| Pages:

1

2

3

4

5 |

nlegaux

Hazard to Self

Posts: 93

Registered: 28-11-2014

Location: East Tennessee

Member Is Offline

Mood: No Mood

|

|

A reaction I haven't seen listed yet is Letts nitrile synthesis. If you react the terepthalic acid with stoichiometric amounts of KSCN, you would be

able to produce 1,4-dicyanobenzene.

nlegaux

|

|

|

FriedBrain

Harmless

Posts: 14

Registered: 10-8-2015

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Do you have any source or literature for that? I don't think that this reaction will take place at normal temperatures and pressure, but who knows?

You always have time to do some chemistry, but maybe you just have other priorities?

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Nicodem, woelen, blogfast25 to name but a few.

|

|

|

Boffis

International Hazard

Posts: 1867

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

I've never heard of Letts synthesis before but having checked it out it actually look plausible particularly the lead thiocyanate modification. I

wonder if you could apply it to the half ester to obtain a 4-cyanobenzoate ester. This reaction would be a more direct route to 1,4-dicyanobenzene

than through the diamide.

|

|

|

Pumukli

National Hazard

Posts: 705

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

Whoa, sorry for the following (almost) entirely offtopic comment, but I couldn't resist:

After Boffis mentioned Letts nitrile synthesis I also got curious and checked it on wikipedia. https://en.wikipedia.org/wiki/Letts_nitrile_synthesis

Then checked reference 5 and to my amusement the first real sentence of that article (after the usual intro and table of contents listings) went like

this:

"Hydrogen cyanide was first prepared in 1782 by Scheele, who was later killed while attempting to isolate the anhydrous material."

Mmm, it was new to me that Scheele (who was a great chemist of his time) had died in a laboratory accident, by HCN.

|

|

|

nlegaux

Hazard to Self

Posts: 93

Registered: 28-11-2014

Location: East Tennessee

Member Is Offline

Mood: No Mood

|

|

It is rather ironic that something so seemingly foolish could kill such a brilliant chemist.

Another interesting reaction of carboxylic acids is the Kochi reaction, which allows for the production of alkyl chlorides from carboxylic acids using

lead tetraacetate and the corresponding lithium halide.

nlegaux

[Edited on 9-12-2015 by nlegaux]

|

|

|

Boffis

International Hazard

Posts: 1867

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

@nlegaux, thank you for another interesting idea and another reaction I have never heard of. However, having delved into this reaction it would appear

that if it worked on terephthalic acid the product would be p-dichlorobenzene. Thus to produce 1g of p-dichlorobenzene (cost £0.01 per g) would

require about 8g (£3.00 worth of lead tetracetate); this is therefore analogous to using a solid gold hammer to turn your Rolls Royce, Porsche,

Ferrari or whatever you drive into scrap metal.

I hope you don't feel that I am pissing on your camp fire but.....

|

|

|

nlegaux

Hazard to Self

Posts: 93

Registered: 28-11-2014

Location: East Tennessee

Member Is Offline

Mood: No Mood

|

|

It is no problem Boffis, just an idea I had (excellent analogy, by the way). I'm currently looking into performing the Kochi reaction on some

Salicylic acid, so when I thought of the carboxylic acid groups on the terepthalic acid that was one of the first things that came to mind.

nlegaux

|

|

|

Boffis

International Hazard

Posts: 1867

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

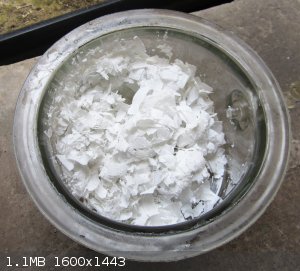

OK I've stop my experiment described above with PET plastic and aqueous ammonia.

I shuck the bottle vigorously to seperate as much as possible of the white product from from the residual plastic and then strained the mixture

through a plastic tea strainer to remove the coarse fragments. The white suspension was gravity filtered and then washed with copious amounts of water

until the smell of ammonia had gone and the wash water was no longer alkaline to red litmus. The filter paper was then air dried. When dry the white

powder readily seperated from the filter as a fine, soft white powder. I don't have scales where I am so I can't give yields but after 5 weeks all of

the thinner side walls of the water bottles had completely disintegrated only the bottoms and necks remained. If the product proves to be

terephthalamide this process represents a very useful route to 1,4-benzene derivatives from PET resin.

The residual pieces of the bottles The residual pieces of the bottles

The product; terephthalamide? The product; terephthalamide?

While I have no means at hand to test the material the only other two likely products are diammonium terephthalate and ammonium terephthalate

monoamide but both of these are likely to be pretty soluble in ammonia solution and certainly the wash water. I didn't think to save the ammonia

soution and try drying it to see if there was any soluble material.

When I get chance I will try a more scientific version of this with weighed quantities and better control.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Inspiring ! Definitely have to try this at home, in the Lab.

[Edited on 20-9-2015 by aga]

|

|

|

nlegaux

Hazard to Self

Posts: 93

Registered: 28-11-2014

Location: East Tennessee

Member Is Offline

Mood: No Mood

|

|

If it is terepthalamide, you can perform a Hofmann rearrangement to produce phenylenediamine.

nlegaux

|

|

|

halogen

Hazard to Others

Posts: 372

Registered: 18-4-2004

Member Is Offline

Mood: No Mood

|

|

Could contain oligomers capped with ammonia, with some ethylene glycol remaining I mean.

F. de Lalande and M. Prud'homme showed that a mixture of boric oxide and sodium chloride is decomposed in a stream of dry air or oxygen at a red heat

with the evolution of chlorine.

|

|

|

Boffis

International Hazard

Posts: 1867

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

@halogen, yes very possibly. Its difficult to recrystallise give the low solubility in the solvent I have to hand so my plan is to repeat this with a

pressure vessel that I have just aquired and see if I can get a product with the same properties/composition but in hours rather than months. I also

intend to try the boric acid/urea process on my purified terephthalic acid. Unfortunately at the present time I am in the Cloud Forests of the eastern

Andes so these experiments will have to waite until I am home again.

|

|

|

Boffis

International Hazard

Posts: 1867

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Since we use ammonia on site I decided to repeat the ammonia decomposition at atmospheric pressure. I used a glass food jar with some polythene mesh

supported on a ring of uPVC water pipe to seperate the PET fragments from the liquid aqueous ammonia solution (25%). I used only the thinner wall

sections of the bottles, about 15g. I filled the jar up to the levelof the polythene mesh with about 70ml of ammonia solution and placed the PET in

largish piece in the space above. I shuck the jar one to wet the PET and then let it stand for 3 weeks undesturbed. After this time the PET had become

completely opaque and when I shuck the jar again the fragments completely disintegrated to white milky slurry. I filtered off the white solid but this

time I preserved the filtrate. I washed and dried the white solid and will investigate this further.

The filtrate I placed in a shallow tray and left it to partially evaporate to remove most of the ammonia. By the evening only about 30ml remained and

the smell of ammonia was very slight. A tiny amount of white solid precipitated as minute ponpoms. I then acidified the clear liquor with 10% HCl to

about pH 1.5 (by test strips) and removed the white precipitate by filtration again. I estimate that about 0.5g of this material remained on drying.

This material could be either terephthalic acid or the mono-amide or more likely a mixture of the two. Does anyone have a simple test to distinquish

the two? I have some good quality filter paper and some solvents (70% ethanol, butyl acetate, THF etc) available here so chromatography may be

possible.

|

|

|

Mesa

Hazard to Others

Posts: 264

Registered: 2-7-2013

Member Is Offline

Mood: No Mood

|

|

Add sodium hydroxide and hold a strip of wetted pH paper above it. If it turns blue it's an amide.

|

|

|

Paddywhacker

Hazard to Others

Posts: 478

Registered: 28-2-2009

Member Is Offline

Mood: No Mood

|

|

Did you do a melting point? Solubility tests?

|

|

|

Pumukli

National Hazard

Posts: 705

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

Melting point of terephthalic acid is around 425 Celsius, its monoamide melts above 340 Celsius, diamide I don't know.

All I wanted to say is you will need a beefy melting point apparatus for sure. :-)

|

|

|

Paddywhacker

Hazard to Others

Posts: 478

Registered: 28-2-2009

Member Is Offline

Mood: No Mood

|

|

Wiki gives the sealed tube MP as 300 C and sublimation with decomposition at 402 C.

It should be possible to characterise it as either a form of PET or as the acid, ammonium salt or amide on the basis of simple tests.

[Edited on 4-11-2015 by Paddywhacker]

|

|

|

Boffis

International Hazard

Posts: 1867

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

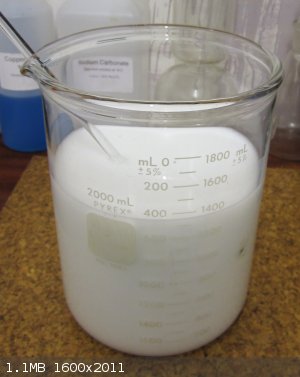

Large scale ammoniolysis of PET resin over aqueous ammonia

Following my earlier small scale experiments exposing PET plastic to the fumes of aqueous ammonia and the reasonable success it appeared to have I

decided to carry out a much larger scale experiment.

I set up an old desiccator with a piece of plastic mesh to replace the zinc plate and then placed 206g of plastic water bottles cut into rings so that

they did not pack too densely. 350ml of concentrated 0.90 density ammonia solution were then poured over the plastic and allowed to drain into the

reagent pit at the base of the desiccator. The mesh kept the plastic out of the ammonia solution and so apart from the initial drenching the plastic

was only exposed to moist ammonia vapor. The rim of the desiccator was greased with vaseline and the lid was placed firmly in place and the whole was

left in a cool dark corner in my outbuilding for nearly 5 months from early November 2015 until mid March 2016. I estimate that the average

temperature during this period was about 7-8 C.

Desiccator after opening and draining the excess ammonia Desiccator after opening and draining the excess ammonia

The now white corroded PET resin The now white corroded PET resin

When the experiment was opened the whole of the content had turned completely white and opaque and it had settled considerably. The aqueous ammonia

that was left was carefully decanted and the PET residue tipped into a large bowl. The desiccator was washed out with about 400ml of water into the

bowl and the now very soft and fragile PET gently crushed to give a thick porridge like slurry. This was filtered using a large Buchner funnel; the

filtrate was preserved for recovery of any free acids while the filter cake was dried for several days.

The washed and filtered amide The washed and filtered amide

The dried cake was ground to a fine powder and dispersed into 800ml of hot water, simmered for a short while (about 10 mins) and then cooled. The fine

white solid was again collected in a large Buchner funnel washed with about 300ml of cold water and dried. The yield of dried solid was 155g. It is

highly insoluble in cold as well as hot water and it is not soluble in dilute sodium hydroxide. It is also very resistant to hydrolysis even by hot

40% sodium hydroxide. The nature of this material was not investigated further at present but the yield is very close to the theoretical yield of

terephthalamide.

The rewashed amide product The rewashed amide product

The combined filtrates were acidified to Congo red paper with 18% hydrochloric acid to precipitate any free acids. The white precipitate was recovered

by filtration at the pump and dried, it weighed 18.87g. The nature of this acid is uncertain but the two most like possibilities are terephthalic acid

and its half amide, 4-amidobenzoic acid; some short chain partial hydrolysis products are also possible if they contain a free acid group.

The residual ammonia solution was partially distilled into fresh water to recover most of the remaining ammonia and the residue in the distillation

flask (now rather cloudy but from which nothing settled out) was acidified with hydrochloric acid and the white precipitate filtered off, washed with

about 50ml of water and dried yielded a further 1.002g of acid that was added to that already recovered, giving a toatl yield of 19.9g.

To determine the likely indentity of this compound it was decided to titrate the acid against standard sodium hydroxide using phenolphthalein as

indicator. The choice of the indicator is important as the final solution should be sufficiently alkaline to neutralise the second base of any

terephthalic acid. An immediate issue, however, is the highly insoluble nature of the acid; to circumvent this problem a known weight of acid was

dissolved in a known volume of standard sodium hydroxide solution and back titrate the excess alkali.

0.2477g of the dried acid were dissolved in 25ml of 0.2025M sodium hydroxide solution. When solution was complete 2 drops of phenolphthalein indicator

solution were added and the excess sodium hydroxide was titrated against 0.2M hydrochloric acid (note 1). 17.3ml were required indicating that 7.7ml

were required to neutralise the acid:

7.7/1000 * 0.2025 = 0.0015593 M of acid - therefore 0.2575g of 4-amidobenzoic acid

Or 0.1295g of terephthalic acid (a dibasic acid so twice as much NaOH required to neutralise it)

Clearly therefore, the monobasic amidobenzoic acid looks the more likely candidate even if it is a little impure. It would appear from the greater

than 100% content that the main impurity is likely to be incompletely hydrolysised PET.

For comparision the titration was repeated using the terephthalic acid recovered by the PET/caustic fusion process described previously.

0.2504 of terephthalic acid were dissolved in 25ml of 0.2025M sodium hydroxide. When the acid had dissolved 2 drops of phenolphthalein solution were

added and the excess alkali titrated with 0.2M hydrochloric acid. 10.1 cc were added ie 14.9cc of sodium hydroxide solution were consumed neutralising

the acid. Therefore:

14.9/1000 * 0.2025/2 = 0.001509 M of terephthalic acid = 0.2506 g ie almost exactly the amount taken, indicating that the terephthalic acid is

eceedingly pure.

Further Work

When time permits I will dissolve this monobasic acid in the minimum amout of sodium hydroxide solution and attempt to recrystallise it to remove the

partial hydrolysis products and isolate the pure acid. I also intend to attempt a faster process using aqueous ammonia in a pressure reactor that I

now have to see if I can produce a purer product and a greater yield of the 4-acetamidobenzoic acid relative to terephthalamide.

Given the very low solubility of the terephthalamide in all the solvents I have tried makes further purification impractical so I am going to try and

convert it into 1,4-dicyanobenzene and 1,4-diaminobenzene directly and purify these compounds.

|

|

|

Pumukli

National Hazard

Posts: 705

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

Hats off, Boffis!

It seems that most of the ammonolysis product is the diamide. If you could find a decent route to the monoamide from the diamide it would be perfect!

:-) I would (will) definitely join in when I have a bit better equipped lab. (I have rbfs now but still lack the ability to measure practically

anything, melting point measurements included.)

Keep up and keep us informed!

|

|

|

Romix

Hazard to Others (Literally)

Posts: 483

Registered: 19-6-2015

Member Is Offline

Mood: No Mood

|

|

Can sodium terephthalate be made by boiling crashed PET in NaOH.

Pan cooling down now. Boilled 200g of dust to 75g of base, 3 beakers full of water.

Some dissolved but not much, not even a gramm.

What about benzene from dry reagents? Is this true?

At room temperature, NaOH solutions some times etch PET, cracks it(Takes months to). Beware of leaks. HDPE are safe.

Isopropanol + NaOH made holes in PET bottle and cracked its neck in less then 10 min.

[Edited on 2-4-2016 by Romix]

|

|

|

Boffis

International Hazard

Posts: 1867

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Hey can one of you moderators make my post above editable again. I have spotted a couple of omissions (note 1 is missing) and errors (the excess

alkali was titrated against acid not alkali).

@Romix, to get rapid hydrolysis requires higher temperatures than you can get with dilute aqueous alkali solutions and after several experiments, some

of which I described above, molten moist sodium hydroxide or a mixture of sodium hydroxide and a glycol type liquid seem to work best. The later

method has the advantage of requiring a smaller excess of alkali and therefore acid to precipitate the product.

Your observations with alcoholic alkalis look interesting. Alcohol KOH is often used to hydrolyse compounds that hydrolyse slowly in aqueous NaOH so

you might be on to something there.

[Edited on 2-4-2016 by Boffis]

|

|

|

Pumukli

National Hazard

Posts: 705

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

Maybe the alcoholic solution can much better "wet" the otherwise hydrofobic PET surface than the simple aqueous alkali solutions?

|

|

|

Romix

Hazard to Others (Literally)

Posts: 483

Registered: 19-6-2015

Member Is Offline

Mood: No Mood

|

|

Ok there's is to much water, I have to boil down to concentrate.

Boiled it one more time, at about 300C+ temp.

Pan were jumping and kicking, had to hold it with a glove, wearing gogles and dustmask.

Solution getting darker and darker.

Fumes coming of were sweet at one point, Wikipedia says that ethylene glycole is sweet tasting chemical.

[Edited on 3-4-2016 by Romix]

|

|

|

Romix

Hazard to Others (Literally)

Posts: 483

Registered: 19-6-2015

Member Is Offline

Mood: No Mood

|

|

What's the solubility of sodium terephthalate? Any one knows?

If high, CO2 can be bubbled through filtered solution, and after filtering precipitate.

It can be recrystallized a few times in distilled water, then by adding acid, can be converted back to terephthalic acid?

Maybe you dear forum members know solvent for glue?

Recommend me some please.

On other forum one member told me that Xylene or Toluene can solve it.

In theory stickers should swim on top, plastic on bottom.

Cellulose cost more then carbon.

After wash solution in theory will separate in to layers.

[Edited on 3-4-2016 by Romix]

|

|

|

| Pages:

1

2

3

4

5 |