| Pages:

1

2

3 |

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

Here are the new pictures promissed in the last post (the colour balance is a bit blue this time - sodium refuses to be photographed in the right

colour tone - have others encountered this problem?)

As an addendum to what I wrote before

1) Paraffin is an excellent medium for clearing oxidation off old sodium with minimum loss. After several hours all oxide flakes-off/disolved

exposing a brilliant metal surface.

2) Coalescing of Na globules is almost impossible below about 120C, at about 140C its dead easy - the surface tension of the two are just right.

3) The lower tip of the pipette is sealed with paraffin glue and immersed in a PVC cup filled with liquid paraffin and containing a small sacrifical

Na globule. The cup is sealed to the pipette by placing vertically in a stand and going round with a glue gun.

4) Na is dispensed by going round the seal with a heat gun and pulling the cup free. Next the paraffin glue plug is prised free, and the tip at the

top of the pipette scratched about 3mm from end and broken by touching with hot rod. The Na is dispensed at 120C, and pipette resealed.

The Na should hopefully last pristine for many years with this storage.

[Edited on 29-7-2008 by len1]

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

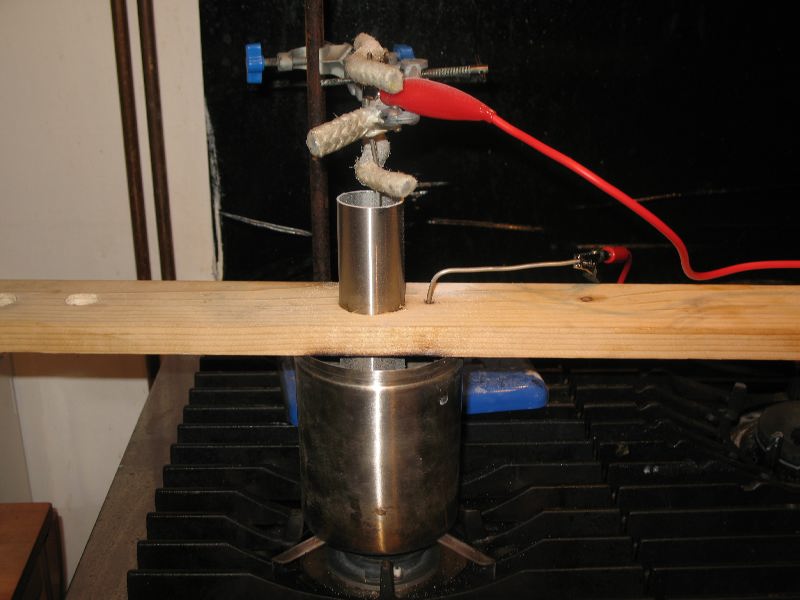

Here is the sodium cell Mark II.

The changes from the previouds version were motivated by speed of setup - the present cell incorporates a number of simplifications over the previous

design which enable it to be fanricated in one days work in a workshop equiped with no more than a drill press, a cut-off machine, and a welder.

The main simplification is in the method of heating - it is done using a standard 500W hotplate dispensing with the more complicated glass-fibre -

heating coil - radiation shield arrangement. The stand is also simplified and consists basically of a cylindrical heat shield enclosing the cell and

bottom reflector.

The anode is essentially the same - the main difference is that collector is pre-drilled rather than milled.

The cell wa stested and easily found able to achieve 400C - thus permitting production of K as welll as Na.

Are the pictures clear enough? Any suggestions of improvements appreciated.

NOTE: Im also looking for new synthesis to perform. If you would like to see am illustrated procedure demonstrated for a useful chemical reagent I

would gladly consider writing it. Essentially Im looking for chemical reagents, which are useful, not instantly availale, whose procedure for

manufacture is lacking in standard texts (in detail, purity analysis, kinetics etc.), is not drug related.

|

|

|

Fleaker

International Hazard

Posts: 1252

Registered: 19-6-2005

Member Is Offline

Mood: nucleophilic

|

|

Once again Len, you have very much impressed me. Your construction skills are admirable. I can't wait until you make detailed plans available of this

cell, once it is proven. I am very interested in building one such unit.

Exactly how large a batch can this cell run? I have many questions that you'll answer when you test it out!

As far as prepublication syntheses go, I have 2 that I am actively working on: synthesis of AlCl3 and perhaps other Lewis acids and also palladium on

carbon, and other PGM catalysts and compounds. I have a few other, long term projects.

I will not get to white P until after I finish working on black P. I assume you'll have it cracked by then, and I greatly look forward to using your

writeup as a guide when I attempt it sometime in October.

Neither flask nor beaker.

"Kid, you don't even know just what you don't know. "

--The Dark Lord Sauron

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

My notes.

Mark II has been upgraded

1) The anode on the long nickel tethers has been raised 3cm

2) A heater element (single coil insulated, bent to the outside radius of the cell) has been inserted at just above the mid point.

These changes are to allay a defect in the original design of mark II. With bottom heating the top of the cell was sufficiently cold, given the cell

has to be operated at close to m.p of NaOH, to freeze most of the bath. Heat being generated internally in the electrolysis zone was too far below

the NaOH surface to melt it. O2 generated below the solid top crust eventually pushed a sizeable portion of the bath to the top and denuded the

bottom. Hence side heating is essential and the electrolysis zone has to be brought closer to the surface. This has now been found to have the

desired effect. Raising the anode however has not eliminated the problem completely necessitating a 'defogging' cycle to be programmed every few

hours (bath temp raised to 330C and maintened for 10mins) after collector emptied of Na. This seems to be an inherent feature of small cells (though

I did not notice it in the Mark I)

3) The cell has been made sturdier by a welded tripod with inclined legs and a heavier piece of stainless steel for the anode ring.

4) Best of all a single GUI has been written to control the cell and display the time graphs of current, voltage, temperature, and moles. Now one

only needs to ladel out the Na at regular intervals.

The control parameters are:

a) Temperature 20-365C in 2hrs - side element run at 500W

b) Bottom heater off at 250C

c) A drying cycle at 350C. When NaOH melts, if substantially wet, bubbles of H2O effuse for up to 30mins. When this ceases, an electrolysis current

of 30A sets up by application of as little as 2.4V. Eventually the voltage rises to 3.1V to maintain a current of 18A. The drying cycle ends when

hardly any bubbles of H2 are observed at the cathode - nearly calm surface. If this is not followed Na generated at this stage will lead to

EXPLOSIONS when mixed with incompletely dry NaOH.

d) 4.6V applied at this stage - same as Mark I leads to a current of 53A rising to 56A. This is too high. Voltage can be decreased and cell

stabilised by length of copper dropping 280mV @47A.

Achieving stability is quite a feat without current control. This is because the cell has an intrinsic positive feedback mechanism. Na will only be

produced with any efficiency within a 10C temperature range of the mp of NaOH. Energy supplied by the current goes to

1) Produce the Na (and H2 and O2)

2) Heat the cell ohmically

The latter is normally enough for a well insulated cell such as this. However if the current should rise by a fluctuation - this increases ohmic

dissipation in the cell and hence temperature in the electrolysis zone. Increased temperature decreases resistance of cell and so can lead to runaway

- but this effect is small compared to the following: increased temp means the cell is less efficient - less Na is produced, more if it dissolves in

the electrolyte and migrates to the anode where it is oxidized generatinh heat - this increases temperature further, making the cell even less

efficient - and so runaway.

A power supply has positive effective resistance coefficient and so to a degree can counteract the negative one of the cell.

Each cell has a particular semi-stable equilibrium current, a balance between the heat this current generates, and the heat conducted away by the

melt. Current can not be raised beyond that as extra ohmic heat this generates will not be conducted thermally away by the NaOH melt at the

maximum10C differential allowed by the cell, will lead to unbalanced temperature rise in electrolysis zone, and eventually, no Na being produced. It

is clear from this that this thershold current is mainly a function of the electrode geometry and size. Indeed so, the stable current for all cells

with a 5cm 20mm diameter cathode, and 5m 70mm diameter anode has been found to be 47-49A.

The thermal parameters of the Mark II cell are somewhat differet due to better positioning and calibration of the thermocouple.

i) On temperature of side heater < 295C

ii) Off high temperature of electrolysis current 308C

iii) Off low temperature of electrolysis current 290C

iv) Temperature hysteresis 6C

v) Off temperature of bottom heater 250C

vi) Effective power of side heater 500W (35% at 1500W)

vii) Optimum current 47A

viii) Voltage at electrodes 4.0V

[Edited on 16-4-2009 by len1]

|

|

|

thereelstory

Harmless

Posts: 41

Registered: 18-1-2010

Member Is Offline

Mood: No Mood

|

|

essential components?

ok, would it be safe to just make all the components as described with the listed dimensions for starters? gage

|

|

|

len2

Harmless

Posts: 32

Registered: 13-9-2008

Member Is Offline

Mood: No Mood

|

|

I would suggest doing it step wise. Make the outer part first. Wind with heater element, check that it heats up. Then the collector with holes in

chamber, make sure it attaches tothe outer case. Then the anode, finally cathode - it takes about 1-2 weeks overall

|

|

|

plastics

Hazard to Others

Posts: 141

Registered: 6-11-2009

Member Is Offline

Mood: No Mood

|

|

Been a long time lurker on the forum. Two things interested me in particular: tube furnace by garage chemist and electrolytic production of Na by len1

Na has for me like many others held a particular fascination since schooldays. I even attempted electrolysis of NaOH on my mother's electric cooker

using a 12v power supply, some carbon electrodes and a stainless steel egg cup. All I managed were some deep gouges on the cooker top where the molten

NaOH splattered.

Somewhat older I revisited this, but without special equipment or welding skills I improvised. This time I used a gas cooker as a heat source. 1Kg of

molten NaOH was contained in a stainless steel coffee pot. A stainless steel tube was fitted snugly into a piece of wood to act as the separator

between anode and cathode and sat on top of the coffee container. A loop of nickel wire was situated on the outside of the inner tube by passing it

through a hole in the wood to function as the cathode. The anode was a nickel wire spiral held inside the inner stainless steel tube by a retort

clamp. Power supply was a 550W QTech PC PSU rewired as per woelens web page to provide 3.3, 5.0 and 12V outputs. Max current outputs were 18A, 30A and

16A respectively (these were obtained from the rating plate, my multimeter couldn't cope with these currents)

In use it took about 90mins to melt 1Kg NaOH prills. The melt fizzed for about 30 mins giving off an unpleasent mist (presumably water evaporating off

with some NaOH). The 3.3v current was passed initially; this was accompanied by considerable effervescence which gradually died away after 90 mins

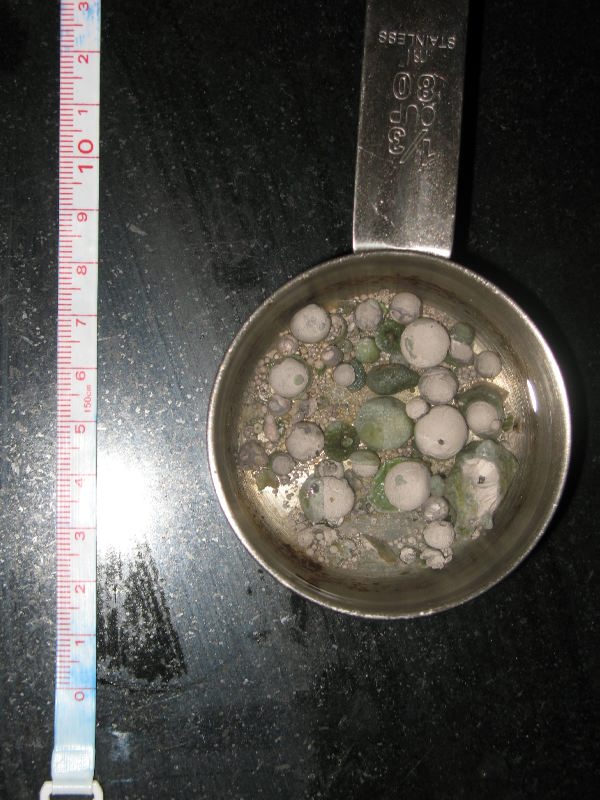

(remainder of water been electrolytically cleaved). Small globules of Na formed at this stage and the voltage was increased to 5.0V Now appreciable

globules of Na formed and rose to the surface eventually coalescing to form more substantial globules. Like len1 I found separating the molten

globules from the melt was very hard. Molten Na is very 'sticky', and the NaOH quickly solidifies once removed from the bath. I eventually used a

stainless steel teaspoon measure to scoop the globules up and then flick them into a container of liquid paraffin

End result 10g Na metal - not a lot but 10g more than I had before

Learning points

Put aside a whole day for one run

Only 'explosion' occurred when I re-used an NaOH melt. Think a small globule of Na had become trapped inside fused NaOH and reacted with some water

when melted

Wood may sound a daft idea but it works to insulate cathode from stainless steel separator. It lasts 2 runs and then needs to be replaced as the heat

and caustic vapour char it

Run the whole thing under an extracter fan - the mist doesn't do your chest any good

Temperature control is very difficult but I got a feel for the cell after a couple of runs

Wear goggles and protective gear. Molten NaOH hurts

Collecting and separating the molten Na is quite hard. It is very sticky. Even the individual globules were hard to fuse together when melted

separately

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

It is not possible to produce 10gm sodium from a single batch of electrolyte with this apparatus.

|

|

|

plastics

Hazard to Others

Posts: 141

Registered: 6-11-2009

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by len1  | | It is not possible to produce 10gm sodium from a single batch of electrolyte with this apparatus. |

BS - got the evidence to prove it. On what basis is it not possible?

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

The theory of the NaOH cell is such, i have investigated it over many years. The one picture with the little globule of sodium you showed is about

as much as youll get out of such a cell in a single go. If youve got some other evidence lets see it.

[Edited on 15-6-2010 by len1]

|

|

|

bbartlog

International Hazard

Posts: 1139

Registered: 27-8-2009

Location: Unmoored in time

Member Is Offline

Mood: No Mood

|

|

Hrm... not to step into the middle of an argument, but what is the presumed limiting factor that would prevent production of multiple grams of sodium

here, if any were to be produced at all? Oxidation and solution of the nickel anode followed by deposition of nickel rather than sodium at the

cathode? I can't think of anything other than poisoning of the cations that would limit production so severely.

|

|

|

plastics

Hazard to Others

Posts: 141

Registered: 6-11-2009

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by len1  | The theory of the NaOH cell is such, i have investigated it over many years. The one picture with the little globule of sodium you showed is about

as much as youll get out of such a cell in a single go. If youve got some other evidence lets see it.

[Edited on 15-6-2010 by len1] |

Exactly how many pictures of little blobs or not so little blobs would you like me to post? Perhaps you would like a video to prove the globules are

sodium and not lead

You know I thought I would post something to show that sophisticated equipment isn't always necessary and all I get is skeptical abuse. Well 10g may

not be in your league but its 10g I didn't have at the beginning and that's good enough for me. If after all the years of study all you have acquired

is a closed mind then I wouldn't give up the day job! If you're still speaking to me after that what were your experiences with KOH

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Oh, there's no argument here, at least not yet. Allow me to

summarize the dialogue so far, in the form of a very short play.

| Quote: | plastics / Man in Black

I have performed a feat.

len1 / Vizzini

Inconceivable! |

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

Irrespective of all the stupidities you wrote about a closed mind etc. and the buffoons in this thread I will respond because there is some

scientifically interesting input here. The amount of Na obtained is substantially more than I ever observed with with this kind of equipment - if

this was indeed produced in a single run, and despite all the errors in the cell. Oh well, well done. Nonetheless soon you'll have to change the

electrolyte.

[Edited on 16-6-2010 by len1]

|

|

|

Anders Hoveland

Banned

Posts: 208

Registered: 15-6-2010

Member Is Offline

Mood: No Mood

|

|

Actually sodium azide decomposes to metallic sodium and nitrogen when heated. Na3N is not very stable because Na will not form covalent bond with

nitrogen, and true nitride ions have low thermal stability because the N atom is too small for 3 extra electrons repelling eachother. Lithium and

magnesium, but not sodium, will burn in nitrogen. Aluminum will not burn either, but in that case it is because it is not reactive enough, Aluminum

will burn hot in pure oxygen, however. Sodium azide can be made by heating sodium amide and nitrous acid solution, or NaNO2 and hydrazine. Danger:

NaN3 in water easily partially hydrolyzes into HN3 gas which is very poisonous, like cyanide. Also AgNO3 solution and NH4OH left standing for a while

or lightly warmed will precipitate some AgN3 explosive at the bottom. Adding thiosulfate to AgN3 will put the solid back into solution.

[Edited on 16-6-2010 by Anders Hoveland]

|

|

|

Lambda-Eyde

National Hazard

Posts: 860

Registered: 20-11-2008

Location: Norway

Member Is Offline

Mood: Cleaved

|

|

The decomposition of sodium azide can be quite energetic (read: explosive) when scaled up. Anyways, this is not the thread topic.

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

I too made small amounts of sodium with such simple apparatus, doing this with several friends back when I was a kid. Yields were highly variable,

maybe averaging 5 grams a run using about 250 grams of NaOH and 25 grams of Na2CO3; several runs were a little too hot resulting in the aforementioned

sodium fog in NaOH. The 1st time this happened we were puzzled, and then surprised as the cooling NaOH hydrated and starting sparking from the tiny

globs of sodium trapped within it.

It works OK if you're after a few grams of sodium for a collection or whatever, for any serious amount of the metal I think a well made apparatus such

as Len's is the way to go unless you lack the resources and skills needed to build it. While not as simple as making a pot of tea, his apparatus

looks to be a much less troublesome way to produce moderate amounts of sodium, more practical for semi-continuous production runs.

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

I never managed to get the 5 or so grams here, with this kind kit, which is essentially two wires in a can (collector around anode can be done away

with). The most i got when i started out with this kind of thing was sub 1 gram.

I suppose it shows if you dont have the inclination to make more complex gear it can be done. What time you save on making things you lose in

operating the cell. And Youll have to chuck the electrolye much sooner. I now use a much simpler cell than in this thread, it gives about 12g/h and

can run for days on same electrolyte

|

|

|

Mildronate

Hazard to Others

Posts: 428

Registered: 12-9-2009

Member Is Offline

Mood: Ruido sintetico

|

|

len1 maybe you can make PDF of this ilustrated guide?

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

Hi,

Yes eventually I will. It occurred to me that the guy who posted the pics earlier might have in reality got upset and gone away. If he is still out

there this is just a clarification that he got it wrong. What he posted was the most interesting thing Ive seen on sodium in 3 years. I did not know

you can make 5g with such an arrangement, now I do. Thanks for putting it right.

The other aspect is learning to take things properly. From his subsequent posts, its clear he took my initial statement as an attack. It wasnt. I

was simply stating what I believed from several years experience, and a theory I had developped. What he seemed to be saying was not technically

contrary to the theory - although it makes it hard to do, but completely contrary to my experience. I thought maybe we would get a clarification -

which we did - but certainly not tears.

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

All your 985 posts are like this, trying to make trouble not one scientific contribution. I guess the name is apt ..

|

|

|

peach

Bon Vivant

Posts: 1428

Registered: 14-11-2008

Member Is Offline

Mood: No Mood

|

|

That is absolutely outstanding work len, well done!

|

|

|

metalresearcher

National Hazard

Posts: 790

Registered: 7-9-2010

Member Is Offline

Mood: Reactive

|

|

@len1, nearly three years after your post about your Castner's ceel replica I find this fantastic !

Do you still use it ?

I am now experimenting with making Na metal but more concentrating on the Na2CO3 + C chemical method as I am scared about the hot lye in the

electrolysis.

|

|

|

Waffles SS

Fighter

Posts: 998

Registered: 7-12-2009

Member Is Offline

|

|

This is possible to get Lithium metal by this system from LiOH?sure temp should increase to 600c

*Molten Lithium float on melting LiOH.

*Molten Lithium has less dense than Molten Sodium.

Anybody know ready system(for buy) for doing that?

This is difficult for build this system

[Edited on 22-12-2010 by Waffles SS]

|

|

|

Waffles SS

Fighter

Posts: 998

Registered: 7-12-2009

Member Is Offline

|

|

I think it is interesting to get lithium metal from Lithium Nitrate by this method

Lithium nitrate melting point:255c

[Edited on 2-5-2011 by Waffles SS]

|

|

|

| Pages:

1

2

3 |