| Pages:

1

..

26

27

28

29

30

..

60 |

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

minor break but i'm getting low on aluminum. i just ordered a huge cache of chems and gear (though i didnt get aluminum, i'll melt some down and

attempt to atomize it myself in the next couple of days). mostly, though, my folks asked me to replace a large section of flooring in their home so i

get to tear down some walls, pull a toilet and shower, install new subflooring, float and linoleum, then put all that back plus a new tub. i've been

hijacked but i was actually planning a run this weekend with a couple of alterations in place. will report soon.

|

|

|

Eclectic

National Hazard

Posts: 899

Registered: 14-11-2004

Member Is Offline

Mood: Obsessive

|

|

Does anyone know if phosphorus is heated by microwaves? If not, a carbon/phosphoric acid reactor and phosphorus condenser totally internal to a

microwave oven might be possible...

[Edited on 10-11-2010 by Eclectic]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Rogeryermaw  | | minor break but i'm getting low on aluminum. i just ordered a huge cache of chems and gear (though i didnt get aluminum, i'll melt some down and

attempt to atomize it myself in the next couple of days). |

Melting and 'atomising' aluminium sounds like at project in itself. Why not attempt to use foil shredded in a food processor? Even pieces of about 1 -

2 mm should react well in your conditions...

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Eclectic  | Does anyone know if phosphorus is heated by microwaves? If not, a carbon/phosphoric acid reactor and phosphorus condenser totally internal to a

microwave oven might be possible...

|

I accept this isn't much by way of criticism but that sounds like thoroughly naff idea to me... You need to get to red heat at least: domestic MW are

definitely not designed for that...

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

http://www.freepatentsonline.com/6207024.html is what you are talking about i believe. there are some scattered reports about this on the web but

i have yet to see documented cases where someone has actually made it work on a lab scale. there is one forum that keeps coming up where a user claims

success but is then unabe to reproduce the effect and is declared a crackpot. i'm looking for that entry but am unable to find it. will keep looking

though.

|

|

|

Eclectic

National Hazard

Posts: 899

Registered: 14-11-2004

Member Is Offline

Mood: Obsessive

|

|

Blogfast, havn't you seen the threads on microwave furnaces? The carbon in the reaction mix is a microwave susceptor and will get up to white heat.

Of course it would need to be insulated. The question is, would the resulting phosphorus be heated by the microwaves as well.

|

|

|

peach

Bon Vivant

Posts: 1428

Registered: 14-11-2008

Member Is Offline

Mood: No Mood

|

|

It is possible to produce crucibles that will absorb microwaves and melt metal.

I can't find the link to the guys site, but I remembering seeing it a couple of years ago, so it may have moved on more from there.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Eclectic  | | Blogfast, havn't you seen the threads on microwave furnaces? The carbon in the reaction mix is a microwave susceptor and will get up to white heat.

Of course it would need to be insulated. The question is, would the resulting phosphorus be heated by the microwaves as well. |

What I was saying was that domestic microwaves aren't suited for this purpose. I've used industrial MWs for various purposes but they're

quite a different kettle of fish to domestic ones.

As regards the P, as it is undoubtedly contaminated, it will probably heat up.

Without a specific, tailor-made set-up, this is a recipe for disaster...

|

|

|

peach

Bon Vivant

Posts: 1428

Registered: 14-11-2008

Member Is Offline

Mood: No Mood

|

|

This guy I was talking about was using domestic microwaves. With them being free from the tip, it's not a problem if you break one in the R&D

phases. I can't remember what he was doing to make it work though!  What he was

using in terms of the absorbent. What he was

using in terms of the absorbent.

Obviously, modifying microwaves at home, almost a kilowatt of invisible radiation emitting death, you better known what you're doing! Or you'll steam

your eyes and brains to al dente without even feeling it.

Resonance and diffraction are a good place to start.

I wouldn't be too quick to dismiss domestic microwaves. From what I understand, the main advantage of a laboratory microwave is that they can produce

single modes. I'm sure I remember reading published papers that were using domestic microwaves. A fridge pump versus diaphragms style debate.

Anyway, this way beyond where it should be. Something more basic is afoot with the yields than flames versus microwaves. A lot of what I've read about

microwaves in the journals hasn't been eye poppingly impressive, as of yet. I've read one paper that is straight out incorrect, and I'm wondering how

it even got published. It claims catalytic activity, yet absolutely there is absolutely NOTHING catalytic about it.

Also, if you start using microwaves for the P method, what are you going to use as a crucible? Even if it absorbs the microwaves, what's it going to

do around the multiple ingredients, over a thousand C? Then you've got a whole other kettle of nasty fish to think about.

Nah, flames, hot wire elements and arcs until it's producing something over 50%. A simple demonstration is, they use arcs commercially. If it was more

efficient to do it with microwaves, the commercial guys would almost certainly be onto it.

[Edited on 12-10-2010 by peach]

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

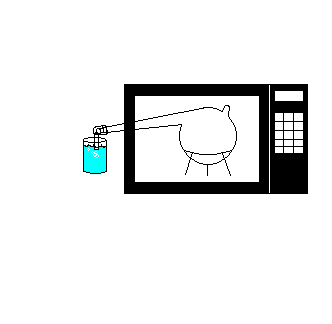

before i had any successful experimentation, i had the thought to use the microwave method. like peach said, it is easy to get a very cheap or even

free microwave. the thought i had was to use a hole saw(about half inch) since the controls and circuitry are normally on the right, cut a half inch

hole through the left side panel and use a file to fit the holes to the neck of a glass retort.

my only concern would be if the heat would destroy the retort or could we find a suitable reducing agent that reacts at lower temp. and, of course,

cutting a hole in the microwave might be dangerous... any thoughts? any thoughts?

|

|

|

peach

Bon Vivant

Posts: 1428

Registered: 14-11-2008

Member Is Offline

Mood: No Mood

|

|

My thought is, you seem very good in paint.

I particularly enjoy the care put into creating the buttons and display.

The file to fit idea is good, the microwaves shouldn't be able to escape through that, unless the retort is made out of something transparent to

microwaves. If it is, you'd need a cage around the collector, made from the screens in the windows of some other tip microwaves.

If you're DIY'ing the screens, you also need a microwave meter to check they're working.

One way around that is to surround the collector with the inside cavity of another microwave, then make sure everyone is a very long way away.

No idea about how it'd work, it'd be easier to try it in the real world. But I still think the flame method should be performing better before going

microscopic on the heating.

The flame method is performing too poorly based on your results for it to be a matter of heat. It's the melt or the collector.

I'd try arcs before microwaves. Microwave transformers can be rewound to provide pretty much whatever you like at a few kW. And you can harvest carbon

electrodes from old Zinc or Alkaline batteries.

I need to stop talking and get busy trying this myself but, at the moment, I'm covered in expanding foam, after a can of it burst mid a seriously DIY

event; I now have a mushroom of urethane foam growing out of the back room floor. Not to worry, the floor sander will sort that.

[Edited on 12-10-2010 by peach]

|

|

|

Panache

International Hazard

Posts: 1290

Registered: 18-10-2007

Member Is Offline

Mood: Instead of being my deliverance, she had a resemblance to a Kat named Frankenstein

|

|

from experience i you're intending to do that to a microwave you need to simply bend up a case for the entire shebang from sheet metal, nothing fancy,

just no gaps, that way you're safe.

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

well it's just tossing ideas around right now. nothing i will try right away. i think i would rather expend energy trying to make the equipment i have

now more efficient. does aluminum block microwave energy? i wonder because we have all seen the arcing of an aluminum foil ball in the micro. does

that not represent the waves bouncing back and forth on the metallic surface? if so then could not the entire neck and collection equipment be wrapped

with multiple layers and sealed with aluminum ducting tape? or use a smaller microwave than the reaction machine, remove its door and place it against

the side of the one the reaction is running in then just seal the cracks?

nothing i am wanting to try right away...just tossing off...some ideas

ok now i have a thought about what may be happening in the reaction with NaPO3+Al+SiO2...i believe bloggy to be correct about the formation of Al2O3

taking precedence due to its HoF driving the reaction but what happens to the rest of the aluminum after the O2 has been scavenged from the other

reactants? it has nowhere to go but to combine with P until the aluminum charge has been exhausted...need to do some equilibrium work on this but it

may just be an issue of being more precise with stoichiometry. i know we talked about this but i think it's time for another test. that may be why

there was an unpleasant stench of phosphorus (possibly AlP or PH3) when breaking open the slag but no smoke as of phosphorus residue oxidizing. the

smell of P2O5 is not as unpleasant as that mess was...

honestly fellas i'm not trying to get this crap in my lungs! i have been doing all my work outdoors but phosphorus and its compounds obviously have

VERY powerful odors.

[Edited on 13-10-2010 by Rogeryermaw]

|

|

|

peach

Bon Vivant

Posts: 1428

Registered: 14-11-2008

Member Is Offline

Mood: No Mood

|

|

As Panache says, a folded box would do. Aluminium will reflect it yar. In terms of simplicity, the foil idea is good, but it'd be quite easy to end up

with leaks or have them form mid micronuking, so I'd go with getting a second microwave and chopping a hole in the side of it for the collector. As

you can weld, and the enclosures are steel, you could weld the two together.

Microwaves from an oven can't escape a metallic enclosure provided the gaps are the same size, or smaller, than the ones on the grill covering the

window. They have a long wavelength, so the grill looks like a solid surface to them. That's why phones are shit in terms of signal, they're "line of

sight" radios, that really need to be able to see the next station. And the signal is strongly absorbed by all the water in the atmosphere. Hence the

phone companies wanting to put masts everywhere, to reboost the signal and resend it to the next one. Saying that, a phone outputs not a lot of energy

compared to an actual microwave, so the absorbency thing is not reliable. But the reflection is.

At one point, for reasons unknown, I placed an upside down wine glass in the microwave and then a Smartie sweet on the upside down base. When I

returned a minute or two later, the glass had actually melted.  I wasn't drunk

either. I wasn't drunk

either.

Since you're dealing with something genuinely toxic, you could pick up a respirator from eBay. You will have to out bid the weapons guys who want

another one to hang on the wall and the kinky pReverts buying them for sex games, who'll probably strap a massive dildo to the intake on arrival (I

have seen this). There is a fun respirator fact at the end.

I will continue filling cracks, in the walls, and have a think about the experiment and if I can easily check that melt (if you still have some lying

around).

{respirator shenanigans}

After the twin towers maga fail, people went nuts buying respirators, thinking they were about to be chemo & bio attacked (places were selling out

of them they were going so quickly). But a number of people have actually killed themselves putting respirators on and then forgetting to remove the

covers on the cartridges, suffocating themselves but thinking they're being gassed. An operation that is as complex as, put it on, remove covers. The

irony is quite outstanding, and fits well with my opinions on safety gear often becoming more of hazard than the original problem.

{edit: wavelengths}

The microwaves thing is kind of related to semiconductors. They produce the billionth of a meter transistors by shining a beam through a stencil onto

the silicon. They want the beam to pass through the tiniest gaps possible. Even UV has too long a wavelength now, so they use electron beams. In

another strange bit of science, solid objects can be treated as waves as well. By accelerating the electrons to very high velocities, the wavelength

fits through the stencil. If they move fast enough, they can teleport through the stencil (seriously). That's how the memory in most digital

electronics works now. So, theoretically, if you run fast enough at that wall, you'll teleport to the other side without actually breaking through it.

Nice.... I have an evil scheme, suggest this to the next meth user you meet. "Just run REALLY fast! You almost did it last time!"

John, out

[Edited on 13-10-2010 by peach]

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Rogeryermaw  | | the thought i had was to use a hole saw(about half inch) since the controls and circuitry are normally on the right, cut a half inch hole through the

left side panel and use a file to fit the holes to the neck of a glass retort. |

A raw half-inch hole like

that is going to leak, at the very least in the near field, and possibly through re-radiation in the far field. If you don't know what the near field

is, I would recommend not playing with high-power microwaves.

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by peach  | As Panache says, a folded box would do. Aluminium will reflect it yar. [...]

Microwaves from an oven can't escape a metallic enclosure provided the gaps are the same size, or smaller, than the ones on the grill covering the

window. They have a long wavelength, so the grill looks like a solid surface to them. |

This only true if the

box pieces are conductively bonded along their entire length. The resistance of a simple folded seam is high enough that the seam will leak. Adequate

bonding means lots of bolts, to be safe, at a spacing of at most 1/8 λ, or alternately welding or brazing the seam. If you've ever seen

commercial waveguides, they have lots and lots of small bolts at all the junctions. These aren't for mechanical strength, but to provide adequate

conduction paths transverse across the junction.

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Also, anybody thinking about rebuilding a microwave oven needs to pay particular attention to the standing wave ratio between the magnetron and the

cavity. The system just is not going to behave the same way it does with food in it. In that situation, you have a good absorber

(think: like a beam dump) from the get-go; not always true for other uses.

At the very least, a thermal cutout on the magnetron is highly desirable. Even better is a field strength transducer near the emitter measure the

field strength and to be part of control system to keep it under a known limit.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by peach  |

Obviously, modifying microwaves at home, almost a kilowatt of invisible radiation emitting death, you better known what you're doing! Or you'll steam

your eyes and brains to al dente without even feeling it.

|

Not to mention your gonads.

Isn't that what I was saying though, inter alea?

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Rogeryermaw  |

ok now i have a thought about what may be happening in the reaction with NaPO3+Al+SiO2...i believe bloggy to be correct about the formation of Al2O3

taking precedence due to its HoF driving the reaction but what happens to the rest of the aluminum after the O2 has been scavenged from the other

reactants? it has nowhere to go but to combine with P until the aluminum charge has been exhausted...

|

Roger, that just doesn't happen when you're in near stoichiometric conditions: there is no Al left to react with any P. Very small amounts of

AlP could form but the equilibria of all reactions involved preclude the formation of AlP, unless Al is present in excess (and even then I'm not

convinced: moisture is probably a greater danger than some excess Al)...

[Edited on 13-10-2010 by blogfast25]

|

|

|

peach

Bon Vivant

Posts: 1428

Registered: 14-11-2008

Member Is Offline

Mood: No Mood

|

|

It, it being Roger, can weld, so he should be able to sort the chamber. But welding aluminium is extremely annoying if you don't have a fair bit of

money spare. There is an aviation company that does rods for soldering / brazing aluminium, for people building or repairing their own planes. I say,

screw all that, just use steel (like the steel chamber from another microwave).

Microwaves usually have a fair few thermostats strapped to the components that will get hot. I've run them many a time with no significant absorber in

there and it's been fine. If you're going the microwave route, it's probably an idea to find the guy who was melting metals in a domestic microwave

and ask about what he was using to catch the microwaves, then use that as the crucible or as a liner it sits in.

But more to the immediate point. You don't have many reagents in there Roger, three knowns. Given the amount missing, it's not going to be some trace

contaminant doing that. If it was the steel, the container would be in a terrible state. So it's either;

- the heat not being enough to drive it all out of the melt (it's too soluble in the SiO2)

- it's not catching in the condenser or

- it's reacting in some unexpected way in the melt

Testing the collector for escape attempts would be the first thing.

- consider using something like a stainless coffee / tea / sugar container from the kitchen that has a tight fitting lid. You can usually get those

real cheap from the budget stores. I have a bunch and the seal is about 1" long and requires a firm push to get it on.

- weld the pipe to the lid. You can always de-weld it later with the angle grinder.

- make another opening in the lid and pipe the atmosphere off

If the P is escaping, it will virtually all end up going down the tube. The end of which can go in another, cooler collector or to some form of test

for it's presence.

If it's still not working after that, I'd consider the heat, solubility and melt.

Working that out, other than just ramping the temperature up and risking melting the container, will be difficult by eye.

The simplest proof of the pudding I can think of, for a gauranteed answer, is to waste some of your hard acquired yield thus far, and try reacting

just the P with Al. oxide. Or add some to the Si. oxide and see if you can drive it back out. That will help tell you if it's getting stuck or

reacting in an unknown manner.

You don't need to use it all. Use something like a stainless pipe nipple to make a tiny container, then use small amounts of the P and heat it in the

same way as you would the normal melt.

So.... say 1g or a few of P, in with an equilivant amount of Al. oxide from the amount you'd expect it the melt. Heat, see if the P reappears.

Then.... small amount of P in with the Si. oxide, heat, see if the same amount comes back out.

If you're thorough, and there's a significant difference, it's in the melt.

I am beginning to suspect the melt more and more. Those arc furnaces they use industrially are insanely hot at the arcs, way over an atmosphere

powered flame.

If it was it reacting with the Si. or Al. oxide, it'd be even worse at those temperatures. Which suggests, it's dissolving and just not efficiently

boiling out at the atmospheric flame temperature.

Another tell tale sign would be you saying how the melt stunk of phosphorus. That's kind of to be expected given what's gone on in there, but the

smell may also be a clue that it's still in there.

Can anyone think of a smart way to dissolve the melt but not alter the P? Or have it recoverable in a format where it could only have started as P,

not an oxide or AlP?

[Edited on 13-10-2010 by peach]

|

|

|

peach

Bon Vivant

Posts: 1428

Registered: 14-11-2008

Member Is Offline

Mood: No Mood

|

|

This is obviously starting to ask a lot of one guy (he's basically doing all the hard work), so I'm 100% happy to muck in with testing the melt and

will commit a fair amount of effort to it if we can devise a solid method for checking it.

Testing it for AlP would be one of the firsts. I have a ton of gas handling stuff, am used to dealing with them and have the super balance and a

respirator is in the post with some cartridges (I need one to sand the damn floor for a start  normal dust masks leak too much over the 6h it takes). normal dust masks leak too much over the 6h it takes).

More ideas for practical tests are needed. We may also need to make a group effort with the chemicals.

[Edited on 13-10-2010 by peach]

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

that's why i said about reducing the aluminum to stoich amount.

| Quote: | | what happens to the rest of the aluminum after the O2 has been scavenged from the other reactants? it has nowhere to go but to combine with P until

the aluminum charge has been exhausted...need to do some equilibrium work on this but it may just be an issue of being more precise with

stoichiometry. |

i'll have to look back but we had discussed using an excess of Al and up till this point that's what i have been doing. on the next run i will reduce

that to stoich or perhaps 1-2% less. i really don't think there is much elemental P in the slag. if there were it would smoke upon being released

through grinding. and since i had been using an excess of Al, that is the main reason i figured it was reacting with the top portion of the P being

evolved in the main reaction.

all this talk of microwaves, while intriguing, is only conjecture until i put more work into the methods we are trying now.and i have no fear about

escaping radiation. i'll put that bitch in the back corner of the yard and stay a couple hundred feet away while its running. c'mon we've all seen the

retarded series "is it a good idead to microwave this?" on you tube. those idiots are still alive!

and microwaving my gonads may just be beneficial...i already have two kids i can barely handle and they won't be out of the house till i'm too old to

party properly. definitely don't need more!

[Edited on 13-10-2010 by Rogeryermaw]

|

|

|

peach

Bon Vivant

Posts: 1428

Registered: 14-11-2008

Member Is Offline

Mood: No Mood

|

|

Have you seen the episode of Southpark where Stan's dad discovers he can get weed legally, provided he has cancer. So he takes up smoking, sunbathing,

drinking and microwaving his balls, then ends up bouncing around town on a space hopper permanently high, with all the women looking at his now

bowling ball sized balls?

I was just checking your numbers. Keeping in mind that I've been on my feet for over 12h today painting, wiring plugs and endless other boring, rage

inducing shit, and that I'm now getting a bit drunk prior to having a sleep, they seem pretty much okay. There is no huge excess of Al that would

explain the lack of P in the result (from what I can see from some very rough calculations; I'll probably try checking them tomorrow depending on how

quickly I start working again). The result is off by an order of magnitude, that is a darn big difference. Kitchen scales, after my examination of the

anti-fatty Weight Watchers set I have, are not very good at all below 50 - 100g. But I'd be mighty surprised if even they weighed out 0.9g in place of

9g. You could easily see that with your eyes, without even picking it up.

You are in the realms, however, where kitchen scales are probably going to give poor results, 10% inaccuracies. They need about 100g on them before

the error drops to a low percentage. 9g, whilst it's not going to weigh out 0.9g, I'd expect it to make about a gram or two of error on that. Anything

between 1 - 50g, expect about 10% error from the kitchen scales, and it will decrease as the weight goes up to about 1%-2 or3% at 100g.

I still think there's something more afoot here. The scales aren't great, but they're not THAT far off. And the reactant masses aren't massively off

either. Yet the yield is.

Nail the collector if you run it again soon, get that out of the equation. If you reduce the amount of Al and it's still doing it, it has got to be

the melt. And I'd vote temperature and it not being driven to completion or fully out of solution. Again, arcs are fearsomely hot. Hot enough to start

messing with the special refractories if too close. If it yielded the same amount with flames, they'd probably switch to that, as a gas flame is

cheaper than an arc in terms of fuel (the electricity needs the gas / coal to be burnt, then converted and transmitted, then down converted, all

involving losses and expensive power plants).

Have your younger Rogers started drawing on the walls yet? Kids are funny. I'd rather they drew on the walls than adults left dirty hand prints all

over the place. Adults should know better, and the scribbling on the walls is at least colourful.

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

i did some looking back at my records and it seems that i have been doubling the stoich amount of SiO2. presumably the excess O2 is turning the P into

P2O5 yes no?

actually i took a bucket of joint compound and covered an entire wall of the house just for purposes of juvenile creativity. i can just sand it

slightly and let em go at it again when they like. the she demon is 5 and the he beast is 2.

i have one of the blade scales from the local head shop. certainly not perfect but it's widely endorsed by dope dealers and you know how finicky they

can be (captain, our sarcasm generators are at critical mass!!)

the collection effort is the first place i will start as it is basically a mechanical problem and that's my specialty. jus gonna hafta swallow my

balls (may be difficult if they were basketball sized) and submerge the pipe deeper to give the vapor more contact time with the water.

ya i love that episode. would not be my chosen method to score weed since in colorado it seems anyone with a sniffle can get it, but i can't hate em

for it. it's a step in the right direction since the govt. uses underground sales of contraband to fund illicit projects. make it legal and that slows

their ability to take advantage of it's illegal status for private gain.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Rogeryermaw  | i did some looking back at my records and it seems that i have been doubling the stoich amount of SiO2. presumably the excess O2 is turning the P into

P2O5 yes no?

|

No, not likely. Al is just about barely capable to reduce SiO2,

because the Heat of Reaction for SiO2 + 2/3 Al ---> Si + 1/2 Al2O3 is just about negative (but for industrial production this reaction has to be

heat boosted, with sulfur or K chlorate).

Off the top of my head P is wholly unable to reduce SiO2 to Si following SiO2 + 4/5 P ---> Si + 2/5 P2O5 because that reaction should be

endothermic.

But because the reaction P2O5 + 10/3 Al ---> 2 P + 5/3 Al2O3 is vigorously endothermic, this MUST be by far the most preferred route for the Al.

Simply put, in a mixture of SiO2, P2O5 and Al, assuming there is just enough Al to reduce the P2O5, the Al will react only with the P2O5 and not with

the SiO2. This is further helped by the fact that the P distills off, while any formed Si would not... If on the other hand there was also an excess

of Al, some SiO2 would definitely be reduced too...

The excess SiO2 would help drive the displacement reaction 2 NaPO3 + SiO2 ---> Na2SiO3 + P2O5 further to the right (that's beneficial).

It would also act as a heat sink: the excess can't react and that means that the reaction mix needs more heat to reach the same temperature.

SiO2 also has a very high MP (1,650 C) and so while the sodium silicate acts as a melt viscosity reducer, the excess SiO2 probably doesn't even melt

in your conditions...

The bottom line remains that for a good determination of yield you should try a strictly stoichiometric mix (but small weighing errors will not affect

results significantly IMHO)...

[Edited on 14-10-2010 by blogfast25]

|

|

|

| Pages:

1

..

26

27

28

29

30

..

60 |