| Pages:

1

2

3

4

5

..

17 |

bio2

Hazard to Others

Posts: 447

Registered: 15-1-2005

Member Is Offline

Mood: No Mood

|

|

How to dry NaNO2?

What is the preferred method of drying NaNO2?

Will one of the inorganic guru's here please take a moment and help me with this question. I would just as soon not re-invent the wheel.

Also would fusing the nitrite at the 271mp be OK being careful not to approach the 320deg decomposition temp??

Alternatively how about vacuum dessicator at 90deg without (with) dessicant?

Thank you very much.

|

|

|

komodo13

Harmless

Posts: 2

Registered: 8-6-2004

Member Is Offline

Mood: No Mood

|

|

oldskool manufacture of sodium nitrite

J. Soc. Chem Ind., 27, 483-5 (may30)-The author reviews various methods for the production of nitrite from nitrate by reduction with metals (see C.A.

1908, 1330). the non-metal , sulphur, has been used with sucess by Messers, Read, Holiday & Sons. The mixture of nitrate, sulphur, and caustic

alkali is fused in open pans, fitted with stirring gear. the following reaction takes place: NaNO3 + S +NaOH= NaSO4 +NaNO2 + H2O. The hot, fused

product is added to sufficient warm water to dissolve the whole of the nitrite, leaving most of the sulphate behind in granular condition. The nitrite

is filtered through vacuum filter and crystallized in fractions from the small amount of dissolved sulphate. Product is good nitrite, and

troublesome by-products are avoided. source Gilbert T. Morgan 1909

|

|

|

jimmyboy

Hazard to Others

Posts: 235

Registered: 1-3-2004

Location: Texas

Member Is Offline

Mood: No Mood

|

|

anyone try this already? what is the yield?

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

This may not seem very exciting but we haven't had many experimental results lately so I though it worth a post or two.

My ultimate goal is to prepare some sodium nitrite using the lead reduction of sodium nitrate according to a procedure from "Laboratory Studies in

Chemistry" (1923) by Robert H. Bradbury.

First off I needed some NaNO3 so have prepared about 30 grams of this by the neutralization reaction of my homemade HNO3 and Red Devil lye (NaOH).

This reaction went well as I first diluted my 65% acid about 2:1 with water. Next I placed this in an ice bath with magnetic stirring. I then added

the lye very slowly as the reaction is highly exothermic. I trimmed to neutral via pH paper then dried this brine at 110C for about 8 hours.

Attached is a photo of the product.

When I get my 6" iron frying pan I will be ready to make the NaNO2.

Edit: Will try again with the photo.

[Edited on 27-12-2005 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

The NaNO3:

[Edited on 30-1-2007 by chemoleo]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

chloric1

International Hazard

Posts: 1159

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

hehe

Oh magpie!

You are not shy about showing off your love of chemistry. The holiday decor really brings out the snowy white hues of your nitrate.

Just so you know, since you are here in the USA you can buy nitrate of soda from garden supply centers. That is where I buy mine and I simply

dissolve in boiling water, filter then cool. It is easy to get a pure white product at about $1 per pound. Save your nitric acid for more dignified

uses. Like making selenium dioxide.

[Edited on 12/27/2005 by chloric1]

Fellow molecular manipulator

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I wasn't aware that I could buy sodium nitrate at garden suppliers, at least not in my area. I'll have another look around. Potassium nitrate,

however, is readily available as a stump remover.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

My attempt to reduce NaNO3 to NaNO2 using the classical Pb reductant was a failure. I was suspicious when I noted all the unreacted lead in my iron

frying pan even though Pb was not in stoichiometric excess.

I did end up with a fair amount of white salt crystals - NaNO3 I think. I tried several confirmatory tests all of which were negative.

So I thought I should read this whole thread. What an education! It's certainly not as easy as indicated in my 1923 lab procedure.

I will try again, if not with Pb, perhaps using the S + NaOH procedure. (I used fishing lead by the way - I suppose this is as good as any. I cut it

into thin slices with a hacksaw.)

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Microtek

National Hazard

Posts: 920

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

If you do the NaNO3 + NaOH + S reaction, you need to find a suitable way to mix the reactants. If you just heat the mixture, it will explode and

scatter hot NaOH.

In my opinion the mixing represents a serious problem because if you melt the NaNO3 and NaOH first and then add the sulfur, it tends to remain on the

surface and burn. This may be allright, but surely some of the oxidation must be from atmospheric O2.

If you melt just the nitrate and then add a mix of the NaOH and S, the latter two will begin reacting to produce polysulfide which may also be OK but

is quite messy.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Thanks, Microtek, for the warning. I really want to make the lead reduction work anyhow - it's classic and would thus be more satisfying.

I tried it again today using about 12 g of NaNO3 and 24 g of Pb. This time I put as much heat to it as I could using MAPP gas instead of propane.

The frying pan did not get red but was close, I believe.

This time I tried to be patient although I was still done in what I estimate as 15-20 minutes. There was much more red mud this time which I take as

PbO and a good sign. I could only see a few tiny BB's of lead at the end of the cook. I extracted the NaNO3 with boiling water and have it drying in

my oven now. The extract had a slight yellow color which I also take as a good sign. When I washed out the frying pan there was some solid particles

other than the fine red mud. I suppose that was lead as I don't know what else it coud be. But not nearly as much as last time.

The proof will be tommorrow when I do the NO2- identification tests. I invented a test of my own based on the different molar heats of solution (very

endothermic) of the NaNO3 and NaNO2. That for NaNO2 is about 2/3's that of NaNO3.

I took some pictures, of course. I'll attach a couple in the next post.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

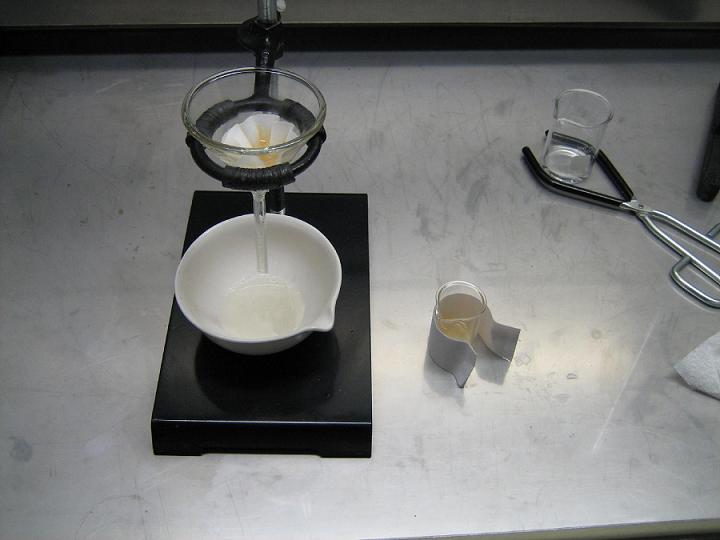

NaNO2 preparation pictures:

Note: there are 2 homemade laboratory aids (fabricated, unpatented) in these pictures (1 ea). I wonder if board members can identify them?

Darkblade48 this is your specialty.

[Edited on 3-1-2006 by Magpie]

[Edited on 30-1-2007 by chemoleo]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

2nd picture for NaNO2 prep:

[Edited on 30-1-2007 by chemoleo]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

Magpie, I am a little confused. Wouldn't you want a strong excess of Pb?

According to my calculation, it is 207 g Pb per 85 g of NaNO3 (Pb + NaNo3--> PbO + NaNO2), or 29.2 g lead per 12 g NaNO3. So I'd use probably 50

grams of Pb, but rather even more. That way you also end up with NaNO2 only, no mixture with NaNO2.

Also, isn't the formation of insoluble product a DIRECT indicator of how well reaction worked?

I.e. you should get theoretically 31.5 g of PbO if you used 29.2 g of lead. This is quite a noticeable yield, and should give a decent precipitate in

solution. The weight of this dried precipitate alone will determine how well the reaction worked! (i.e. weigh filter paper, then filter extract, wash

with h2O, and dry again, then weigh, to find out the total amount of PbO). From your filter paper, it didnt look like there was 25 g worth of PbO!

AT last, another suggestion would be to heat Pb in a can/cradle/crucible until it melts (not teflon gear, as when it decomposes, it is at 322 deg C.

If it didnt compose your temperature is too low anyway). Then add, gradually, NaNO3. Wait until it has reacted. Add more NaNO3. EVentually scoup out

the product, and continue this until all your NaNO3 is used up. This should facilitate a much greater efficiency of reaction, as the excess of lead is

always enormous. Run this through a sieve to remove any Pb particles prior to water extraction.

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Chemoleo I'll try to remember your 3 questions and answer in order:

1. I agree that it is short on Pb. I noticed this when checking the stoichiometry before doing any experimentation. The procedure called for 10 g

NaNO3 and 20 g of Pb. I'm guessing that the tremendous heating drives off some of the oxygen and a full complement of Pb is not required.

2. Yes, I take it that the red/orange mud is PbO and should be a direct indicator of the progress of the reaction. There was quite a bit of it.

After adding the boiling water to extract the NaNO2 I just drained it off the mud, leaving it in the frying pan. Besides, the picture I show is of

the 2nd filtration. There was more in the first filtration. I also wonder if some of this is Fe2O3 and if some of the oxygen came from the

air. But, really, I think it mostly PbO and the oxygen came from the NaNO3.

3. These are not really homogeneous reaction conditions I don't think. The Pb sort of goes into very small droplets. I don't know if flooding it

with more Pb would actually drive the reaction by LeChatlier effect.

The proof of the (hasty) pudding will be in the testing tommorrow. First off I should get some pale blue nitrous acid when I mix the salt with water

and a little H2SO4.

I should also get some NO generated. When a little FeSO4 is added I should see the brown complex [Fe(NO)]+2.

Right now I am patiently evaporating the brine under gentle heat.

My procedure is all of about 5 sentences long. I'm thinking that every word is important. If it works I'll conclude that it is a masterpiece of

brevity.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Chemoleo it just dawned on me why you mentioned teflon - my frying pan? No, my 16cm frying pan is pure iron. You know, the kind granny used to cook

biscuits and gravy on, only much smaller.

My salt was almost dry this morning so I tested it. Results:

1. color: white

2. acidified dilute solution color: clear

3. very small bubles generated when cold dilute solution is slightly acidified with 5N H2SO4 - assume nitric oxide, NO

4. FeSO4 test with solution of "4" above: brown color indicating [Fe(NO)]++

So the first two tests are negative and the last two are positive. I would rank the last test as most important.

When completely dry I will calculate a yield. I am now wonderng what test I could use to determine purity. Any suggestions?

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Microtek

National Hazard

Posts: 920

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

I'd suggest a redox titration with acidified KMnO4 which goes all the way to colorless Mn(II) so the end point is very clear. Of course, you will need

a standard to calibrate your KMnO4 soln.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Thanks Microtek! I have the KMnO4 but will have to find some nitrite standard. Then I'll do it for sure. I actually like analytical chemistry, at

least the wet methods.

My NaNO2 finally dried today. I never let my drying oven get over 150F (66C). I did the final drying in a dessicator over CaCl2. Measured yield was

64%. This was after I had taken some out for analysis. So I'm fairly pleased. Perhaps my yield would have been better if, like Chemoleo suggested,

I used more Pb, and if I had cooked it longer. But I just tried to follow my 1923 procedure to the letter. I did notice that my NaNO2 handled and

dried differently than my NaNO3. When I placed it in my small bottle where it is more in bulk I could see that it has a very faint yellow cast.

I thought that I could also use it for a diazotization. If that is successful then it is should be good enough for my mad science.

Edit: I think I could have increased yield by washing my PbO mud also, which I didn't do.

I checked the MSDSs for NaNO3 and NaNO2 after doing my NaNO2 preparation. NaNO2 is highly hygroscopic whereas NaNO3 is not. This is also

confirmation that I do indeed have NaNO2.

Speaking of the MSDSs. It is a good thing I didn't read them before doing the NaNO2 preparation. All the WARNINGS ABOUT KEEPING AWAY FROM HIGH HEAT

would have stopped me.

[Edited on 5-1-2006 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

woelen

Super Administrator

Posts: 8080

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

Magpie, that is a very nice result. Sodium nitrite indeed is not white. I have some quite pure sodium nitrite (it is lab grade, commercial sample from

a lot of 1 kg) and it is light yellow. I also have lab grade KNO2 and that also is light yellow, exactly the same color, but the crystals are smaller.

Here follows a picture of the NaNO2:

http://woelen.scheikunde.net/science/chem/compounds/sodium_n...

I was so lucky to be able to buy this for just $12.50 per kg.

So, if yours also is light yellow, then I think that is a good sign, if you compare it to commercial samples.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Woelen thanks for the nice picture of NaNO2. Mine doesn't appear to be quite that yellow. But it is hard to tell as I only have about 5 grams.

Food grade NaNO2 is available on the internet for about $88/kg. You did get a good bargain.

I asked a pharmacist at Wal-Mart if he would sell me some sodium nitrite that I could use as a standard. I was surprised and elated that he went

right back and looked for some. But US pharmacies don't compound much anymore so didn't have any. Emboldened I tried this again at a Rite-Aid

pharmacy. Same result: willing but not able. I then asked for some chloroform - he would have sold me this also if he would have had any. I must

indeed look harmless.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

neutrino

International Hazard

Posts: 1583

Registered: 20-8-2004

Location: USA

Member Is Offline

Mood: oscillating

|

|

How much nitrite is in that picture, woelen? It's a little hard to get an idea of how yellow the crystals without knowing how much crystal matter

there is to scatter the light.

|

|

|

woelen

Super Administrator

Posts: 8080

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

The vial, containing the NaNO2 has a size of approximately 5 cm (2 inch) from bottom to top of the black cap and the diameter of the vial is

approximately 2.5 cm (1 inch). This should give you a sufficient indication of the amount of NaNO2 in the vial.

The glass of the vial is very thin, less than 1 mm.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I performed another confirmatory test today, i.e., pH. The pH of my NaNO2 was 9; that of my NaNO3 was 7. This agrees with the MSDSs.

I tried again to get the faint blue color of nitrous acid by acidifying some dissolved NaNO2 with HCl. But it was still clear. I wonder why? I have

seen nitrous acid at work: when dissolving uranium in nitric acid we absorbed the generated NOx in water. This water had a beautiful faint blue color

which we attributed to the presence of nitrous acid.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

woelen

Super Administrator

Posts: 8080

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

Try with cool dilute H2SO4 or cool dilute HNO3 instead of HCl. HCl is reduced quickly and Cl2 is formed in small amounts. With dilute H2SO4 and HNO3

you don't have that problem. Also, the liquid should be cool, but not freezingly cold.

Try another nice experiment, forming HNO3, but not nitric acid, but one of its isomers, HOONO (peroxynitrous acid). That acid is red.

You can make it by first making a solution of HNO2 by mixing some dilute HNO3 with NaNO2. This must be ice cold. Then add a few drops of ice cold 10%

H2O2. The liquid turns orange, but this orange color quickly fades. The HOONO quickly rearranges to HONO2.

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Magpie:

Just add a few drops of 20% HCl to a spatula of your solid NaNO2 product. If there are appreciable amounts of NaNO2 in it, there will be a vigorous

reaction, liberating lots of brown gas (NO2, from initially produced NO by reaction with atmospherical oxygen).

This is the easiest and most reliable test for nitrite. Nitrate gives absolutely no reaction here.

An equally good test for nitrite is to add a solution of an ammonium salt, like NH4Cl or NH4NO3 and warm gently.

Nitrite ions readily oxidise ammonium ions to elemental nitrogen:

NH4+ + NO2- -----> N2 + 2 H2O

The reaction takes place in dilute aqueous solution on gentle warming.

The reaction goes to completion. If an excess of ammonium salt is added to the test substance, all of the resulting gas is collected and the volume

measured and the reaction allowed to get complete by warming to near the boiling point (cool down before measuring the amount of gas! Otherwise your

measurement will be way too high, due to expansion of the gas and water vapor), a quantitative measurement of the percentage of NaNO2 in your product

is possible.

|

|

|

Esplosivo

Hazard to Others

Posts: 491

Registered: 7-2-2004

Location: Mediterranean

Member Is Offline

Mood: Quantized

|

|

| Quote: | Originally posted by garage chemist

Magpie:

Just add a few drops of 20% HCl to a spatula of your solid NaNO2 product. If there are appreciable amounts of NaNO2 in it, there will be a vigorous

reaction, liberating lots of brown gas (NO2, from initially produced NO by reaction with atmospherical oxygen).

This is the easiest and most reliable test for nitrite. Nitrate gives absolutely no reaction here. |

Not to miss is also the very evident blue colour of the HNO2 (during addition of HCl to NaNO2) if the NaNO2 solution is concentrated enough. The

'strength' of the blue colour can be used to approximate conc. of NaNO2.

Theory guides, experiment decides.

|

|

|

| Pages:

1

2

3

4

5

..

17 |