| Pages:

1

2 |

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

So, refluxing the EtOAc with say 50 % NaOH, followed by fractioning off the EtOH azeotrope? Sound like a route to fairly pure EtOH I've never

considered.

[Edited on 22-11-2014 by blogfast25]

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Quote: Originally posted by blogfast25  | | So you reflux the ester straight over pure NaOH? No water whatsoever? If so, is it practical to distil off the EtOH while hydrolysis in on-going

|

Does not the thread title "ethyl acetate hydrolysis" and my own word "concentration" imply water...so I didn't put an "aq." before NaOH...

There's probably an ester hydrolysis in whichever lab manual; there happens to be one in Systematic Organic Chemistry that works.

|

|

|

Dronami_inc

Harmless

Posts: 13

Registered: 10-2-2011

Member Is Offline

Mood: No Mood

|

|

elegant solution

If I understand properly, author used solid NaOH (not a solution)?

If so, obtained ethanol and acid are almost completely waterless. Please correct me if this is not so.

...I skiped this topic by accident and created a new thread https://www.sciencemadness.org/whisper/viewthread.php?tid=47958 where i'am interested in obtaining both anhydrous ethanol and

glacial acetic acid, but probably using gas phase hydrolysis with catalyst. How can it be implemented? i.e. without NaOH involved

|

|

|

Dronami_inc

Harmless

Posts: 13

Registered: 10-2-2011

Member Is Offline

Mood: No Mood

|

|

Thanks for all, the question A is still on the agenda

Bert, I took your suggestion and continued that branch

By the way, how do you think, what impurities other than water contained in technical EtAc?

|

|

|

Bert

|

Threads Merged

22-11-2014 at 16:18 |

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

It's probably not possible.

|

|

|

CaptainPike

Hazard to Self

Posts: 68

Registered: 21-12-2012

Member Is Offline

Mood: No Mood

|

|

Neat and Cheap – EtOH, GAA!?

Okay, I'll probably appear to be cocky,this is not my intent, but could this thing be as perfect as it seems? I'm new at this stuff, so I need help. I

wanted to describe a summary of my intention. Please slap me around, where necessary.

First, a kind of Claisen condensation, of ethyl acetate with itself using a sodium hydroxide catalyst, is attempted. May as well go with a one molar

first run.

I'll set up for reflux, but have an ice bath ready, with one mole ethyl acetate( 98.23 mL) in a suitable(at least 2neck) RBF, say 500 mL. I'll use my

good, trustworthy reflux condenser and top it off with a calcium chloride guard tube.

I'll begin with moderate stirring and then add a small amount of my 40 g sodium hydroxide – POWDER, no aqueous solution. Observe the temperature of

the reaction mixture and add this mol of NaOH.

If I get 20 g sodium hydroxide in the stirring mole of EtAOc without appreciable temperature rise, I will hold here. I will look for signs of some

kind of reaction and perhaps the precipitation of sodium acetate prills.

If also, the thing begins refluxing exothermiclly, I will be happy, I will attempt to keep the reaction temperature under control(77 – 78°C) with

an ice bath. I believe that at this point the ethyl acetate will be beginning to be replaced by dry ethanol.

I will continue addition, until I've added the whole mole of sodium hydroxide. When the temperature begins to cool off, I may even heat this reaction

mixture. I can measure the pH, and odor (I told you, I'm new here).

Just judging things, I may continue refluxing. I'm not sure whether I need two equivalents of the ester, since I'm reacting it with itself. But it

seems like one acetate ion will be created by the condensation of each example of ethyl acetate.

The great thing about this is the possibility that we will be refluxing nearly completely ethanol at the endpoint and all of the sodium ions will be

hooked up with acetate ions. At this point I will treat the reaction mixture as hygroscopic, and switch over to regular atmospheric distillation

(still using a guard tube on the receiver. I think positive.) Theoretically I'll wind up with 58.4 mL dry ethanol.

Then (if by some a lark of a chance, or ultimately, after tuning) the still pot(having been very carefully distilled to dryness?) can be reset up with

an air condenser and an addition funnel with an appropriate amount of concentrated sulfuric acid and distill off glacial acetic acid!

Okay, now throw stuff. I'm going to try this, so please, offer cautions, considerations, modifications, etc. This would be a really cost justified

answer to the production of two elusive solvents which I need.

Some Notes:

1) even dry ethanol has some solubility for anhydrous sodium acetate. But surely, the atmospheric distillation with a double-sided, efficient

condenser should leave the solid material behind, right?

2) if the first reaction works and goes to completion,, then we won't have to worry about an ethyl acetate/ethanol azeotrope (EtOAc will be gone). I

don't expect much trouble separating excess concentrated sulfuric acid from GAA.

3) But, can we do the first reaction with no water? I think the use of an aqueous solution of sodium hydroxide leads to watery results, that are

difficult to get rid of. The idea of creating ethanol in an environment where water can't be formed is very intriguing.

4) It's damned convenient, about the boiling points of these two organic compounds. I mean, ethyl acetate boils at 77°C and ethanol just about 78°C.

It's terrible (impossible really) if you're trying to fractionate them apart. But of one is being converted to the other – it's just too convenient,

makes me suspicious.

[Edited on 26-12-2014 by CaptainPike]

|

|

|

Yugen

Harmless

Posts: 23

Registered: 20-12-2014

Member Is Offline

Mood: No Mood

|

|

This is too easy

What isn't already easy about making ethyl acetate? It's simple Fischer esterification. Aren't there already free resources for this synthesis everywhere? Check out page 73 of this free google ebook for example.

Is it the procurement of glacial acetic acid that bothers you?

|

|

|

smaerd

International Hazard

Posts: 1262

Registered: 23-1-2010

Member Is Offline

Mood: hmm...

|

|

Uhm I am totally confused. It looks like captian pike wants to create ethanol and glacial acetic acid from ethyl acetate. I'm just entirely confused

why this post is here?

I don't know where to comment about the uhm... prep. Here or in the link?

|

|

|

Bert

|

Threads Merged

26-12-2014 at 09:25 |

CaptainPike

Hazard to Self

Posts: 68

Registered: 21-12-2012

Member Is Offline

Mood: No Mood

|

|

THERE! I have officially gotten tomatoes thrown at me

Are you talking to me?

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

See your PM, not throwing tomatoes!

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

CaptainPike

Hazard to Self

Posts: 68

Registered: 21-12-2012

Member Is Offline

Mood: No Mood

|

|

Does anybody believe this reaction can occur (and go to completion) in a reaction media of ethyl acetate which changes to ethanol in the end?

CH3COOCH2CH3 + OH- ––––> CH3COO- + CH2CH3OH

I mean will the saponification continue with the last hydroxide ion attacking the last carboxyl? Or should I have an excess of either reagent?

I think it would be wonderful if the whole thing could occur with no water at all! But will it ever actually complete? And Yes, I am "of age", able

to buy booze, etc. etc. I just want to understand this reaction better. I also would like to see some glacial acetic acid (that I created) going in

and out of a solid form at somewhere around room temperature – don't you think that is cool?

And Another Thing – what if ethanol forms complexes with lye? And I mean, after the collapse of the tetrahedral, is there some way to protect the

newly formed ethanol from having its hydrogen(from the OH) abstracted or otherwise interfered with by the ongoing reaction?You can probably tell I

have very little experience in organic chemistry, either practical or hypothetical

PS: Happy New Year :-)

[Edited on 1-1-2015 by CaptainPike]

|

|

|

CaptainPike

Hazard to Self

Posts: 68

Registered: 21-12-2012

Member Is Offline

Mood: No Mood

|

|

GAA/ethanol prep – Harmless Home Lab Version

Background

A one mole scale experiment was performed along the lines of a procedure posted by have2know, Acetic Acid Synth. Easy Home Version.

Have2Know's post outlined a two step process, first, the saponification of ethyl acetate by way of sodium hydroxide yielding sodium acetate and

ethanol and second, the pyrolysis (?) of the sodium acetate to make glacial acetic acid (either using sodiumbisulfate or concentrated sulfuric acid).

I intend to do both parts of the experiment, but only the first part has been so far attempted, and outlined here.

Some Initial Calculations and Assumptions

One mole of ethyl acetate, having density 0.897 and molar mass 88.11 grams/mol. 88.11 g of ethyl acetate will be 98.23 mL.

One mole of sodium hydroxide, in solid form 39.997 g/mol

one mole of ethanol having density 0.789 g/cm³ and molar mass 46.07 g would be 58.39 mL.

EQUATION: CH3COOCH2CH3 + OH- ––––> CH3COO- + CH2CH3OH [1]

MECHANISM: attack by a hydroxyl group – tetrahedral intermediate – kicked out alkoxide with rapid proton transfer creating the alcohol (resulting

in acetate ion) [2]

What I Did

In a nice, heavy, two necked, 250 mL round bottom flask was placed just under 40 g (one mol) sodium hydroxide in fine prills. This flask having one

major, central neck and the other splayed off to the side, was fixed just above a stirring hot plate, but initially in an ice bath. A thermometer was

placed in the off vertical neck, with the bulb extending below the midpoint of the flask but above the activity area of a stir bar which was then also

added. An efficient reflux condenser was fitted in the central, main neck and the circulation of ice water was begun. All tapered glass where joints

were greased with high temperature vacuum grease.

After a short time, roughly 99 mL (1 mol ) of hardware store ethyl acetate (Klean Strip MEK Substitute) was added in two separate approximately equal

additions. After a couple of minutes of heavy stirring, the 40 g of NaOH was suspended as a slurry in the one half mol of ethyl acetate. The

suspension remained at a temperature of 11°C with little or no exothermic action so the other portion of ethyl acetate was added, and a thermometer

adapter reinserted.

The ice bath was removed and the flask was heated gently on air bath. Shortly after reaching about 70°C, obvious refluxing began. This was allowed to

continue for approximately 2 hours after which time the liquid phase became limited and the solid volume increased markedly. Heating was increased

moderately in an attempt to melt the growing mass of crystals. Magnetic stirring was insufficient to move this mass significantly. Very little liquid

remained but this did continue to reflux.

The heating was stopped and a calcium chloride guard tube was added to the top of the reflux condenser to prevent the entry of moisture.

Observations And Discussion

One of the goals of this experiment was to produce ethanol and sodium acetate in an anhydrous form. Instead, some of the white solid material was

charred and darkened possibly due to oxidation. Very little liquid seems to exist separately from the wet solid.

I am at a loss as to what has happened. I could find no reference to any attempt at performing this saponification with no water added to the initial

liquid phase. My guess is that the reaction is halted somewhere short of completion. The still pot smells strongly, as one might expect, somewhere

between the ester and the alcohol. The crystals do appear damp and there is some liquid remaining. It was calculated that 58 mL of ethanol would

result from 100% conversion.

I attempted to put some litmus paper to a sample drawn out shortly after stopping. I'm not sure what it means the stuff is wet but not with water and

doesn't seem too weep into the paper. It may have represented significantly alkaline conditions.

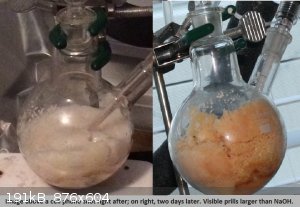

I have some photos. Something I've noticed since halting a couple of days ago. It seems as though the charred coloring has pervaded an ever enlarging

mass of crystals. Meaning, initially a dark spot was on the bottom, now the whole large mass of crystals has taken on the discoloration almost evenly.

A photo was taken shortly after shutting down using a cell phone. Then, I took some photos today with a somewhat better camera and a lower aspect.

Lighting, resolution, angle, camera and time are all changed, so surely my perception is subjective. But clearly the volume of white material is

larger now than when we halted a couple of days ago.

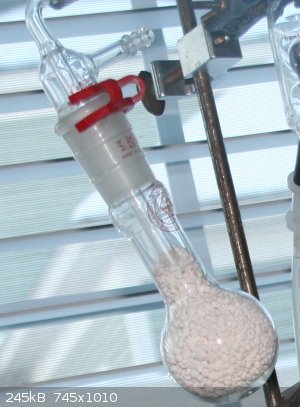

I also include a shot of my calcium chloride drying arrangement – I wanted to get something on there quick, before cooling down drew in appreciable

air. I wasn't able to pack my tube, plus, it's "college rule" (19/22). That adapter is a nice fritted bubbler (I had lying around), that fits

perfectly into that oddly shaped Erlenmeyer flask (stem almost touching the bottom). The barbed end of the fitted tube is unfortunately off screen,

but leads through a short piece of rubber tubing to a little 14/20 gas fitting in the top of the condenser.

And speaking of condensers, that little bantumware 14/20 reflux condenser is a really nice rig. It doesn't sweat but you can drive a lot vapor into it

and you won't even smell solvent in the room.

What to Do Next

I'm thinking I will rearrange the setup for normal distillation and pull off what liquid I can.

Alternately, I could add in some more dry ethanol , chop up the mixture with a stirring rod and try refluxing some more – push the

reaction further to the right?

Maybe this worked! I'm sure if there was pure ethanol, I have probably lost some through evaporation – could that really happen through the calcium

chloride packed tube? I could distill to dryness (using a heating mantle, instead of the hot plate?) and then continue with the pyrolysis using

concentrated sulfuric acid.

I could add in the slight excess of sodium pyro sulfate, begin the dry distillation, pulling off a for-run of whatever liquid is still present, and

then collect glacial acetic acid. (Well, it might happen!)

Questions

1) is this even possible – to do this reaction with no water? That is, starting with an ethyl acetate reaction media, then having this diluted with

the newly formed ethanol, ultimately ending in pure ethanol?

2) Relating to above, can I expect this theoretical reaction mechanism [2] to continue, unaffected by the increasing concentration of ethanol being

formed?

I would really appreciate any comments, suggestions, etc. I still haven't done anything else yet.

References

1. Chemical Engineering Education, Summer 2004, page 228

2. http://www.colby.edu/chemistry/PChem/lab/KineticsEster.pdf

|

|

|

gdflp

Super Moderator

Posts: 1320

Registered: 14-2-2014

Location: NY, USA

Member Is Offline

Mood: Staring at code

|

|

This is a nice writeup, but why did you start a new thread? This is an identical topic and similar scale to the thread you mentioned.

|

|

|

CaptainPike

Hazard to Self

Posts: 68

Registered: 21-12-2012

Member Is Offline

Mood: No Mood

|

|

Yes, I started a new thread.

Maybe as you imply, it should be just a post in the thread that I indeed mention.

It is basically the same thing done by have-two-know, but it's also different in that is done using glassware, etc. If the powers that be think it

should be moved in, as a post, or elsewhere, it is OKAY by me. I did have some discussion with O Most Powerful One, and I think it will stand alone. I

thought it might be better off over in the organic branch, even. So we shall see. Thank you.

|

|

|

Nicodem

|

Threads Merged

13-1-2015 at 12:54 |

CaptainPike

Hazard to Self

Posts: 68

Registered: 21-12-2012

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Dronami_inc  | elegant solution

If I understand properly, author used solid NaOH (not a solution)?

If so, obtained ethanol and acid are almost completely waterless. Please correct me if this is not so.

...I skiped this topic by accident and created a new thread https://www.sciencemadness.org/whisper/viewthread.php?tid=47958 where i'am interested in obtaining both anhydrous ethanol and

glacial acetic acid, but probably using gas phase hydrolysis with catalyst. How can it be implemented? i.e. without NaOH involved

|

I got nowhere with this link. Is it dead, has it been moved or am I not allowed?

I'm trying to figure out whether this process can be done using pure lye, not a 50% solution or something. Once we start adding water ethanol doesn't

give it up so easily (nor does sodium acetate!)

I'd be interested in the opinion of S.C.Wack and others possibly following this discussion.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

People always regret my opinionating. There is a way to do things and a way to isolate things and you're not there. You need lab manuals. This is why

I scanned several of them. Note the book that I suggested. And that there is a www button here. Perhaps djvu plugins are still available.

20 g of ethyl acetate are refluxed with 80 g (excess) of 25% aqueous caustic potash for 1 hour, until the layer of ester has disappeared, and the

mixture no longer smells of it. The whole is then distilled to 100°; ethyl alcohol can be separated from the distillate by addition of anhydrous

potassium carbonate. The residue in the flask is neutralised with dilute sulphuric acid and evaporated to dryness on a water bath. The solid residue

is powdered and distilled with 50 g of conc. sulphurlc acid to 130°, and the distillate fractionated between 115° and 120°.

Cooling in ice until solidification takes place, and subsequently draining away the still-liquid portion, gives crystals of glacial acetic acid.

Yield.-90% theoretical (12 g). Colourless liquid or crystals; characteristic odour; miscible with water; mp 16.7°; bp. 119°

|

|

|

CaptainPike

Hazard to Self

Posts: 68

Registered: 21-12-2012

Member Is Offline

Mood: No Mood

|

|

That wasn't too bad a, "Whack", after all!

Thank you, S.C., for the following procedure, which makes sense. I do have a handful of questions about what you have said which follows.

Quote: Originally posted by S.C. Wack  |

20 g of ethyl acetate are refluxed with 80 g (excess) of 25% aqueous caustic potash for 1 hour, until the layer of ester has disappeared, and the

mixture no longer smells of it. The whole is then distilled to 100°; ethyl alcohol can be separated from the distillate by addition of anhydrous

potassium carbonate. The residue in the flask is neutralised with dilute sulphuric acid and evaporated to dryness on a water bath. The solid residue

is powdered and distilled with 50 g of conc. sulphurlc acid to 130°, and the distillate fractionated between 115° and 120°.

Cooling in ice until solidification takes place, and subsequently draining away the still-liquid portion, gives crystals of glacial acetic acid.

Yield.-90% theoretical (12 g). Colourless liquid or crystals; characteristic odour; miscible with water; mp 16.7°; bp. 119°

|

Some Questions On the above:

1.) can I use sodium hydroxide ("caustic soda")?I have this on hand. Although it would seem that 80 g would be a lot of lye to use with 1/2 mol EtOAc

– straighten me out on this?

2.)What exactly is a 25% aqueous caustic potash? How do I prepare, "80 g of 25% aqueous"?

3.) "the whole is then distilled to 100°" – does that mean as opposed to dryness? The still pot temperature or the still head temperature (going

into the condenser)? You mean normal distillation and the temperature will rise and I stop at 100°C? Right?

4.) It seems like there will be more water (from that 25% aqueous solution of sodium or potassium hydroxide) in the distillate then can be absorbed by

a drying agent such as potassium carbonate. Oh, maybe that's why you say, "to 100°". My experience with distilling aqueous solutions of ethanol says

that if I take the fraction up to 100°, there will be appreciable water in the distillate.

5.)I always thought CaO was the best drying agent for ethanol. Is potassium carbonate better? What about sodium carbonate… and can I dehydrate that

to the anhydrous form by baking in a conventional oven to 525°F? I have some washing soda here on the farm. [Shucks]

– – – – – – – –

Help with any of these questions will be greatly appreciated.

I blundered on blindly and drew about 25 mL of some clear liquid that came over around 78° from my yellow colored sticky snow. I used an interesting

recombination of my apparatus and provide a crow's nest view of the set up. I have a lot to learn, but it sure is fun.

Attachment: phpsSVpCx (1.3MB)

This file has been downloaded 1088 times

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

The idea with the potassium carbonate is to form (at least) a saturated solution and separate layers, like NaCl and IPA. I've never tried sodium

carbonate. Hopefully you can figure out everything else.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

I tried this process a couple of times to obtain water-free EtOH over the past 2/3 days at a 2 mol scale.

In practical terms, the NaOH prills do swell up, presumably trapping any EtOH formed, as it becomes a solid lump.

Strong heating in a disty rig didn't even get close to any distillate after 10 minutes, and i suspect (not looked it up) expansion co-efficients would

end up with more cracked glass than product, so i stopped. (value the glass more than the booze).

When the solid mass was broken up there was still the distinctive smell of ethyl acetate.

The easiest way to get the lump out of your glassware is to add water, which kind of makes it useless for anhydrous EtOH production for an amateur.

Strong heating was noticed when the water was added, so presumably a lot of unreacted NaOH as well.

At a 0.25 mol scale or less, this reaction will probably work (for getting anhydrous ethanol) if stirred strongly for 24 hrs and with pure reagents.

For producing sodium acetate, it does work, although at bigger scales the yield of sodium acetate will be limited by how well you can thoroughly mix

slightly damp solids whilst controlling the temperature.

Personally i'll stick to vinegar/sodium bicarb and a lot of boiling, then a recrystallisation or two.

[Edited on 27-5-2016 by aga]

|

|

|

halogen

Hazard to Others

Posts: 372

Registered: 18-4-2004

Member Is Offline

Mood: No Mood

|

|

EtOAc + NaOH -> heat + other stuff

NaOAc + H2SO4 -> heat + other stuff

"there has to be an easier way!"

Maybe you could polymerize it in a hot tube to split off ethylene.

F. de Lalande and M. Prud'homme showed that a mixture of boric oxide and sodium chloride is decomposed in a stream of dry air or oxygen at a red heat

with the evolution of chlorine.

|

|

|

| Pages:

1

2 |