| Pages:

1

2

3

4 |

Hey Buddy

Hazard to Others

Posts: 429

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Quote: Originally posted by MineMan  | I wrote those things because I don’t want someone blowing up firings melt cast because of sulfuric acid in the crystals.

You do fit in. You may not have noticed but you actually revived this forum which was pretty much dead. You have done great investigative work.

We’re just impatient because it seems so damn promising.

The CHP works, every time. If you get the grain sizes even remotely close.

Standard tests are great. But we can also tell a lot from 1 melt cast gram in a tube placed on scrap steel. Or burying a 6mm copper tube in a 5 gallon

bucket of sand and collecting the fragments.

You have done insane work, but everyone here wants a 9kms melt cast…. So you must deliver. Then we can be business buddies  and hopefully find a way to use your invention. and hopefully find a way to use your invention.

Also, invite your wife into the garage with a little lab coat role play so she is more willing of your project  )) ))

PS. If I sound insane it’s just the genius in me

[Edited on 16-11-2022 by MineMan] |

I understand, I will try to get some testing done. Here's where I'm at as of tonight:

Prepared new CHP per LLs videos. Exact copy. In contact with LL to clarify ammonation. CHP is monochromatic crystals slightly damp, not sticking to

walls of glass vessels/spoons/pan. 6mm load testing in morning, similar to LL but I only have Ti right now, I assume that should be fine for CHP (in

terms of confinement properties of metal). If not, I can prepare some 6mm SS casings. Will calc in morning to determine press distance within that

cavity to match density quoted, (no pressure figure was given).

If CHP cap firing is a go, will move on direct to testing melt cast samples on steel and lead. If theres a no-go issue, will recircle and focus on a

quick primary to get firing. After initial comparison to ETN, can load PETN. Tonight finished fuming nitric, so will prepare the K-6/RDX quick mix.

Big bottle of PETN already made. Melt casted ETN earlier tonight. So it's all on the CHP (No pressure), then after that its all on this compound (no

pressure, well, hopefully >30GPa)

I dont know if it will "deliver" or not, but its a triazine that is deflagrating and melting, so it's going to be energetic and the fact that it melts

means it is useful regardless of its comparative performance. Even if it's det velocity were 7000 m/s it would still be useful because TNT is

difficult to prepare and ETN is too sensitive for large castings, without phlegmatizing or plasticizing or adding inerts. Other state of the art melt

casts are very niche and are not applicable to amateurs, like melt azoles or propyl-Nitroguanidine. But this melt cast is immediately reproduceable by

anyone with the basic materials. No triple stage nitration, nothing like that. Just throw in a big bottle and filter rinse, recrystallize and melt.

anyways, we will get to performance tests asap

|

|

|

Hey Buddy

Hazard to Others

Posts: 429

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

I have steel meshed mixed the CHP into a small grain, does it need to be large grain like original TACP? Hopefully not.

|

|

|

MineMan

International Hazard

Posts: 1004

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

CHP is very forgiving… any metal confinement is fine.

Of course I have mentioned the best primary here before. Copper amino guanidine perchlorate. I am not encouraging or suggesting. Rather it’s

something you will probably read about so it exists is all I am saying.

|

|

|

Microtek

National Hazard

Posts: 869

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

Personally, I prefer the nickel variant, but copper probably produces less toxic compounds on detonation. It's mainly a matter of taste.

Anyway, I have been doing some preliminary synthesis experiments with NTNT. I did it once via sulfuric and once via hydrochloric acid. During the

H2SO4 mediated synthesis (scaled down to 1/10 of the reactants) I noted that if the prescribed method is followed using pristine needle crystals of

NQ, large amounts of it are recovered on filtration. I extracted the filtered mass of crystals and amorphous powder several times with acetone,

neutralised the acetone soln with NaHCO3 and evaporated the solvent at room temp in an airstream. This produced 1,766 g of yellow flaky crystals

corresponding to 36% yield, assuming the product to be pure NTNT. I then tested the melting point in a glass capillary, and found an onset of melting

at 75 C, but the bulk of the material remained unmelted at 100 C. I haven't tested any detonics yet.

I then read the papers with the original experiments, and noted that the un-nitrosated triazine must be quite stable (the authors prepare it by

heating at 50-55 C for 3 hours). I then tried the HCl mediated procedure (as per the bit-chute video, and again scaled to 1/10), but did not add ice

or cool the reaction until I was about to add the NaNO2. I also used lab-grade HCl and magnetic stirring instead of intermittent swirling. The NQ was

still not very soluble in aqueous HCl, but when the hexamine was added it evidently reacted and the solution turned clear after about 5 minutes of

stirring. Then ice was added and the nitrite solution was added all at once. Some effervescence was observed, but only slight foaming. After 30

minutes a dense pricipitate had formed, similar to RDX in its tendency to settle. This was easily filtered (I had set up for Buchner filtration, but

that would not have been necessary), washed on the filter and air dried overnight to yield 1,17 g of crude product.

The mother liquor had been set outside to off-gas overnight, and significant amounts of additional precipitate had formed in the morning. I have not

had time to isolate it yet, so I don't know how much. 1,17 g would correspond to about 31% yield.

I don't quite understand why you would assume that ionic derivatives might be formed. I think NTNT must be a very weak base; even the un-nitrosated

parent molecule is a weak base and its HCl salt can be converted to free base by heating with 18% HCl. Even partially nitrosated derivatives must be

orders of magnitude weaker.

I find it much more likely that what you are seeing is either differing degrees of nitrosation or maybe presence of impurities such as sulfuric acid

(which can be notoriously difficult to remove), or maybe unreacted starting materials in differing amounts.

|

|

|

Hey Buddy

Hazard to Others

Posts: 429

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Quote: Originally posted by Microtek  |

Anyway, I have been doing some preliminary synthesis experiments with NTNT. I did it once via sulfuric and once via hydrochloric acid. During the

H2SO4 mediated synthesis (scaled down to 1/10 of the reactants) I noted that if the prescribed method is followed using pristine needle crystals of

NQ, large amounts of it are recovered on filtration. I extracted the filtered mass of crystals and amorphous powder several times with acetone,

neutralised the acetone soln with NaHCO3 and evaporated the solvent at room temp in an airstream. This produced 1,766 g of yellow flaky crystals

corresponding to 36% yield, assuming the product to be pure NTNT. I then tested the melting point in a glass capillary, and found an onset of melting

at 75 C, but the bulk of the material remained unmelted at 100 C. I haven't tested any detonics yet.

I then read the papers with the original experiments, and noted that the un-nitrosated triazine must be quite stable (the authors prepare it by

heating at 50-55 C for 3 hours). I then tried the HCl mediated procedure (as per the bit-chute video, and again scaled to 1/10), but did not add ice

or cool the reaction until I was about to add the NaNO2. I also used lab-grade HCl and magnetic stirring instead of intermittent swirling. The NQ was

still not very soluble in aqueous HCl, but when the hexamine was added it evidently reacted and the solution turned clear after about 5 minutes of

stirring. Then ice was added and the nitrite solution was added all at once. Some effervescence was observed, but only slight foaming. After 30

minutes a dense pricipitate had formed, similar to RDX in its tendency to settle. This was easily filtered (I had set up for Buchner filtration, but

that would not have been necessary), washed on the filter and air dried overnight to yield 1,17 g of crude product.

The mother liquor had been set outside to off-gas overnight, and significant amounts of additional precipitate had formed in the morning. I have not

had time to isolate it yet, so I don't know how much. 1,17 g would correspond to about 31% yield.

I don't quite understand why you would assume that ionic derivatives might be formed. I think NTNT must be a very weak base; even the un-nitrosated

parent molecule is a weak base and its HCl salt can be converted to free base by heating with 18% HCl. Even partially nitrosated derivatives must be

orders of magnitude weaker.

I find it much more likely that what you are seeing is either differing degrees of nitrosation or maybe presence of impurities such as sulfuric acid

(which can be notoriously difficult to remove), or maybe unreacted starting materials in differing amounts. |

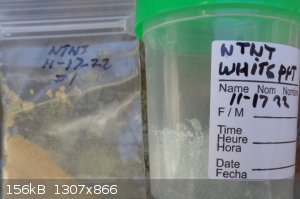

Microtek, I really appreciate your further development of this compound. I agree with your assessment completely. Presence of needles is indicative of

unreacted NQ. For most experiments I used Metelkinas methods for small batch NHHT, and mod'd it with .072 mol (4.96 g) nitrite rounded up to excess @

5 g. With HCl there is a rubicon, either a foam precipitate or a fizz reaction. It is possible to precipitate "m1" (see photos) which is a white

powder free of the lemon color and more dense. "m1" appears to perhaps be NHHT (Im not sure yet, my NHHT control is evaporating today). This m1 was

achieved by using 12.5 ml HCl / 5 g NaNO2 / 2.5 g NQ / 2.6 g Hexamine. Added NQ+Hexamine to HCl @ 10.9 C, then wetted NaNO2 to dissolve it and dripped

in. Opaque foam is produced instantly then after ~2minutes turns clear. White material on filtering. Seems different color, different morphology,

powder not a foam or fiber, on open flame burning the white powder burns very fast and projects (blows apart and projects out) small pieces of white

material.

This and the slight differences in H2SO4 made me assume there was a possibility of ionic species but I wasnt sure, it could also be NHHT, the only

problem is where did the nitrite go? it's not in rxn vessel, material is white, perhaps its in solvent? I would yield to your better judgement, you

are obviously more experienced and knowledgeable in this sort of thing. If there shouldn't be ionic species there probably aren't.

On stability of NHHT, I agree it seems stable enough and seems like it could be a good candidate for thermal stimulated ddt, if it's true that it

explodes at 102 C, it should have a low critical diameter of <2 mm similar to other energetic triazines. The claim of 102 C explosive decomp was

found in was "Nitroguanidine Poly nitro compounds Zhuang" pdf, found in first page of thread.

[Edited on 16-11-2022 by Hey Buddy]

[Edited on 16-11-2022 by Hey Buddy]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1387

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Microtek couldn't take it anymore and made his own synthesis......

By the grams I see a good yield...... .....The theory surrounding NTNT is

starting to become clearer. .....The theory surrounding NTNT is

starting to become clearer.

Basically works any size of CHP grain. 0.5 x 0.5 mm, 1x1, or 2x2. Bigger grain has generally more reliable DDT. With execpt output segment, which is

monolite as stone.

[Edited on 16-11-2022 by Laboratory of Liptakov]

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Hey Buddy

Hazard to Others

Posts: 429

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Quote: Originally posted by MineMan  |

Copper amino guanidine perchlorate. I am not encouraging or suggesting. Rather it’s something you will probably read about so it exists is all I am

saying. |

I would very much like to learn more about this. Zinc is commonly used for reduction of NQ to pimagedine but it's very messy. The electrolytic

reduction works very cleanly on basic lead, I've found most people are unaware of this method.

Attachment: AMINOGUANIDINE ELECTROLYTIC.pdf (599kB)

This file has been downloaded 239 times

|

|

|

Hey Buddy

Hazard to Others

Posts: 429

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Don't want to drop a nail biter, but I had failures to prime on the CHP using TiH2/Mg/KCLO4/NC firstfire and either Pyrodex or Triple based rifle

powder as a prime.

I was able to initiate CHP on third cap attempt, but no-go on DDT, just deflagration. Earlier this week, I was able to detonate CHP with a hammer when

it was dry but I learned that is the incorrect state, to be detonating CHP dry. It should be slightly damp with NH4OH. I thought I was going to see no

issue in this regard.

I'm not saying the CHP failed, I'm sure it's my preparation that failed or some other factor, but I replicated the process as best as I could and had

no luck. I should mention I do tend to have a lot of misfires generally, and the only caps I prefer are high powered M14s which are azide and RDX, but

most importantly, not made by me. Everything else Ive tried besides high voltage EBW or azide, has not had good luck. So take the report of failure

lightly because I have not found a primary that works for me.

Im taking the rest of the day off. Hopefully I have time to cook the rdx/k-6 quick mix tonight and consider what to try next. Maybe just stage some

8mm loads so they are all ready when I find a new primary. I have found that using 8mm SS straws with a ~1mm wall are somewhat more easily bulged than

other SS tube stock. I may switch to all tube stock, but I was really hoping the straws would handle high pressure pressing as they are so plentiful

and cheap. They still work excellent for hand pressing. ETN seems to press very well as LL suggested, melting, then breaking up and pressing, same is

true of the NTNT.

If anyone is interested in this compound and you are set up to go and willing to accept the risk of experimental preparation of an unknown compound,

you are more than welcome, this is not "my thread" or "my compound", but most of all, I don't like being on the spot for failure, (HELP ME), I'm sorry

I couldn't deliver timely field tests today.

I noticed during preparation that the NTNT from H2SO4 (when crude and Un recrystallized) does not melt as easily as recrystallized HCl, it still melts

to a high density but some early preparations of NTNT that I made heat up easily and can be poured like runny mustard. See video example on page 1, I

was able to just slap it on a hot plate in a coors bowl and watch it melt, then roll it around in the bowl. Im pretty sure that was all NTNT from the

LLNL mod synth first posted. but I wasnt separating samples at first. Hopefully HCl and H2SO4 both melt well when recrystallized.

|

|

|

B(a)P

International Hazard

Posts: 1139

Registered: 29-9-2019

Member Is Offline

Mood: Festive

|

|

Quote: Originally posted by Hey Buddy  | Quote: Originally posted by MineMan  |

Copper amino guanidine perchlorate. I am not encouraging or suggesting. Rather it’s something you will probably read about so it exists is all I am

saying. |

I would very much like to learn more about this. Zinc is commonly used for reduction of NQ to pimagedine but it's very messy. The electrolytic

reduction works very cleanly on basic lead, I've found most people are unaware of this method.

|

I have experimented with the nickel salt quite a bit, but Microtek would be a better source of knowledge than me on this. Check this thread out for

some more information including a patent with a procedure for a large number of salts including diaminoguanidine nickel diperchlorate.

https://www.sciencemadness.org/whisper/viewthread.php?tid=158381

Well done on your work to date and thanks very much for sharing.

I am definitely watching on with interest.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1387

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

CHP does not need any additional primary substance. It is a primary-secondary substance. The output segment is pressed to approximately 1:5 g/cc.

The rest of the resistive bridge cavity (around the bridge) is filled with low-density CHP. Estimated 0.8 - 1g/cc. The condition is, of course, a

steel (or copper) cavity with a 1mm wall. And central electric ignition. The fuse only lights from one end. But a centrally placed electric bridge to

all sides at once. It call hotline system, or Berta system.

Desing of bridge on page 2 of this thread. If you will use method with the fuse, it can failed often. By your picture it seems, that your cavity has

thin the wall. I estimate 0.3 - 0.5 mm of aluminium or SS. It is not enough for CHP. CHP is safe to handle but requires a 1mm wall.

Next: On picture are basic value for shooting to the Lead. Especially for ETN 300mg and 1000mg.

[Edited on 16-11-2022 by Laboratory of Liptakov]

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

MineMan

International Hazard

Posts: 1004

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

No explosive will ddt when wet

|

|

|

MineMan

International Hazard

Posts: 1004

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Hey buddy. DM me and let’s talk on discord. Let’s get this nailed down. I see easy mistakes

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1387

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Hey Buddy, I tried a 0.4 mm weak wall brass cavity just to be sure. The CHP operates at full capacity in this cavity. Drying was 15 minutes at 50 C.

So if your CHP is not working, the problem is not a weak cavity or too dry CHP. Everything else in the picture.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Hey Buddy

Hazard to Others

Posts: 429

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Quote: Originally posted by Laboratory of Liptakov  | Hey Buddy, I tried a 0.4 mm weak wall brass cavity just to be sure. The CHP operates at full capacity in this cavity. Drying was 15 minutes at 50 C.

So if your CHP is not working, the problem is not a weak cavity or too dry CHP. Everything else in the picture.

|

Thank you LL. The cavity was a Ti 1mm nominal wall, it measured in actual .8mm. I liked to try the CHP, and its simplicity for preparation as a quick

solution is attractive to me for situations like this, but it is too difficult a preparation for me in overview of what is necessary in the process,

and I have had trouble with understanding it's behavior dry/wet. I prefer azides, but I dont think azides are ideal and I think it means its time to

find a new primary. I am going to probably try nitriminotetrazole, aminonitroguan or aminoguan salt. Guanidium and triazines are the main focus of my

interest so if I can locate a good-performance primary from that family tree, it would be the best choice for simplicity and the use of reagent stock.

The NTNT preparation is very fast and a few grams can be made and dried in a couple of hours if the NQ is already prepared. I have dried it up to 80c,

that maybe too high. Microtek claims a capillary mp of ~75, so maybe 60 C is a more-appropriate drying temp. Point being, a person with a primary

already made and ready to fire can make NTNT faster than I can make CHP.

--Other note: I believe the NHHT is dry now and I will test that and compare it to M1 to see if they are the same. If it can be detonated at 102C,

perhaps I can use it to detonate NTNT samples. Perhaps...

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1387

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Thanks for reply, Buddy......If I ever make NTNT I will force him to DDT.....

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Hey Buddy

Hazard to Others

Posts: 429

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Update on this general effort: Ive tried the NHHT HCl preparation twice now and I can't get it. Directly attempting hexahydro triazine

monohydrochloride leaves me with a ~1.7 -2 g yield of a white powder that is not flammable and doesnt hammer det. Presumably the 18% HCl free base

version would be easier to yield something but it wouldnt be the HCl that purportedly explodes at 102 C, which is what any concern was around the

issue in the first place.

I would say that the possibility of producing either variant of NHHT during an attempted NTNT synthesis is low and when excess nitrite is used and the

reaction is given plenty of time, the probability is even lower. It is still not established that NHHT HCl detonates at 102 C and literature is a bit

conflicting on this.

Beyond that there is definitely a second material, (pictures earlier in thread) labelled "M1" that has different burning and melt characteristics than

NTNT. This "M1" was found by beginning the HCl version of NTNT synthesis, but using no ice cooling, or additional water and only using a few ml of

water to dissolve and add NaNO2. It begins forming as a white foam and then the foam contracts into an opaque liquid that then becomes clear and

fizzes. While that is happening there is a bit of red gas evolved. The material is white and burns much faster than NTNT. This "M1" material doesnt

melt at 110 C like NTNT. It doesn't transition to detonation confined in Al foil. I dont know what it is, because of lack of dilution, it seems

unlikely to be NHHT free base, but it's beyond my ability to identify. There is a chance it could be a nitrimino version of DNPT which is the acetic

acid derived version of TMTN R Salt, but in this case it would have the nitrimino that would make it whiter in color, but this is just a wild

speculation. Regardless, It seems unlikely that a person would inadvertently synthesize this m1 material accidentally because the lack of cooling and

dilution leads to loss of NTNT, and so the entire course of using deficient water and ice seems like it would be naturally avoided. If it were

produced it doesnt decompose nor explode at the working mp of NTNT, so it seems there is no danger there for a potential accident in the production of

NTNT.

I haven't tested with partially deficient nitrite yet (which is another possibility) but I think as long as three moles of nitrite are used per mole

of hexamine (at minimum. excess is better though), there's not much danger there.

---

I think the only risk learned with NTNT at this point is if you drink it, or its dramatic decomposition to H2SO4 which is something already seen in

other nitrososamines, Hydrazine Nitrates etc. and so is no unexpected surprise. I diverted from metal compatibility testing because of worry about

these issues but now I will refocus on that, melt castability and compatibility with common metals and charcoal. To avoid H2SO4 decomposition issues,

I recommend using the slightly lower yielding HCl derived version. The ratio of NQ could be lessened as there seems to always be excess unconverted NQ

in the HCl method. To simplify testing, I'm going to be only the HCl derived NTNT using that for future study unless a good reason comes up to change

it or try a different method.

Other developmental interests with NTNT that are way out of scope for now but possible future investigation includes mild oxidation of NTNT to an even

more oxygen rich version. That could be a nitrimino/nitro/dintitroso variant or something unexpected. Avoidance of HNO3 is critical to keep the

reagents as simple as possible. I seem to have had partial success oxidizing TMTN and a "keto" TMTN using AcOH/NH4NO3 in the past. Electro oxidation

in a 30% ammonium sulfate solution seems like a promising unexplored possibility for these nitroso compounds. I have had success in reduction of

nitroguanidine with the same method in high yield. I have not had success with perborate or percarbonate AcOH oxidation nor H2O2. Peroxynitrite might

be another OTC possibility that seems mostly unexplored in energetic materials but if Im not mistaken all the right radicals are there and I believe

peroxy nitrite goes through phases in reation and may even become HNO3 in later stages of some reactions but is a nitrite salt plus a percarbonate or

perborate or peroxide, (at least I think, I have only made peroxynitrite once, i think once I may have even used grocery store citric acid, cant

remember). Digression. Anyways, IMO there are a range of possible routes to higher oxidation of nitrosamines in general to get them into nitro ball

park that are unexplored but could be very useful.

In the case of NTNT, the highest appeal is melt castability which is most likely dependent on its being a nitrosamine, so it's likely already in its

most useful form and might suffer loss of that characteristic if it were altered.

[Edited on 19-11-2022 by Hey Buddy]

[Edited on 19-11-2022 by Hey Buddy]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1387

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

It seems that preparing dangerous NHHT makes considerable difficulties. This is good news. You still seem to have 10 fingers and other organs intact.

After a lot attempts. The NTNT preparation appears to be sufficiently safe. When following the procedure with HCl. (Is time to tear up some iron)

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Microtek

National Hazard

Posts: 869

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

A small update: I redissolved the material that I had extracted with acetone from the sulfuric acid mediated process (again using acetone), and then

added the clear solution to water. There was no immediate precipitate, but over the next 12 hours a yellow, crystalline product appeared. I tested the

melting point of this material in a standard glass capillary. At a heating rate of ca. 5 degrees (C) per minute, the product melted cleanly at 75 C,

and upon further heating decomposed at 125-140 C.

The material reacts as a typical secondary when exposed to flame, but I was unable to initiate it by hammerblow.

I also tested the material I had prepared by the slightly modified HCl mediated method (the one that didn't foam, and didn't produce red fumes). This

product which in appearance is a very pale yellow amorphous powder, is only slightly soluble in acetone. I haven'tmeasured it exactly, but I would

estimate around 1g per liter of acetone. This material deomposes without melting at 175-180 C, but reacts to flame in much the same way as the other

material. I wasn't able to hammer-initiate this one either.

I don't know if either of these materials are the same as what Hey Buddy has produced, but they are definitely two different chemicals. I will try to

get a basic plate dent test done soon. If this gives promising results, I will measure VOD.

[Edited on 24-11-2022 by Microtek]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1387

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

If it didn't go with a hammer blow, it should go with an even bigger hammer blow. The reason I haven't tried NTNT yet is because I haven't seen a

single explosion of this substance. Respectively any hole from this.

Thanks, Microtek for your examination about NTNT. Your paralel research is same important as from Buddy. We appreciate it, even if the whole effort

maybe will for naught.

[Edited on 24-11-2022 by Laboratory of Liptakov]

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Hey Buddy

Hazard to Others

Posts: 429

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Quote: Originally posted by Microtek  | A small update: I redissolved the material that I had extracted with acetone from the sulfuric acid mediated process (again using acetone), and then

added the clear solution to water. There was no immediate precipitate, but over the next 12 hours a yellow, crystalline product appeared. I tested the

melting point of this material in a standard glass capillary. At a heating rate of ca. 5 degrees (C) per minute, the product melted cleanly at 75 C,

and upon further heating decomposed at 125-140 C.

The material reacts as a typical secondary when exposed to flame, but I was unable to initiate it by hammerblow.

[Edited on 24-11-2022 by Microtek] |

This makes corroborative sense. I found a seeming mp on attempting crude melt on Thiele tube with propylene glycol media at 95 C (not entirely

accurate). And an observed crude working mp at ~110 C with an observable reversion to solid phase at 68 C. A 75 C mp lines up perfectly with naked eye

observation of solid phase reversion at 68 C.

This is very exciting. 75 C is a very good mp for a practical energetic material. About as ideal as can be, lower mp can become problematic in some

practical situations and 75 C is low enough under boiling water temp to permit that method for melting.

I suspect the seeming inconsistencies Ive seen in getting a good melt cast off of NTNT are due to the low density state of non recrystallized

material. In the unrecrystallized state, NTNT appears to loosely hold itself up out of the melt making melting more challenging where as when using

dense crystal for melt cast, it falls into its own melt and melts completely. It is certainly thin enough to pour.

In my testing I was only able to initiate detonation by hammer blow by striking on a 50lb vise with a 16 oz flat face hammer. The force needed was

enough to tilt over the vise when sitting on the ground. It was a pretty hard strike. Much harder than comparable force needed for ETN or PETN. In

fact it was so hard that in my initial notes from early testing of the material, I wrote "no hammer det" assuming that it was not that energetic, it

is simply somewhat insensitive compared to other stuff like K-6 or PETN. Assuming performance is there, this also lends quite favorably to NTNT

profile.

Microtek, no pressure, but if you get the opportunity to measure density on some casted NTNT, it would be helpful confirmation measurement. I recorded

density of 1.83 g/cc but there were visible air bubbles solidified in my sample.

Currently drying out some trays pf NQ for NTNT and building an electroreduction apparatus to prepare aminoguanidine (metal) perchlorates in quest for

next in-house primary. NTNT metal compatibility testing soon. Will hopefully get to performance testing sometime probably after microtek arrives at

his conclusions.

Things looking good. Performance tests are the only hold up at this juncture.

Microtek I'd like to more know about your method of acetone extraction that you briefly mentioned. I have only used acetone for recrystallization and

so I'm curious what you found on extraction technique.

|

|

|

Microtek

National Hazard

Posts: 869

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

The extraction I did was just adding acetone to the mix of crude product and unreacted nitroguanidine, then decanting the liquid phase (NQ is almost

insoluble in acetone). I extracted three times (about 7 ml acetone on extraction 2 and 3. Number one required a little more to properly wet the

crystal mass), at which point the yellow colouring of the solid phase was almost gone. The collected extracts were then poured into a dish and

evaporated to dryness in the airstream from an aquarium pump.

I then later (after measuring the mp) redissolved the recovered crystals in more acetone and poured the solution into water to recover the material

melting at 75C.

I agree that the mp is close to ideal for a meltcast energetic, though I would have liked the decomposition temperature to be a little higher, maybe

180C. If I can see gas evolution at 125-140C, there is a high likelyhood that the decomposition onset is lower than that. Of course, it remains to be

seen if the product I have made is even NTNT at all. I speculate that the difference in product characteristics may be due to one or more of them

being a linear nitrosamine rather than a cyclic one, a less nitrosated variant or maybe a combination of the two.

|

|

|

KNEWKID

Harmless

Posts: 5

Registered: 24-11-2022

Member Is Offline

|

|

There are at least 2 groups of compounds here in this mixture. I extracted yellow to orange crystals using NM and white powder was left over. Pics

later

|

|

|

KNEWKID

Harmless

Posts: 5

Registered: 24-11-2022

Member Is Offline

|

|

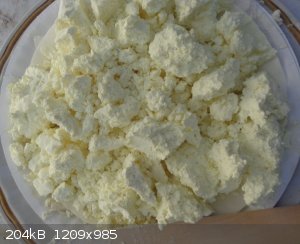

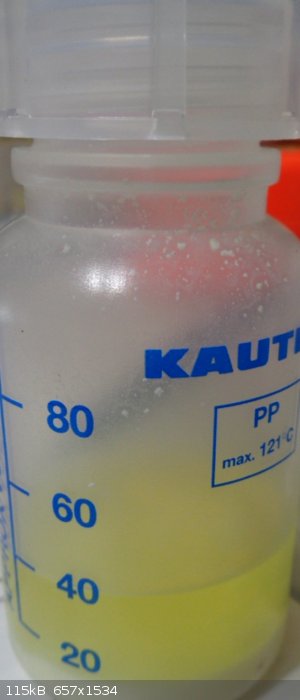

Extraction NTNT with Nitromethane

Orange crystal fraction soluble in pure nitromethane white powder insoluble in NM. Large mass of NTNT crude about 1/2 to 3/4 lb when dry.

Note: first extraction in NM cool yielded yellow crystals. 2nd extraction heated to 100F NM product turned orange...possible secondary rxn.

Will upload Raman spectra of each material later

|

|

|

KNEWKID

Harmless

Posts: 5

Registered: 24-11-2022

Member Is Offline

|

|

NTNT bulk 1/2 to 3/4 lb when dry

|

|

|

KNEWKID

Harmless

Posts: 5

Registered: 24-11-2022

Member Is Offline

|

|

NTNT soaking in pure NM

|

|

|

| Pages:

1

2

3

4 |