| Pages:

1

2

3

4

..

9 |

Drunkguy

Hazard to Others

Posts: 172

Registered: 23-12-2005

Member Is Offline

Mood: somewhat pissed.

|

|

Ich habe jetzt deine furnace gesehen.

Jawohl! Bravo! Prima!

Now I know who i'll will be employing to make me my Raney Nickel catalyst.

Also, you say u are interested in oleum (SO3). That's also a chemical that could have uses to me although I dont know how far I want to go into the

workshop when most things are commerically available already.

[Edited on 26-12-2007 by Drunkguy]

|

|

|

chloric1

International Hazard

Posts: 1159

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

| Quote: | Originally posted by Drunkguy

I dont know how far I want to go into the workshop when most things are commerically available already.

[Edited on 26-12-2007 by Drunkguy] |

Well, for starters, it could be cheaper to make what you need with shipping charges and all. SecondLY, making something can give you hands on

understanding.

Fellow molecular manipulator

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

| Quote: |

Hi len1, I've been looking on the internet for a triac temperature controller circuit with thermocouple feedback for a while now. I'm sure there used

to be heaps of them, but I can't find anything suitable now! I'd be interested in anything you have. |

@Xenoid

No problem. The controller circuit I have is more complicated than triac with thermocouple feedback - thats on/off control. I have one with

microprocessor PID control which eliminates overshoot. It does mean you have to build a microcontroller circuit, and program it with the program

downloadable off the Silicon Chip web site. Please tell me if you actually want a PID controller and I will email you the circuit.

@magpie

Yes they can be bought in the US for US$50 or so, thats no a problem. But these are cheapo types, you cant program them youraelf, and they dont come

with computer control and interface such as the one Im referring to above.

@Davster

You are right in that the thermocouple needs only be as short as the junction of the two metals, and any two different metals will produce a voltage

difference, the key is that they and their alloy shouldnt melt at the measurement temperature.

The need for having long leads comes from the fact that if you join the first thermocouple to a different wire set AT THE SAME TEMPERATURE as the

measurement point the voltages will cancel and you will get no measurement. To get a result the only requirement is that the junction with the longer

(cheaper) wire must be made at a point where the temperature is substantialy different from the measured temperature.

So the ideal approach for the amateur is to locate the Pt couple as close as possible to the exit of the furnace where you believe the temperature is

representative of the furnace temperature. The wire needs to be taken as far as the outer end of the furnace, where the temperature is below the max

temperature of Cu/Const. There you can attach screw-on terminals of copper wire, and place a normal thermocouple. The whole apparatus can now be

calibrated at a few points, and there you have it. The only problem is where does one get the primary high temperature t-couple from.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

from len1 to Magpie:

| Quote: |

Yes they can be bought in the US for US$50 or so, thats no a problem. But these are cheapo types, you cant program them youraelf,

|

They are programmable in the sense that you can set the P, I, & D parameters, type of thermocouple, T in Celsius or Fahrenheit, etc. They also

have an auto-tune feature. Did you mean something different than this?

[Edited on by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

Well I guess I meant you can program it to follow a temperature regime. Different temperatures for different durations, and the tuning I think is

better too, and you have control over that because you have access to the program. Len

|

|

|

Fleaker

International Hazard

Posts: 1252

Registered: 19-6-2005

Member Is Offline

Mood: nucleophilic

|

|

| Quote: | Originally posted by len1

You are right in that the thermocouple needs only be as short as the junction of the two metals, and any two different metals will produce a voltage

difference, the key is that they and their alloy shouldn't melt at the measurement temperature.

The need for having long leads comes from the fact that if you join the first thermocouple to a different wire set AT THE SAME TEMPERATURE as the

measurement point the voltages will cancel and you will get no measurement. To get a result the only requirement is that the junction with the longer

(cheaper) wire must be made at a point where the temperature is substantialy different from the measured temperature.

So the ideal approach for the amateur is to locate the Pt couple as close as possible to the exit of the furnace where you believe the temperature is

representative of the furnace temperature. The wire needs to be taken as far as the outer end of the furnace, where the temperature is below the max

temperature of Cu/Const. There you can attach screw-on terminals of copper wire, and place a normal thermocouple. The whole apparatus can now be

calibrated at a few points, and there you have it. The only problem is where does one get the primary high temperature t-couple from.

|

That is very good to know. Platinum and rhodium are both trading at all time high prices, and even a few inches of wire are very expensive. I have

maybe a 11g piece of 50cm long Pt wire, but no PtRh alloy wire, and that will be troublesome to procure. My main concern with connecting a type S to a

type K is that the business end might conduct enough heat to melt the connections. How would one connect the type S from the center of the tube ( BTW,

that is the best place for thermocouple, it is most representative of horiz. chamber temp.) to the cheap type K? That is a problem I think, otherwise

it would be great: type K is very cheap, type S, damn expensive. Len, you seem to know what you're doing with electronics, how would you solve the

conduction problem?

I am very interested in building a tube furnace for home that is about 75 cm/30 inch in length with a 6 cm inner diameter. Originally I planned on

using a fused alumina tube and heating it with molybdenum disilicide elements but it would cost me about $1200 to do that. It would give me 1750*C

though, suitable for many things!

Yet for really cheap, about $50, I can buy some A1 kanthal that uses 240V in series, 14.5 amp, and 3500 watts. I think that would be sufficient, the

furnace won't heat as fast as garage chemist's but it will still be plenty powerful. A1 Kanthal is good til about 1450C/2550F. This would also mean

that I could use a cheap mullite tube or silimantite tube. Probably under 200 dollars I would think. I think I would want a PID and some sort of stand

so I can make the furnace vertical as well.

I have several hundred square feet of kaowool and plenty of Al2O3 and MgO, so that's no problem.

My biggest question is, how one would make a clamshell design? It would be difficult because you would not be able to just wrap the wire around the

tube, plus you would need to have the tube cut in half.

Despite the evident construction problems, they are still very convenient--quick cool downs, allows easily introducing reaction system, best part I

think is that it could make for easier ''zoning'' of the tube furnace.

That's another question for you electronics wizards: how would I make one end of the tube 500*C, while the other end would be 1000*C? I know I would

need some sort of insulating barrier in between, but how do I control current supply to the elements, do I run several heating element circuits?

Edit: found one interesting supplier, and they're relatively local: http://www.clevelandelectriclabs.com/welcomeCEL.html

More:

http://www.sentrotech.com/accessories.php

http://www.zircarceramics.com/

[Edited on 26-12-2007 by Fleaker]

Neither flask nor beaker.

"Kid, you don't even know just what you don't know. "

--The Dark Lord Sauron

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

Here is an explanation of what I had in mind

____________V2(T0)_____________________

V(T)

____________V3(T0)_____________________

The high temperature thermocouple is at the temperature of interestT, the contact to the cheaper wire (which must be the same at both contacts is at a

location where the temperature is T0.

All junctions generate voltage, and as most multimeter type thermometers assume a linear relationship, Ill assume that too (but its inessential to the

result, just makes thing seasier to see).

V(T) = a T

V2(T0) = b T

V3(T0) = c T = (a - b) T0

the last equation arises from conservation of energy. Then the voltage measured on the multimeter is

a T + b T0 - (a - b)T0 = a (T - T0)

(note that b wil cancel out even if its a function of T)

i.e. the tempearture at the measurement point is the sum of the temperatures measured by the two thermocouples, one with short leads located at the

measurement point, the other at the point of contact with the copper leads. The later could be located on the outer iron casing of the tube, with

holes cut for the high T thermocouple leads, which would need to be about 6 cm long.

There is also the ambient temperature. Most thermometers take this into account by adding it onto the temperature measured by the thermocouple (else

at ambient we get zero). So the relation is actualy

V(T) = a T - a Tambient

To avoid adding this twice from the two multimeters the formula becomes

Tactual = T + T0 - Tambient

Tambient you can get by noting the thermometer reading prior to measurements.

I didnt quite understand why you want a temperature gradient across the tube, or a clam type arrangement.

PS Do you have suppliers for the molyb elements and alumina tube? Len

|

|

|

WizardX

Hazard to Self

Posts: 61

Registered: 11-8-2005

Location: wizardx.4shared.com

Member Is Offline

Mood: wizardx.suddenlaunch3.com

|

|

Temperature Controller Circuits. http://www.schematicsforfree.com/archive/dir/Misc/Temperatur...

Albert Einstein - \"Great ideas often receive violent opposition from mediocre minds.\"

|

|

|

WizardX

Hazard to Self

Posts: 61

Registered: 11-8-2005

Location: wizardx.4shared.com

Member Is Offline

Mood: wizardx.suddenlaunch3.com

|

|

| Quote: | Originally posted by garage chemist

I completed my new powerful tube furnace. Look here for pictures:

http://www.versuchschemie.de/ptopic,168531.html#168531

You can see that I have successfully taken it to 1300°C (2370°F- thats above the maximum continuous use temp for quartz glass!) already before I put

it into a casing.

The core of the furnace is a ceramic tube, 500mm long, 40mm OD, 32mm ID. The ceramic is called "pythagoras" and is good up to 1400°C (some sources

say 1500°C), it is also absolutely gastight (even high-vacuum tight).

14.7m of 1mm Kanthal A1 wire (1.8 ohm per meter, giving about 2000W of power at 230V) is wound onto the tube and covered with a paste of equal parts

MgO (dead-burned magnesia) and Al2O3. |

I would coil the 14.7m of 1mm (or thicker) Kanthal resistance wire around at tube with a outer diameter of 30-31mm to make a coil that is the 32mm

internal diameter of the ceramic tube.

Similar to an induction coil.

The 14.7m of 1mm (or thicker) Kanthal resistance wire coil is then fed inside the length of the ceramic tube with spacers between the windings.

Albert Einstein - \"Great ideas often receive violent opposition from mediocre minds.\"

|

|

|

Xenoid

National Hazard

Posts: 776

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

Whilst not being in the same league as garage chemist's tube furnace a smaller, simpler version could be built with components purchased from our

friends the pottery suppliers.

In their "Kiln Furniture" sections they have tubular ceramic props. These are used for building up layers of shelves for pots in the kiln. They are

about 45 mm diameter and come in a range of lengths from about 3cm upto 30cm (12"). They are very cheap, with a 30cm length costing about NZ$10. They

also supply Kanthal wire and Kaowool blankets.

I have thought about using one of these 8cm "props" (in a vertical orientation) as a single crucible mini electric furnace.

|

|

|

Fleaker

International Hazard

Posts: 1252

Registered: 19-6-2005

Member Is Offline

Mood: nucleophilic

|

|

| Quote: | Originally posted by len1

Here is an explanation of what I had in mind

____________V2(T0)_____________________

V(T)

____________V3(T0)_____________________

The high temperature thermocouple is at the temperature of interestT, the contact to the cheaper wire (which must be the same at both contacts is at a

location where the temperature is T0.

All junctions generate voltage, and as most multimeter type thermometers assume a linear relationship, Ill assume that too (but its inessential to the

result, just makes thing seasier to see).

V(T) = a T

V2(T0) = b T

V3(T0) = c T = (a - b) T0

the last equation arises from conservation of energy. Then the voltage measured on the multimeter is

a T + b T0 - (a - b)T0 = a (T - T0)

(note that b wil cancel out even if its a function of T)

i.e. the tempearture at the measurement point is the sum of the temperatures measured by the two thermocouples, one with short leads located at the

measurement point, the other at the point of contact with the copper leads. The later could be located on the outer iron casing of the tube, with

holes cut for the high T thermocouple leads, which would need to be about 6 cm long.

There is also the ambient temperature. Most thermometers take this into account by adding it onto the temperature measured by the thermocouple (else

at ambient we get zero). So the relation is actualy

V(T) = a T - a Tambient

To avoid adding this twice from the two multimeters the formula becomes

Tactual = T + T0 - Tambient

Tambient you can get by noting the thermometer reading prior to measurements.

I didnt quite understand why you want a temperature gradient across the tube, or a clam type arrangement.

PS Do you have suppliers for the molyb elements and alumina tube? Len |

Thanks very much for clearing it up for me. That calibration looks simple enough. I still maintain that there will be a problem with finding a minimum

amount of wire required to not melt your connection. Anyone want to volunteer to do the math on how much heat Pt/Rh wire conducts over a given

distance at a given temperature with a given amount of insulation preventing radiative and convective losses?

I suggested taking the temperature in the middle of the tube with the thermocouple for the reason that it will be where the highest temperature is

obtained, and will show you your max temp. for the furnace. Refer to my thread on sulfur trioxide from V2O5 catalyst tubes--I noted there how temp at

one end of a tube furnace can vary by several hundred degrees.

As for why a clam shell is desirable, well, I guess you've never used a tube furnace before. I've used both a simple type and a clam, and I much

prefer the clam for the ease with which I can install my reaction tube, thermocouples, and most importantly, how quickly I can cool the apparatus

down.

IF you looked at those links you might have noticed that both zircarceramics and sentroTech sell MoSi2 and the requisite alumina or zircon tubing.

It's not cheap, but a well built tube furnace is very nice to have.

http://www.sentrotech.com/custom.php (Moly disilicide)

Neither flask nor beaker.

"Kid, you don't even know just what you don't know. "

--The Dark Lord Sauron

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Pt isn't very conductive, AFAIK. The wire will basically be at the same temperature as the tube, give or take a hundred degrees or so. The copper

end might cool the joint by maybe up to a hundred degrees, depending on how well insulated it is. We're talking wire here, it's nothing amazing as

conductivity goes.

The thermocouple wire I have (K I think) is wrapped in woven glass fiber. Nice.

Tim

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Watlow has some good reference charts and other information .

http://www.watlow.com/literature/catalogs/files/sensors.pdf

http://www.watlow.com/literature/catalogs/

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

No the contact V2 and V3 must be at the temperature of the outer (iron) tube. They must be electrically insulated from the tube, but well thermally

attached to it ( high T thermal grease is best). A low temperature thermocouple must be attached between them. This ensures all three are at a

stable intermediate T, a few hunder degrees. Theres hardly any point calculating their thermal flux as their mass is tiny and the entire temperature

gradient will the fall across the wires. The high T couple must be well afixed to the alumina tube with a suitable bracket, and insulated from the

heating wire. There is of course a temperature gradient along the length of tube, but that doesnt matter if you afix the thermocouple in the middle,

if your reaction volume is small. Len

[Edited on 27-12-2007 by len1]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

clamshell vs fixed tube

Fleaker said:

| Quote: |

As for why a clam shell is desirable, well, I guess you've never used a tube furnace before. I've used both a simple type and a clam, and I much

prefer the clam for the ease with which I can install my reaction tube, thermocouples, and most importantly, how quickly I can cool the apparatus

down.

|

I have never used a tube furnace but understand your reasoning. My original plan was also for a clamshell design. I was going to make the shell out

of a pipe with welded end-faces, or even use a 16 gallon steel drum. This would be cut in half lengthwise, and hinged. The center of the furnace

would be two clam faces made from castable refractory. I have found refractories with nominal temperature limits of 2600F(1427C) and 3000F(1648C),

available on-line for around $40/50 lb sack. It would take some craftsmanship to form a cavity with metal supports for the coiled resistance wire.

These two clam shells, in turn, would have to be supported by steel rods that would extend out to the shell and be anchored there. The annulus would

then be filled with ceramic blanket or ceramic wool. Removeable saddles would allow the use of test tubes of various diameters and lengths.

This would make a very flexible furnace. But it is all so complicated and would take so much work that I might never do it! That's why I like garage

chemist's design so much.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

At work we have a clamshell type tube furnace. I can take pictures of how they orient the heating elements, if noone is using it next time I am

there.(if anyone is interested that is)

[Edited on 27-12-2007 by The_Davster]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

| Quote: |

At work we have a clamshell type tube furnace. I can take pictures of how they orient the heating elements, if noone is using it next time I am

there.(if anyone is interested that is

|

Sure, take some pictures if it is not too much trouble. Try to get some good ones of the construction details.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

LSD25

Hazard to Others

Posts: 239

Registered: 29-11-2007

Member Is Offline

Mood: Psychotic (Who said that? I know you're there...)

|

|

Slightly off topic - but the nearest I could find at a glance - how would one go about cutting the vycor tubing in tungsten-halide lamp bulbs in order

to make use of the vycor tube? Of some interest may also be the molybdenum seal, the platinum and/or tungsten wires, etc.

Will an ordinary glass-cutter do the trick? If not, would the scratch and chase technique work?

If either of these techniques work, any glass blowers out there with knowledge or suggestions how to join two lengths of vycor tube?

Also somebody mentioned above the possibility of using the tubular shelving supports offered by kiln providers - which are rated to around 1300C (and

quite probably, indeed almost certainly, consisting largely of alumina). I have several differenr lengths of this on order at present and wish to know

if anyone has tried using this?

Whhhoooppps, that sure didn't work

|

|

|

Fleaker

International Hazard

Posts: 1252

Registered: 19-6-2005

Member Is Offline

Mood: nucleophilic

|

|

Scratch and chase really sucks for quartz, I rarely ever get clean breaks when using the old file, rub, and snap method. Often I end up having to

clean the edges (since it's hard to flame polish quartz) using a metal support gauze.

I would think a regular glass cutter would work. If not, I'm pretty sure a carbide pipe cutter would do the trick too if you were ginger with it.

Neither flask nor beaker.

"Kid, you don't even know just what you don't know. "

--The Dark Lord Sauron

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

I have rather extensive quartz cutting experiance... The key to clean breaks is not just to notch it in one spot, but the scratch/notch must go

completly around the quartz tube, and must not have any 'mistake' scratches that are not where you want the break to be. The scratch also must be

deeper than in regular glass; when you can see powder coming off when you deeply file, you are almost there.

EDIT: As for joining the quartz tubes, be prepared to fail on many before you get it right. I probably went through several metres of tubing before I

was 'sufficient' at joining quartz. (although I was working with diameters varying by a cm or two, so it was more difficult). You will absolutley

need a very high temp torch...oxyhydrogen is what I used. The procedure is to circularly heat the quartz tube, untill its glowing followed by drawing

out the glass as if you were about to make pipettes, but instead only pull it untill you estimate that the thinner OD of the quartz is less than the

ID of the undrawn out quartz. Notch and snap off excess quartz. You only want 5mm or so of the thinner quartz to be within the larger diameter

quartz. Insert the drawn out part into another normal diameter quartz tube, and while only applying light pressure(only enough to hold it in place)

axially forcing the tubes together, circularly heat the joint untill the quartz is glowing all around. Then and only then apply greater force causing

the semifluidic quartz to smush together sealing the joint. If all the holes are sealed, you are done, there will be a lump on the inside, but that

is unavoidable, and would probably require a real glassblower to fix. If there are any difficult holes, a graphite shaft can be used to manipulate

semifluidic quartz, and push it where you want it. Have water nearby to dunk the graphite rod in when it starts glowing orange. Joints like this

have survived 1000C to ice water shocks without incident. It is also why quartz rocks.

[Edited on 18-1-2008 by The_Davster]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

homemade 2000w dimmer

Wanting to have a 1300C tube furnace I began by installing a 230VAC outlet in the wall next to my lab bench. In consultation with garage chemist I

decided that a dimmer using a thyristor would be best for a power controller. I wanted to use the Kemo 028 thyristor module as did GC but these are

only available on the German eBay. So I decided to build my own dimmer using the circuit of figure AN1003.15 in Littlefuse document:

http://www.littelfuse.com/data/en/Product_Catalogs/PowerThyr...

The only exception I made to the circuit was to use quadrac Q4015LTH instead of the diac/triac shown. This allowed use of the higher current (8.7amp)

needed to provide 2000w. A larger triac could have been used as well.

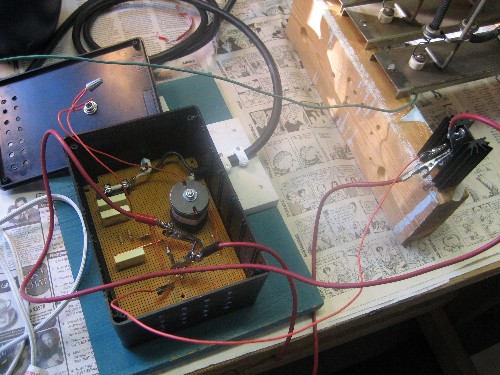

The first picture shows the assembly with the quadrac/heat sink mounted outside the enclosure for test purposes. The enclosure is a 5"x7"x3"H plastic

box from Radio Shack.

The 2nd picture (next post) shows the circuit in full operation at 7.5amp using the power resistor bank I salvaged from my old houshold electric

furnace. Sorry I didn't show this in dim mode - you'll have to trust me that it dims. BTW it dims smoothly and with no flickering, even at 0.33 amp

load.

Some lessons learned:

1. Start off with a large enough enclosure before doing any hardwiring/soldering.

2. Try to get all your components in one order from as few suppliers as possible. For US builders I highly recommend Mouser and Newark. To a much

lesser extent try Allied Electronics and Digi-Key. These suppliers, together, provide a great selection but if you are not careful shipping charges

will kill you. For example, Allied charged $10 in shipping for that dinky little heat sink.

3. Most importantly, make sure that on the quadrac or triac that the Main Terminal 2 (MT2) has the same polarity as the gate (trigger).

[Edited on 8-3-2008 by Magpie]

[Edited on 8-3-2008 by Magpie]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

The 7.5 amp test:

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Does the heat sink on the quadrac even get warm at full power now that the circuit is correct?

[Edited on 8-3-2008 by garage chemist]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

GC: Yes, but I am not sure how hot yet. I ran it at the 1800w load (7.5a) for ~15 minutes then felt it with my hand. I would guess about 60C. It

wasn't a realistic test though as there was a fair amount of heat coming off the nearby resistor bank, and the quadrac/sink wasn't in the enclosure

with the lid on. I have hardwired everything in its permanent configuration now. I need to run a good test at full load with a thermocouple in place

to monitor the sink temperature.

The data sheet for the quadrac says to expect a heat dissipation of ~1w/amp. Overheating of the quadrac (max allow case temp @ 10a=95C) is a concern

but the heat sink thermal resistance is rated at 2.6C/w. So at 8.7a the temperature shouldn't exceed 50C even if drawing 10 amps. But I don't know

how realistic this is, especially when in the enclosure.

How hot does your thyristor module get at full load?

[Edited on 8-3-2008 by Magpie]

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Your enclosure looks plastic. Don't be putting that heatsink in there!

A bigger heatsink could come in handy. Got any junk laying around with heatsinks? Monitors, power supplies, stereos, all sorts of things.

If your box is actually diecast aluminum, that might be conductive enough that you can bolt it to the case and go. You may still want a heatsink

mounted flat to the outside, though (something your current heatsink wouldn't exactly be able to accommodate..).

Tim

|

|

|

| Pages:

1

2

3

4

..

9 |