| Pages:

1

..

37

38

39

40

41

..

47 |

PolarSmokes

Harmless

Posts: 14

Registered: 26-10-2009

Member Is Offline

Mood: No Mood

|

|

I was thinking- since so many seem to have a hard time with a perfect coating of PbO2, why not get a somewhat decent coating of PbO2, and find

something you can clog the pinholes with in a vacuum? That something COULD be epoxy, but due to it's higher viscosity, it would take quite a long time

to suck the epoxy in- also, the epoxy would be prone to chemical attack- I just chose it as a "something" because it more or less demonstrates my

idea.

I know it's not perfect, you have to worry about thermal expansion gradients of the two materials to minimize stress; You would also have to have some

surface treatment to get whatever is blocking the pores off of the surface. For the second part, removing the "something" off of the surface,

techniques such as (gentle) sandblasting still may be enough to cause cracks in the PbO2.

I've thought of sodium silicate for the "something", but it has a number of problems, but it can also solve a lot of other problems...

Now that I mention this, I do seem to recall reading something about coating the surface with it, but i'm too lazy to go back and look, pardon the

laze (:

There is the option of leaving it as a viscous fluid within the anode, kept in place by gravity, if it composed (part) of the floor of the cell. But

then you have to worry about changes in volume from different states of hydration, and if it would act as an electrolyte. If it did, would the sodium

ions be transferred to more cathodic regions of the cell? If so, then sodium silicate for the "something" is a horrible idea. I am just trying to

think of a good "something"- preferably "something" that is simple and won't shred the anode from the inside out.

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

All 'pin hole problems' have been solved with the arrival of the fault tolerant substrate

(MMO on Ti, Tin Oxide on Ti and others).

Stay away from Graphite. It's been giving Lead Dioxide Anodes a real bad name for the last twenty years, which is enough to make any grown man (not

to mention a Lady!) weep.

Dann2

|

|

|

PolarSmokes

Harmless

Posts: 14

Registered: 26-10-2009

Member Is Offline

Mood: No Mood

|

|

what about tin oxide on glass?

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

With all non conducting substrates you are back to the problem of obtaining a good permanent connection to the Anode when it goes into service. The

only way to do this is to use a Silver metal connection (paint or plate or perhaps wire).

The Lead Dioxide at the top end must carry all the current going to the Anode. You are better off with a conductive substrate IMO. Thats not to say it

will not work.

I started to plate some Lead Dioxide today and after some time I tested the tank for Nitrites (Nitrites form at the Cathodes and are undesirable) and

got a positive. I commenced to add some Hydrogen Peroxide (recommended here and there for the removal of Nitrites from a Lead Dioxide plating tank) to

the plating tank and got a mass of bubbles coming to the surface. It appears that the solution was attacking the plated on LD. That is where all the

bubbles were coming from. There was a tiny piece of LD at the bottom of the tank and it dissolve away.

Looks like you cannot do anything about Nitrites in the tank while plating is going on.

Thats a bummer!

Dann2

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

I had to abandon ship with my latest effort at coating a Tin Oxide coated Ti strip.

The Alpha (first coat of LD), which is put on using a Alkaline bath when on very badly. It only went on in places on the substrate for some reason or

other. When I started with the Beta bath (Lead Nitrate bath) the coating went OK but the set up I had let me down. Bubbles kept appearing in a siphon

tube and I had to stop. Will need to set up a new rig.I

The Anode has a coating of LD on it so I decided to try in out in a Perk. cell just to see how long it lasts.

I also wanted to try out an idea seen over at AmateurPyro.org for attaching connections to Anodes. It looks as if you do not need to weld Ti straps

to Anodes, simply attaching the Ti strap using bolts or rivets will do. The fact that solution gets between the strap and Anode does not seem to

effect the flow of current . Hydrogen dopeing I guess must be keeping all the Ti Oxide conductive (both on the extension strap and the Anode coating

or the Anode (Ti) sutstrate).

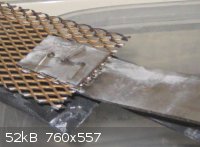

The picture attached shows the original Platinum coated Ti Anode + strap from AmateurPyro.

With my Anode + strap I simply bolted an extension Ti strap to the top of the LD Anode Ti substrate and submerged the Anode and bolted connection

underneath the Perk. electrolyte where it has been working away quite happily now for about 8 hours.

Some pictures of LD Anode are in zip.

Attachment: Anode.zip (357kB)

This file has been downloaded 733 times

[Edited on 9-9-2011 by dann2]

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

MOTHER OF ALL ANODES

Hello,

Just finished plating an Anode.

Seems to be OK.

Hopefully it will work for years?

Details enclosed in attached zip.

In relation to the last (very bad) Anode I made (few days ago) it worked for a few days in a Perk cell before I removed it. It was hard to know if the

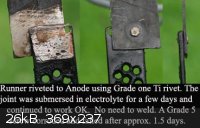

Tin Oxide or the LD was the active coating as the LD was chipping off. As a test I riveted a piece of Ti to it using a homemade Grade one rivet and

it worked OK. No need for welding etc. A Grade five screw corroded.

See picture.

Dann2

[Edited on 18-9-2011 by dann2]

Attachment: cu.zip (394kB)

This file has been downloaded 748 times

[Edited on 18-9-2011 by dann2]

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

GRANDMOTHER OF ALL ANODES

Hope I am not 'done' for double posting!

Cranked up anothe LD Anode. The substrate is 'LaserRed' (ebay seller) MMO, which was 1.6mm thick. The openings were 7.5 by 3mm. Coating thickness is

about 1.75mm of LD, probably should have let it coat for longer. I used a two tank system. Flow rate between tanks was 17ml per minute per Amp

(revised up from the last

Anode I made). pH of plating tank hovered around one. Constant current power supply used. Plating tank was stirred with a magnetic stirrer bar and the

Neutralizing

tank was stirred using an aquarium air pump and air stone (a magnetic stirrer bar would be much better). Temp. around 67C.

Cable ties and silicone sealer are not compatabil materials for an Lead Nitrate plating tank. Don't use them. The containers were polyethyene and the

filter cloth was

polyester.

Plating for this Anode started off at 60mA per square cm for two hours, 30mA/cm^2 or half an hour and the rest (about 22 hours) 20mA per cm^2.

Some red Lead was added to the Neutralizing tank to counteract Nitrites (not too sure if they are even a problem). 6 hours into plating session no

Nitrites

were showing up in the plating tank as shown by an aquarium test kit. Lead Carbonate + Copper Carbonate Hydroxide was added to Neutralizing tank as a

slurry/paste.

Some Cu Nitrate was added to the plating tank now and them as Cu was getting low (blue colour disappearing).

Some pictures in zip.

Attachment: cats.zip (1.1MB)

This file has been downloaded 753 times

|

|

|

Griffin

Harmless

Posts: 1

Registered: 27-10-2011

Member Is Offline

Mood: No Mood

|

|

Hello,

Sorry if this is a stupid question. Are there companies that manufacture PbO2 anodes?

Many thanks

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

'Patsroom' was selling them here some time ago.

Try www.amateurpyro.com

Dann2

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello,

Been running two Lead Dioxide Anodes for some time now (2.5 months) as posted in 'Thoughs on Anodes'.

Blow by blow (by blow by blow) details are in the files attached.

They are the same two files as was attached in a previous post with some more

info. added.

The bottom line is that the Anodes are working well. They are suffering very

little wear in the tasks that they are being used at. The larger Anode (187g)

has lost 3.8 grams and the small Anode (84g) has lost 0.5 grams.

The Ti/Tin Oxide substrate Anode was used in Perchlorate cells to 'scavenge'

Chlorate, that is, running the cells from approx. 20 grams per liter Chlorate

to less than one gram per liter Chlorate (high concentration of Perchlorate).

This is a low current efficiency process but is better than using Chemicals

to destroy residual Chlorate IMO.

The other Anode has an MMO on Ti substrate and it was mainly running in

Perchlorate cells that were started with approx. 100g/l Chloride + 500g/l

Chlorate and ran all the way to below one gram per liter Chlorate.

This role causes the most wear but it is very small.

%CE is low at around 40% when Chlorate concentration is high. Don't know why.

Stirring does not seem to help when Chlorate 'scavenging'. I have used Persulphate

and H2SO4 as an additive but I don't know if it helped or not.

Acid demands (to keep cell around 7) is very high in a Perk. cell from

approx. 20 grams per liter Chloride (high Chlorate conc.) to a day or so

after all Chloride is gone. Anyone know why this is so or what is escaping

from the cell to cause pH to go up?

I have yet to run a 'proper' Perchlorate cell. A cell with both high

concentration of Chlorate and Perchlorate (no Chloride).

Dann2

Attachment: LD.rar (423kB)

This file has been downloaded 668 times

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello Folks,

Anothe paper here using Gold coated Ti as the substrate for Lead Dioxide.

Dann2

Attachment: Ti_GOLD_Pb02 Anodes.pdf (283kB)

This file has been downloaded 923 times

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Exploding Perk. cell

I checked the pH of a Perchlorate cell today (3.8 liter size)and it was 11.0 so I decided to add some 12% HCl acid. I add it by putting it in a small

container which drops the acid into the cell over a five minute period approx.

After adding approx. 50cc acid the pH was only down at 10.5. Started adding another 50cc acid and after about 20cc had gone in, the cell exploded. The

lid consists of a piece of thin perspex sitting on top of a container. The lid is not actually attached, just sits there. The lid was also slid to one

side to allow addition of the acid.

I was standing close by, and only I was, I probably would never have known there was a bang. It was similar in loudness to when you break a hot

incandence bulb (light bulb) if you accidently spray water onto it (or perhaps a bit louder).

A puff of (I presume) water mist came out from under the lid. The lid was not blown off and the cell continued to work OK.

The electrolyte was very yellow in colour, (more yellow than it was before I started to add acid) and I think it may have been caused by ClO2.

There were no sparks or red connections to ignite Hydrogen or a mixture of H and Cl gasses.

Anyone any suggestions as to what may have caused it?

Dann2

|

|

|

Pulverulescent

National Hazard

Posts: 793

Registered: 31-1-2008

Member Is Offline

Mood: Torn between two monikers ─ "hissingnoise" and the present incarnation!

|

|

| Quote: | | 'Patsroom' was selling them here some time ago. |

IIRC d2, the consensus here was that the Indian manufacturer involved used PbO<sub>2</sub> coatings that were much too thin and fragile

for sustained perchlorate synthesis for the amateur . . .

There are, I think, a plethora of companies in India making PbO<sub>2</sub> anodes for industry!

P

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Does the cell have a stirrer or recirculation pump? If

not, there's a class of reactions to be considered that occur in acidic environments.

|

|

|

Pulverulescent

National Hazard

Posts: 793

Registered: 31-1-2008

Member Is Offline

Mood: Torn between two monikers ─ "hissingnoise" and the present incarnation!

|

|

Something similar happened me once d2; for expediency I'd just drop in some undiluted acid from time to time, but I accidentally added too much one

day and the electrolyte bubbled and fizzed furiously for a few seconds.

There was a slight mist emitted through the vent and it was very lacrymatory!

The vent on a gallon cell should preferably be at least 1"dia.!

P

|

|

|

Pulverulescent

National Hazard

Posts: 793

Registered: 31-1-2008

Member Is Offline

Mood: Torn between two monikers ─ "hissingnoise" and the present incarnation!

|

|

| Quote: | | Does the cell have a stirrer or recirculation pump? |

With electrodes reaching close (3mm) to the floor of the cell, H<sub>2</sub> evolution at the cathode is enough to provide the necessary

circulation . . .

P

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

The cell in question has the Anode and Cathodes going close to the bottom so I do not believe there is a 'dead layer' at the bottom.

The electrolyte was very basic (up at 10.0) when I add the acid yesterday.

The appears to be some buffering going on when adding acid to Perchlorate cells. The cell was at a pH of eleven (yesterday). I added 50cc of 12% HCl

acid and pH went down to 10.5. (I added some more and the small explosion occured).

Today the cell was back up at 11.5.

I added 50cc acid and the pH went to 5.5.

The quantity of acid needed to control pH seems to be eratic.

My pH monitoring and acid additions are very eratic too. I would need to monitor pH more consistently.

Today the electrolyte did not turn a very yellow colour when I added the acid. I stated that the electrolyte DID turn very yellow when I added the

acid yesterday but I am not too sure about that now.

There is some Chloride in the cell that is going in with the (homemade) Chlorate solution that I am addding to the cell which complicates (I guess)

things even further.

The only reason that I bother to add acid at all is that I read somewhere that Anode dissolution (Lead Dioxide) has been observed when pH goes above

11. Don't want any Anode dissolution. Have not observed any yet even though the cell has been run for periods of time a a high pH (10 to 11.5)

Dann2

[Edited on 12-1-2012 by dann2]

|

|

|

Pulverulescent

National Hazard

Posts: 793

Registered: 31-1-2008

Member Is Offline

Mood: Torn between two monikers ─ "hissingnoise" and the present incarnation!

|

|

Hmmm, have you tried adjusting the pH with the electrodes out of the cell and the electrolyte at RT?

P

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

I made some Perchloric acid and it seem to be the 'real macoy' (good stuff) when it comes to controlling the pH of Perchlorate cells.

I set up a pump to pump HCl acid into a Perchlorate cell to keep pH low and all I got was lots of explosions, horrid smells, and a cell with a high pH

once the acid had stopped pumping for a few hours.

My smaller Lead Dioxide Anode has come to its end rather suddenly. I put it into a Potassium Chlorate (not Perchlorate) cell to run up some time on it

and it split apart. See attachement.

This file is a a file that was attached above with some stuff added to the end of it.

Dann2

Attachment: tiatold_3.zip (70kB)

This file has been downloaded 668 times

|

|

|

gilbert pinkston

Harmless

Posts: 9

Registered: 22-9-2004

Member Is Offline

Mood: No Mood

|

|

pH in a perchlorate cell

you dont have to control pH in a perchlorate cell

where did anyone get that idea?

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

I agree there is little or no point in controling the pH of an Amateur Perchlorate cell. It is not needed as far as current efficiency is concerned.

There may be small gains to be had if you are running under specific, will controlled circumstances. (see link) Most commerical Perk. cells are pH

controlled as stated in the Book 'The Perchlorates' by Schumacher (perhaps a cousin of Michael, who knows!)

I think that the pH may be controlled for reasons of equipment corrosion (pipes, tanks, the crystallizer section etc) or perhaps Anode erosion. I

don't really know myself.

I have read in JES Aug 61 page 801 (link) that 'dissolution of the Lead Dioxide Anode occured when the pH went above 11'

I have never seen dissolution of my Anodes even though the pH was very high (above 11).

I was adding some HCl just to see how it went. If there is much Chloride in the cell you CANNOT controll the pH using HCl acid AFAICS. You would need

Pechloric acid (hardly much point in bothering anyways).

The same paper describes problems when there is too much Chloride in the cell too.

(table close to end)

Dann2

|

|

|

Pulverulescent

National Hazard

Posts: 793

Registered: 31-1-2008

Member Is Offline

Mood: Torn between two monikers ─ "hissingnoise" and the present incarnation!

|

|

| Quote: | | Hmmm, have you tried adjusting the pH with the electrodes out of the cell and the electrolyte at RT? |

I had just assumed you were talking about a simple chlorate-cell . . .

P

"I know not with what weapons World War III will be fought, but World War IV will be fought with sticks and stones"

A Einstein

|

|

|

Vikascoder

Hazard to Others

Posts: 309

Registered: 28-1-2012

Member Is Offline

Mood: No Mood

|

|

I have made my electrode by dissolving PVC and adding MnO2 it also works pretty well

|

|

|

Pulverulescent

National Hazard

Posts: 793

Registered: 31-1-2008

Member Is Offline

Mood: Torn between two monikers ─ "hissingnoise" and the present incarnation!

|

|

For what? ( ) )

P

"I know not with what weapons World War III will be fought, but World War IV will be fought with sticks and stones"

A Einstein

|

|

|

Vikascoder

Hazard to Others

Posts: 309

Registered: 28-1-2012

Member Is Offline

Mood: No Mood

|

|

It works very well for chlorate if ph is correct but little slow for perchlorate overall it is perfect for me because lead oxide is very toxic so why

to deal with it if you have an alternative

|

|

|

| Pages:

1

..

37

38

39

40

41

..

47 |