| Pages:

1

2

3 |

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Quote: Originally posted by ManyInterests  | My gas wash bottle is quite small, so I will need to do extra of filling the bottle AND covering my upcoming air pump (it's an air mattress and

pool/beach toy pump with both vacuum and pump. It should work very well for anything I need pumping for.). I have a 450 gram unopened bag of calcium

chloride that I bought and I will be filling the bottle up as much as I can and cover the air in-take section of the pump completely with calcium

chloride. I will need to make an improvised setup to make sure that I have as dry of a setup as possible.

Heat the acid to 50C (with a water bath) and keep pumping dry into it. I pray that this will succeed. I might make more nitric acid tomorrow and

practice on making clean, concentrated WFNA and make it well. |

If the air is dry it will definitely succeed and your setup sounds solid so don't worry about that.

The process will be more efficient if you also have the acid on stir. This will get all the molecules moving around even more and increase the number

of collisions with the dry air. The heat (50°C) will also increase reaction rate and effective collisions.

Best of luck and dont forget to post your results

Be good, otherwise be good at it

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

I didn't stir, maybe I should have, but I think it is ultimately OK.

So some things to note about what I did. From a starting 325ml I ended up with just around 290 or so ml, a little less than 300. It is cloudy, but

that is because a small piece of calcium chloride managed to get blown in the acid. I am not sure how, but it happened.

The specific gravity is less than what I expected. Around only 1.47 in total, but I don't think that is the end all be all of it for two reasons.

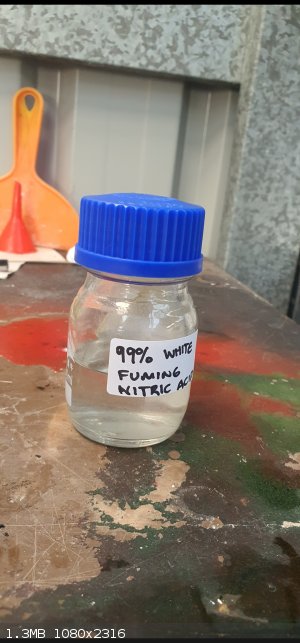

1: it fumes white as hell. I mean massive clouds of white, that is one characteristic of WFNA (hence the name, White fuming nitric acid). That haze

you see in one of the pics are the fumes.

2: It burned a huge smoldering hole in a nitrile glove that I drizzled an itty bitty bit on it. Not even 0.5ml, but it let a tiny drop go and it made

a huge hole burning hole. I did not see flames. But it was there. This is another characteristic of WFNA.

I think that despite the lower SG, it should still work. It is mildly cloudy due to the piece of calcium chloride, but that shouldn't be a problem.

Either way this is a huge learning experience. I will use it for RDX synthesis. Like all of it. Wish me luck.

Picture below is my setup and the final results.

[Edited on 14-1-2023 by ManyInterests]

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

On second thought (I cannot edit my message for some reason) I decided to not go for an RDX synth since I really don't think that it will work. the

specific gravity is too low. Perhaps it is closer to 90%, which is not good enough

I did see Darian Ballard's video where he made PETN using 68% HNO3 and 98% H2SO4. I am going to try to use that method. I did make ETN using stronger

nitric acid with sulfuric acid added, so I believe this should work.

Edit: the use of my 90% HNO3 to make PETN has been a 'good' success. I say that because when I was trying to heat the nitrating mixture I did see some

mild brown fumes start to appear that indicated the start of the runaway. I realize that I could not keep the heat for longer and I needed to dump it

in water. Due to the fact that I was using 98% pentaerythritol I did see a bit of yellowing as well, but over all the I find the yield to be good

(haven't weighed it yet) and I was able to wash out the impurties with a ton of water and a few hot sodium bicarbonate washes.

The sodium bicarbonate wash is not something I've done previously. I think I should include it in all nitrations from now on since... wow. I thought I

cleaned up all the acid with just water, but I was wrong. There was a lot of other impurities that the bicarbonate wash removed, and that is good.

[Edited on 16-1-2023 by ManyInterests]

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Quote: Originally posted by ManyInterests  | I didn't stir, maybe I should have, but I think it is ultimately OK.

So some things to note about what I did. From a starting 325ml I ended up with just around 290 or so ml, a little less than 300. It is cloudy, but

that is because a small piece of calcium chloride managed to get blown in the acid. I am not sure how, but it happened.

The specific gravity is less than what I expected. Around only 1.47 in total, but I don't think that is the end all be all of it for two reasons.

1: it fumes white as hell. I mean massive clouds of white, that is one characteristic of WFNA (hence the name, White fuming nitric acid). That haze

you see in one of the pics are the fumes.

2: It burned a huge smoldering hole in a nitrile glove that I drizzled an itty bitty bit on it. Not even 0.5ml, but it let a tiny drop go and it made

a huge hole burning hole. I did not see flames. But it was there. This is another characteristic of WFNA.

I think that despite the lower SG, it should still work. It is mildly cloudy due to the piece of calcium chloride, but that shouldn't be a problem.

Either way this is a huge learning experience. I will use it for RDX synthesis. Like all of it. Wish me luck.

Picture below is my setup and the final results.

[Edited on 14-1-2023 by ManyInterests] |

The loss in volume happened to me too when I used this method. I think it is due to the added temperature and agitation from the air bubbling in.

The specific gravity will read higher when the dissolved nitrogen dioxide is present in the acid so you will get a drop in density after you have

removed it.

The fact that it is fuming so heavily is a good sign. The name red/white fuming is to describe the colour of the acid not the colour of the fumes

(white fuming =clear colour).

The reaction with the glove is interesting. I tested with the red acid and the gloves smoked and then auto-ignited but I don't think I ever tested

with the clear stuff. Maybe the dissolved NOx has an effect on reaction or you do have a bit of water or something mixed in there.

Here is an old picture of mine, looks as harmless as water in there:

[Edited on 16-1-2023 by greenlight]

Be good, otherwise be good at it

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Quote: Originally posted by ManyInterests  | On second thought (I cannot edit my message for some reason) I decided to not go for an RDX synth since I really don't think that it will work. the

specific gravity is too low. Perhaps it is closer to 90%, which is not good enough

I did see Darian Ballard's video where he made PETN using 68% HNO3 and 98% H2SO4. I am going to try to use that method. I did make ETN using stronger

nitric acid with sulfuric acid added, so I believe this should work.

Edit: the use of my 90% HNO3 to make PETN has been a 'good' success. I say that because when I was trying to heat the nitrating mixture I did see some

mild brown fumes start to appear that indicated the start of the runaway. I realize that I could not keep the heat for longer and I needed to dump it

in water. Due to the fact that I was using 98% pentaerythritol I did see a bit of yellowing as well, but over all the I find the yield to be good

(haven't weighed it yet) and I was able to wash out the impurties with a ton of water and a few hot sodium bicarbonate washes.

The sodium bicarbonate wash is not something I've done previously. I think I should include it in all nitrations from now on since... wow. I thought I

cleaned up all the acid with just water, but I was wrong. There was a lot of other impurities that the bicarbonate wash removed, and that is good.

[Edited on 16-1-2023 by ManyInterests] |

I think you definitely should have gone for glory and had a go at the RDX synthesis, maybe with a bit longer heating before crashing into ice. From

what you described apart from the glove reaction your acid seemed fine, you may have just got a little less yield depending on water content if that

was the impurity. I'm confident you wouldn't have just ended up with nothing.

Yes, PETN is quite forgiving with acid strength l, I have used as low as 62% nitric acid before and still got decent yields but I usually use 70% and

I don't notice a difference.

It is a different nitration mechanism though forming a nitrate ester bonding the nitrogen to an oxygen whereas with RDX your bonding the nitrogen to

another nitrogen (nitrolysis) in simple terms. Water is your main by-product when nitrating alcohol and doesnt interfere with the nitration so it's

prevention from the reaction mixture (within reason) is not required, the sulfuric acid does the job of "holding the water out of the way".

The yellowing and mild brown fumes during your synthesis are both big warning signs of a runaway. Always have a bucket of water at the ready or just

turn it on its side in the ice bath if one properly starts because you can't stop it when it kicks off and not being able to quickly quench it is

dangerous.

The repeated washing with weak sodium bicarbonate solution is a very important step and should never be skipped. I am glad you have done that, if

done thoroughly you can store it safely til use.

I usually recrystallise my PETN by dissolving in hot acetone and then dripping into a ice water solution with heavy stirring and a small amount of

bicarbonate or ammonia to mop up any excess acid stuck in there. This results in uniform grains that do not stick to things like the original dust

and is storage stable. I have a sample from 2017 with no signs or degradation or acidity.

[Edited on 16-1-2023 by greenlight]

Be good, otherwise be good at it

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

| Quote: | The loss in volume happened to me too when I used this method. I think it is due to the added temperature and agitation from the air bubbling in.

The specific gravity will read higher when the dissolved nitrogen dioxide is present in the acid so you will get a drop in density after you have

removed it.

The fact that it is fuming so heavily is a good sign. The name red/white fuming is to describe the colour of the acid not the colour of the fumes

(white fuming =clear colour).

The reaction with the glove is interesting. I tested with the red acid and the gloves smoked and then auto-ignited but I don't think I ever tested

with the clear stuff. Maybe the dissolved NOx has an effect on reaction or you do have a bit of water or something mixed in there.

Here is an old picture of mine, looks as harmless as water in there: |

Yeah, getting it water white is quite exciting when you also realize just how deadly the whole thing is!

And I will be trying again with this method in the future. Maybe it won't be the 98% minimum that I am looking for, but I actually believe that it

will get RDX. I think the first time I did RDX synth (it was yellow-tinted with a specific gravity of around 1.50-something. But that was a while ago)

I only got around a 50% yield from the HDN I used. While 50% is quite little, it is better than nothing. I consider making RDX to be the most

challenging not because of the dangers involved, but simply that getting a good yield is so difficult. With every other nitrated stuff I've done, you

always end up with more than you start, but with RDX it is the opposite.

| Quote: |

I think you definitely should have gone for glory and had a go at the RDX synthesis, maybe with a bit longer heating before crashing into ice. From

what you described apart from the glove reaction your acid seemed fine, you may have just got a little less yield depending on water content if that

was the impurity. I'm confident you wouldn't have just ended up with nothing.

Yes, PETN is quite forgiving with acid strength l, I have used as low as 62% nitric acid before and still got decent yields but I usually use 70% and

I don't notice a difference.

It is a different nitration mechanism though forming a nitrate ester bonding the nitrogen to an oxygen whereas with RDX your bonding the nitrogen to

another nitrogen (nitrolysis) in simple terms. Water is your main by-product when nitrating alcohol and doesnt interfere with the nitration so it's

prevention from the reaction mixture (within reason) is not required, the sulfuric acid does the job of "holding the water out of the way".

The yellowing and mild brown fumes during your synthesis are both big warning signs of a runaway. Always have a bucket of water at the ready or just

turn it on its side in the ice bath if one properly starts because you can't stop it when it kicks off and not being able to quickly quench it is

dangerous.

The repeated washing with weak sodium bicarbonate solution is a very important step and should never be skipped. I am glad you have done that, if done

thoroughly you can store it safely til use.

I usually recrystallise my PETN by dissolving in hot acetone and then dripping into a ice water solution with heavy stirring and a small amount of

bicarbonate or ammonia to mop up any excess acid stuck in there. This results in uniform grains that do not stick to things like the original dust and

is storage stable. I have a sample from 2017 with no signs or degradation or acidity.

|

I will be washing out my old ETN with hot bicarbonate water after this. This is even though I used a urea infused methanol recrystalization for the

whole thing, so I believe that should have done away with all acids even if there was still a bit left. But I want to be sure.

Also I might want to do that with the RDX sample that I made. I still haven't recrystalized it since I only had 10 grams of it. I thought I would make

a few more batches before I bothered. But I will give it a wash regardless.

I will be doing a recrystalization of the PETN that I made soon. I kept it drying for a day then crumbled up the chunks (there was a lot of moisture

trapped there) and set it to dry again. I will be adding around 4ml of 28% ammonia to the hot acetone before crashing it out in 1% urea water. Then I

will be giving it a final wash after filtering.

Edit: Yeah, I wanted to also mention that the next time I try for WFNA even after blowing it with dry air I will use it for RDX. I think I might end

up with another 50% yield, but 50% is not 0%, which is fine.

Also the yellowing of the PETN mixture was happening well before that, which is why I thought it was more to do with the impurities. What I will do in

my next PETN synth, however, is to maybe double the time I have in adding the PE to the mixture. I was mildly in a hurry because I did hear from

Darian Ballard that yellowness means that the impurities are ruining the final product, which is why I figured I wanted to get this stuff done more

quickly.

I guess my time frame was off. At any rate, the yellowness was there before I brought it on the heat. When I was bringing it up to room temperature

putting it back in the ice bath certainly brought the temperature down quite readily. The temperature was rising when I got it out of the ice bath,

but that is to be expected. I set my room temp around 25C, but the area near the floor is actually colder than higher up. What I should have done is

obviously let it stay at room temp for a good long time (like 25 or 35 minutes) to make sure that no runaway is happening before I turn the heat up on

it. But it was the yellowness that was already there that made me worried about the whole thing.

Next time I won't worry as much about the yellowness when adding the PE. Also I will try to let the addition temperature be higher than what it

started. I originally tried to keep the temperature at 0C or less throughout, this became untenable as the additions went on, but I did let the whole

setup cool further outside instead of putting it back in my freezer. The temperature at that time was -4C (it is snowy where I live) so the ambient

temperature was going to pull the overall temp back down no matter what, and I would rather have a runaway happen outside than I would in my freezer

for very obvious reasons.

Perhaps letting a lot of the addition happen more slowly and at higher temperatures will prevent temperature spikes. Just obviously don't let it go

beyond 15C for obvious reasons.

Edit 2: I weighed out the dry PETN (before recrystalization) yeah I was right when I thought I was cutting my losses. The yield is far from the 2.2x

the yield that others had, but still, it is a respectable yield.

Edit 3: OK an update after recrystalization... wow! This was funny! I used a large excess of acetone and I added 3.5ml of 28% ammonia water to it, and

I prepared a water tub with 3000ml of ice cold water with 2.5 gram to 3 grams of urea dissolved in it for use.

When I dissolved my PETN in the acetone the whole solution turned... orange! I don't know why but it did. I've never seen that happen in any video or

mentioned anywhere. There must have been a lot of impurities in my stuff. after that, it took a long time to just get the liquid on top filtered off

and I needed to change filters many times since they got saturated with something or the other. I added much more water to the filtered water to see

if any PETN precipitated out, but none did, so I believe I didn't lose anything. But there was a LOT of stuff I needed to get out of there. After I

finally got to getting my PETN in the filters I gave the stuff a few washes with warm water and I took a pH test on the liquid. It was either 6.5 or

7, either way it was clean of pretty much all acids and it should be OK for a good long time. I wonder why it was like that when it was almost

slightly basic when I washed it before recrystalization.

But the recrystalization liberated a LOT of crap that needed to go. I am so glad I did it quickly.

[Edited on 18-1-2023 by ManyInterests]

[Edited on 18-1-2023 by ManyInterests]

[Edited on 18-1-2023 by ManyInterests]

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

I thought I'd bump this thread up because of one question I have regarding HDN. I made some HDN a few months ago and when I first made it, I let it

dry in a box with some calcium chloride in it, and since then I put it in a sealed tupperware. I opened that tupperware recently and there didn't seem

to be any change in the HDN. But I am not sure if it is still dry or has absorbed some moisture.

So I have this question regarding drying HDN... is it possible to do so in the oven? What I am thinking of doing is to preheat my oven to 120C (the

melting point of HDN is 170C or so) and then turning off my oven, and then putting in a glass baking dish with the HDN I wish to use and another glass

baking dish with calcium chloride. Will this work to allow it to dry quickly and completely? Would there be any danger involved?

[Edited on 29-5-2023 by ManyInterests]

|

|

|

Hey Buddy

Hazard to Others

Posts: 429

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

You can dry HDN in an oven, but Im not sure about the drying temp, (120 C is high in general) water can be driven off at much lower temperatures under

100 C, usually over a longer period of time. but I would strongly recommend against using any kitchen stuff that you use for food being double dutied

for chemical processing of any kind. Personally, I would never use my kitchen food stove for any lab process other than maybe boiling water or drying

chlorides.

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

Maybe I will use a water bath and with a slightly lower temperature?

I would also wish to ask for advice regarding on my new nitric acid setup. If you can look at the picture I posted on my thread in beginnings.

|

|

|

Hey Buddy

Hazard to Others

Posts: 429

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

I dont know if 120 C is too high for HDN. In general 120 C is high for drying temp. Perhaps yuo could test a small amount to see how it dries and

handles drying at 120 C? Then drop temp if necessary. Who knows, maybe 120 C will be a good temp to dry it quickly?

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

I am a very unhappy man right now.

So here is what happened, I managed to get 232ml of excellent quality WFNA (only a little yellow, with no red) and I decided to use it to finally make

some good RDX after waiting a long time for this. I decided I wanted to use it all up, so I used 93g of HDN prepared (using the 25g to 60ml ratio that

others have recommended) and I froze the beaker with the nitric acid in salt water. so after that, I used my magnetic stirrer to start stirring and

over a period of 1 hour and 45 minutes or so, I added 63g of the HDN, the temperature did rise from the starting -9C to 18C, but as soon as I added a

bit more HDN I decided that I needed to recool the ice bath. Even though there was still a wheel of ice in it, the additions were so exothermic that a

lot of the ice around it did melt.

However once the temperature rose above 20C, I felt that either a major temperature spike was happening, or it was in the early stages of a runaway.

There were no red fumes or anything, but it was rising steadily from 22C all the way to 29C and I decided that it was gonna run away. So I dumped the

entire thing in a large tub of water instead of taking any risks.

So the usual process is that after the final bit of hexamine or HDN is added, it is allowed to reach room temperature and sit there for 20 minutes

before the temperature is made to rise to 50C to destroy the impurities within it before cooling back down to room temperature and it is then crashed

in a large amount of water.

I am not happy at all. But I need to see what needs to be done to salvage what I got now. So I wasn't able to heat everything up to destroy the

impurities, would the recrystalization step remove them? Or can I after filtering and washing put the crude RDX in hot water to see if that helps? I

need some assistance here.

I will not allow this to happen next time... It stinks to go through all the trouble and still have issues.

|

|

|

DennyDevHE77

Hazard to Others

Posts: 167

Registered: 15-9-2014

Member Is Offline

Mood: No Mood

|

|

Even after the filtering step, no one prevents you from loading your RDX into 50-60% nitric acid, and heating it there at 60-65°C until the brown

vapors stop emitting. Recrystallization in acetone as far as I know does not remove all impurities, it is carried out to remove intracrystalline acid.

Not because it is dangerous for rdx (as for example with petn), but because releasing from the crystals during storage, can cause corrosion of

ammunition and destruction of polymeric binders and components in mixed explosives.

I have encountered methods of purification by boiling in distilled water and acute steam treatment, but these were usually carried out after oxidative

crystallization. That is, in fact, after the main purification.

[Edited on 27-8-2023 by DennyDevHE77]

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

Quote: Originally posted by DennyDevHE77  | Even after the filtering step, no one prevents you from loading your RDX into 50-60% nitric acid, and heating it there at 60-65°C until the brown

vapors stop emitting. Recrystallization in acetone as far as I know does not remove all impurities, it is carried out to remove intracrystalline acid.

Not because it is dangerous for rdx (as for example with petn), but because releasing from the crystals during storage, can cause corrosion of

ammunition and destruction of polymeric binders and components in mixed explosives.

I have encountered methods of purification by boiling in distilled water and acute steam treatment, but these were usually carried out after oxidative

crystallization. That is, in fact, after the main purification.

[Edited on 27-8-2023 by DennyDevHE77] |

Thank you. Yes, I am going to make more nitric acid anyway (you can never have too much of that when you're into energetics). And if all you need to

do is put it in 50 or 60% HNO3 then that is what I will do. I will do it after drying them and very carefully for obviously reasons.

RDX has been a huge challenge for me, largely in making the appropriate strength HNO3 for the task. So I plan on trying to making a few more synthesis

of it until I feel like I got the hang of it... and I will not hestitate to recool and refreeze the water if needed to bring the temperature down. I

want to avoid runaways, but at least I am happy that I was well prepared for one and avoided any disaster.

I will put aside the current RDX I made this time in a separate container and mark it that it needs further purification.

|

|

|

DennyDevHE77

Hazard to Others

Posts: 167

Registered: 15-9-2014

Member Is Offline

Mood: No Mood

|

|

I would just like to point out that such aggressive purification is only needed in the nitrolysis method of RDX synthesis.

In nitration of compounds with already formed sym-triazine ring, hexogen is already obtained with high purity and in fact may not require purification

at all. These are such methods as nitration of cyclotrinitrosoamine, or nitration of "white salt" potassium perhydrotriazinetrisulfonate (synthesized

from sulfamic acid, usually a descaler). Note that nitration can be done with ordinary sulfur-nitrogen mixtures, but the yield will drop slightly,

ideally you need phosphoric anhydride, it is legal, but may be a little more expensive than sulfuric acid, although in my opinion, the use of

phosphoric anhydride is the most convenient way specifically for this method of synthesis.

[Edited on 28-8-2023 by DennyDevHE77]

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

Quote: Originally posted by DennyDevHE77  | I would just like to point out that such aggressive purification is only needed in the nitrolysis method of RDX synthesis.

In nitration of compounds with already formed sym-triazine ring, hexogen is already obtained with high purity and in fact may not require purification

at all. These are such methods as nitration of cyclotrinitrosoamine, or nitration of "white salt" potassium perhydrotriazinetrisulfonate (synthesized

from sulfamic acid, usually a descaler). Note that nitration can be done with ordinary sulfur-nitrogen mixtures, but the yield will drop slightly,

ideally you need phosphoric anhydride, it is legal, but may be a little more expensive than sulfuric acid, although in my opinion, the use of

phosphoric anhydride is the most convenient way specifically for this method of synthesis.

[Edited on 28-8-2023 by DennyDevHE77] |

I assume by nitrolysis you mean mean using WFNA as the nitrating agent. I am aware there are other methods of making RDX, but I only know of two

methods of making RDX. The first is using WFNA, and the second is using ammonium nitrate along with formaldehyde and acetic anhydride. Making acetic

anhydride is a challenge for another time for me, but I have an unopened 1 liter bottle of formaldhyde and I can probably make some ammonium nitrate

(and I will) in the future. Via the double displacement reaction of aqueous solutions of pure calcium nitrate and ammonium carbonate. Ammonium

carbonate is pricey, but the end product will be much easier to purify since it will result in ammonium nitrate in solution while the calcium

carbonate is practically insoluble in water, so recovering the ammonium nitrate will be very easy and only evaporating the water will be needed with

no further purification.

I don't have access to phosphoric acid, but that is a method I have no considered. I do remember reading about it in one of Urbanski's books, I'll

need to look back at them.

|

|

|

DennyDevHE77

Hazard to Others

Posts: 167

Registered: 15-9-2014

Member Is Offline

Mood: No Mood

|

|

What I meant by nitrolysis was a type of nitration in which the C-N bond is broken in the organic substrate during nitration.

There are many methods of producing RDX:

1) Direct nitration of urotropine (or urotropine dinitrate) with concentrated nitric acid (oxidative method)

2) Method "K". Same, but ammonium nitrate is added to the nitric acid at a certain stage to condense the formaldehyde in the nitro mixture into

additional urotropine and thus into additional RDX.

3) "Method E". Preparation of hexogen by condensation of paraform with ammonium nitrate in acetic anhydride, preferably (but not necessarily) with

boron trifluoride catalyst.

4) "Bachmann-Ross Method". Essentially a combination of methods. Nitrolysis of urotropine by nitric acid with glacial acetic acid, acetic anhydride,

and ammonium nitrate.

5) Nitration of 3,7-derivatives of 1,3,5,7-tetraaza[3,3,1,1]bicyclononanes (Known as DAPT and DPT). But this is probably not profitable as it is

easier to prepare HMX from them.

6) Nitration of compounds with already formed sym-triazine ring. Cyclotrimethylene trinitrosoamine or nitration of the "white salt" of potassium

perhydrotriazinetrisulfonate.

7) Rarer methods, such as nitration of urotropine with nitric acid, with acetic or phosphoric anhydride in the presence of ammonium nitrate and

lithium nitrate. Or nitration of urotropine with nitrogen pentaoxide in tetrachloromethane or dichloropropylene.

I would also add that methods with acetic anhydride produce impurities of diacetoxytetramethylnitramine (BSX). Long-term boiling in water helps to

remove it.

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

I had no idea there were that many methods of making RDX. So far the thing that I have a problem with this is the yield. Of all of the energetics I

made, I notice that RDX is the only one that gives you less back than the others.

Would the method with ammonium nitrate, acetic anhydride, and formaldehyde have a higher yield than the others? You did mention long-term boiling in

water. What does that mean exactly? Like I would put the crude RDX in a large beaker of water and boil it for a few hours?

|

|

|

DennyDevHE77

Hazard to Others

Posts: 167

Registered: 15-9-2014

Member Is Offline

Mood: No Mood

|

|

The yield of the formaldehyde method is as high as 80% (for formaldehyde) usually 60-70% (this is considered a lot of for RDX). But it should be taken

into account that it should be in the form of paraform, not formalin. However, paraform is legal and not very expensive. RDX by this method is highly

contaminated and requires additional purification by boiling with water and recrystallization (before purification m.p. is 190-195°С). After

purification, the nitrolysis product typically consists of 93.4% RDX, 6% HMX and 0.6% 1-acetyl-3,5,7-trinitroazacyclooctane. Typically, 1 kg of RDX by

this method requires 630-635 g paraform, 1800 g ammonium nitrate, 5-5.1 kg acetic anhydride, and optionally 19 g boron fluoride (it is not required,

it just makes the reaction more easily controlled, and reduces the formation of HMX and other impurities)

And yes, you read me correctly, RDX is simply poured into 9-10 amounts of water, and boiled for a few hours. Dirty raw RDX contains many substances

that reduce its stability. For example, dinitrotriaminotrimethylamine, which is partially converted into trinitrotriaminotrimethylamine, it is

relatively stable in the cold, but above 60°С it decomposes, also formed trinitrodiaminodimethylamine [TDA], it can sometimes be up to 10%, but at

75-80°С it decomposes into formaldehyde, nitrous oxide and water. Well linear esters of nitramines,

1,9-diacetoxy-2,4,6,8-tetranitro-2,4,6,8-tetraazanonan and 1,7-diacetoxy-2,4,6-trinitro-2,4,6-triazoheptane (BSX). The above-mentioned substances are

not a complete list of impurities in the reaction mass, but all of them decompose on boiling in water, it is especially important to get rid of BSX as

it is very sensitive. Although of course boiling in dilute nitric acid is more effective. With nitric acid it is possible to obtain RDX with m.p.

203.5°С. And several recrystallizations from acetic acid will give almost chemically pure RDX with m.p. 204.5-205°С. I note that it is impossible

to remove the 6-7% HMX impurity without proper recrystallization, but I think a home chemist does not need this. Moreover, in industry, RDX produced

by the Bachmann-Ross method contains about 10% HMX and it is still not separated in order to avoid increased production costs.

I should note that recrystallization from acetone will also make RDX purer, but rapid infusion of RDX solution into water will cause the HMX impurity

to fall out in the form of a sensitive α-form, which is highly sensitive, so that RDX will be somewhat more sensitive. This is why HMX used to be

regarded as harmful additives to RDX, increasing their sensitive

In general, this method is more suitable for those who have a productive ketene lamp at home. And ideally, ammonium nitrate is freely sold in

kilograms.

As an alternative, if you have formaldehyde, you can buy acetaldehyde and make pentaerythritol. Of course, this is worth doing if pentaerythritol

cannot be purchased.

Sorry for the many letters, I just wanted to tell you as much as possible.

[Edited on 8-9-2023 by DennyDevHE77]

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

Quote: Originally posted by DennyDevHE77  | The yield of the formaldehyde method is as high as 80% (for formaldehyde) usually 60-70% (this is considered a lot of for RDX). But it should be taken

into account that it should be in the form of paraform, not formalin. However, paraform is legal and not very expensive. RDX by this method is highly

contaminated and requires additional purification by boiling with water and recrystallization (before purification m.p. is 190-195°С). After

purification, the nitrolysis product typically consists of 93.4% RDX, 6% HMX and 0.6% 1-acetyl-3,5,7-trinitroazacyclooctane. Typically, 1 kg of RDX by

this method requires 630-635 g paraform, 1800 g ammonium nitrate, 5-5.1 kg acetic anhydride, and optionally 19 g boron fluoride (it is not required,

it just makes the reaction more easily controlled, and reduces the formation of HMX and other impurities)

And yes, you read me correctly, RDX is simply poured into 9-10 amounts of water, and boiled for a few hours. Dirty raw RDX contains many substances

that reduce its stability. For example, dinitrotriaminotrimethylamine, which is partially converted into trinitrotriaminotrimethylamine, it is

relatively stable in the cold, but above 60°С it decomposes, also formed trinitrodiaminodimethylamine [TDA], it can sometimes be up to 10%, but at

75-80°С it decomposes into formaldehyde, nitrous oxide and water. Well linear esters of nitramines,

1,9-diacetoxy-2,4,6,8-tetranitro-2,4,6,8-tetraazanonan and 1,7-diacetoxy-2,4,6-trinitro-2,4,6-triazoheptane (BSX). The above-mentioned substances are

not a complete list of impurities in the reaction mass, but all of them decompose on boiling in water, it is especially important to get rid of BSX as

it is very sensitive. Although of course boiling in dilute nitric acid is more effective. With nitric acid it is possible to obtain RDX with m.p.

203.5°С. And several recrystallizations from acetic acid will give almost chemically pure RDX with m.p. 204.5-205°С. I note that it is impossible

to remove the 6-7% HMX impurity without proper recrystallization, but I think a home chemist does not need this. Moreover, in industry, RDX produced

by the Bachmann-Ross method contains about 10% HMX and it is still not separated in order to avoid increased production costs.

I should note that recrystallization from acetone will also make RDX purer, but rapid infusion of RDX solution into water will cause the HMX impurity

to fall out in the form of a sensitive α-form, which is highly sensitive, so that RDX will be somewhat more sensitive. This is why HMX used to be

regarded as harmful additives to RDX, increasing their sensitive

In general, this method is more suitable for those who have a productive ketene lamp at home. And ideally, ammonium nitrate is freely sold in

kilograms.

As an alternative, if you have formaldehyde, you can buy acetaldehyde and make pentaerythritol. Of course, this is worth doing if pentaerythritol

cannot be purchased.

Sorry for the many letters, I just wanted to tell you as much as possible.

[Edited on 8-9-2023 by DennyDevHE77] |

My knowledge on making it via the formaldehyde/AN/acetic anhydride method comes from one of those Paladin press books. I know it is covered in better

and more scientific detail elsewhere, but that is the first thing that comes to mind.

I only have 37% formaldehyde solution. I did find a seller for paraform on amazon.ca (I live in Canada) but it is quite expensive. Acetic Anhydride

was sold by westlab.ca, but they stopped selling to individuals. I would need to start a company and have a business address if I am to buy anything

from them again. As for ammonium nitrate, I believe it is sold in Canada and may not necessarily require paperwork. I did look at the gardening

section of my local hardware store, I did find one that was marked 34-0-0 and for real cheap. This is normally ammonium nitrate, but the MSDS kept the

actual contents secret, so while it is nitrogen rich, I really wasn't sure if I finally would have been able to get ammonium nitrate via a big bag and

not have to go through the process of making it. In the end of the day I do plan on buying a 25kg bag of calcium nitrate, which is available without

restriction (and for the price at which it is sold, it would be by far the most economical way to get nitrates where I live). With that I can make

potassium and sodium nitrates easily(via potassium/sodium carbonates), as well as ammonium whenever I need it.

Can I turn formalin into paraform? Because I was unable to find any information on doing that. The book did state that regular formalin can work.

I am exploring various ways of making acetic anhydride. The ketene lamp is one of them, and sulfur chloride is another (albeit a stinky one) I did

read that it was possible to make acetic anhydride with only sulfuric acid, anhydrous calcium chloride, and glacial acetic acid. I will attach the

document below.

But overall, the method seems that it would need a lot of reagents. Certainly it would be prohibitive. It seems that when it comes to making RDX, I'll

be stuck with smaller quantities. Because if I wanted to make 1kg of picric acid or TNT or most other energetics, I will need far less reagents. Not

that I would really want a whole kilogram of the stuff! That is a lot.

Edit: Thanks for the info. I really do wants lots of info since it will leave little room for error when I go about making this stuff.

Attachment: AceticAnhydridePhosphorouspentoixde.pdf (1.5MB)

This file has been downloaded 399 times

[Edited on 8-9-2023 by ManyInterests]

|

|

|

DennyDevHE77

Hazard to Others

Posts: 167

Registered: 15-9-2014

Member Is Offline

Mood: No Mood

|

|

Yes, this is how it is usually obtained by evaporating ordinary formaline under vacuum and separating the white flaky precipitate. I believe this also

works at atmospheric pressure, but for a longer time and at lower temperatures.

And by the way, thank you for this method of producing acetic anhydride. I didn't know about him. So far my main method has been S2Cl2

[Edited on 9-9-2023 by DennyDevHE77]

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

Quote: Originally posted by DennyDevHE77  |

Yes, this is how it is usually obtained by evaporating ordinary formaline under vacuum and separating the white flaky precipitate. I believe this also

works at atmospheric pressure, but for a longer time and at lower temperatures.

And by the way, thank you for this method of producing acetic anhydride. I didn't know about him. So far my main method has been S2Cl2

[Edited on 9-9-2023 by DennyDevHE77] |

Yeah, those methods are preposterously simple. Glacial acetic acid and calcium chloride + a little sulfuric acid? That sounds really stupidly simple.

The only issue that I buy my calcium chloride online (I have an unopened bag with me) and I am not sure if it is anhydrous as is, or it needs to be

dried more, and if it can be rendered anhydrous via oven drying (max 230 or so Celsius) or do I need to do it via a crucible and a blow torch.

Also my acetic acid is around 95% (specific gravity is just short of anhydrous). Now that I have a better way of controlling temperature on my mantle

due to the thermometer adapter I got. I can make sure it never rises above the boiling point of glacial acetic acid and no water. I hope I will be

able to do that without the need for molecular sieves.

For formalin, how much temperature are we talking about for a regular distillation? not vacuum.

|

|

|

DennyDevHE77

Hazard to Others

Posts: 167

Registered: 15-9-2014

Member Is Offline

Mood: No Mood

|

|

We are not talking about distillation, but evaporation, partial evaporation. I can’t say the exact temperature, these are just guesses, and

experimentation is needed here, I would try to warm the formalin to 70-80C to begin with, in the end, even at room temperature, paraform is formed, it

usually falls to the bottom of the container with formaldehyde.

Another thing is that I’m not sure about the feasibility, it’s much easier for you to make RDX using the usual nitrogen method, if you don’t

have a distiller, then make it with nitrate salts through sulfamic acid.

Or switch to mannitol/pentaerythritol

And calcium chloride is dehydrated at a red-hot temperature (600-700C). So an oven won't be enough.

[Edited on 15-9-2023 by DennyDevHE77]

|

|

|

Microtek

National Hazard

Posts: 869

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

If you manage to produce acetic anhydride by that method, I suggest you look at the patents by Lukasavage on HMX. There are a number of them, but the

ones on DADN -> SOLEX -> HMX are excellent. Essentially 100% yield and 100% purity. They do require P2O5 though, but only a small amount of

acetic anhydride is needed for the DADN. It's a very economical procedure, more so than producing RDX.

|

|

|

DennyDevHE77

Hazard to Others

Posts: 167

Registered: 15-9-2014

Member Is Offline

Mood: No Mood

|

|

In brief, I will quote the method of manufacture from one person known in narrow circles.

1. Obtaining potassium PHTS (potassium perhydrotriazinetrisulfonate). 5 ml of 37% formalin solution is mixed with 10 g of potassium sulfamate,

maintain pH = 8), add a few ml of water to dissolve all the sulfamate. Then add sulphamic acid (or any other acid) while stirring in small portions

until pH = 5. Keep stirring and after a few minutes the mixture will become viscous from the white powder, keep the mixture for another 2 hours until

the end of the reaction and filter it in the cold. Rinse on the filter with 2-3 ml of cold water and dry at room temperature (it is better to dry

under a fan, e.g. computer cooler), Grind the dried potassium PGTS into flour. Unlike ammonium PHTS, potassium salt can be stored without problems.

It should be noted that to obtain potassium sulphamate it is better to take sulphamic acid of "pure" grade or higher.

If the technical grade is used, the sulphamic acid should be neutralised with potassium alkali or potassium salt to increase stability during storage

with potassium alkali or potash to pH = 8 and heat the solution for a few minutes until the ammonia odour disappears.

2) Obtaining of RDX proper:

15g of potassium nitrate is poured in two steps to 30ml of 97% sulphuric acid, stirring until the substrate is dissolved. The heated nitro mixture is

cooled in a bowl of cold water.

Add a few ice cubes to the water, cooling to 5-10°C. The mixture of 12 g of potassium PHTS with 6 g of potassium nitrate is ground into a fine

powder, divided into 5-6

portions and, stirring thoroughly, pour into the nitro-mixture for 10 min. It is desirable to avoid the formation of lumps.

Stir the mixture for another 10 minutes (the mixture thickens and becomes very viscous), then stir periodically for the next 30 minutes, adding a few

ice cubes to the bowl of water every 10 minutes.

Then add a few ice cubes to the nitro mixture and stir thoroughly until the ice melts, wait a few minutes until most of the foam disappears and add

200ml of water.

Filter the hex suspension, rinse with water and then with soda solution on the filter and then again with water. Drying. The yield is 3.7g (56%).

For purification it is enough to warm the RDX in 50% nitric acid for a few minutes. Then you will get very pure RDX with melting point above 204C.

Ammonium PHTS can be used, but it is more difficult to dry (decomposes above 40-50°C), and cannot be stored for long periods. This is why the Germans

in WWII preferred to nitrate the more expensive potassium salt

This method is good because it doesn't require nitric acid, and would probably work for those who can't distill >90% nitric acid. But getting RDX

through nitric acid is generally faster and easier

In the sulfamate preparation step, if the pH is kept below 3, a sulfo derivative of DPT can be obtained. And nitrate it with sulphuric acid and

nitrates, obtaining disulpho-dinitro-tetraazacyclooctane, but I do not remember how to convert it into octogenes, although there was some patent.

[Edited on 15-9-2023 by DennyDevHE77]

|

|

|

ManyInterests

National Hazard

Posts: 930

Registered: 19-5-2019

Member Is Offline

|

|

Decided to bump this up since I have been working on making nitric acid again, and I am doing it using my new mantle which is being... problematic.

despite making everything as dry as possible I am ending up with azeotropic nitric acid, and nothing wants to distill under 115c. I will figure it out

with a few more experiements I am sure.

At any rate, I do almost 300ml of 70% nitric acid, how much would I need to dissolve it? I don't have the solubility of it in nitric acid.

|

|

|

| Pages:

1

2

3 |

|