| Pages:

1

2

3 |

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Simply washing with water several times should remove most impurities other that the carbon/graphite.

I believe KNO3 melts a bit lower than KClO3, but either should oxidise then carbon away. The nitrate will contribute alkali to the mix, chlorate just

chloride. But enough of either can be used to oxidise the carbon.

It is important to remember that the chemistry in molten hydroxide at >300C is much different than happens in aqueous solutions at 100 C. For many

D block elements higher temperatures, to a point, increase the relative stability of the higher oxidation states. You see this in ceramic glazes,

MnCO3 gives dark red Mn(III), black MnO2, and under some conditions what may be even higher oxidation states.

Good exposure to air is needed, except in the thinnest layers some stirring is needed. In the similar process for producing cromates from Cr2O3, a

mixture of alkali hydroxide or carbonate and lime - Ca(OH)2 - was used; the lime mostly serving to give a porous mass that increased the surface

exposed to air.

One reason you see KMnO4 used so much more than NaMnO4 is that the sodium salt is hard to crystallise, because of its high solubility and maybe

because it's just contrary. For many applications you want to control impurities, easily meter the amount of oxidiser by simply weighing it, or just

to be able to keep a jar of it onthe shelf. All MnO4- salts are unstable in water, the decomposition to MnO2 is slow for KMnO4 but it does happen. So

you want the dry salt for long term storage.

For some applications you just want the strong oxidiser, the sodium salt may be better because its high solubility means you don't have to move so

much solution. So long as you sell the stuff pretty quickly, the stability shouldn't be an issue. (OK, you're having problems, I talking about the

industrial manufacturers)

There are several manufacturers listed here

http://www.powersourcing.com/se/sodiumpermanganate.htm

Interestingly the US DEA wants to put NaMnO4 onto the Class II list. The USA sure seems to be interesting in slitting its own throat.

|

|

|

Cesium Fluoride

Harmless

Posts: 48

Registered: 26-1-2005

Member Is Offline

Mood: Cupric

|

|

Thanks for that information not_important.

I'm not sure, but I think KClO3 decomposes into oxygen before it melts. Also, I am working at just above 330C (well below red heat). Does KClO3/KNO3

readily oxidize carbon at this low of a temperature?

My layers have been thin (next time I'll measure actually how thin) and I do stirr occasionally. I will try another trial in a couple of hours. This

time I will use 10g MnO2/graphite, 10g NaOH, and 5g KClO3. I will thoroughly wash the MnO2/graphite with water as suggested and I'll use my slightly

more powerful hot plate and keep the reaction going for 8 hours instead of 2.

I found an industrial process that uses NaOH/MnO2 and no mention of problems so this should be possible! I guess my problems are a) impurities and b)

a low yield.

Can somebody give a valid explanation of why I get a red color instead of purple when I increase the acidity of my MnO4-2 solution? This occurs even

when there are K+ ions floating around in solution.

Thanks guys for all your help. You have inspired me to keep on trying!

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

The only red Mn I know is somewhere around Mn(III), which can be seen in a strong acid solution. I have a solution sitting in my lab which is deep

burgundy red. It hydrolyzes very readily.

KClO3 melts at a rather high temperature, but I could see if KClO3 + charcoal (note: not graphite) ignites on top of freezing lead.

I don't know how fast graphite oxidizes. It should be completely stable in solution (against MnO4 I don't know), and it doesn't usually oxidize

appreciably in air until a good glowing redness. I don't know what an oxidizing melt would do to it, especially if it has capacity to absorb CO2.

Tim

|

|

|

Cesium Fluoride

Harmless

Posts: 48

Registered: 26-1-2005

Member Is Offline

Mood: Cupric

|

|

Ok, I aborted my trial today after 30 minutes of strong heating. I washed my MnO2/graphite and noticed that there was some silvery impurity (zinc I

suppose) which floated around. I removed this and since my <10g MnO2/C was very wet I dissolved my KClO3 (5g) and NaOH (10g) along with it. I

boiled my solution down to dryness. I figured this would ensure an intimate mix of the reactants. As my mix was boiling the last bits of water away, a

light green color appeared on the top of the mix. Some manganate seemed to form even before the NaOH was molten, which is odd. I then transfered my

container to a more powerful hot plate (which I previously had not used), and within minutes part of the mix started to burn! I guess this was the

KClO3 oxidizing the C? Pieces of the mix would glow red and then smoke a bit. At this point, the top of the mix was grey and was no longer green.

After 30 minutes of heating, it was still grey and I thought that the trial was a failure. I cooled the mix down and added water for disposal, but

then I noticed the water turned dark green! I did not even extract with boiling water because at this point the mix was half way down the drain, but I

added vinegar and I got the familiar red color. This time the solution seemed a little more stable. I separated the solution in two containers and

boiled one. It mangaed to stay red for longer than any other similiar solution I've worked with, but it soon turned brown. To the other half, I added

some KCl in an effort to increase K+ concentration, but upon doing so the mix immediately turned brown. I then remembered that my KCl

is only about 96% pure (or so I had calculated from the nutrition facts of a salt subsitute). I looked at the other ingredients and one of the

impurities is fumaric acid! My MnO4- surely had oxidized across fumaric acid's double bond. I make my KClO3 from this KCl source so any mix that I use

KClO3 with is going to be contaminated with fumaric acid. Hence, the instability of my solution. This, however, still does not explain the instability

of my solution that is formed with only NaOH and MnO2.

I guess I will try another trial- this time with washed MnO2, NaOH, and KNO3. I only have 3g of KClO3 left and I don't really feel like purifying

it/making some more pure KClO3 just yet. I think that using water to ensure an intimate mix of the reactants and the more powerful heat source helped.

It is odd, however, that I did not see the mix turn green on the surface.

I still do not understand why my solution is red. The burgundy color you describe Tim is precisely what I have when I add an acid. This is a guess of

what may be happening.

MnO4-2 (green) + H+ --> MnO2 + MnO4- (purple)

but immediately some impurity (in this trial, fumaric acid) partially reduces the MnO4-

MnO4- --> Mn(III) (red) + CO2?

Could this explain the gas formation?

[Edited on 19-8-2006 by Cesium Fluoride]

Edit: I have read that acidified MnO4- oxidizes and cleaves alkenes to a carboxylic acid and a ketone. But in the case of fumaric acid (2-butenedioic

acid), you have two carboxylic groups as well. How would this affect oxidation?

[Edited on 19-8-2006 by Cesium Fluoride]

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Better question- why is what little fumaric acid present causing the whole thing to reduce?

Is there any likely catalyst that causes MnO4 to break down to O2? H2O2 aside.

Tim

|

|

|

Cesium Fluoride

Harmless

Posts: 48

Registered: 26-1-2005

Member Is Offline

Mood: Cupric

|

|

My thinking is that my yields are so low that the fumaric acid is able to cause the whole thing to reduce. I am firing up another reaction now and

expect better yields. Will post results in 3-4 hours.

Did some more research and found some more stuff about the Na2MnO4 decomposing. Still don't understand it though; if I have a potassium salt in the

melt I should have K2MnO4. Furthermore, there should just be MnO4-2 ions in solution that aren't particularly attached to any one cation.

“Sodium manganate, Na2MnO4, is formed when a mixture of equal parts of manganese dioxide and soda-saltpetre is heated for sixteen hours; the mass is

then lixiviate with a small quantity of water and the solution cooled down, when the salt separates out in small crystals isomorphous with Glauber’s

salt, and having the composition Na2MnO4 + 10H2O. These dissolve in water with partial decomposition, yielding a green solution.”

A similiar description of K2MnO4 is given, but nothing is mention of partial decomposition.

Edit: I admit the fumaric acid explanation is not entirely adequate, but it does explain what happen when I added KCl to solution.

[Edited on 20-8-2006 by Cesium Fluoride]

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Consider that you

1) did a more thorough washing, and saw some crud separate

2) saw a distinct oxidation during the heating, suggesting carbon being oxidised.

3) use a potassium source that included a decent reducing agent.

If what you removed in 1 and 2 were busy reducing the manganese in higher oxidation status in your fusion mix, you might have been having very low

yields of manganate; low enough that small amounts of reducing substances could overwhelm your desired product.

It sounds as if you are doing everything correctly, so it likely is a problem with unwanted reducing agents. Long ago I tried to make KMnO4, and had

better luck than you. But I was using MnO2 made from the remains of chlorine generation, and fertiliser KCl.

Adding a potassium based oxidiser may cause some KMnO4 to crystalise out, but you need enough K(+) and MnO4(-) to exceed the solubility products for

KMnO4 else it's just ions, as you said.

Permanganate will at first convert one of the double bonds into a pair of hydroxyl groups, giving a diol. That is then further oxidised with breaking

of the remaining C-C bond, to give a pair of carbonyl oxygens; depending on the structure around the original double bond those will be ketone or

aldehyde oxygens, aldehydes generally get quickly oxidised to carboxylic acids.

So in the case of fumaric acid you create two carboxylic acids groups, each being one half of an oxalic acid molecule; one fumaric => two oxalic

and the oxalic is further oxidised to H2O and CO2

C4H4O4 + 6[O] => 4CO2 + 2H2O

plug KMnO4 => K(+) + MnO2 + 2[O] into the above and you can see why that 4% might be causing problems for you.

|

|

|

Cesium Fluoride

Harmless

Posts: 48

Registered: 26-1-2005

Member Is Offline

Mood: Cupric

|

|

not_important, with your help and that of others I think I may be close to figuring this whole thing out. I suppose it is safe to assume that the gas

formed was indeed CO2. Thanks for that explanation.

| Quote: | | If what you removed in 1 and 2 were busy reducing the manganese in higher oxidation status in your fusion mix, you might have been having very low

yields of manganate; low enough that small amounts of reducing substances could overwhelm your desired product. |

Precisely, what I'm thinking.

| Quote: | | Long ago I tried to make KMnO4, and had better luck than you. But I was using MnO2 made from the remains of chlorine generation, and fertiliser KCl.

|

I'm curious. Were you using NaOH and did you get a purple solution upon acidification? And you used the KCl to make KClO3 or added it to the NaMnO4

solution?

I have another brand of KCl salt substitute here in front of me. Its impurities are <1% cream of tartar (potassium bitartrate), silicon dioxide,

and natural flavor. Silicon dioxide shouldn't be too problematic as it'll just react to form silicates. It looks to me as if the hydroxyl groups on

the bitartrate ion wold be easily oxidized by MnO4-, however. I suppose I could easily purify both brands of KCl by fractionally crystallizing the

fumaric acid/potassium bitartrate out as they are both almost insoluble in water.

I think if I properly purify my reagents I should be able to get the desired purple solution. I would have never guessed that impurities would be so

problematic  . .

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

I reproduced the reactions this evening.

I put eyeballed amounts of NaOH and MnO2 (pottery grade) into a steel crucible (with some zinc still brazed in that I was too lazy to dissolve out).

I heated the crucible with my induction heater, so open air, no CO2 or H2O besides what's in the basement. The NaOH melted uneventfully (if a bit

sticky at first, from the humidity). Adding MnO2 immediately produced bubbling as it was wetted (CO2? H2O?), and the sludge turned dark forest green

and reached a thick consistency. No further change was observed, though bubbling continued, especially when heated further (I have only guesses at

the temperature).

The second attempt was identical (give or take), but I added KCl to the mixture. It didn't dissolve well, and the final (molten) product had lumps at

the bottom.

Both materials dissolve in water to give a green solution which hydrolyzes easily, ultimately producing abundant brown sludge (MnOOH or whatever). A

sample of the green solution, acidified with H2SO4 (~20%) immediately turns to pink or red, and hydrolyzes. The color is indeed very similar to my

strong acid solution of Mn(III). HCl added to this solution causes the color to turn yellow, then mostly colorless (it was a weak solution), and

brings the odor of chlorine.

Both solutions are still sitting, I'll check them tomorrow.

It is worthy of note that I have the same potential impurity: zinc. In addition, my stir stick was copper plated graphite, and I think some of the

copper dissolved, causing the melt to occasionally produce blue coloration on creep surfaces (e.g., over the crucible's rim). Also, when the fusion

was cooled, breathing on the product (while still reasonably hot) produced a chalky blue surface in spots. I'm guessing this is from sodium cuprate

of some description.

I would like to know if these reactions can be approached from the other side; does a KMnO4 solution decompose when Na ions are present in a basic

solution of MnO4(2-)? Does zinc catalyze decomposition? Graphite powder? Copper? Iron?

Tim

[Edited on 8-20-2006 by 12AX7]

|

|

|

Cesium Fluoride

Harmless

Posts: 48

Registered: 26-1-2005

Member Is Offline

Mood: Cupric

|

|

Tim, thank you for proving I am not crazy- I appreciate it! All of what you describe sounds identicle to what I observed. I once quickly filtered some

of the red solution and stuck it in the freezer. I checked two hours later and it was completely brown.

Aside from perhaps focussing on ridding of the zinc impurity, I don't really know where to go from here. Do you think that there is something

inherently problematic about using NaOH instead of KOH? This logic makes no sense to me though.

Also, I actually may have seen some of that blue stuff in one of my trials and I don't think I had any copper around. It was a very small amount and

was only concentrated in one small section of the melt atop of intensely colored green area.

In the library here, I found this info about NaMnO4 (Condy's liquid) being produced industrially.

"The substance [sodium permanganate] is obtained by mixing the caustic soda obtained from 1,500 kilos of soda-ash with 350 kilos of finely-divided

manganese dioxide in a flat vessel, and heating this mixture for forty-eight hours to dull redness. The product is then lixiviated with water, and the

solution either boiled to the requisite degree of strength or evaporated to dryness. If the manganate is to be completely converted into permanganate

it is neutralized with sulfuric acid, the solution concentrated until Glauber’s salt separates out, and these crystals are then removed and the

liquid further evaporated."

Edit:

| Quote: | | I would like to know if these reactions can be approached from the other side; does a KMnO4 solution decompose when Na ions are present in a basic

solution of MnO4(2-)? Does zinc catalyze decomposition? Graphite powder? Copper? Iron? |

This is an ingenious idea! I hope somebody can try this out, but unfortunately I don't have KMnO4 (that's why I'm trying to make it) Four different

Sears in my area and the local hardware stores don't have it.

[Edited on 20-8-2006 by Cesium Fluoride]

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Or just roast either KCl source in the open air, up to where it is just starting to glow dark red if you can reach that; stirring a bit. Should break

up any organic and the air will take it to CO2 and H2O.

I just used KCl as a source of potassium, plain NaOH + MnO2 for the roast. I rigged a small pan with a 'propeller' stirring bar, using a battered

boys' construction kit, so the mix was constantly being churned. I think it took about 15 seconds to do a revolution, which is much faster than

needed.

Dissolved in hot water, added KCl, then bubbled CO2 from dry ice through it for some time. It was sitting on a warming tray, designed to keep cooked

foods warm, used to pick them up for next to nothing at second hand stores. But it wasn't hot, around 40 to 45 C, and got that nice permanganate

purple when a bit was squirted into a test tube and let stand so the MnO2 would settle. Finally filtered, stoppered the filter flask and put it on

the warming tray, kept the vacuum going to quick concentrate until I thought I saw crystals, poured into a small beaker and let cool.

It was a lot of work, needed some scale up design. I did one more run to verify that using crude MnO(OH) from mixing hot MnCl2 solution with Ca(OH)2

and blowing air through the hot mix, would work in place of MnO2. Used NaOH + Na2CO3, didn't get hot enough to decompose CaCO3 so it came out with the

MnO2.

About the I ran into a description of the electrolytic process to replace the acidification stage, you get a lot less MnO2 formed. That put things on

hold until I could find out more about the electrolytic process, and then I found a fairly cheap source of the commercial product - water treatment -

so there wasn't a need to make my own.

If I was going to try it again, I would go for making a rotary klin out of a longish piece of iron pipe and a portable cooking grill, some extra

piping to preheat air being blown into the pipe. A motor and gearing/belts to slowly rotate the pipe to stir the mix. Big enough to run at least a kg

at a time. And the electrolytic route from manganate to permanganate.

Consider how difficult making hydrazine can be, impurities can be a real problem. Or put a tiny bit of cobalt oxide into H2O2.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

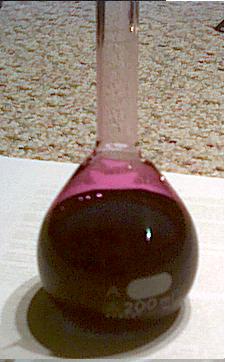

OoooooooOOOoooooooo...

Don't ask me how exactly I got this... I just did. LOL

This was from the second solution, the one with (at least some) potassium.

The first solution, which I idly added a little spare acid to last night, is fully hydrolyzed. The liquor is a little yellowish, and I think very

basic. Lots of brown sludge.

The solution with potassium is still dark green to blue, though containing ample sludge.

Both solutions sat out overnight, so have absorbed CO2, and who knows what else.

I took some of the potassium solution and added a mild acid, carbonic acid. Hey, we have club soda in the house! w00t! Not much effect besides

dilution (even with a large amount of soda, a small solution remained greeney/bluey), so I then added drops of diluted H2SO4. After enough addition,

it turned pink and became efforvescent -- probably CO2. (In the RBF, I tested the gas with a match and it extiguished it; most likely CO2, not O2

loss.) The strongly basic solution ought to have absorbed CO2, after all. The smell was sort of musty, like wet rock.

I added acid until a floc precipitated. The solution looked depressingly red, but tantalizingly it also looked purple around the meniscus. So I set

the flask down, and as the floc settled I discovered what is shown in the above photo.

So, I don't really know -- dilution perhaps? CO2? Something in the club soda? (Shouldn't be anything other than H2O and CO2, eh?)

I'll try this somewhat more controlled...like measuring things for instance.

Tim

|

|

|

Cesium Fluoride

Harmless

Posts: 48

Registered: 26-1-2005

Member Is Offline

Mood: Cupric

|

|

Wow, I am SOOO jealous! This second batch that worked- you waited a day before you added the acid to what was a green mixture? Odd that the first

mixture completely reduced and the second one did not.

|

|

|

woelen

Super Administrator

Posts: 8012

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

I don't want to disappoint you guys, but how much starting material did you have? If I look at that RBF, then I can only say that this is a VERY VERY

dilute solution of KMnO4, most likely less than 0.01% by weight. KMnO4 has an increadibly strong color, and even a tiny crystal of 1 mm size makes a

whole liter of water almost opaque, so the yield of your experiments is very low I expect. But anyways, you made some KMnO4 and you might be able to

optimize the procedure to get a better yield.

|

|

|

Cesium Fluoride

Harmless

Posts: 48

Registered: 26-1-2005

Member Is Offline

Mood: Cupric

|

|

I was doing some more experimenting today and though what the heck I am just going to try adding some oxidizers to this Na2MnO4 solution. I first

added some 3% H2O2 to the green solution and I got a slightly yellow liquid with MnO2 precipitate at the bottom and lots of gas given off. I added

some vinegar to another batch and got the old red solution. To this I added H2O2, and it turned colorless (I couldn't see any pink but presumably

these were Mn+2 ions).

Then I tried bleach. I added lots (didn't measure) of bleach to another green solution of Na2MnO4 and no color change was observed. I then added some

vinegar to this and it turned purple!

purple

Woelen, a little more concentrated, no?

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

I've got better results now, by fusing the reaction:

2NaOH + 2KCl + MnO2 (+ O) = 2NaCl + K2MnO4 + H2O

-- Presumably. I don't know if potassium or sodium manganate is preferred. XRD of the glom could probably figure it out...

The stoichiometric mixture (17.5g KCl, 20g NaOH, 22.5g MnO2) reacted at about the melting point of NaOH, forming a solid mass. I continued heating

and it fully melted (to about half the solid volume) around the melting point of KCl (also around the curie temp of the steel crucible, about

1400-1500°F) to a black, slightly greenish mess. This dissolved to a green solution, with much hydrolysis.

Interestingly, the green solution hydrolyzes in large volumes of water to a weak purple color (which is what, ppm MnO4?).

I took some of the solution, at any concentration, and acidified it until purple. After settling the MnOx out, I put the solutions together and

evaporated it. The solution is currently cooling in the 'fridge, a deep purple color but I'm not sure just how deep it is. For sure, I've lost a

*lot* of manganese from hydrolysis. Damn its strong color!

I may try weighing the fused crud and adding it to a stoichiometric acid solution. Not sure what the excess of acid is going to do, though...

probably oxidize the chloride present...

Bleach, huh? That's a possibility

Tim

|

|

|

Cesium Fluoride

Harmless

Posts: 48

Registered: 26-1-2005

Member Is Offline

Mood: Cupric

|

|

With those high temperatures, I expect you should get some pretty nice yields. I left this last reaction going for 6 hours, but at only 370C, I can't

hope for much. I have read that if you add enough water to Na2MnO4 it dispropotionates because in such dilute concentrations the pH is lowered enough

for the conversion to occur. I made a larger purple solution now and I added some KNO3 and am currently boiling it down. I have so many ions in

solution- acetate, sulfate, hypochlorite/chlorate, chloride, nitrate, etc. that I'm not sure if I'll be able to get KMnO4 to crystallize out. The

color is a deep purple but I have no idea of its concentration. There isn't too much MnO2 crud on the bottom (I filtered it), but probably more will

form during boiling.

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

I figured I would join the permanganate party

8g KOH and 3g KClO3 were melted in a metal crucible(either SS or nickel, not sure, acquired by dumpster diving) in an electric furnace. When it

melted I slowly spooned in 5g MnO2 while stirring with a graphite rod. As more and more was spooned in the mix solidifed to a green mass. The

heating was continued for 15 min. I thought the crucible was reacting at one point because the mix was a faint red and no longer green, but then I

relaized I just had the heat too high and the crucible was glowing red. It was around this time I realized the crucible was stuck in the furnace

hole. I did not bother to wait for the mix to cool, I just dumped 150mL H2O into the crucible after turning off the furnace, not ideal, but it was

getting late. Made a minor mess, very little lost. I then boiled the deep green solution while adding some dry ice lumps to it. Two lumps of dry

ice added and the solution was completly turned to very very dark purple. Filtered through a glass filter, MnO2 was collected.

Procedure based off Walton's Inorganic Preparations, I was too lazy to bother filtering once before adding dry ice though. Might isolate it

tomorrow, but boiling a concentrated highly coloured staining solution is not my idea of a good time.

[Edited on 22-8-2006 by rogue chemist]

|

|

|

guy

National Hazard

Posts: 982

Registered: 14-4-2004

Location: California, USA

Member Is Offline

Mood: Catalytic!

|

|

Using CO2 to acidify may result in purer solutions because bicarbonate is relatively insoluble in high concentrations and in cold water.

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

Forgot the picture

|

|

|

woelen

Super Administrator

Posts: 8012

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

| Quote: | | Woelen, a little more concentrated, no? |

It is more concentrated, butI still can look through it. Solutions of KMnO4 must be totally opaque, even a few mm of it, otherwise you will have a

solution of no more than a few hundreds of percent only. The color of KMnO4 is REALLY strong.

Rogue chemist, your picture looks more promising. It is really dark and also along the glass, a thin layer still looks quite purple. It is sad that

your prep requires more exotic stuff. Dry ice is not something most people have at their home and the use of KClO3 also is a drawback, but the latter

can be made by means of an electrolysis cell, so that is less of a concern.

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

The use of dry ice can be replaced by bubbling in CO2 from the standard baking soda and vinigar reaction.

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

In North America, dry ice is available at many supermarkets and elsewhere for much less cost than making the same amount of CO2 from a cheap carbonate

and acid. In other areas this site http://www.dryicedirectory.com/ might help you find a retailer by asking a listed wholesaler.

CO2 has the advantage that the mother liquer after crystallisation of KMnO4 may be reused as part of the alkali for the next batch. At the low red

heat of the roasting process, the Na/K carbonate will react as the hydroxide does with MnO4 or MnO(OH).

The use of chlorate is simply a speed-up device. When I ran this, I leave it roasting for 4 or 5 hours with mechanical stirring going. Many of the

industrial process documents roast for much longer than that, but they are using thicker layers.

|

|

|

Cesium Fluoride

Harmless

Posts: 48

Registered: 26-1-2005

Member Is Offline

Mood: Cupric

|

|

Nice job, rogue chemist!

Woelen: I have a feeling that the temperature of the reaction helps improve yields more than the means of acidification.

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

Actually, as I have been messing around with this reaction a bit tonight without oxidizer in the mix, it seems time is more important than

temperature.

Do not add all the MnO2 at once, at it little by little, stirring the melt for quite some time until it is pure green after each addition. I have

noticed that after adding a lump of MnO2 the size of a BB to the molten KOH that the melt darkens, and then after a time of stirring, then lightens to

the origional green. Adding all the MnO2 at once produces a paste that is grey and almost solid. If this putty is blown on, it darkens on the

surface to green. Kneeding this putty with the stirrod causes it to reveal gery areas of unreacted MnO2 which slowly react with oxygen in the air

turning green, unfortunatly just on the surface.

As it took me over an hour to add 1g(out of 5g) to the molten KOH while assuring it had all reacted before adding more, doing this reaction without

oxidizer present seems a waste of time. After an hour and a half I simply was out of patience and dumped the MnO2 in, causing a mess of solidifing

putty, which in my opinion can be ground and reheated as many times as you want, but which will never equell a good dissolved oxidizer or slow

addition.

The literature says to add the MnO2 to the molten KOH and chlorate right after it melts for good reason, as this is when the chlorate will be

decomposing into oxygen, so it is beneficial to make sure you have the MnO2 and oxygen in the same place to get the manganate.

If you are wanting to pursue this reaction without extraneous oxidizer I cannot stress enough to add the MnO2 slowly making sure it is all reacted

before adding the next portion.

|

|

|

| Pages:

1

2

3 |