| Pages:

1

2 |

cyanureeves

National Hazard

Posts: 744

Registered: 29-8-2010

Location: Mars

Member Is Offline

Mood: No Mood

|

|

thanks tanker my joints glide smoothly also when greased.last time i made nitric ,a leak ate one of my clips at the flask over the burners but sealed

itself again.i have silicone bands i ordered on line,they came in shapes of different zoo animals.i might just have to strap a hippopotomus on the

joints if i run out of clips.

|

|

|

m1tanker78

National Hazard

Posts: 685

Registered: 5-1-2011

Member Is Offline

Mood: No Mood

|

|

Reeves, let's not resort to animal cruelty when making nitric acid

It's my understanding that you shouldn't clip the boiling flask unless your crude stuff is low boiling. Also, you may have applied too much grease to

the joint(s).

Quick question: What's the best way to remove silicone grease from glassware joints after use?? Soap and gentle scrubbing doesn't seem to work as well

as I had hoped.

Tank

Chemical CURIOSITY KILLED THE CATalyst.

|

|

|

Hexavalent

International Hazard

Posts: 1564

Registered: 29-12-2011

Location: Wales, UK

Member Is Offline

Mood: Pericyclic

|

|

I have always found that dabbing acetone on a paper towel and simply wiping the joint works well, followed of course by cleaning the item in hot soapy

tap water, then with fresh tap water, and then a final rinse in distilled water.

"Success is going from failure to failure without loss of enthusiasm." Winston Churchill

|

|

|

Pyro

International Hazard

Posts: 1305

Registered: 6-4-2012

Location: Gent, Belgium

Member Is Offline

Mood: No Mood

|

|

i personally use a standard clamp with rubber hose over the fingers, and i make my own stands as they cost a lot.

i buy a 1 metre long steel rod of the right diameter, and a 3/4 inch steel plate. i drill a hole in the plate and put threads in it, put threads on

the rod and screw them together, it costs almost nothing.

all above information is intellectual property of Pyro.  |

|

|

Hexavalent

International Hazard

Posts: 1564

Registered: 29-12-2011

Location: Wales, UK

Member Is Offline

Mood: Pericyclic

|

|

I like that idea, Pyro. I suppose if you had the required materials and equipment, you could weld the metals together for extra stability. I also like

to install, on the base of my stands, some of those little rubber feet you can get from the pound/dollar store or supermarket. They help stop the

stands from sliding on my laminate workbench, and help avoid scratching it unnecessarily too.

"Success is going from failure to failure without loss of enthusiasm." Winston Churchill

|

|

|

Pyro

International Hazard

Posts: 1305

Registered: 6-4-2012

Location: Gent, Belgium

Member Is Offline

Mood: No Mood

|

|

well,

I live on a boat where there is loads of equipment.

truly, the threads fit together perfecty, and because storage space is a problem i can just unscrew and store them.

i glued a sheet of rubber to the bottom :p

to buy new costs 45$ and is just plain steel, mine are stainess.

i know that problem hex, when i worked on painted steel they used to slide around like crazy, i used to hot glue them down

all above information is intellectual property of Pyro.  |

|

|

Hockeydemon

Hazard to Others

Posts: 218

Registered: 25-2-2013

Member Is Offline

Mood: No Mood

|

|

I really need to get a few clamps, rings and stand, but once again on my poor budget I am hesitant to buy anything I can make..

I think I would be pretty happy with a couple of the stands M1Tanker put together. What did all of that total to if you happen to remember?

I really wanted to build clamps also but I haven't figured out how to properly attach the rotating arm..

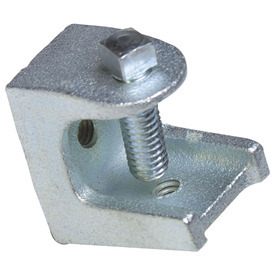

Rather than use the beam clamps as M1tanker did I found Gampak .5" rigid clamps which have a screw whole on all sides so you could attach two of them

at the back to effectively make a bosshead without needing a welder.

This would then grab the base rod and a 6" steel rod with a 1/4" diameter going to the clamp.

I would then pre-drill a hole in the 6" rod's center so I can thread this two arm hanger into the rod for the stationary portion of the clamp.

Then I could wrap a 2 hole pipe strap around the 6" rod which would give me a pivot for the adjustable arm. Maybe drill a hole through the middle of

the strap & rod to prevent the strap from ever moving.

Now then I need to find an acceptable movable arm.. Maybe just offset the same arm I found already for a 4 arm clamp?

I was thinking I'd screw this into the side of the 6" rod, and then drill a hole from the adjustable arm to this piece and run a fly nut to tighten

everything down?

Hopefully I communicated this well enough.. I had started to draw up schematics, but I draw like a disabled child.

|

|

|

| Pages:

1

2 |