| Pages:

1

2

3 |

feacetech

Hazard to Others

Posts: 163

Registered: 12-2-2007

Member Is Offline

Mood: No Mood

|

|

so basically your condensate return is very similar to distilled water + little bits of your pipes and heat exchangers from that pesky CO2. Hence the

low TDS means high purity.

Test the pH of your condensate return to get and idea of how corrosive it is.

The steam is pure and then condenses and returns to the system.

High purity water can be more corrosive to metals below the water line. hence the treatment is more advanced requires gentle pH correction, metal

passivation, chelation(to remove unwanted metals ions among other things) and oxygen control.

It sounds more like oxygen attack from the description of the tide line corrosion.

You should also find a liquid or tablet that treats your steam side it will be volatile and travel with your steam condensing out at different stages

neutralising the carbonic acid and passivating your metal.

something like this from a quick look (there might be a better home option somewhere)

http://www.accepta.com/water-treatment-chemicals-wastewater-...

When you shut down you should find a treatment for this as well like a slug dose of oxygen scavenger.

plug the leaks and close of the pressure relief when its shut down for the summer.

you could also put an injection fitting in the steam line and dose some treatment in that way like vitamin c analogues and a mild pH adjustment.

This link may be helpful when learning about water treatment of boilers.

http://www.gewater.com/handbook/boiler_water_systems/ch_11_p...

Your tablets appear to be self indicating so once the system is violet you have enough.

once you have steady state of chemical in the boiler add enough tablet to make up then add the water

boil the water before for 10-15mins add the right amount of treatment and dose the boiler

it looks like you can clean your boiler (hence the citric acid mild acid good and dissolving iron oxide and scale) with the tablets as well.

get some a sulphite test kit to see how good the tablets are might be hard considering the violet colour you water will take on.

If you can find a better home treatment to use in conjunction high quality feed water (DI, softened) would be good it wont have as much phosphate in

it as it wont need it to react with the hardness

it can be bad to use hard water treatment on good feed water and vice versa

Over dosing with old technology phosphates can cause foaming.

[Edited on 9-1-2015 by feacetech]

|

|

|

ChrisJ

Harmless

Posts: 33

Registered: 7-1-2015

Member Is Offline

Mood: No Mood

|

|

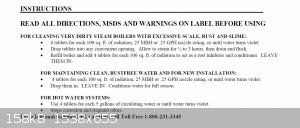

Here are the instructions to the Steamaster tablets.

What's confusing is they say to add four tablets per 100sqft of radiation (I have 392sqft) OR until the water turns violet. They are recommending I

use 16 tablets and yet 1 turns the water a light violet color, 2 turns it a darker violet color.

This is why I'm so curious about the color. What is it and how does it work? Adding more only seems to make it darker.

The pills themselves are blue and stay blue even in water. It's either not until it gets hot, or until it dissolves into the water that the color

changes.

[Edited on 1-9-2015 by ChrisJ]

|

|

|

feacetech

Hazard to Others

Posts: 163

Registered: 12-2-2007

Member Is Offline

Mood: No Mood

|

|

I was just editing my post if you want to reread. By the sound of it go by colour as it appears to be designed for higher output boilers.

when you shut her down for summer slug dose her. Or drain her and pressurise with an inherit gas if you want to be nerdy.

halfway through he winter follow the slug dose cleaning treatment if you are worried about build up.

over dosing can actuality eat your boiler since it contains citric acid as well. nowhere near as much as oxygen though.

Im not sure how the indicator works but it my not be linked to the sulphite which you want to use for oxygen scavenging. Then again it may be. If the

boiler water loses the violet colour you may have to add a little more over time.

this may be a better product they also have one with anti foam surgex

http://www.rectorseal.com/index.php/8-way/

they are not very forthcoming with design of treatment in there PDS i.e. hard, soft or di water

these guys sell home boiler treatment but its looks large scale and expensive you might end up with 2 lifetimes worth of chemical. Its Hard to find

residential boiler treatment products.

http://diyboilertreatment.com/shoppingcart/index.php?main_pa...

[Edited on 9-1-2015 by feacetech]

|

|

|

ChrisJ

Harmless

Posts: 33

Registered: 7-1-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by feacetech  | I was just editing my post if you want to reread. By the sound of it go by colour as it appears to be designed for higher output boilers.

when you shut her down for summer slug dose her. Or drain her and pressurise with an inherit gas if you want to be nerdy.

halfway through he winter follow the slug dose cleaning treatment if you are worried about build up.

over dosing can actuality eat your boiler since it contains citric acid as well. nowhere near as much as oxygen though.

Im not sure how the indicator works but it my not be linked to the sulphite which you want to use for oxygen scavenging. Then again it may be. If the

boiler water loses the violet colour you may have to add a little more over time.

this may be a better product they also have one with anti foam surgex

http://www.rectorseal.com/index.php/8-way/

they are not very forthcoming with design of treatment in there PDS i.e. hard, soft or di water

[Edited on 9-1-2015 by feacetech]

[Edited on 9-1-2015 by feacetech] |

I went back and re-read, thanks!

I just emailed them and I'm hoping for a response this time. All I'm asking them for is how to know when I'm using the proper dose. The thing that

confuses me is all I ever get is light purple, purple, or purpler but what's correct?

You mentioned using a slug dose during the winter for cleaning, and then again for summer storage. But then said too much can eat the metal so I'm a

bit confused by that in regards to summer shutdown. How much is too much at that point?

Again, thank you for such thorough responses. I really appreciate it.

[Edited on 1-9-2015 by ChrisJ]

|

|

|

feacetech

Hazard to Others

Posts: 163

Registered: 12-2-2007

Member Is Offline

Mood: No Mood

|

|

as in under pressure and hot, having an overdose for a long time can eat metal

it wont be so bad when its shut down for summer?

do you drain it for summer? that might be just as good with a little system. as long as you get it nice and dry.

I was just reading the guide the clean is for a short time 3hours.

Try and find a steam treatment or combo water and steam treatment if you are getting corrosion in your steam pipes and valves. Or a non foaming

formula if you cant get the right dose, I guess they are design for normal hard water since they have PO4 in them?

The TDS of your condensate does look good but it may vary during operation i.e. if its been cold the initial slug might be acidic and full of rust.

From CO2 dissolving in the film of water in you steam system.

[Edited on 9-1-2015 by feacetech]

[Edited on 9-1-2015 by feacetech]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Assuming that the Colour is a pH indicator of some kind, grind up a bit of a tablet and dissolve it in water.

Add a small amount of vinegar (= an acid) and see if it changes colour.

Then add some ammonia (=a base) and see if it changes back.

For the Nerdy Air Purge, use an old 5 gallon bottle, a bit of pipe, vinegar & sodium bicarbonate to make a Carbon Dioxide generator.

Remember that humans can't live in a CO2 atmosphere, so take care !

|

|

|

ChrisJ

Harmless

Posts: 33

Registered: 7-1-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by aga  | Assuming that the Colour is a pH indicator of some kind, grind up a bit of a tablet and dissolve it in water.

Add a small amount of vinegar (= an acid) and see if it changes colour.

Then add some ammonia (=a base) and see if it changes back.

For the Nerdy Air Purge, use an old 5 gallon bottle, a bit of pipe, vinegar & sodium bicarbonate to make a Carbon Dioxide generator.

Remember that humans can't live in a CO2 atmosphere, so take care ! |

I'm assuming I could add small amounts to a pot of boiling water until it's violet and then add some vinegar to see if it changes and if so, add more

of a tablet to see if I can bring it back to violet?

|

|

|

feacetech

Hazard to Others

Posts: 163

Registered: 12-2-2007

Member Is Offline

Mood: No Mood

|

|

it could also be linked to a phosphate or sulphite

If its linked to pH there's a good chance that your sulphite levels could drop off over time

Do you have a sulphite test kit/ strips

|

|

|

ChrisJ

Harmless

Posts: 33

Registered: 7-1-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by feacetech  | it could also be linked to a phosphate or sulphite

If its linked to pH there's a good chance that your sulphite levels could drop off over time

Do you have a sulphite test kit/ strips

|

Not yet.

Sounds like I should though?

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Quote: Originally posted by ChrisJ  | | I'm assuming I could add small amounts to a pot of boiling water until it's violet and then add some vinegar to see if it changes and if so, add more

of a tablet to see if I can bring it back to violet? |

Welcome to Chemistry !

Just Experiment with it in small (e.g. 5 g) amounts.

Measure and write down stuff like weight of tablet, temperature of water, how much vinegar, what % it says on the vinegar bottle, and what you see

happen, and when.

Personally i'd start with cold water (room temperature), records the results, then do it all exactly the same way, but with boiling water.

Amazingly enough, that kind of data can be calculated back into an insight into what is actually happening at a chemical level.

Edit:

You will get more mileage using an acid and a base : i.e. vinegar or ammonia.

The 'depth' of the colour isn't as important as the Change in colour from state 1 (nothing added) to state 2 (acid or base added).

An excellent pH indicator for beginners is Red Cabbage juice.

Whizz up some red cabbage, add hot water, wait 10 mins, strain out the purple juice.

Add a few drops to a Base (opposite of an acid) and it goes green.

Do the same to an Acid and it goes pink.

Fresh red cabbage juice goes about 8 different colours depending on pH, and the individual's colour perception.

[Edited on 9-1-2015 by aga]

|

|

|

feacetech

Hazard to Others

Posts: 163

Registered: 12-2-2007

Member Is Offline

Mood: No Mood

|

|

One other thing

does your sight glass have a blow down

you can use that to blow down floating solids since it takes water from higher in the boiler

its important to blow down sight glasses (on larger boilers) as they can become blocked.

shut glass steam valve blow out with bottom valve open

shut bottom blow out with steam open

repeat 2 or three times

it may not have a blow down on the glass as I cant see a third valve

In industrial boilers over time the gage glass can become thin down the bottom from the hot caustic water

Also you might like this

https://www.youtube.com/watch?v=PsSVfAg1kRg

larger fire tube boiler failure at a school

[Edited on 9-1-2015 by feacetech]

|

|

|

ChrisJ

Harmless

Posts: 33

Registered: 7-1-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by feacetech  | One other thing

does your sight glass have a blow down

you can use that to blow down floating solids since it takes water from higher in the boiler

its important to blow down sight glasses (on larger boilers) as they can become blocked.

shut glass steam valve blow out with bottom valve open

shut bottom blow out with steam open

repeat 2 or three times

it may not have a blow down on the glass as I cant see a third valve

In industrial boilers over time the gage glass can become thin down the bottom from the hot caustic water

Also you might like this

https://www.youtube.com/watch?v=PsSVfAg1kRg

larger fire tube boiler failure at a school

[Edited on 9-1-2015 by feacetech] |

The gauge glass used to have a tiny drain you opened using a wrench. I replaced it with a 1/4 turn ball valve.

Also, I have a skim port to remove stuff floating on the surface. The skimmer is the 1 1/2" port with a plug in. I used a brass coupler and brass

plug to ensure I could always get it apart easily.

|

|

|

feacetech

Hazard to Others

Posts: 163

Registered: 12-2-2007

Member Is Offline

Mood: No Mood

|

|

That looks nice, seems like your doing a good job.

I guessing with that valve arrangement you cant do what I said to the sight glass as when you shut the bottom valve you cant purge it with the steam

side?

I would get a sulphite test kit to make sure u keep a sulphite reserve. buy some sulphite or catalysed sulphite extra on the side, if your reserves

drop.

Read about Hydrazine if you can get your hands on some. it has some bad properties but if handled carefully it might make a nice boiler  . .

Normal sulphite I think should be >30 ppm (mg/L) but not too much or its a waste

catalysed sulphite 10-30 ppm

Boil your water for some time before you use it as make up, so you don't add unneeded dissolved gasses. Add just the right amount of treatment and

make up with that.

Find a volatile steam treatment you can add

and keep an eye on condensate returns pH and TDS

You shouldn't need to DI or soften your water if that treatment is for hard water, good feed water and better treatments are superior however.

Where do you work, does your employer have a larger boiler with chemical treatment, make friends with the boiler man. See what they are doing. If its

a decent size I'm sure they could spare a few mils of treatment. You could also look at their test record and see what treatment programme they are

running.

Get a log book keep track of stuff

How much water you add(If you don't do any blow down, constantly add water, and know your system volume you can use this to figure out your cycles

etc) , tests of water (ideally pH, TDS, sulphite, p2 alk, PO4), condensate (pH, TDS if you worried about steam side corrosion) and when you have

flushed and cleaned the system etc. The logs will give you an idea of how long your sulphite is lasting etc. The trouble with an all in one is just

what you notice your sulphite is low, every thing else might be still in the sweet spot so you add more and get every thing too concentrated and it

starts to foam and carry over small amounts of boiler water or worse. With your Product query ask them what the ideal parameters are for your feed

water (soft/hard) max impurities. Ideal boiler water PO4 levels, pH etc.

My guess with a small boiler like that is you wouldn't even need to blow down as annual draining and cleaning should be enough. Do a good job of

cleaning, the sludge in the bottom can set like concrete if left to dry.

On/off seasonal operation isn't great for boilers but that's just the way it is.

Judging by the colour it looks like your tablets a pH indicator http://en.wikipedia.org/wiki/Phenolphthalein

If you add Acid (vinegar, sprits of salt, or H2SO4 drain cleaner) it should go from pink to colourless if its Phenolphthalein.

[Edited on 10-1-2015 by feacetech]

|

|

|

ChrisJ

Harmless

Posts: 33

Registered: 7-1-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by feacetech  | That looks nice, seems like your doing a good job.

I guessing with that valve arrangement you cant do what I said to the sight glass as when you shut the bottom valve you cant purge it with the steam

side?

I would get a sulphite test kit to make sure u keep a sulphite reserve. buy some sulphite or catalysed sulphite extra on the side, if your reserves

drop.

Read about Hydrazine if you can get your hands on some. it has some bad properties but if handled carefully it might make a nice boiler  . .

Normal sulphite I think should be >30 ppm (mg/L) but not too much or its a waste

catalysed sulphite 10-30 ppm

Boil your water for some time before you use it as make up, so you don't add unneeded dissolved gasses. Add just the right amount of treatment and

make up with that.

Find a volatile steam treatment you can add

and keep an eye on condensate returns pH and TDS

You shouldn't need to DI or soften your water if that treatment is for hard water, good feed water and better treatments are superior however.

Where do you work, does your employer have a larger boiler with chemical treatment, make friends with the boiler man. See what they are doing. If its

a decent size I'm sure they could spare a few mils of treatment. You could also look at their test record and see what treatment programme they are

running.

Get a log book keep track of stuff

How much water you add(If you don't do any blow down, constantly add water, and know your system volume you can use this to figure out your cycles

etc) , tests of water (ideally pH, TDS, sulphite, p2 alk, PO4), condensate (pH, TDS if you worried about steam side corrosion) and when you have

flushed and cleaned the system etc. The logs will give you an idea of how long your sulphite is lasting etc. The trouble with an all in one is just

what you notice your sulphite is low, every thing else might be still in the sweet spot so you add more and get every thing too concentrated and it

starts to foam and carry over small amounts of boiler water or worse. With your Product query ask them what the ideal parameters are for your feed

water (soft/hard) max impurities. Ideal boiler water PO4 levels, pH etc.

My guess with a small boiler like that is you wouldn't even need to blow down as annual draining and cleaning should be enough. Do a good job of

cleaning, the sludge in the bottom can set like concrete if left to dry.

On/off seasonal operation isn't great for boilers but that's just the way it is.

[Edited on 10-1-2015 by feacetech] |

Sadly, nothing at work but forced hot air.

I find your comment about sulfite interesting. Another water treatment company, Rhomar makes products for steam boilers. They have an all in one

product as well and from what I recall, the main thing they recommend is testing sulfite levels.

What does sulfite do in a boiler and where is mine currently coming from?

[Edited on 1-10-2015 by ChrisJ]

|

|

|

ChrisJ

Harmless

Posts: 33

Registered: 7-1-2015

Member Is Offline

Mood: No Mood

|

|

Here is a PDF to Rhomar's 903 boiler treatment.

To me, their instructions look far more professional and it just seems like it's probably a better product. The problem is the cost and trying to

find a place to buy it.

http://www.rhomarwater.com/media/W-903.pdf

|

|

|

feacetech

Hazard to Others

Posts: 163

Registered: 12-2-2007

Member Is Offline

Mood: No Mood

|

|

You have sulphite in you tablets

it is acting as an oxygen scavenger, it reacts with oxygen to form sulphate.

2 Na2SO3 + O2 → 2 Na2SO4

info about oxygen scavengers

http://www.subsport.eu/wp-content/uploads/2012/05/alternativ...

These foreign MSDS sheets cant see what's in the product lucky everything in NZ is more hazardous so it has to be listed :p

[Edited on 10-1-2015 by feacetech]

|

|

|

ChrisJ

Harmless

Posts: 33

Registered: 7-1-2015

Member Is Offline

Mood: No Mood

|

|

Ah, interesting!

However, sodium sulphite isn't in the MSDS to these tablets?

1: Sodium Nitrite. % by weight 44.04

2: Sodium Triphosphate % by weight 23.52

3: Sodium Metasilicate % by weight 1.34

4: Citric Acid. % by weight 3.36

It looks like I can buy 5 pounds of it pretty cheap though.

Is this the stuff?

http://www.amazon.com/Photographers-Formulary-10-1341-Sodium...

|

|

|

feacetech

Hazard to Others

Posts: 163

Registered: 12-2-2007

Member Is Offline

Mood: No Mood

|

|

Typical hard water treatment programmes have 4 parts

Phosphate/phosphonate treatment

precipitate Mg and Ca Carbonates as serpentine sludge, Carbonates form a concretion layer on the hot surfaces as stated earlier they have retro grade

solubility (this is unusual as normally most solids are more soluble in hot water) so when that cold water gets heated at the metal water interface

they precipitate out forming and insulating layer over you heating surfaces reducing thermal conductivity and cause something called under deposit

corrosion.

caustic (NaOH)

Keeps system alkaline, helps other chemical reactions (can help with magnetite formation), keeps silica volatile (silica is tetrahedral in nature so

forms hard coatings sort of like diamond these are not acid soluble and only dissolve in hot caustic slowly)

Dispersant/polymer

keeps the sludge's you make mobile and flowing so when you blow down they leave the system

Oxygen scavenger

remove dissolved oxygen to help prevent corrosion, some also encourage magnetite formation the like the vitamin c analogue erythorbate (Vitamin C is

an anti oxidant)

The extra part that you are missing is steam treatment

Typically a filming or volatile amine often a special blend, these travel through the steam system condensing out at different stages and reacting

with any acidic condensate (from CO2 as you mentioned earlier)

Some of the other treatments on high purity water use chelation as well/instead of

The word chelation is derived from Greek χηλή, chēlē, meaning "claw"; the ligands lie around the central atom like the claws of a lobster

Ligand could be described as a positive seeking entity with a non bonding electron pair

Basically chelation involves encapsulating on a molecular level the positive ions in solution like a claw grabbing something.

EDTA would be your stereotype chelating agent and coincidently (well not really) is used as the titrating agent in the Mg and total harness testing.

The edta binds to the Ca and Mg removing them from the indicator and changing colour once all is consumed

If chelation treatment is done wrong in a high pressure water tube system they can rapidly eat the metals and the protective coatings.

[Edited on 10-1-2015 by feacetech]

|

|

|

feacetech

Hazard to Others

Posts: 163

Registered: 12-2-2007

Member Is Offline

Mood: No Mood

|

|

However, sodium sulphite isn't in the MSDS to these tablets?

1: Sodium Nitrite. % by weight 44.04

2: Sodium Triphosphate % by weight 23.52

3: Sodium Metasilicate % by weight 1.34

4: Citric Acid. % by weight 3.36

Opps my bad you have nitrite scavenger theses are typically used in hot water closed loop system in the industrial setting

Basically works the same way Nitrite to Nitrate, however there must be a reason these are not typically used in higher pressure industrial steam

boilers.

however its a better at metal passivation than oxygen scavenging

In closed cold water loops bacteria can get the nitrite and make nitric acid which will then lower the pH and eat the metal

You can get nitrite test strips too.

http://www.accepta.com/water-treatment-chemicals-wastewater-...

that might explain why you have nitrite instead of sulphite

[Edited on 10-1-2015 by feacetech]

|

|

|

ChrisJ

Harmless

Posts: 33

Registered: 7-1-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by feacetech  |

However, sodium sulphite isn't in the MSDS to these tablets?

1: Sodium Nitrite. % by weight 44.04

2: Sodium Triphosphate % by weight 23.52

3: Sodium Metasilicate % by weight 1.34

4: Citric Acid. % by weight 3.36

Opps my bad you have nitrite scavenger theses are typically used in hot water closed loop system in the industrial setting

Basically works the same way Nitrite to Nitrate, however there must be a reason these are not typically used in higher pressure industrial steam

boilers.

You can get nitrite test strips too.

http://www.accepta.com/water-treatment-chemicals-wastewater-...

that might explain why you have nitrite instead of sulfite

[Edited on 10-1-2015 by feacetech]

[Edited on 10-1-2015 by feacetech] |

Ah ok.

I also should have mentioned, my boiler has rubber gaskets between the sections so anything that can harm rubber is out of the question.

Many have steel push nipples, but Weil-McLain has always used gaskets. When I bought the boiler I had found most if not all home steam boilers failed

from rotting and practically none failed from gaskets leaking so I didn't really care about the steel push nipples "feature" some brands brag about.

However, I think it is a concern when it comes to using treatment. The Steamaster tablets say they are safe, so I went ahead and started using them.

Will buy some nitrite testing strips.

|

|

|

feacetech

Hazard to Others

Posts: 163

Registered: 12-2-2007

Member Is Offline

Mood: No Mood

|

|

you could get the sulphite as well for good measure

Just be aware it will lift TDS in the form of sulphates

it wont be as good as catalysed sulphite but you can add it to any treatment

Then you'll get passivation and two forms of oxygen scavenger.

[Edited on 10-1-2015 by feacetech]

|

|

|

ChrisJ

Harmless

Posts: 33

Registered: 7-1-2015

Member Is Offline

Mood: No Mood

|

|

What levels of nitrite am I likely testing for?

Also, is there any chance the violet color is actually showing nitrite levels? If so, is there any test I can do to confirm it?

|

|

|

feacetech

Hazard to Others

Posts: 163

Registered: 12-2-2007

Member Is Offline

Mood: No Mood

|

|

do the pH test first its most likely a pH indicator

off the top of my head im not sure what level of nitrite is good I think it was higher than sulphite

I think cold water I use to look for 50-100 don't quote that though

you will have to query from the manufacturer a quick look on the net gave me all sorts of answers one was 1000ppm but sometime these guys want you to

use more than you need

http://www.nucalgon.com/assets/prodlit/3-87.pdf

[Edited on 10-1-2015 by feacetech]

|

|

|

ChrisJ

Harmless

Posts: 33

Registered: 7-1-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by feacetech  | do the pH test first its most likely a pH indicator

off the top of my head im not sure what level of nitrite is good I think it was higher than sulphite

I think cold water I use to look for 50-100 don't quote that though

you will have to query from the manufacturer a quick look on the net gave me all sorts of answers one was 1000ppm but sometime these guys want you to

use more than you need

http://www.nucalgon.com/assets/prodlit/3-87.pdf

[Edited on 10-1-2015 by feacetech] |

Can I use baking soda instead of Ammonia? I have vinegar and baking soda on hand and can do the test right now.

I'm assuming I should use vinegar and not bleach?

|

|

|

ChrisJ

Harmless

Posts: 33

Registered: 7-1-2015

Member Is Offline

Mood: No Mood

|

|

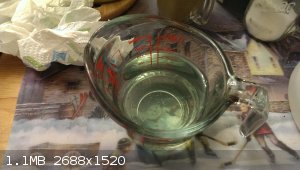

Ok so I took a small bit of water I had left over from when I did some maintenance.

The dose didn't seem very high because the color was faint but I figured it was good enough for now.

As soon as I added white vinegar it turned a pale blue color. The issue is I may have added too much vinegar, or, baking soda is not the right

choice.

Right now all I have is cloudy blue water, can't get the violet back. I have plenty more water on hand to do further testing.

|

|

|

| Pages:

1

2

3 |