| Pages:

1

2

3

4 |

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

I don't have access to the shaft at all so can't go down that road.it has the polarity written on it which usually signifies that correct polarity is

important which for most DC motors isn't important.the green circuit board bit it's contacts are connected to signifies that it has somesort of

internal circuitry that a normal DC motor doesn't have.so polarity important, internal circuitry what type of motor am I looking at here?

What kind of driver will I need?

As for the driver I already have I'd say it's fucked.when first powered with 12v300mA

Its led came on but when the motor was connected it didn't do anything so it was unplugged and rewired and when the pot cord was plugged in after it

was powered on and the led was on it just went out like the pot cord was causing a short .the led won't come on at all now.

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

The motor works fine when the 12v charger is directly connected to it.im just wondering if I can just directly put the pot between the charger and

motor? There's also the old mantle board I can pick a resistor and voltage regulator off if I need to make my own driver.

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Wired in the thyristor and turned it on for a minute and it heated up so all good there.next step is drilling holes for the fuse and an on/off switch

which sucks bcoz I don't have a drill with me.just need to get the stirring working and then it's all good.

|

|

|

wg48temp9

National Hazard

Posts: 784

Registered: 30-12-2018

Location: not so United Kingdom

Member Is Offline

|

|

Quote: Originally posted by draculic acid69  | | The motor works fine when the 12v charger is directly connected to it.im just wondering if I can just directly put the pot between the charger and

motor? There's also the old mantle board I can pick a resistor and voltage regulator off if I need to make my own driver. |

Yes you can put a variable resistor in series with power supply to the motor if that's what you mean. When you say "the pot" if you mean the

potentiometer that was connected to a motor control board then its probably not a suitable resistance (ohms) or power rating.

Its best to drive the motor from a variable regulated supply as its rpm will be less effected by it load and provided a more reliable start up at low

rpm. But if you have a suitable pot that is a simple uncomplicated solution. if you do have start up problems you can turn the pot up to its lowest

resistance to get the motor going then reduce the speed.

I am wg48 but not on my usual pc hence the temp handle.

Thank goodness for Fleming and the fungi.

Old codger' lives matters, wear a mask and help save them.

Be aware of demagoguery, keep your frontal lobes fully engaged.

I don't know who invented mRNA vaccines but they should get a fancy medal and I hope they made a shed load of money from it.

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Ok so using the potentiometer in between the charger and motor is a no-go as a 500k pot is easily fried by 12v 300mA.you can really smell the

clorinated plastic in the fumes.the motor started reluctantly and was very finicky about being slowed down and would stop altogether when the pot was

turned down too fast it was a fine line between struggling to start and completely stopping.so with this information is anyone onto what type of motor

I'm dealing with here?

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Got the stirring happening so that's no longer an issue but the thyristor circuit is problematic as even when it's turned down to zero it can boil a

flask 1/3rd full of water

and the mantle fabric is sitting at 185'c and hovers around that.someone mentioned that with the thyristor circuit you lose control over the lower end

of things which basically means it's useless for nything that boils under 150'c.trying to maintain a 80'c reflux just won't happen. Don't even want

to think what happens when turned up to halfway.im going to try a dimmer circuit next.

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Quote: Originally posted by draculic acid69  | | Ok so using the potentiometer in between the charger and motor is a no-go as a 500k pot is easily fried by 12v 300mA.you can really smell the

clorinated plastic in the fumes.the motor started reluctantly and was very finicky about being slowed down and would stop altogether when the pot was

turned down too fast it was a fine line between struggling to start and completely stopping.so with this information is anyone onto what type of motor

I'm dealing with here? |

I realized that the pot I used the original one from the the mantle for the heating was probably too much resistance for the motor and I should have

just used the pot from the stirrer as I think it's only 100k instead of 500k.

|

|

|

wg48temp9

National Hazard

Posts: 784

Registered: 30-12-2018

Location: not so United Kingdom

Member Is Offline

|

|

Quote: Originally posted by draculic acid69  | Quote: Originally posted by draculic acid69  | | Ok so using the potentiometer in between the charger and motor is a no-go as a 500k pot is easily fried by 12v 300mA.you can really smell the

clorinated plastic in the fumes.the motor started reluctantly and was very finicky about being slowed down and would stop altogether when the pot was

turned down too fast it was a fine line between struggling to start and completely stopping.so with this information is anyone onto what type of motor

I'm dealing with here? |

I realized that the pot I used the original one from the the mantle for the heating was probably too much resistance for the motor and I should have

just used the pot from the stirrer as I think it's only 100k instead of 500k. |

You need to swot up on basic circuit theory try one of these sites: https://www.google.com/search?q=electrical+resistance+for+be...

In short and approximately. If the motor at full power uses 12V @0.3A it has a resistance of 4 ohms. If you want to reduce that to say 10% then you

must decrease the voltage/current to 10% then means adding a variable resistance in series with the motor of 36 ohms max. 100k ohms is way too large.

Power dissipation with a maximum resistance of 40 ohm would be 0.9((12x12)/40) 3.2W that too much for many variable resistors.

But the maximum power is with a resistance of only 4 ohm the power would then be 9W but dissipated in only 3/36 of the variable resistors track. So

you need something like the following

Attachment: reo200ws-l225.webp (7kB)

This file has been downloaded 358 times

see ebay: https://www.ebay.com/itm/200W-50-OHM-Wirewound-Potentiometer... 0UAAOSwxada-xyO 0UAAOSwxada-xyO

PS: sorry the last link confused the forum

[Edited on 9/24/2019 by wg48temp9]

I am wg48 but not on my usual pc hence the temp handle.

Thank goodness for Fleming and the fungi.

Old codger' lives matters, wear a mask and help save them.

Be aware of demagoguery, keep your frontal lobes fully engaged.

I don't know who invented mRNA vaccines but they should get a fancy medal and I hope they made a shed load of money from it.

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by draculic acid69  | Got the stirring happening so that's no longer an issue but the thyristor circuit is problematic as even when it's turned down to zero it can boil a

flask 1/3rd full of water

and the mantle fabric is sitting at 185'c and hovers around that.someone mentioned that with the thyristor circuit you lose control over the lower end

of things which basically means it's useless for nything that boils under 150'c.trying to maintain a 80'c reflux just won't happen. Don't even want

to think what happens when turned up to halfway.im going to try a dimmer circuit next. |

Are you sure the mantle is rated to operate at line voltage AC? Perhaps it was operated at a lower voltage from the main transformer in the original

setup? That transformer looked a bit bulky just for powering the stirring motor as I remember.

If the mantle is rated to operate at a lower voltage then you will get the kind of overheating effects by trying to tune down with a thyristor/dimmer

circuit. Even in the low end of power setting it manages to draw enough current for getting to high temperatures.

Try measuring the resistance of the heating mantle. It will be lower in the cool condition as the heating elements resistance is a function of

temperature, but it should give you at least a ballpark figure wether you can operate it at line voltages:

P=U2/R

P- dissipated power

U- voltage drop across the resistance (line voltage if directly connected)

R- resistance of the mantle

If according to the above formula your dissipated power is much higher than the rated power of the mantle (it should be marked on the apparatus), then

it is likely that it is meant to be operated at lower voltages.

Reasonably such heating mantles should operate near 400-500W at full power.

Exact science is a figment of imagination.......

|

|

|

Keras

National Hazard

Posts: 900

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

What the heck is all that about? I mean:

1. A motor has a resistance and a counter-EMF. If your source voltage doesn't exceed the motor's counter-EMF, nothing happens (you don't have enough

power to set up a suitable magnetic field). You can't say that a motor which consumes 300 mA @ 12 V has a resistance of 4 Ω because that disregards

its counter-EMF.

2. A thyristor doesn't work with DC. Once you've switched it on with the gate, you can't turn it off. A thyristor only "chops" AC, and turns off when

the voltages crosses 0, and cannot be turned on when it is reversed polarised. So you get at most 50% duty cycle. AC choppers use triacs, which are

basically two thyristors in head-to-tail mode.

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Don't need to worry about the motor and stirring.got that half of the equation sorted out.the reason I tried sticking the pot between the 12v charger

and the motor is I remember using an ATX power supply from an old computer and a plastic computer fan with a pot in between them and even though

there's way more current in the ATX box it didn't fry the pot and worked fine for dimming the fanspeed. And yes I'm fairly sure the mantle runs off AC

line voltage and is controlled somehow with the original board which is fairly similar to the thyristor circuit I've been trying to use.i can't

completely trace the flow but it seems like the transformer just lowered the voltage for going to the motor but I can tell it's only for the motor and

that the mantle runs on AC.

I've got a dimmer circuit on the way and hopefully that works.if not then FUCK!!!!. other ppl seem to support the dimmer switch idea as it's what they

use and a new mantle is cheaper than a variac so that's a worst case scenario.

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Are you sure the mantle is rated to operate at line voltage AC? Perhaps it was operated at a lower voltage from the main transformer in the original

setup? That transformer looked a bit bulky just for powering the stirring motor as I remember.

If the mantle is rated to operate at a lower voltage then you will get the kind of overheating effects by trying to tune down with a thyristor/dimmer

circuit. Even in the low end of power setting it manages to draw enough current for getting to high temperatures.

Try measuring the resistance of the heating mantle. It will be lower in the cool condition as the heating elements resistance is a function of

temperature, but it should give you at least a ballpark figure wether you can operate it at line voltages:

P=U2/R

P- dissipated power

U- voltage drop across the resistance (line voltage if directly connected)

R- resistance of the mantle

If according to the above formula your dissipated power is much higher than the rated power of the mantle (it should be marked on the apparatus), then

it is likely that it is meant to be operated at lower voltages.

Reasonably such heating mantles should operate near 400-500W at full power.

[/rquo

When I first opened it up I also thought it ran off DC as well bcoz I didn't know you

could put AC thru a nichrome element but you can and it has to run off AC as no amount of 12v will make 400w without a 20amp transformer and there

big and heavy and the one in there was only 12v 350ma.

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

If you measure the resistance of the mantle, the guesswork becomes reduced. You know that the dissipated power in the mantle at full blast should be

400W (in case it is directly connected to 220V AC plug).

So accordingly your mantle resistance should be in the approximate range of 120ohm to arrive at such a power using 220V AC:

R=U2/P = 2202/400 = 121ohm

If you work off 110V AC mains then correct the values for this voltage. For 110V AC mains your mantle resistance should be near 30ohm to get 400W

power output.

If your measured resistance is significantly lower than the values that lead to 400W output, then you know that it was used in a different

configuration in the original setup. And it will be very difficult to lower the power output with a dimmer/thyristor circuit.

Was the original apparatus intended to run off a particular line voltage or was there a selector switch to choose between 220V and 110V option?

Exact science is a figment of imagination.......

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Nope.no switch to select 110v it's 240v AC rated. I'm thinking about putting my other thyristor back to back with the one I got in there as in the

output of on turned on to like 10-20% who's output goes through the second thyristor circuit input so as to get a finer control of the temp.

|

|

|

Keras

National Hazard

Posts: 900

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

Could you please post a closer picture of the PCB hosting the thyristor?

Thanks!

|

|

|

Sulaiman

International Hazard

Posts: 3697

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

The dimmer controllers that I have bought, as well as the main potentiometer also have a small preset potentiometer to set the minimum power,

maybe yours ha a similar preset potentiometer ?

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

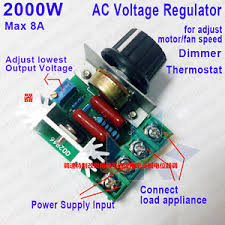

Picture below is the type of thyristor I'm talking about.it does have what I assume is a variable resistor of somesort.ill try adjusting it tomorrow

and see if that makes enough of a difference

[Edited on 25-9-2019 by draculic acid69]

|

|

|

Keras

National Hazard

Posts: 900

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

Ok, I see. Well yeah, try tinkering with that trimpot. Let us know what you get out of it

[Edited on 25-9-2019 by Keras]

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

It's a variable resistor isn't it?

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by draculic acid69  | Picture below is the type of thyristor I'm talking about.it does have what I assume is a variable resistor of somesort.ill try adjusting it tomorrow

and see if that makes enough of a difference

[Edited on 25-9-2019 by draculic acid69] |

I'm using a module like that to control the temperature of my soldering iron from barely warm to scorching hot....works like a charm through the whole

scale. It's only a 25W soldering iron, so it should be able to handle a 400W mantle with ease. My module does not have the additional blue pot on it

so your's probably is a newer iteration of the circuit. Makes sense that it is put there to shift the scale of voltage regulation. Perhaps it was

turned to such a position that one can not reduce the power to get a reasonable temperature in the mantle. Try adjusting it. These types of pots are

not sensitive to small adjustments. It takes more than ten turns of the screw to scroll through the scale from one end to another. So do not be

surprised if turning the adjuster by half a turn does not seem to make a great difference. Also they do not come to a dead stop when the end of scale

is reached. Instead they start to jump over the threads on the inside of the pot with a very quiet click. It's a safety measure, so one does not break

the thing by turning all the way to end of scale. So if you hear the quiet clicking then you know that it will not go any further in that direction.

Some specimens do not make an audible click, so it can be difficult to judge if one has reached the end or not. In that case you can just turn it for

10-15 revolutions in one direction and claim with confidence that it is now in one of the extremes.

Exact science is a figment of imagination.......

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

7turns counter clockwise seems to be keeping the temp in the120'c range for 15mins but now it's starting to creep up to about 130.i was hoping it

would find a temp and sit there but apparently not.

Creeping up to 140 now.dammit

[Edited on 26-9-2019 by draculic acid69]

|

|

|

Keras

National Hazard

Posts: 900

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

I'm not sure what's going on. If you have no digital multimeter, it's pretty much a crapshoot game.

|

|

|

Sulaiman

International Hazard

Posts: 3697

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

Quote: Originally posted by draculic acid69  | | Picture below is the type of thyristor I'm talking about.it does have what I assume is a variable resistor of somesort.ill try adjusting it tomorrow

and see if that makes enough of a difference |

That is exactly the model of controller that I use

(I have three of them, one for my diy 380W mantle, one for a 500W hotplate and one for a 1500W hotplate)

The controller sets a phase angle,

(a time delay before the triac is turned on after zero-crossing of the input voltage)

which for a constant voltage, frequency and load,

equates to a constant POWER (W)

So the temperature will climb as 'stuff' around the heating element heats up,

after a while thermal equilibrium will be attained.

BUT

if the environment changes, e.g. breeze/draught/wind/ambient temperature etc.

then the temperature will change.

In my experience, temperature is most affected by wind.

The power semiconductor is a triac, not a thyristor,

a triac is equivalent to a bi-directional thyristor. (two thyristors in inverse parallel)

For heating I set the preset potentiometer (the little blue one)

so that there is almost no power output when the main potentiometer is set to minimum,

this allows control in all circumstances.

You can temporarily replace the load with a filament lamp to adjust the preset potentiometer if you do not have a suitable meter.

If you put the controller in an enclosure (for convenience and/or safety)

then ensure that there is some ventilation to prevent the triac from overheating.

__________________________________________________________

@draculic acid69 : it is a preset potentiometer wired as a variable resistor.

[Edited on 26-9-2019 by Sulaiman]

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

I've turned it counter clockwise about 15 turns and got to the point where it clicks it seems to get the mantle to 110'c and then slowly creepup to

120'c and it's sat around there for 15mins and now it's slowly getting to 125 and it'll probably hit 130..this circuit seems to not be able to sit at

a minimum temp.ill let it sit there now for an hour or two and see what happens then report back but there's been a definite improvement since I

started adjustment. Once I get a constant temp with no rising I'll adjust the pot and see how it goes from there.seems to be sitting around 125 for

now

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by draculic acid69  | 7turns counter clockwise seems to be keeping the temp in the120'c range for 15mins but now it's starting to creep up to about 130.i was hoping it

would find a temp and sit there but apparently not.

Creeping up to 140 now.dammit

[Edited on 26-9-2019 by draculic acid69] |

It is not a temperature control setup, just a variable power source. You can not expect it to hold a certain temperature point according to the

position of the knob. There is no feedback in the system, so if anything changes (line voltage fluctuations, heating element resistance change due to

temperature, amount and composition of liquid in the flask, shielding, heating up of the surroundings, etc.) then there will be a change in the system

temperature. The same will happen if one uses a variac to control the power. In essence it will eventually hold a certain temperature point once the

inflow of energy matches the losses, but it will not be possible to determine at what exact temperature this will happen on a certain setting of the

control knob.

To be honest it is very difficult to force such a system into holding an exact temperature setpoint even using PID controllers that are able to

monitor and even predict certain changes so they can act prevetively.

What we have here is a rather high powered (400W) small scale system that has very different rates of heating vs. cooling. It shoots up very fast due

to the powerful mantle and creeps down way slower due to convection or radiation losses. Boiling of liquids in the flask will act as an accelerant for

cooling rate though and stabilize the system.

Also with PID control such systems tend to have profound fluctuations around setpoints because the heat spikes from mantle tend to overshoot the

setpoint. A "garden variety" PID assumes cooling and heating rates to be the same and tries to work on a linear trendline. If cooling and heating

rates are not matching then we shall have two trendlines with differing slopes.....understandably it is difficult to tune in a set of parameters that

match both at the same time

Exact science is a figment of imagination.......

|

|

|

| Pages:

1

2

3

4 |