| Pages:

1

2

3

4 |

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

There have been reports of runaway reactions which have been quenched to avoid further " complications " . Think about it and you will

realize that the potential is there for a thermally induced

" cook-off " , when the batch size is large and the proportions of materials present is not a safe mixture to be subjecting to a sudden

temperature spike which can sometimes keep right on going to reach the ignition point . Picric acid is probably the safest trinitration of an

aromatic , but I personally wouldn't ever perform its synthesis operating on the assumption that there is no danger about the process . One

safety enhancement is provided by keeping the temperature high enough to guarantee that the nitration reaction proceeds without accumulation of

unreacted nitrate or nitric acid which would aggravate the danger if the reaction suddenly surged and became uncontrollable , going into an oxidation

decomposition mode which is autocatalytic and therefore self-accellerating . That uncontrolled process is limited only by the quantity of material

present , and so it becomes a matter of

whether or not there is " critical mass " for the reaction mixture .....and if that condition is present , then the geometry lesson for the

day pertains to " blast radius "

|

|

|

pdb

Hazard to Self

Posts: 90

Registered: 8-4-2004

Member Is Offline

Mood: No Mood

|

|

Rosco's TNR procedure

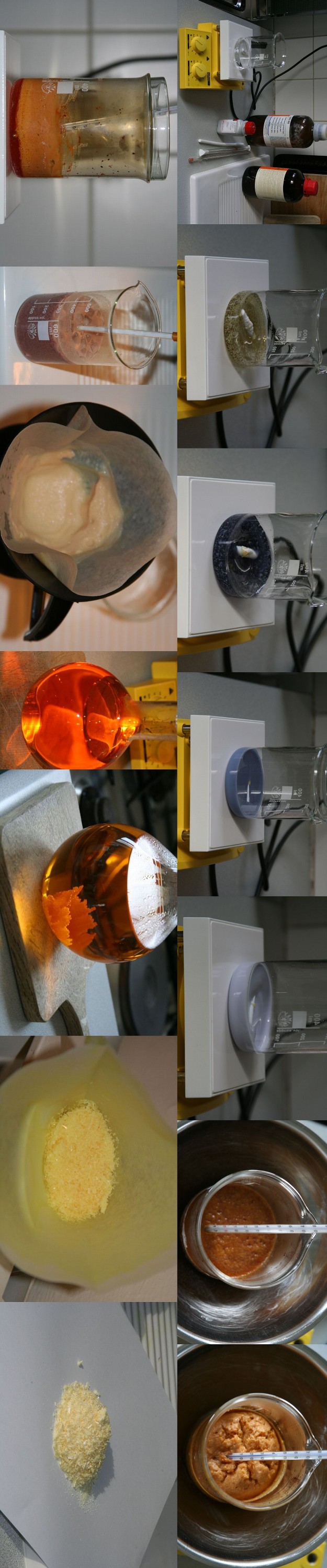

I prepared TNR using Rosco's procedure (page 1 of this thread) and same starting quantity, i.e. 10 gr commercial grade resorcinol. I thorougly

followed the times and temperatures indicated, just taking some liberty from the recipe by accelerating somewhat HNO3 addition (68%, then 100%) after

having observed than the temperature rise would be much weaker after dropwise addition of the first 10 ml of 68% HNO3. But at no time did the

temperature overpassed 22°C.

After slow crystallisation from boiling distilled water, the crop of dry crystals was 16,2 gr iso 20 gr expected. However, I didn't try to recover the

part of TNR still dissolved in the cold solution, although by evaporating a few ml of it, it left crystals in a non neglectable amount. Although TNR

is notably less soluble in water than picric acid, the literature mentions 0,45 gr per 100 ml at 15°C. As I separated the crystals when the solution

had reached 4°C, I assume that about 2 gr remained in the discarded 900 ml liquid... which would makes a total crop around 18 gr, still 2 gr short

compared to Rosco's record.

EDIT: made pic slightly smaller and rotated it to avoid page stretching

[Edited on 8-23-2010 by Polverone]

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

Your picture collection is very well done. I was looking at various methods of styphnic acid production just now and found a "NITRITE" synth. I have a

collection of material from patents and sources that have proven to be worthwhile keeping (Roscoe's stuff, etc) and this had an old date and no lab

notes....For what it's worth, I don't know it's background (what patent it came from, etc) but since this thread has had so much material added to it

over the months...here it is:

Step 1. Preparation of Dinitroresorcinol monohydrate

To 16 liters of water add and dissolve 440 grams of resorcinol, then 452 grams of 98% sulfuric acid. Immediately thereafter, add 6800 grams of

crushed ice to mixture, and then stir the mixture vigorously until the internal temperature of the mixture reaches about 0 Celsius. Then prepare a

solution by dissolving 600 grams of sodium nitrite into 3200 milliliters of water, and then add this sodium nitrite solution to the

sulfuric/resorcinol mixture over a period of 6 minutes while vigorously stirring the mixture and maintaining its temperature below 5 Celsius. After

the addition of the sodium nitrite solution, continue to stir and cool the reaction mixture below 5 Celsius for 30 minutes. Note: A precipitate will

begin to form. After the 30 minute period, filter-off the precipitated dinitroresorcinol monohydrate, and wash with several hundred milliliters of

cold water (use gravity filtration).

Step 2. Preparation of Styphnic acid

Place 3000 milliliters of 40% nitric acid into a beaker, and then gently heat this mixture to about 30 Celsius. Thereafter, carefully mix the moist

filter cake, prepared at the end of step 1 to the nitric solution over a period of about 30 minutes, while stirring the nitric acid and keeping its

temperature around 30 Celsius. Immediately after the first addition of the filter cake, nitrogen oxide gases will be evolved, followed by the

formation of a foam (the foam will dissipate after about 10 minutes). After the addition, raise the temperature of the mixture to 95 Celsius, and

then hold this temperature for 1 hour. After heating for 1 hour, remove the heat source and allow the mixture to cool to room temperature. Note: A

precipitate will form. When the reaction mixture reaches room temperature, filter-off the precipitated product, wash with 300 milliliters of 2%

nitric acid, and then with 600 milliliters of cold water. Then air-dry the product. The result will be pale yellow crystals, well suitable for use

in preparing lead styphnate, or Styphnic acid compositions.

As you can see it was designed to lab production size. I do not know if scaling it down would intail problematic issues but if it worked on a smaller

scale it would be interesting as it cuts down on materials, etc.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by pdb

I thorougly followed the times and temperatures indicated, |

Really ?

| Quote: |

But at no time did the temperature overpassed 22°C. |

Then your cooling was too agressive for the reaction to

proceed from its own exotherm . The way to patch things

would have been to remove all cooling and even nudge the

reaction with a little supplemental heat . When I use the term " keeping below a certain temperature " that is not to say that any temperature way

below that will be fine , but

it is usually a temperature limit very near where you want to be with the reaction , but observing it as a point where

the reaction may not self-regulate very well or may show signs of decomposition byproducts . Generally for nitrations

you want to stay just under that temperature to keep the reaction rate steady , but not to exceed that temperature

during that time when the reaction is being regulated by rate of addition . When the reaction is not maintaining its

temperature , then you have to adjust the conditions so

that it does stay on track , understanding that there is

an optimum thermal curve the nitration should follow for

best results .

|

|

|

pdb

Hazard to Self

Posts: 90

Registered: 8-4-2004

Member Is Offline

Mood: No Mood

|

|

I do understand your point and agree. However, in my mind, 22°C was not that far from 25°C... Maybe this would deserve a wording precaution next

time

BTW, isn't it a characterisation of a major difference between O- and C- nitrations ? E.g., NG is prepared while keeping temperature under 25° or

30°C (depending on authors) as a safety precaution, and good yields are still obtainable at quite lower temperature, while, in order to secure high

yields, phenol-like nitrations have to navigate as close as possible of an upper limit, beyond which the likelihood of runaway is too high.

[Edited on 6-2-2006 by pdb]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by pdb

I do understand your point and agree. However, in my mind, 22°C was not that far from 25°C... Maybe this would deserve a wording precaution next

time |

Indeed I could have done a better job of writing up the

details , but just had a paragraph in a lab notebook to

reference . Next time I do the synthesis I will be more thorough with my notes . A few minutes is not very specific

for example , and the minutes do count on a finite curve

where a reaction is affected by temperature and time .

| Quote: |

BTW, isn't it a characterisation of a major difference between O- and C- nitrations ? E.g., NG is prepared while keeping temperature under 25° or

30°C (depending on authors) as a safety precaution, and good yields are still obtainable at quite lower temperature, while, in order to secure high

yields, phenol-like nitrations have to navigate as close as possible of an upper limit, beyond which the likelihood of runaway is too high.

|

Yes good yields can be obtained at lower temperatures

with things that are easily nitrated but also easily oxidized ,

but the reaction rate slows so it becomes something of a tradeoff to choose a good working temperature . But it generally requires driving aromatic

nitrations pretty hard to

effect their complete nitration , on the order of 3 times the temperature you would need for completely nitrating an aliphatic . Even at the elevated

temperature , it is safer

for the nitration of the aromatic . You actually can completely nitrate an aromatic at the lower temperatures , if you don't mind waiting three days

or even a week for the nitration to complete  I never actually tested this but

it would seem so . I never actually tested this but

it would seem so .

BTW the picture file you posted above won't completely download for me , maybe a corrupt file or the forum server

is dropping out . It has been acting wierd for a couple of days , dropping out completely at times . Could you maybe reattach the file and see if

that helps anything .

|

|

|

Quince

National Hazard

Posts: 773

Registered: 31-1-2005

Location: Vancouver, BC

Member Is Offline

Mood: No Mood

|

|

Something's wrong on your side, Rosco, as his photo loads just fine on my machine.

[Edited on 7-2-2006 by Quince]

\"One of the surest signs of Conrad\'s genius is that women dislike his books.\" --George Orwell

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

The pictures are loading fine for me now so the file

is okay . I think it was the server acting out a bit

from time to time and I just tried during a temporary glitch .

It does load the first picture and then jump to a blank screen

until I wave the cursor of my mouse around a bit in the upper right part of the blank field and see that box for

resizing the image . When I click that box then the first

frame reappears and all is well scrolling to the other pictures also .

|

|

|

ppoowweerr

Harmless

Posts: 5

Registered: 13-8-2007

Location: USA

Member Is Offline

Mood: No Mood

|

|

I am working on some physical properties of lead styphnate, and since TNR is somewhat difficult to purchase, I had to make some before I can begin

working with it. I have had some difficulty getting a decent product but thanks to rosco, I have now achieved very nice pale yellow hexogonal

crystals. The only problem is that I am not sure about the best means to prepare it for impact detonation. I think I have too much h2o present. I used

an ATR IR and got an awesome spectra with even the fingerprint region is all accounted for compared to a spectra I found online. So now my questions:

Will simply using a vacuum oven work to dry? What does the dinitro version look like on IR and to the eye? And thanks again to rosco and othersw who

have posted on this thread.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Somebody needs to edit the image widths above

to about 550 pixels , and post the images sequentially ,

so they scroll vertically , instead of the horizontal panorama that appears now

and screws up the text formatting for the whole page .

Good pictures .....but the formatting stinks .

[Edited on 1-9-2007 by Rosco Bodine]

|

|

|

tito-o-mac

Hazard to Others

Posts: 117

Registered: 30-6-2007

Member Is Offline

Mood: No Mood

|

|

Was the residue crude or pure?

|

|

|

ppoowweerr

Harmless

Posts: 5

Registered: 13-8-2007

Location: USA

Member Is Offline

Mood: No Mood

|

|

my residue was pure. It was pale yellow hexagonal crystals and i have been drying it in a low temp oven.

The IR was perfect and the MP was 177-181 C. I was very happy with the small range and Merck 12th Ed

says 180 MP. I am going to run it through a bomb calorimeter just for fun, tomorrow I hope. If not tomorrow then next week. Oh and by the way fuming

red nitric is expensive. Thanks

|

|

|

ppoowweerr

Harmless

Posts: 5

Registered: 13-8-2007

Location: USA

Member Is Offline

Mood: No Mood

|

|

I havent done any math yet so I dont have any numbers but I did get to run about .75g of TNR

in the bomb calorimeter. It yielded a net change of 0.8 C degrees in 2 L of h20. when I get the

numbers worked out tomorrow (or this weekend) I will be able to compare to published numbers

with mine for another test of purity.

What is the best method adding lead to make lead styphnate?

|

|

|

ppoowweerr

Harmless

Posts: 5

Registered: 13-8-2007

Location: USA

Member Is Offline

Mood: No Mood

|

|

Thanks for all of your help, guys. I have finally made a satisfactory product of lead styphnate that yielded a surprisingly large detonation. thanks

all

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

reciprocal solubility NH4NO3 - NaNO3 and NaNO3 - KNO3

Quote: Originally posted by quicksilver  | | Quote: | Originally posted by Rosco Bodine

The use of nitrates as concentrated solutions does simplify addition of the nitrate to the sulfuric acid solution of

the sulfonated organic material to be nitrated . I have mentioned that using

a solution of two or more different nitrates

can make possible an even more concentrated solution having less water content which would dilute the nitration mixture . Such solutions of mixed

nitrates have been developed to provide a liquid oxidizer phase having low water content for use in manufacture of emulsion explosives . Some of

these solutions are

essentially a eutectic salts mixture which

also exhibit a enhanced cosolubility in the presence of a small amount of water , similarly as they have a much lowered melting point even in the

absence of water altogether.

I know I have seen other compositions mentioned and I will share any others I find . |

I was unawair of the "mixed-nitrates" concept...and PLEASE; if you do find material related I would deeply apprieciate seeing it!

- I too use the PATR but find that patents are making much more impact in finding answers, new proceedures, & use of my time. Some of the most

interesting stuff I have found have come from US patents thus far.

As I have the same trouble accessing UK patents, as you have noted yourself, that site is a real pain. But the older, valuable patents (where they

were nitrating everything under the sun) and the older techniques, seem to originate in the UK. |

Here are some reciprocal solubility charts for a couple of the binary systems of mixed nitrates which indicate the co-solubility enhancement which

occurs at certain temperatures anyway for certain unique proportions of salts in mixture in water solution. There are definitely other binary and

tertiary and possibly quaternary systems where a peculiar increase in water solubility occurs for certain specific proportions of particular nitrates

in mixture. Calcium nitrate and ammonium nitrate exhibit reciprocal solubility, and I think it is also true for magnesium nitrate with other

nitrates which would be very interesting. Where the indexing of such reciprocal solubility data is to be found I do not know.

To anyone who may be helpful with reciprocal solubility data references for nitrates, please add to these references.

Attachment: Reciprocal Solubility of NH4NO3 and NaNO3.pdf (119kB)

This file has been downloaded 906 times

Attachment: Sodium Nitrate Solubility and Reciprocal KNO3 Solubility.pdf (129kB)

This file has been downloaded 966 times

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

RB - Thank you very much for those.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Our page format is falling off the ends of the earth....

To those who post pictures: PLEASE reduce your size level if you see it distorts the page format. This has implications of both "read-ability" and if

someone else happens (look how far you have to go to get to the "edit" button!)

to do that, the page can become totally illegible.

It's best not to "TILE" the pictures in any event.

Post one after another or drop them to 400/600 but

keep the sharp synthesis photo separate so everyone

can see the color.

[Edited on 5-8-2010 by quicksilver]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

nitrate reciprocal pairs, double salts, and eutectics

The use of specific combinations of nitrates in a specific proportion appears to be a valid strategy for loading up of solutions with the highest

content of total nitrates in solution for a given temperature. And it also appears that specific combinations of nitrates do form double salts and

eutectics which are capable of exluding some or all of the water of hydration which would normally have such great affinity for one or more of the

nitrates that it would otherwise be impossible to obtain that nitrate in anhydrous form by heating to drive away the water and leave the completely

dry salt. Magnesium nitrate is the nitrate of particular interest. While this is not fully described as being verified by weighing and moisture

analysis figures, some references are indicating that Magnesium Nitrate forms anhydrous double salts and/or eutectic melts with Ammonium Nitrate, with

Sodium Nitrate, with Potassium Nitrate, and other nitrates. Some combinations are of particular interest having potential value with regards to

nitration mixtures where the dehydrating property of the nitrate and / or the sulfate which may be produced as a byproduct, can improve the nitrating

power of the acid by sequestering H2O already present or H2O produced as a nitration or nitrolysis byproduct. Information in the literature is not

very extensive concerning this potentially valuable technique which could be applied not only to nitration and nitrolysis mixtures, but could also

have value in formulation of oxidizer melt mixtures for pyrotechnic compositions. There are a few mentions of this scattered among the patent

references for fertiliziers, and pyrotechnic related compositions, and for energy storage by phase change salt systems, but there is very little

information found pertaining to the usefulness for nitrations. I have found a few more references that I can share concerning the reportedly

anhydrous melts. I also found a more extensive solubility table for different temperature aqueous solutions related to the reciprocal solubility of

KNO3 and NaNO3. I will add to these mixed nitrates references as I find any more.

Attachment: Reciprocal Solubility KNO3 and NaNO3 warm solutions.pdf (132kB)

This file has been downloaded 1209 times

Attachment: Ammonium Magnesium Nitrate solubility.pdf (118kB)

This file has been downloaded 946 times

Attachment: US3729351 Eutectic Oxidizer mixtures for FLARE_COMPOSITION.pdf (103kB)

This file has been downloaded 1386 times

Attachment: GB382368 Anhydrous NaNO3 - Mg(NO3)2 - Ca(NO3)2 tertiary eutectic 138C.pdf (341kB)

This file has been downloaded 928 times

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Mg(NO3)2 - NH4NO3 double salts and eutectics

Here is some additional data from a Monsanto patent US3173756 and a journal article by the inventor regarding the anhydrous binary system Mg(NO3)2 -

NH4NO3 double salts and eutectic mixtures. Also attached is the US1952849 patent parallel issue to the British patent already posted above. Example

3 which is 65% anhydrous Mg(NO3)2 - 35% KNO3 is interesting. Example 4 which is 51.8% anhydrous Mg(NO3)2 - 48.2% NaNO3 is also very interesting.

I have found mention that there exists a ternary anhydrous eutectic system of slightly lower melting point for Mg(NO3)2 - KNO3 - NaNO3 but I have not

found the ratios stated.

Also it would seem that a quaternary system with those three and NH4NO3 would be likely, as well as ternary systems of Mg(NO3)2 - NH4NO3 - NaNO3 (or)

KNO3 , but I have not found any of them published. There are mentioned also systems where urea is an added component which can substantially

decrease the melting point and also result in anhydrous mixtures. Heating along with vacuum may be required for complete dehydration of some of these

mixtures at reasonably low temperatures, while vacuum may not be strictly required for others. I have no specific information what is the spread on

that, however vacuum appears to be a drying rate increaser more than an absolute requirement.

Attachment: US3173756 Griffith Magnesium Nitrate Ammonium Nitrate Anhydrous Double Salt and Inventor Journal article.pdf (884kB)

This file has been downloaded 2244 times

Attachment: US1952849 Mg(NO3)2 Anhydrous Eutectics.pdf (185kB)

This file has been downloaded 890 times

[Edited on 30-8-2010 by Rosco Bodine]

|

|

|

grndpndr

National Hazard

Posts: 508

Registered: 9-7-2006

Member Is Offline

Mood: No Mood

|

|

US PATENT 1840229, jan5,1932. (double salts)

Aimed primarily @ producing less hygroscopic,high nitrate fertilizers incorporating a wide variety of nitrates.

FWIW excuse the nonexistent link I have a hard copy of the patent

"I have now found that nitrogenous products which do not have said objections are obtained in a simple manner by combining the said basic nitrates

with the nitrates of alkali metals such as potassium,or monovalent radicles such as ammonium or urea radicals to form double salts.

[Edited on 27-1-2011 by grndpndr]

|

|

|

otonel

Hazard to Self

Posts: 84

Registered: 9-4-2005

Member Is Offline

Mood: No Mood

|

|

I try to make styphnic acid and lead styphnate like in that site powerlabs but the result was a brown "misery" not yellow, I dissolved that in a mixture of water with ethanol and heated with intention to make

more pure but all was a black colored mixture and I add some lead oxide and in the attachment picture is my disastrous result.

Can extract and purify lead styphnate or styphnic acid from my final result or is good to drop to garbage?

What was wrong with my synthesis, I follow procedure from powerlabs but I don`t have thermometers and anyway I don`t leave the mixture to become too

hot,next time I will use your procedure from first page for my 4 grams of remaining resorcinol

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

Obviously it's not possible to comment on your synthesis as you didn't post it. However whatever you did, did not have the desired result.

|

|

|

otonel

Hazard to Self

Posts: 84

Registered: 9-4-2005

Member Is Offline

Mood: No Mood

|

|

Here is my synthesis :

-8grams of powdered resorcinol are weighted and added to the 250ml beaker containing the 10ml of concentrated sulfuric acid.

-the mixture is stirred for several minutes untill the resorcinol dissolves and forms into a yellow liquid and heated for 30 minutes during which it

quickly solidifies into a pink - brown cream

- the resultant product is than chilled to -5C on a water bath with salt added, and 15ml of nitric acid are added

-the mixture react very slowly but when I heated on the hotplate reaction become more fast with NO2 fumes

-after complete reaction the mixture color become brown-black and I added 100ml distilled water

-the mixture is cooled to 5C so as to precipitate styphnic acid (or what I make) , and than was quickly filtered and washed with 400mL of cold

distilled water

-I dissolve the resultant filtrate in a boiling mixture of 1 volume ethanol and 2 volumes water and I add some amount of lead monoxide

You see the result , and that was synthesis followed by me

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

Periods of time and crystal "set-up" periods were not outlined so I will assume nothing but what had been written. However the idea is that the

styphnic acid be allowed to form, crystallized and dry prior to moving onward to the synthesis of the lead salt. If that period of time and formation

is missed it's possible that is why the synthesis failed. There needs to be ordered "steps" in this process and it should not be rushed. Since I was

not looking over your shoulder; I certainly cannot say for sure but the progression has some important time elements to it.

From what I have seen the "powerlabs" synth was not a notably successful one; that's why there have been many other designs implemented. It's not too

difficult & many have had great results but the general lab to lead styphnate must progress in stages wherein the synthesis is well defined. I've

seen great success with both trinitro and lead-trinitroresorcinol labs which offered good "repeat-ability" but they had strong emphasis on time and

temperature. Very often when a nitration fails those two factors play a powerful role in the failure.

Whenever one has a problem with nitration/esterfications or where there is a sulfonation prior to the process one should always make every attempt to

look to temperature, timing, addition of precursor. & consistency. These are the major issues that result in success or failure.

[Edited on 17-4-2011 by quicksilver]

|

|

|

otonel

Hazard to Self

Posts: 84

Registered: 9-4-2005

Member Is Offline

Mood: No Mood

|

|

Quicksilver I try your synthesis on the first page and the resultant product was a yellow- red crystals, not very pure stypnic acid but my first

accomplish synthesis and I don`t have thermometer or something else to control temperature.

Tomorrow will try a recrystallization and next step will be to make lead stypnate and silver stypnate

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

Unless you can control elemental conditions such as temperature, you'll never get a very pure product in many synthesis. Controls of variables such as

time, exposure, temperature, volume, & density are vital.

You can get yourself a lead salt and see if you can produce a functional lead styphnate; that would tell you something. The synthesis I use produces

a remarkably potent product & resultant lead stypnhate is of high quality, good yield & brisant (for lead styphnate anyway). The emphasis on

a careful sulfonation was suggested to another fellow's web site as his synth for the same had recurrent troubles.

[Edited on 2-5-2011 by quicksilver]

|

|

|

| Pages:

1

2

3

4 |