| Pages:

1

2

3

4

5

6

..

8 |

Jor

National Hazard

Posts: 950

Registered: 21-11-2007

Member Is Offline

Mood: No Mood

|

|

Mgapie. i'm sorry I don't have a fan curve. But every fan should be able to blast at at least 50% power if there is minimal resistance besides a

smaller duct at the end right?

Thank you watson. I remember all those hints!

I Have been searching for a second hand hood, and found one, but it was too big (2 meter wide).

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

from Jor:

| Quote: |

But every fan should be able to blast at at least 50% power if there is minimal resistance besides a smaller duct at the end right?

|

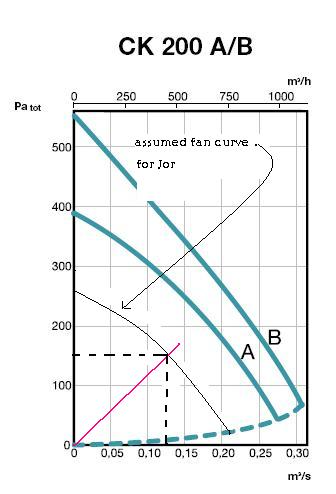

Let's take an educated guess. Below is the fan curves originally posted by DNA. On this graph I have drawn in an assumed fan curve for your fan

based on it's maximum capability of 760m3/h = 0.211m3/s. From this we see that at 450m3/h = 0.125m3/s the expected fan pressure capability is 150 Pa

= 15mmH2O. Since I calculate you would need 9.3mmH20 it seems you will be OK.

Remember, this is an educated guess. I really don't know what your fan curve looks like.

|

|

|

Jor

National Hazard

Posts: 950

Registered: 21-11-2007

Member Is Offline

Mood: No Mood

|

|

Here some pics on the process.

This is the hood it self. It's so crowded in the garage at the moments, So I can only stand very close to hood, so cannot zoom out. It's really as

mess there, with tools all over the place.

http://img135.imageshack.us/my.php?image=cimg1058kk1.jpg

This is upstairs in the garage. The left pipe you see is the exit pipe. The right one is coming from hood. Well have to make the right one a little

shorter, and then make a 40 degrees angle, followed by the motor and another 40 degrees angle. This will be a hard part to go, ass I'm not sure if we

can make it in such a short horizontal distance. We cannot do this this weekend, as we sended back the 200mm/760mm motor, as 200mm ductwork is very

hard to get and very expensive. Besides , it will look like a factory when people look at the roof

Motor will arrive monday or tuesday. The one whos helping me will be here again in 2 or 3 weeks, and then we'll finish it off, and do some smoke

tests. The new motor will be less powerfull (450m3 WITH carbon filter, so probably more without), so if power is not satisfactory, well have to send

it back again and buy another one. But I doubt it, there's not much resistance in the entire system.

The sash was ready, but to make work easier, we ripped it apart again  . The

idea is that there is one stationary plate of glass, wich covers the upper half of the opening. The other half will be moveable. So the hood can be

maximum open to about 40-45cm, and it can be closed to about 4-5cm. So I do not worry too much if hood has not enough power, in case

chlorine/bromine/etc will be realeased, I will close it to those 4-5cm. I have no bypass. . The

idea is that there is one stationary plate of glass, wich covers the upper half of the opening. The other half will be moveable. So the hood can be

maximum open to about 40-45cm, and it can be closed to about 4-5cm. So I do not worry too much if hood has not enough power, in case

chlorine/bromine/etc will be realeased, I will close it to those 4-5cm. I have no bypass.

http://img236.imageshack.us/my.php?image=cimg1053qf7.jpg

It will certainly not be the kind of hood Magpie owns, but it will greatly protect me from harmful vapours. I will be limited in qunatities anyway, as

I live in an area where people live.

Finally this is the exit of the system on the roof:

http://img406.imageshack.us/my.php?image=cimg1052tu8.jpg

A picture from the side:

http://img100.imageshack.us/my.php?image=cimg1056xy4.jpg

Soon I will also get a safety cabinet for hazardous chemicals. When I have these safety resources, I think my lab will be close to completion!

I miss one most important thing... A lab partner

[Edited on 31-10-2008 by Jor]

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Well now I have nothing against engineering, and I know enough HVAC to be dangerous, but I'm not sure that this needs to be so involved. Not trying to

be a dick here, I'm just saying.

We have a Very Big Hood at work, powered by a number of Dayton 3C411 belt-driven explosion-proof axial fans. The company spends huge sums on the

explosive and toxic chemicals that are reacted in it (outside, there is at all times a line of railcars, in addition to many large tanks) so you'd

think that money would be no object in making OSHA happy. But instead of consulting chemical and HVAC engineers and buying special things, the

mechanics just made a frame, bolted sheet metal to it, and stuck a bunch of fans on top, which are connected to 24" round ducts. There are screens in

the intakes so nothing solid gets sucked in. That is all. Maybe they have more fan power than they need, oh well. But there are several chemical

monitors, and everything is OK.

I'm not so sure of the need for explosion-proof fans on the smaller scale. If you turn them on before there is any vapor, it is difficult for

explosive vapors to reach explosive concentrations, due to dilution. The hoods of yore were powered by flame.

Can't recommend a corrosion-proof fan - the internally exposed part of my Soler and Palau TD-150 6" inline fan is 99% plastic, but unfortunately

(these are over $100) it has a gap between the blade and the housing for the aluminum rotor.

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Very neat Jor!

\"You can battle with a demon, you can embrace a demon; what the hell can you do with a fucking spiritual computer?\"

-Alice Parr

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Looks very good Jor. I think your 150mm duct is going to be just fine with your hood size. If the new fan you are getting has an outlet size of

150mm that will work out perfect. No need for any transition pieces.

Good luck finding 40 degree angle pieces. Wouldn't 45 degree pieces work? They are much more commonly available. I was even able to buy 22.5 degree

pieces for my duct. Then again if you have a sheet metal fabricator helping you then you can get whatever angle you want.

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by S.C. Wack

We have a Very Big Hood at work, powered by a number of Dayton 3C411 belt-driven explosion-proof axial fans [...] which are connected to 24" round

ducts. |

Sounds adequate.

All the engineering is to protect the not-yet-knowledgeable from an inadequate system.

|

|

|

Jor

National Hazard

Posts: 950

Registered: 21-11-2007

Member Is Offline

Mood: No Mood

|

|

Today we have finished the sash and electricity as well  . So there only remains

one thing, wich is putting the motor in place. This will not be to easy. We will do that next week or the week after. . So there only remains

one thing, wich is putting the motor in place. This will not be to easy. We will do that next week or the week after.

Then there will be tests to determine how safe the hood is.

The motor can be put at 4 different speeds (25,50,75 and 100%). The sash at 4 different heights (42 cm, 30cm, 17cm, 4cm). I will test all

possibilities (4x4=16), with the following:

-Opening a bottle of 25% ammonia.

-Making some smoke (How? Maybe some KNO3+sugar? Or a safer method? I would not like to use HCl, wich will any time soon be unavailable forever)

-A piece of paper in front of sash, at different points.

- But because I work with loads of heavy gasses, like chlorine, SO2, Br2, NO2,etc. I must test if the hood is laso capable of effectively venting

heavy gasses. I do not have baffles, wich commercial fume hoods have. The baffle in the back usually sucks out heavy gasses. But I do not have this

feature. What would be a safe heavy gas to test, wich would also indicate whether the hood is effective for NO2/Cl2/Br2/SO2/organic vapours? I was

thinking about some solvent, but most are detected at too high levels, to give a good indication if things are working well. Any ideas?

Any other tests I must do?

[Edited on 1-11-2008 by Jor]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

A strong solution of aqueous ammonia would be good. You can also use a strip of tissue paper. For smoke it seems like a cigarette would be a handy

generator.

If, after a time, you decide that you want a baffle or two, they are very easy to construct and install.

|

|

|

pyro6314

Harmless

Posts: 16

Registered: 30-11-2007

Member Is Offline

Mood: No Mood

|

|

I picked myself up a blower with heater attachment from Princess Auto. It`s rated for MAX 300CFM which equates to about 500m3/h. Somehow I don't feel

that this is enough flow for even say a 100cm x 50cm opening. I don't have a fan curve but the fan is small so I would assume it won't build much

pressure. After the restriction from ducting, is this blower going to do the job? I hope so because the heater comes with a hefty amount of NiCr wire

I would like to turn into a mantle.

On a second note, how wide have most of you made your fume hoods? I would like to fit a 24/40 distillation rig with room to spare but I can't measure

because its in the mail.

|

|

|

Jor

National Hazard

Posts: 950

Registered: 21-11-2007

Member Is Offline

Mood: No Mood

|

|

Well I just finished my hood. It works really great. It has 4 sash opening heights, I cannot move it freely, that;s the only downpart. In this post I

will call the height were it is fully open 1, one height down 2, another one down 3, and when sash is almost closed (4-5cm left) 4.

I did several test at the motor speed 3 (4 is most powerful but also quite noisy).

Ammonia conc.: I opened bottle at all sash heights and didn't smell anything.

bromine: Opened sash at all heights and only smelled a SLIGHT smell at sash height 1 (absolutely less than 1ppm, I hardly smelled it). I putted a 0,5

mL of bromine on a petri dish so quite some vapour was released.

Smoke test. I hold a bottle of HCl and a bottle of NH3 in front of the sash. At all sash heights, all smoke is sucked in.

NO2 test. A small coin was added to 3mL of conc. HNO3. The sash height was 2 (working height). All fumes are sucked away nicely, and no smell was

observed at all. When I lowered the sash to 4, at once, ALL brown gas in the beaker was gone, and the air was colorless, and even though it still

bubbled, no brown vapour could be observed.

Pictures will follow.

Video, quality is not as good as I thought it would be:

http://www.youtube.com/watch?v=bus-QQgbrWk

Im very happy, this hood gives me a good feeling of safety.

My motor has about 600m3 max power at full speed (4), and 75%, 50% and 25% of that for the speeds 3,2 and 1 respectively.

[Edited on 16-11-2008 by Jor]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Well done Jor!

Please post some pictures of your fan installation in the attic.

Did you stay with 150mm duct all the way or do you have a mix of 150mm & 200mm duct?

How is the noise level to neighbors?

Did you place anything on your stack to keep out rain?

|

|

|

Jor

National Hazard

Posts: 950

Registered: 21-11-2007

Member Is Offline

Mood: No Mood

|

|

http://i405.photobucket.com/albums/pp133/Joris12345/CIMG1180...

http://i405.photobucket.com/albums/pp133/Joris12345/CIMG1179...

http://i405.photobucket.com/albums/pp133/Joris12345/CIMG1177...

http://i405.photobucket.com/albums/pp133/Joris12345/CIMG1176...

These are some pictures.

When I'm standing outside I hear nothing. Maybe the neighbours can hear a SLIGHT noise when in their garage, but I'm not too worried.

It's an all the way 160mm ducting.

[Edited on 16-11-2008 by Jor]

|

|

|

Picric-A

National Hazard

Posts: 796

Registered: 1-5-2008

Location: England

Member Is Offline

Mood: Fuming

|

|

It all looks so neat and tidy! well done!

I wish i could say the same for my lab

|

|

|

Jor

National Hazard

Posts: 950

Registered: 21-11-2007

Member Is Offline

Mood: No Mood

|

|

It's not always like that. After we finished the hood we cleaned everything.

At the moment, it doesn't look as tidy anymore as yesterday

It still is tidy however. I clean every month or so, including the workbench.

|

|

|

Picric-A

National Hazard

Posts: 796

Registered: 1-5-2008

Location: England

Member Is Offline

Mood: Fuming

|

|

I am having a few problems with my Hood.

It is homemade, i only made it a few weeks. I will try get a few pictures of it next week as i am away form home at the moment. It consistes of an

extrctor fan (fairly powerfull) against tthe wall and i basically built a wooden box around it painted in a special fireproof, waterproof paint.

Once finished i decided to test it by igniting a small amount of KNO3 + sugar mix to produce lots of visible smoke.

once lit it seemed to manage ok but i cant help noticing quite a bit is blown out at me. When using it for things like NOx ect.. i dont want any

gasses comming out so what can i do to stop this probelm?

thanks,

|

|

|

panziandi

Hazard to Others

Posts: 490

Registered: 3-10-2006

Location: UK

Member Is Offline

Mood: Bored

|

|

Do you have a sash on the front? You want a sash so you can pull it down to reduce the inlet area, creating more displacement. If you already have a

sash, perhaps baffles at the back to distribute airflow better?

|

|

|

Jor

National Hazard

Posts: 950

Registered: 21-11-2007

Member Is Offline

Mood: No Mood

|

|

Maybe it's the power of your motor. It might be too strong, or too weak.

My blower has 4 speeds. You would think that speeds 4 is the best, or 3. It's not. Speeds 1 and 2 are the best with mine, they make no turbulence and

suck everything away. When I open the sash fully, I feel no wind or anything at all, and I don't smell anything, not even when I put a coin in conc.

HNO3. And I have NO baffles.

So maybe your motor moves too much air, and creates turbulence. Or not enough air is sucked out. You should try different speeds with your motor. With

some knowledge on electricity components, you should be able to experiment.

It's worth the time, really. The fume hood was the best thing I ever had in my lab, for 2 reasons:

-It makes me feel so much safer, I remember the nights at 1:00 AM making bromine, when I had a small cough after every synthesis. Or opening bottles

of ammonia. I must say, that I have not smelled a single chem last 2 weeks, besides some acetone (cleaning) and sulfur dioxide when cleaning MnO2.

-I use it for storage. I have some real nasties, like 250ml benzene, a few mL of bromine, 30mL CCl4, 10mL SO2Cl2 and 250mL aniline. I keep those in

the hood in a plastic containment container. I also have my waste containers (Heavy metals and chlorinated hydrocarbons) in the hood. My hood is

running all day long, I havent turned it off until now. But I always have some experiment running, and I just put it in my hood overnight.

Now I think of it, I haven't thanked the people who gave me advice yet !

Especially Magpie! Hereby, thank you very much, I have used all the advices as much as possible, and the result is very good.

[Edited on 5-12-2008 by Jor]

|

|

|

Picric-A

National Hazard

Posts: 796

Registered: 1-5-2008

Location: England

Member Is Offline

Mood: Fuming

|

|

This is the motor i have:

https://www.machinemart.co.uk/shop/product/details/cam200-po...

I feel i need air foils to direct the suction better to stop the blowing effect.

I will post pictures as soon as i can.

|

|

|

Jor

National Hazard

Posts: 950

Registered: 21-11-2007

Member Is Offline

Mood: No Mood

|

|

How large is your hood?

This one moves a lot of volume, similar to that of Magpied. And Magpie has a big hood (with baffles).

So if you have a small hood you should really take a less powerfull motor. It's not the power that's that important, it's the airflow.

|

|

|

Picric-A

National Hazard

Posts: 796

Registered: 1-5-2008

Location: England

Member Is Offline

Mood: Fuming

|

|

I cant give accurate details as i am away form home at the moment but it is around 1 meter high and 1.5m wide and 80cm deep.

I feel the motor is too powerfull... I will try make baffles but this will be failr hard as my extractor is right agains the wall.

|

|

|

Lambda-Eyde

National Hazard

Posts: 860

Registered: 20-11-2008

Location: Norway

Member Is Offline

Mood: Cleaved

|

|

What does the crowd think about this one?

It's used for vacuum systems in woodworking shops, and it pulls 14,15 m3/M which is equal to 849 m3/h, enough for even a 150 cm hood!

The problem is the motor placement. Well, actually I can't see it, but I assume it's in harm's way when talking about corrosive and explosive gases

(considering it's only made to tackle sawdust after all).

If the motor is in the way, I think I can move it and put it to the top and attach a belt drive, as I'll soon have my own metalworking shop capable of

such modifications.

Does anyone in here have any experience with modifying fans? Will it be as easy as I hope?

[Edited on 9-12-2008 by Lambda-Eyde]

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Lambda-Eyde

The problem is the motor placement. Well, actually I can't see it, but I assume it's in harm's way when talking about corrosive and explosive gases

|

That's a centrifugal fan. Since it's made for wood dust it likely has a radial blade impeller on it. That

impeller style sheds dust rather than collects it. Most fans of that style use a direct drive motor; it's mounted on a plate on the back side of the

fan housing.

|

|

|

Lambda-Eyde

National Hazard

Posts: 860

Registered: 20-11-2008

Location: Norway

Member Is Offline

Mood: Cleaved

|

|

Yes, I assumed it would be a radial configuration, but that doesn't mean it'd be insufficient for my use?

As for the motor placement, if your statement is correct, would it be safe to use it for my fume hood?

Edit: Forgive my noobish question, but what do I want from the hood? Pressure or flow? I assume pressure, so a fan with a backward-curved

configuration would be preferable, right? Forgive my ignorance, but physics never was my strong subject...

[Edited on 10-12-2008 by Lambda-Eyde]

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Lambda-Eyde

[...] a radial configuration, but that doesn't mean it'd be insufficient for my use?

[...] motor placement, [...] would it be safe to use it for my fume hood?

[...]Pressure or flow? |

Radial blade impellers are a little less efficient than other

impeller types, such as curved blade or squirrel cage, but that's fine. For equivalent flow rates, it just means the motor needs to be a little

bigger. If you've got motor capacity to spare, then it's not a problem. You choose an impeller type, not on pure motor efficiency, but on what else is

in the air stream. For wood dust collection, you don't want the impeller air surfaces to become coated with dust, so the self-shedding action of

radial blades is ideal. It will work fine with a fume hood.

The motor placement on a centrifugal fan is the preferred placement for a fume hood, since the motor is outside the air flow path. Secondarily,

and also useful, the power transmission path goes through a bearing, so there's no penetration in the air path. Another common fan configuration has

an inline fan, driven by a belt or chain, also with the motor outside, but with penetrations for the drive belt. All things being equal, it's better

to have a sealed duct system. (Although I will add, for completeness, that with only modest engineering it's possible to get the Δp pointed

in the right direction so as to avoid fume leakage.)

You want both pressure and flow. The result you want is completely inward flow in the face of ordinary sources of turbulence. You

achieve this both with proper hood geometry and air flow that is neither too slow nor too fast. The means by which you

generate flow is a pressure difference, which is why you pay attention to fan curves (which give a relation at the fan between pressure and flow) as

well as duct resistance (which is a pressure drop that must be overcome). You need good hood geometry in order to avoid turbulence generated by poor

geometry. You want minimum air flow so that the vector sum of the average air flow plus the locally opposing flows of turbulence is still directed

inward. There's a maximum flow because at some point too much flow generates its own turbulence and containment efficiency suffers.

|

|

|

| Pages:

1

2

3

4

5

6

..

8 |