| Pages:

1

..

32

33

34

35

36

..

68 |

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

Quote: Originally posted by Pard  | Quote: Originally posted by NeonPulse  | i was wondering if anyone else has tried the bottoms of wine bottles as a liner? I thought that they may be too thick but after testing one to see for

myself, the results were OK. so i used 225g ANNM but in fairly weak confinement- a high pressure plastic gas pipe. The liner was epoxied in place.the

target was 4 6mm structural steel plates stacked up, and i gave it minimal standoff of 1.5 cone diameter and was very surprised at how well this

liner performed. A nice round 25mm hole and 30mm deep. The first two plates had full penetration and the others dented fairly hard. There was also a

rather large plug of highly compressed powdered glass that was slightly fused by pressure and heat i suspect. These plugs were very hard. A lot harder

than the actual glass it was made from and almost like stone. Took a while to clear them out to see the damage.. All up i would say the cone did well

and i will be testing another one or two very soon but this time using stronger confinement and greater standoff distance.

|

Why to use just the bottoms? I've seen before to use the whole bottle without the neck. Like wine bottles. Is it better using just conical bottom?

By the way, how do you guys design your copper cones? I thought about maybe going to metal work place to ask to do it. It is a strange request but I'm

sure they would. It's not like they'd realise what it is for. |

I just used the bottom so I could get better confinement for the annm. I also made another one like this but with steel tube and it worked a lot

better.check it out on my YouTube channel annm shaped charge by putitbak. Cones can be made in many ways. I've used copper sheet beaten into form,ans

thin sheet bent int a cone too. The solid cones worked the best. I'm not too sure how you would go at getting one made as its not that simple a task.

Browse this whole thread sa it is full of helpful hints and methods on making cones and the concept of ad's inggeneral. It really helped me out.

|

|

|

franklyn

International Hazard

Posts: 3026

Registered: 30-5-2006

Location: Da Big Apple

Member Is Offline

Mood: No Mood

|

|

Methodology for modeling of the jet formation process in linear sharped charges

www.chemikinternational.com/pdf/2011/01_2011/chemik_2011_65_1_32-35.pdf

.

Techniques to Disrupt, Deviate and Seize Control of

an Internet Forum In case you wonder W T F ! is going on here

?

www.zerohedge.com/contributed/2012-10-28/cointelpro-techniques-dilution-misdirection-and-control-internet-forum https://web.archive.org/web/20120814124000/www.washingtonsblog.com/2012/08/the-15-rules-of-internet-disinformation.html

___________________________________________________________________________________________________________________

___________________________________________________________________________________________________________________

___________________________________________________________________________________________________________________

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Anyone ever tried these as liners?  : :

http://www.ebay.com/itm/500-UK-77-Cone-Studs-Spike-Charged-G...

Works pretty sweet....

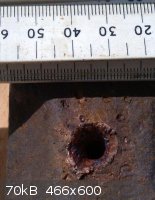

12mm aluplex tubing as the casing with the stud attached...the witness plate underneath is 8mm mild galvanised steel:

Loaded with 2,88g phlegmatized PETN (10% PIB+methyl riccinoleate):

Standoff attached...20mm :

Primed and ready to go:

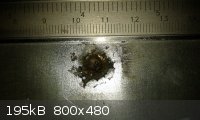

From the top after firing under sand:

From the bottom after firing...clean through 8mm mild steel:

Judging from the entry point I would say that the standoff was a bit too small...an additional 5-10mm would have probably been beneficial.

[Edited on 11-2-2014 by markx]

Exact science is a figment of imagination.......

|

|

|

VladimirLem

Hazard to Others

Posts: 204

Registered: 24-5-2010

Member Is Offline

Mood: Have no fear <Vlad> is here.

|

|

well done....thats a really sweet project

and i thought my 1" cone was pretty little

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Impressive that it works so well even though it's so small. Nice test.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Yes, I did not expect much of a result from this makeshift test...hence the sloppy design. But as it worked against all odds, I think that many

improvements are in order.

Exact science is a figment of imagination.......

|

|

|

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

Quote: Originally posted by markx  | Anyone ever tried these as liners?  : :

http://www.ebay.com/itm/500-UK-77-Cone-Studs-Spike-Charged-G...

Works pretty sweet....

12mm aluplex tubing as the casing with the stud attached...the witness plate underneath is 8mm mild galvanised steel:

Loaded with 2,88g phlegmatized PETN (10% PIB+methyl riccinoleate):

Standoff attached...20mm :

Primed and ready to go:

From the top after firing under sand:

From the bottom after firing...clean through 8mm mild steel:

Judging from the entry point I would say that the standoff was a bit too small...an additional 5-10mm would have probably been beneficial.

[Edited on 11-2-2014 by markx] |

Great test.It just goes to show that you dont need to go big for good results. i actually looked at similar items on ebay but never found any suitable

looking ones. i guess i did not look hard enough! i only as looking at copper though and that is why my searches turned up nothing. right now im

working on electroformed copper liners and they look really promising to test, consistent and very easy to produce.. much more consistent than say

hammering a liner from copper or shaping thin sheet into cone forms. I do have some pics to post of a 25gMHN linear SC when i get around to it, it

worked good but not great. ill do that soon .

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Electroforming is a versatile tool....I earned my bachelor degree on the subject of pulse plating thick layers of metal/alloy on geometrically

complicated substrates (concave horrors with near zero electrical field in them). Initially electroforming moulds for production of plastic details

out of copper and nickel. Then electroforming Ni/Mo/Cu alloy details for hi temp fuel cell construction. The idea was to plate an alloy with

adjustable thermal expansion coefficient (ceramic electrodes of the fuel cell did not like the excessive expansion of the support frame  ). The main problem with plating thick layers (beyond decorative or corrosion

resistant effect) is the formation of dendrites. To counter it, one can use basically three approaches: ). The main problem with plating thick layers (beyond decorative or corrosion

resistant effect) is the formation of dendrites. To counter it, one can use basically three approaches:

a) very low current density

b) additives (mostly surface active detergent type compounds)

c) pulse plating

The most effective being pulse plating....it allows the cathion concentration near the electrode surface layer to replenish between current pulses,

therefore minimizing the formation of dendrites. And one can reverse the polarity of applied voltage to turn the cathode into anode for a certain

percentage of duty cycle. As dendrites are predominantely formed during the cathodic cycle, they also are predominantly dissolved during the anodic

portion of cycle.

Exact science is a figment of imagination.......

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Utter success!!

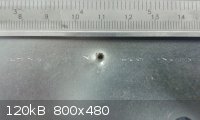

The same type of setup as seen in my previous pictures. But this time the target was 15mm steel sheet.

With 3,5g 10% phlegmatized PETN charge at 20mm and 40mm standoffs:

The 40mm standoff did not penetrate the target...it was 2mm shy of the objective after measuring channel depth.

But the 20mm standoff:

Like a hot needle through butter

Btw. I really do need a decent camera and some practice in the field of photography...these blurry pictures are frankly embarrassing.

[Edited on 14-2-2014 by markx]

Exact science is a figment of imagination.......

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

A bit clearer pictures of the last test are in order....

Comparison of targets:

The construct for creating the jet:

Entry points on the 15mm target at 40mm and 20mm standoff:

Exit point of the 20mm standoff:

Entry and exit points on the 8mm target from the first test (20mm standoff)

Exact science is a figment of imagination.......

|

|

|

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

so finally i got around to testing an electroformed liner produced using a method found in this thread. i suspected that it would have performed quite

well and i was not disapointed! the liner thickness measured 1mm evenly after cleaning it up some.i forgot to measure the angle but i guess around

60deg. the portion of the cone used was 20mm wide at the bottom to fit in the tube used and with the end cap gave excellent confinement for the

charge, which was a mix of 75%MHN and 25%ETN and weighed 16g. initiation was electric, using 400mg lead azide (more than enough...)

Standoff was 2 cone diameters at 40mm. Penetration was pretty good: 38mm into a very hard steel sledgehammer head with a perfectly formed jet that

went straight down. No carrot but a nice copper colour lining the hole. looking forward to testing some more perhaps with a liquid ester or cast ETN.

i think with some tweaking the penetrating distance could be more. i have always wanted to try a lens.

|

|

|

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

also a linear SC was tested on a 10mm thick bit of hardened steel. This charge was 24g MHN with a 400mg lead azide cap fired electronically also.

Results were a poor 5mm penetration which i think was due to a poor design and next to zero standoff distance. The casing was a 70mm long Al channel

that had 2.5mm thick walls with 2mm thick liner at 90 degree angle the ends were also Al and it was all held together with JB cold weld epoxy. that

stuff is brilliant! the liner was mangled in the groove and most of it eventually was pried out in order to see the cut. results could certainly be

improved here. seems a jet was formed but im guessing that lack of stronger confinement and no standoff played a big part in its reduced cutting

ability.

|

|

|

VladimirLem

Hazard to Others

Posts: 204

Registered: 24-5-2010

Member Is Offline

Mood: Have no fear <Vlad> is here.

|

|

Quote: Originally posted by NeonPulse  | also a linear SC was tested on a 10mm thick bit of hardened steel. This charge was 24g MHN with a 400mg lead azide cap fired electronically also.

Results were a poor 5mm penetration which i think was due to a poor design and next to zero standoff distance. The casing was a 70mm long Al channel

that had 2.5mm thick walls with 2mm thick liner at 90 degree angle the ends were also Al and it was all held together with JB cold weld epoxy. that

stuff is brilliant! the liner was mangled in the groove and most of it eventually was pried out in order to see the cut. results could certainly be

improved here. seems a jet was formed but im guessing that lack of stronger confinement and no standoff played a big part in its reduced cutting

ability.

|

nice projects

I think that the 2mm thick liner at the linear shaped charge should be replaced to a 0.5-1mm to get optimal results

how did you get the coppercone off the kathode?

I made some 1" diametre 42dagree cone and fucked it up...i couldnt get it off the kathode

|

|

|

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

it was hard, going around it with a knife several times and tapping it with a hammer,the Al not the copper, and the viabrations caused it to just fall

off, alot of it i did not need to use so i could bend and tear also. before placing it in the plating bath i sanded it to a glass like finish too, i

think that helped it pop off easier.

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by NeonPulse  | | it was hard, going around it with a knife several times and tapping it with a hammer,the Al not the copper, and the viabrations caused it to just fall

off, alot of it i did not need to use so i could bend and tear also. before placing it in the plating bath i sanded it to a glass like finish too, i

think that helped it pop off easier. |

Try conductive silver paint as the intermediate layer between cathode and the plating. It makes separation much easier and one can use a nonconducting

object as the mould for the plating.....paint will act as cathode on the surface. The only downside is the cost of the paint, but a failure to

separate the liner is probably even more frustrating.

You could also try a graphite coating as the intermediate layer, although I don't have any personal experience to claim or deny it's effectiveness.

Exact science is a figment of imagination.......

|

|

|

VladimirLem

Hazard to Others

Posts: 204

Registered: 24-5-2010

Member Is Offline

Mood: Have no fear <Vlad> is here.

|

|

Quote: Originally posted by markx  |

Try conductive silver paint as the intermediate layer between cathode and the plating. It makes separation much easier and one can use a nonconducting

object as the mould for the plating.....paint will act as cathode on the surface. The only downside is the cost of the paint, but a failure to

separate the liner is probably even more frustrating.

You could also try a graphite coating as the intermediate layer, although I don't have any personal experience to claim or deny it's effectiveness.

|

cool idea

i had the idea of plating a extreme thin layer of tin- or lead on the cathode and then plating the copper cone...after the cone is ready, then heating

to the melting point of tin/lead....but im too lazy to try that, so i think im going to buy silver paint

|

|

|

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

Another attempt was made using another electroformed liner. instead of plating for 24 hours it was left to plate for 32 hours. the thickness was

increased to around 1mm.

the performance of this liner was also excellent. the filling this time was 11mls of good old NG and to increase the density, 8g ETN and 1g NC were

added. fired with a 600mg MHN/200mg Lead azide. A nice even jet was formed and no carrot left in the hole.

the penetration was a rather nice 42mm which is just over 2 cone diameters.

I am pretty impressed with these little liners perfomance especially considering how hard this particular steel is.

My aim is to go all the way through it and with a little tweaking i think that it is realistic as there are only another 30mm to get through. As for

the conductive paint i have ordered some- no shit it is expensive, but worth it since i dont have access to a lathe to make my own forms. A form is to

be made at the optimal angle of 42 degrees and plated- well see how it goes if it works as well as the others then it will be formidable.

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by NeonPulse  | Another attempt was made using another electroformed liner. instead of plating for 24 hours it was left to plate for 32 hours. the thickness was

increased to around 1mm.

the performance of this liner was also excellent. the filling this time was 11mls of good old NG and to increase the density, 8g ETN and 1g NC were

added. fired with a 600mg MHN/200mg Lead azide. A nice even jet was formed and no carrot left in the hole.

the penetration was a rather nice 42mm which is just over 2 cone diameters.

I am pretty impressed with these little liners perfomance especially considering how hard this particular steel is.

My aim is to go all the way through it and with a little tweaking i think that it is realistic as there are only another 30mm to get through. As for

the conductive paint i have ordered some- no shit it is expensive, but worth it since i dont have access to a lathe to make my own forms. A form is to

be made at the optimal angle of 42 degrees and plated- well see how it goes if it works as well as the others then it will be formidable.

|

Excellent work! What kind of plating bath are you using for the copper electroforming? The regular acidified sulfate? I see a familiar healthy

dendrite formation on the cone. Have you tried any brighteners in the bath, they do supress some of the dendrite growth and make for a more uniform

coating.

The price of the conductive paint is really demotivating, but a small amount will go a long way with this substance. I have found it is best applied

via an airbrush...guaranteed uniform coatings and no blind spots that could ruin the plated detail. Since you have already ordered the paint, I would

suggest the minor additional investment into a cheap airbrush. They can be had for about 20$ or less on ebay and make for a very decent tool in that

application.

Exact science is a figment of imagination.......

|

|

|

ecos

Hazard to Others

Posts: 464

Registered: 6-3-2014

Member Is Offline

Mood: Learning !

|

|

Did anybody try to do shaped charges with NG Gel ?

I mean to pour the NG Gel in the container and let it cool down and use it afterwords.

|

|

|

Dornier 335A

Hazard to Others

Posts: 231

Registered: 10-5-2013

Location: Northern Europe

Member Is Offline

Mood: No Mood

|

|

Correct me if I'm wrong, but isn't gel one of the worst things to put in a shaped charge? Air bubbles will easily form and get trapped inside it, and

that will create hot spots that affect the shock wave. Just using a liquid explosive would be better.

|

|

|

magneet

Harmless

Posts: 19

Registered: 30-12-2007

Location: on a forum somewhere

Member Is Offline

Mood: lurking mostly

|

|

At what point does a NG gel have to cool down?

why gelling it?

Hi,

|

|

|

ecos

Hazard to Others

Posts: 464

Registered: 6-3-2014

Member Is Offline

Mood: Learning !

|

|

Quote: Originally posted by Dornier 335A  | | Correct me if I'm wrong, but isn't gel one of the worst things to put in a shaped charge? Air bubbles will easily form and get trapped inside it, and

that will create hot spots that affect the shock wave. Just using a liquid explosive would be better. |

I am not sure about how fine are the air bubbles inside the Gel are. I also don't know if it would affect it that much or not. I think using EM

powders also have bubbles. Nothing perfect

as a general speaking->yes you are right but I read that the mass of Gel will make the air bubbles get out. just a matter of time and it will be

free of air bubbles but it would need a military detonator.

[Edited on 25-5-2014 by ecos]

|

|

|

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

Quote: Originally posted by ecos  |

Did anybody try to do shaped charges with NG Gel ?

I mean to pour the NG Gel in the container and let it cool down and use it afterwords. |

are you gelling it with NC/Acetone? or using gelatin? i was wondering why you would need to heat it? just use more acetone. I myself wouldn't really

want to heat any mixtures containing NG. i guess if you had enough diameter in in the charge it may work well, but personally i would go for a solid

ester for ease of loading...

|

|

|

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

Use of conductive coatings for unconventional liners

So i recently decided to try making another electroplated liner. For this process i filled a plastic funnel with car body filler and after it hardened

i shaped a tip on the end as it was flat. The angle of the funnel is around 55-57 degrees. The resin form was sanded with some 800 grit sandpaper

after this it was then coated with 3 nice even coats with a conductive silver paint. copper wire was threaded through 4 pre drilled holes on the base

of the form and it was plated as usual. the coating of copper onto the form was nice and even all around and there was no thin or bare spots. In a

previous experiment only one coat of the silver was applied but this produced poor results and a rather slow plating which was uneven in places. I

also think the plating bath attacked the coating before a layer of copper was plated to protect it so 3 coats is needed for a faster plating and

better coverage all round.The coating goes on very easily and any brush strokes with an artist's brush level out on drying leaving a nice even surface

to plate onto. Using this process opens up an avenue to create liners of many sizes and shapes. fluted, trumpet and bi-angled or stepped liners are

possible as long as you can form them out of the resin. i guess most materials that can be shaped conically or otherwise can be used (sealing porous

surfaces first) and there also is no real limit to the size that can be formed like with cutting metal forms on a lathe. The cone was very easy to

remove from the form and the paint stuck to the inside of the liner which is very easily removed with some acetone if it is a problem. The drawbacks

are the general cost of a liner as a whole unit, the silver paint is pretty expensive at $10 for a mere 3mls vial but it really does go a long way if

used sparingly. throw in the costs of the body filler, copper sulfate, Cu metal, acid and electricity to plate and you have a pretty expensive liner

to produce. I haven't any access to a lathe so spinning liners is out for me else i would certainly attempt it.

|

|

|

Manifest

Script Kiddie Asshole

Posts: 229

Registered: 7-12-2012

Member Is Offline

Mood: No Mood

|

|

Aluminium is easy enough to melt, there are many videos on youtube with people melting it using make-shift furnaces.

I'm thinking it would be easy enough to make a aluminium cone.

I am not sure how you could make the mold of it.

|

|

|

| Pages:

1

..

32

33

34

35

36

..

68 |