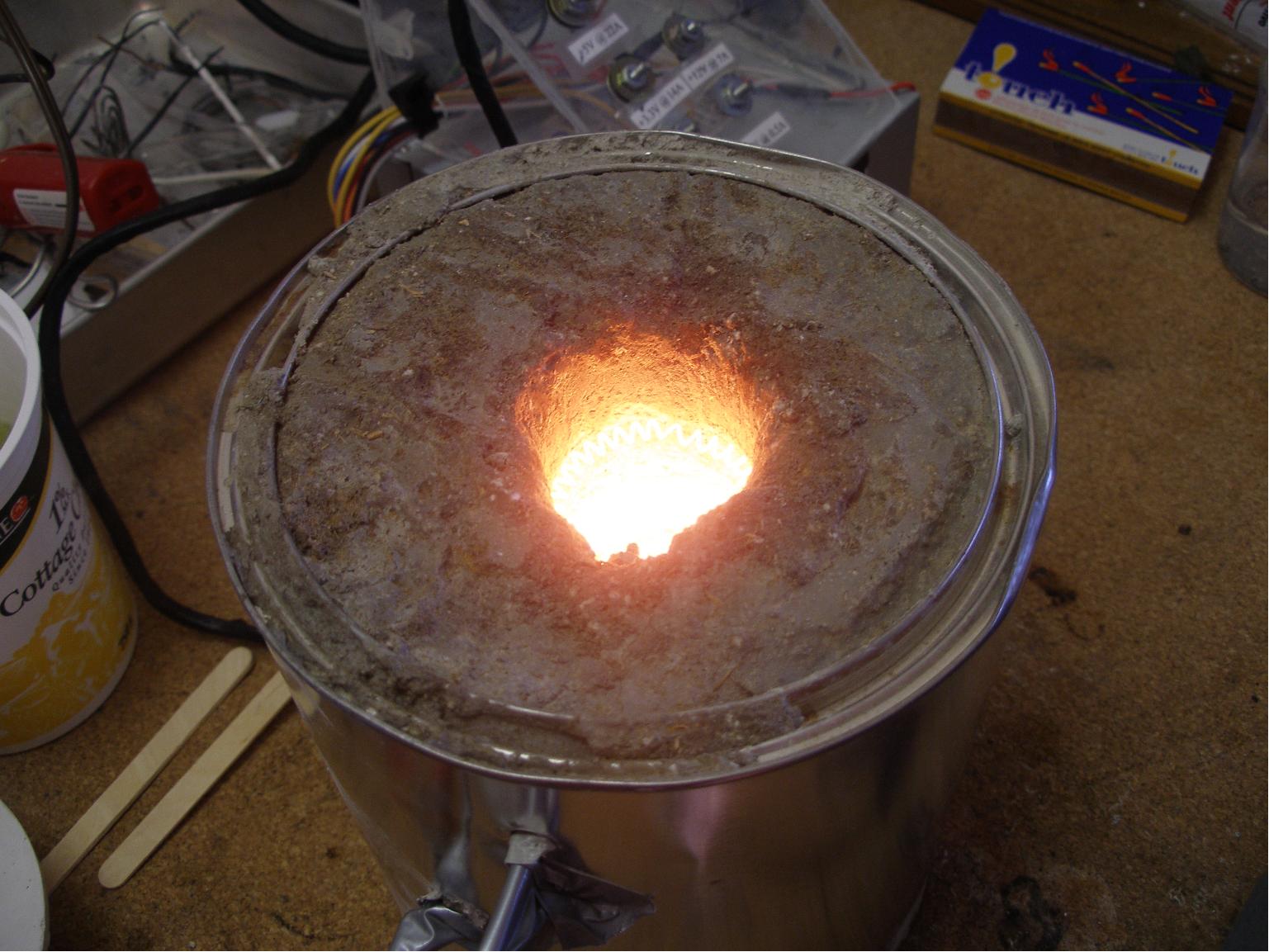

Well the furnace is done, it is currently drying at 40v outside. It turned out OK, not as good as I had hoped due to the following reasons:

-I used a big thick wooden dowel to make the hole, removing it took me several hours with a hammer, chisel and power drill. As a result some of the

indents for the resistance wire were badly damaged.

-I used 5 year old cement in the refractory

-Ended up making 2 batches of refractory, the second perhaps a bit too fast as I did not make enough the first time.

EDIT: Cost to me: around 20$ I had most things lying around except bentonite and the nuts and threaded rod. And I keep blowing the 8A fuse in the

variable transformer

EDIT: All galvanized parts(threaded rod and nuts, not the paint can it is in) that will be exposed to high temps were soaked in HCl until major

bubbling stopped, hopefully most of the zinc was removed this way.

[Edited on 7-1-2006 by rogue chemist]

|

|

|

hinz

Hazard to Others

Posts: 200

Registered: 29-10-2004

Member Is Offline

Mood: No Mood

|

|

Nice furnace rogue chemist.

How do you manage your temperature controller. I always measured the temperature of my furnace while heating to prevent overheating of the coils. As

much I know, most Kanthal heating alloys are melting at 1450-1500°C and are rated for 1300-1400°C at continous operation. (150°C is not that much

at high temperature) The resistance doesn't increase much at high temperature. At the Kanthal's (http://www.kanthal.com) homepage are some good informations about it.

I've ordered a thermocouple and I'm learning how to programm an AVR at the moment, because I don't like to spent much money on a controller. (If I

would do so, I could also waste my money for an used furnace at ebay)

My idea is to connect the thermocouple on an operation amplifier to amplify the few mV (here is a good table for Type N Thermocouples http://www.rescal.com/type%20n.htm)up to 5V at 1533°C. Then I connect the amplified output to an 9bit A/D converter of an AVR Mega8, this gives

(9bit are 512-1) 511*3=1533°C.Then I only have to programm my AVR that "he" switches off the furnace at a defined point and swiches it on if the

temp. falls under a defined point. The power relais and the AVR-power relais interface (100W amplifier) and the LED-Display are already finished but

I've still some problems with the AVR software.

Mr. Wizard

Thank's for your comment, I've coated the top and both sides with sodium silicate liquid glass to prevent burning of the wood.I'll see how hot it gets

and then I'll maybe cover the wood with aluminium foil and a second thin layer of stone wool to prevent that hot gasses can come in contact with the

wood.

[Edited on 7-1-2006 by hinz]

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

| Quote: | Originally posted by hinz

How do you manage your temperature controller.

|

The fuse blows at 8A, or whenever I turn the power up to 130-140v. If the furnace doesent reach the temp needed to melt Sb and Al, I guess I will

switch to a higher amp rated fuse or if I am feeling crazy...just bypass the fuse...Let the beakers limit me instead . .

EDIT: I am probably kidding about bypassing the fuse...probably...

EDIT: The lid for the furnace is about 1.5" thick, I put a metal strip around it, to hold a handle in place. The metal strip was found in a

construction site, but the refractory should keep any heat away from it if the metal contains zinc...I hope.

Also, the furnace is currently running at around 60v, nice glowing coil inside, and steam coming out of the furnace like mad.

Any zinc that was missed by the acid wash should hopefully be burnt out while the furnace is running outside, as the furnace will ideally be used

indoors when the drying is complete.

[Edited on 8-1-2006 by rogue chemist]

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

AARG....the coil melted through...and I only have one more left. Perhaps I should just break down and buy a spool of it from resistancewire.com.

Waffle iron resistace wire just does not hold up too well I guess.

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Have you considered buying a small furnace for pottery/enamelling/ceramics from ebay?

I searched for "brennofen" in german ebay and got some interesting furnaces, some of them small and with an affordable price (below 100 Euro) but

suitable for very high temperatures (usually 1200°C, and none of them under 1000°C).

When having little time and lack of construction skills, this is a good alternative to a home- built furnace for things like making cyanides from

cyanates, melting metals and making phosphorus.

|

|

|

MetalCastr

Harmless

Posts: 6

Registered: 5-3-2006

Member Is Offline

Mood: No Mood

|

|

Nice stuff. Check out www.backyardmetalcasting.com for furnace designs and help,

alsohttp://www.dansworkshop.com/ he built an aluminum melting 240V furnace. He also sells instructions, which I bought, and they are very detailed. I

am thinking of making this furnace soon.

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

Found this source of graphite electrodes:

http://www.geselectrodes.com/specialtygraphite.htm

|

|

|

MetalCastr

Harmless

Posts: 6

Registered: 5-3-2006

Member Is Offline

Mood: No Mood

|

|

I recently bought that controller from payne engineering. I think they meant "pain" engineering because of the 111 dollar cost total for thier 240V

controller

To run my 240V furnace, I had to make a 240V extension cord out of 1 plug, one receptacle, and 10 gauge wire ( had to wrestle it) to get a 240 supply

outside of the garage from the dryer outlet. MY controller came with a 15A fuse so it can handle moderately heavy loads.

I recently rewound the secondary coil an old microwave transformer with 12-guage wiring hoping to power my furnace with tons of amps from a 120

supply, this failed. Apperently the windings deliver enough current but not enough volts to get across the coil, you could hold it with your bare

hands (it was only about 100 degrees).

What happened: 120 In, 27 out. I can't measure the amps because my multimeter only goes to ten.

Mabey I wil make a small spot welder with it or something.

Don't overload the 15 amp rating on the 240 controller. I burned mine out, and had to manually bypass the fuse

[Edited on 18-3-2006 by MetalCastr]

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

| Quote: | Originally posted by MetalCastr

and had to manually bypass the fuse

|

|

|

|

MetalCastr

Harmless

Posts: 6

Registered: 5-3-2006

Member Is Offline

Mood: No Mood

|

|

Not to worry, I have it on a heatsink with a small blower fan. Thing doesn't even get warm. Oh yes, I've found a lower cost website for good SCR

controllers

http://www.thermalinc.com/power/tbp.htm

[Edited on 25-3-2006 by MetalCastr]

I have a question. Is a Router speed control the same thing/circuitry as a lamp dimmer?

[Edited on 25-3-2006 by MetalCastr]

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Yeah. Most variable speed power tools have a "universal" motor.

Tim

|

|

|

Cloner

Hazard to Others

Posts: 150

Registered: 7-12-2004

Member Is Offline

Mood: apocalyptic

|

|

In the case of using any kind of resistance wire in a coil, what will the impedance be at 50 Hz? I kind of forgot how to calculate, but remember there

was a formula for the effective resistance for coils and capacitors as a function of the frequency.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

That's called reactance, and depends on the inductance, which depends on the turns and whatnot. The equation you are thinking of is probably

something like L = N^2 + R^2 / (9R + 10X), where N is turns, R is radius, X is length and L is in microhenries or something. (Seems to me there

should be a constant in there, too.) Eh, Google it.

Unless you're cooking an utterly massive chunk of ferrite (which is a ceramic  ),

inductance is negligible. ),

inductance is negligible.

Tim

|

|

|

Cloner

Hazard to Others

Posts: 150

Registered: 7-12-2004

Member Is Offline

Mood: apocalyptic

|

|

Yeah well I have been googling for this, it's that I do not trust what I found. In fact, I know a book which is somewhere in my basement which

describes it. Finding that book, though, isn't as easy as it seems Assuming that

nichrome has almost the susceptibility of vacuum, I still get a significant inductive effect on 50 Hz from the googled formula... Assuming that

nichrome has almost the susceptibility of vacuum, I still get a significant inductive effect on 50 Hz from the googled formula...

But if everyone else simply uses AC and has no problems whatsoever, then the correct formula isn't so important

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

I would listen to Tim, the resistance alone is your only consideration here. The inductive reactance is such a small part of the equation it does not

even matter. The current flow change due to this parameter is so small you are not likely to even measure it. Worry about the actual ohmic resistance

of the wire and forget any inductive effects.

|

|

|

| Pages:

1

2

3

4

5

6

7 |