| Pages:

1

..

10

11

12

13

14

..

17 |

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

Ah, thanks for the input. I thought you were long gone, as this is a few years old topic.

Is the ratio of starch/sucrose indeed 1mol per 12mol of nitrate and hydroxide? I used 100g of KNO3, 48 grams of NaOH and 20g of starch (16g would've

been the original, but the amount was so insignificant I upped it just in case).

I was originally gonna use calcium hydroxide, but I thought that since you got it working, I should follow is as exactly as I can, because I urgently

need the nitrite. Good thing is, I'm gonna react it with nitric acid, so any nitrate or carbonate residue does not matter, they will just be either

consumed or be a spectator in the reaction.

If I need more, I'll use your instructions, use sucrose and calcium hydroxide and probably I'll blend them together with mini blender as I've done

prior with different similar reactions.

I'm just currently cooling the solution to 0C. After filtration I'll put it in desiccator.

|

|

|

Σldritch

Hazard to Others

Posts: 309

Registered: 22-3-2016

Member Is Offline

Mood: No Mood

|

|

Im still here but as i no longer have year round access to my lab i can usually not add much to the discussion. To this one, however, i can.

The stochiometry is correct. Starch is basicly carbon hydrate and theoretically we want the carbon to end up as carbonate which means two nitrate

molecules for every carbon atom. Without the base the acidic Carbon Dioxide probably displaces much of the nitrogen dioxide. But really you might have

success using more carbon, i have never had a reason to try because the Potassium Hydroxide is the most valuble to me. Theoretically using more carbon

means using more base to keep the acidity down but since so much nitrate always is left over this may not reflect reality. I guess a lot of the carbon

is oxidized to carbon monoxide which is much less acidic leaving base and nitrate. From the crude product this seems to be the case, which is another

reason to use Calcium, the hydroxide salts are easy to separate.

If you make the mix from Calcium Hydroxide and Potassium Nitrate you may want to add something to slow down the reaction. Normally water does it. I

think the reaction running too hot is the cause of it going reddish. It forms a foam of Nitrogen Dioxide which can be smelled.

Another thing is, i never fractionally crystallize the crude nitrite but use it as is. With the amount of Alkali Hydroxides and the very soluble

nitrite itself it is hard to do from water. You may have more luck with methanol or ethanol-water.

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

Could it be beneficial to actually use less nitrate compared to base and carbon, or does this kill the reaction kinetics?

I did not check if the stuff was red hot, I just left it cool when it stopped under a steel lid and came back when it was cold and rock hard. I

ignited the reaction by simply heating the can, and definitely not too much to make it glow, more like how I heat my liquid reactions. It started very

easy, foamed and bubbled a little, and then the big smoking started, lasted maybe 10 seconds or more, and ceased. The reaction seemed going extremely

smooth, like it was buffered by something.

I first filtered the liquor after cooling a little when dissolving the rock, removing all solid impurities and crashed out stuff, cooled it to 0C,

decanted off the formed crystals of likely KNO3, and concentrated it by boiling, and during boil, white mass crashed out.

When I cooled down this with the crashed white mass, a lot more of sharp crystals formed, and a liquid was left. I drained this liquid in another

petri dish, and scraped the crystalline mass off from the clearly separate layer of white hard stuff, that is likely carbonate of something, and

collected this crystal mass, which formed a watery slush in another dish, and placed them both in a desiccator with lots of CaCl2. I'll trickle some

HNO3 on them samples when they are in a more solid form. My interest in optimizing this reaction due to other ventures is little, and I only need the

nitrite in catalytic amounts, hence I'm well happy with tens of grams of it, and if this nitr-o-pot method works to produce at least that per run, it

probably lasts more than my need for it. But I'll write on any notes I come up with.

|

|

|

Σldritch

Hazard to Others

Posts: 309

Registered: 22-3-2016

Member Is Offline

Mood: No Mood

|

|

Maybe it could be beneficial. But depends on what you are optimizing for, if it is yield from nitrate you can probably increase it as there tens to be

a lot left over. There is risk of overreduction, and kinetics will probably be faster not slower. Faster kinetics means higher temperature, which may

not be a problem. However what may be a problem with increased rate is that it should become more sensitive to particle size to some degree, this

effect should get stronger with increased proportion of reductant, too.

I suspect the best way to increase yield is to increase the amount of base making sure to capture all the nitrogen oxides. Calcium Oxide/Hydroxide can

be very cheap, problem is just getting it fine enough, which is why is why i recommend using Calcium Nitrate/Potassium Hydroxide. Another way is to

replace the carbon which has the problem of forming carbon monoxide making it harder to get the amount of reductant correct because different amounts

of carbon monoxide is formed depending on rate and physical conditions changing the stochiometry.

When i first did this i tried using sulfur. It seems to be able to reduce nitrate at a lower temperature with one caveat, it loves to explode - even

with excess oxidizer and base present - think some solvent could make it work but nitrite is so soluble it is probably not worth it (the solvent would

probably have to be 200 C + so no distilling away an organic solvent without fire/explosion hazard). I would not recommend it but if someone is mad

enough this is probably the route to very high yields.

I should probably have documented this when i did it but i did not bother because interest was so low anyway. If not you maybe someone else will

optimize it further, verification helps either way.

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

Calcium hydroxide is sold in hardware store 50c a kg, so the base is the least of the issues.

I'm not sure which method is best or better than this, but this is the first one that I found documented and working, because I already struggle with

the endless scale of economies, where I have to make every reagent's pre- and even pre-precursors, and if I have to test and try all different

methods, no time in the world is enough.

Calcium hydroxide probably allows for better separation, because what's insoluble is always easier to process than soluble, unless the sol curve is

very steep. Potato starch residues should have very limited solubility in water in cold temps.

The stuff is half-dried by now, I'll keep it in desiccator for one or more days to get it completely dry, and then measure the collected weight. I

presume this is far from pure, though.

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

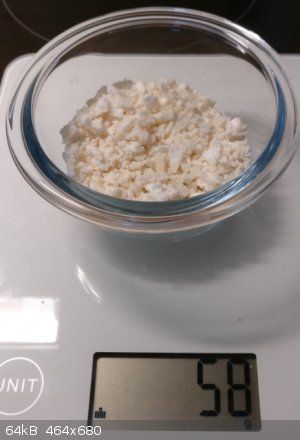

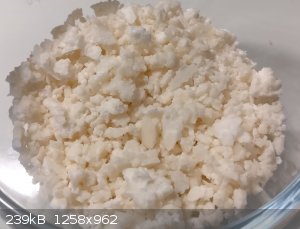

I got it dried. Desiccator dry weight is 58g. I suppose the product is not very pure because the yield is so high. Maximum theoretical yield would be

about 85g, hence the starting point is 68%.

Like I previously said, I first dissolved it in boiling hot water, filtered, cooled to 0C, filtered again from KNO3 and carbonates, and concentrated

about half, cooled, decanted what was likely more Na2CO3 and KNO3 off, and then evaporated. If there is more than 50% of KNO2 I'm highly happy.

Gonna test it soon so I'll tell if it works. Can't determine yields though because I will be using just a catalytic amount.

|

|

|

Fantasma4500

International Hazard

Posts: 1681

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

hey i would just like to put out a warning for method similar to which was posted

im trying to find the best and most efficient method for nitrite as i have a way of purifying it and quantifying how much the specific yield for each

method happens to be

one of these bags i mixed up happened to be..

20g NaNO3 10g NaOH 4g D-glucose

as from flour 165g - 3.3g

NaNO3 85g 1020 20g

NaOH 40g 480g 9.6g

which i acquired from the original post of this thread

scaled it down to fit the sizes im doing for test

initially i used way too much flour and too little NaOH- of course this turned into a flare, only had about 10g of mixture however. so i fixed the

ratios with my bag of nitrate glucose and NaOH and put, 2-3g into my crucible, put it on the gas burner, covered it up with some aluminium foil just

for good luck and stood back, eventually left the room as 10 seconds had passed

then all of a sudden a loud explosion came about

https://gyazo.com/5a22662db19e4ff9ed53b7e6d9d24db2

the aluminium foil was blown off, but not torn to shreds and there was barely any smoke

now im having flashbacks to playing around with a mixture that explodes when being melted down, yellow powder i believe it goes by, its a mixture of

KNO3 K2CO3 and S

could i just have created a more OTC friendly version?

"Yellow powder is potassium nitrate, potassium carbonate and sulfur melted together in a 3:2:1 ratio. "

and i was using 20-10-4 NaNO3 NaOH d-glucose

with the loud explosions im gonna have to let this one method go for producing nitrite, i might give it a go in aqeous solution- not sure if i dare

yet to try with flour instead

|

|

|

LuckyWinner

Hazard to Others

Posts: 163

Registered: 27-8-2018

Member Is Offline

|

|

why is nobody talking about this?

'Thermal decomposition of sodium nitrate under isothermal conditions at around 600 °C is sequential reaction, which is NaNO3 → NaNO2 → Na2O.'

1.how long do you place the NaNO3 into a furnace, till no more oxygen bubbles escape?

2.how do you prevent further decomposition of the created NaNO2?

3.it may be better to use KNO3 → KNO2 since its easier to separate unreacted KNO3 from KNO2?

Quote: Originally posted by Antiswat  | alright. i think ive just came across the ultimate preparation of nitrite, works with sodium nitrite. ive just tested it using dilute H2SO4 and a bit

of the suspected material with a bit of iron sulfate solution. immediate black precipitate

its ridiculously simple: NaNO3 decomposes into mainly NaNO2 at temp of 300-500*C. a hotplate can easily reach glowing red hot temperatures, my

infrared thermometer said hotplate was 450*C hot but having worked with steel i'd say easily 600*C

shortly after it melted an aroma of pyrotechnics was present, possibly from some NOx, i wouldnt call it NO2 however, Na2O was mentioned as one minor

decomposition product in a study about it.

i reacted the finished product with H2SO4 and a bit of copper, around 10mL H2O to 1mL conc H2SO4, faint bubbling, no visible NO2

it was heated for something past 30 minutes in a small stainless steel tray, covered with aluminium foil

the aluminium foil was attacked by something, seemed very fragile but mostly intact, once it has been heated for a while the pyrotechnic smell is no

longer present and this could be a hint at the reaction being mostly over

once the thing finished crackling a solid mass could be broken apart and chipped out

essentially you may be left with a bit of impurities, mostly NaNO3, but relatively pure from something as lazy as throwing it on a hotplate

i didnt measure out exact amounts before and after, finished product was quite dense, but the stainless steel appears to have been darkened greatly,

most likely from either NOx or oxygen along with intense heating, nice matt dark.

low viscocity NaNO2 + ~800*C hotplate https://i.gyazo.com/bf38097573567358c1d5f48eb38b0934.jpg

i can see NaNO3 is insoluble in acetone, but i cant find anything on NaNO2, so for purification it may be easier to do it with potassium nitrate, as

theres major difference in potassium nitrite/nitrate solubility in water, KNO2 is also soluble in ethanol where KNO3 isnt really.

tl;dr thermal decomposition of NO3 = NO2, KNO2 can be extracted with ethanol, KNO3 cant |

|

|

|

Fantasma4500

International Hazard

Posts: 1681

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

KNO3 thermal decomposition? im in the nightmarish midst of experimenting, turns out my bucket of NaNO3 is contaminated with SODIUM CHLORATE

this gave me some funny results for about a week, including loud explosions with NaOH and glucose

KNO3 thermal decomposition, i can share some already now here, the nitrite test i prepared with about a teaspoon of FeSO4 (bought, nice grade) and 20%

H2SO4

keeping KNO3 molten at 550*C for about an hour i got a very vague positive, but a positive the none the less, so it does decompose at that

temperature, quite slowly- but generally they write its 650-850*C, some places faultily mentioned 300something but thats sodium nitrate

i never quantified how much NaNO2 is formed by my quite careless decomposition reaction- but i might get to collect some real data eventually,

probably not a whole lot, but indeed some. you might wanna reach a high temperature and hold it there for a bit, and ignore the whole logic of science

that it will decompose when reaching x temperature

only positive with KNO3 thermal decomp is that KNO3 isnt very soluble compared to KNO2 so you can do a crude seperation if you have great yields. its

a furnace reaction youre looking at though.

i also looked into sodium/potassium oxide formation and it was at +850*C, so barely feasible unless-- unless you have a furnace. which i might get to

once i have enough of messing around with hotplates, or they get enough of me messing around with them. if anyone wanna take a step ahead of me its

quite doable, dampening some sand with sodium silicate, drying it out, preferably over fire. ive tested different compositions of this material and

found just straight up sodium silicate/sand to be the best, calcium silicate mixes just gave crumbly texture, CaSiO4 is easily made by CaCl2 + NaSiO4

in case anyone wanna try some with that.

one last note, i dont think KNO2 is that soluble in ethanol after all, sometimes they list 4g/100mL as "soluble", my latest research didnt imply

ethanol as a way of purification of nitrites.

|

|

|

BAV Chem

Harmless

Posts: 28

Registered: 9-5-2021

Location: In the middle of nowhere

Member Is Offline

Mood: Thoroughly confused

|

|

Nitrate reduction via starch

Over the past few weeks of playing around with this reaction I came up with the following procedure:

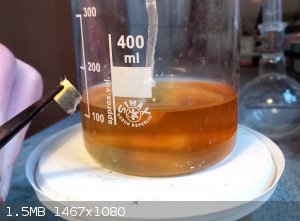

100g of finely powdered sodium nitrate and 25g of starch are thoroughly mixed together and placed in a metal can of about 1L in size. The can is

heated from below (in this case using an electric hotplate) until the mix ignites. With a slight pop the can starts to put out clouds of white smoke

and some sparks and in about 10s the reaction mix quickly turns from a white powder to a grey melt. After the reaction the contents are allowed to

cool and dissolved in water and the solution is filtered to remove suspended carbon and other insolubles. Now the yellow solution is boiled down until

it starts to bump horribly or something precipitates, both indicating it's saturated. On cooling in an ice bath a white solid precipitates (likes to

supersaturate) which is filtered off. This precipitate is mostly sodium carbonate (from decomposition) and some remaining nitrate. Then some dilute

nitric acid is added to the solution with strong stirring until a slight odor of NO2 is detectable and the PH is around 9. This is done to

neutralize traces of NaOH. Once again the solution is boiled to saturation, chilled and filtered. The filtrate is then simply evaporated to dryness

(boiling will only cause it to bump horribly and make a mess).

Most of the nitrate seems to be consumed using this method. The product obtained is around 50% pure, yield is around 30%. I also came up with a way of

measuring its purity.

For this 200mg of product and 1g of urea are dissolved in 30ml of water and 5ml of dilute nitric acid (~20%) is added all at once with strong

stirring. The amount of gas generated is measured. This reaction takes some minutes so it may be heated a little but allow the gasses to cool and

contract again. In theory 200mg of nitrite should generate 130ml of gas.

I'm uncertain if this test is any good so some kind of confirmation would be appreciated. It seems to be somewhat accurate (+-5%) and I already used

the nitrite to make 5-ATZ. Also this test is easily thrown off by carbonate impurities so ideally a control run without any urea is carried out (no

heating needed!) to correct for carbonate.

[Edited on 13-3-2022 by BAV Chem]

|

|

|

Fantasma4500

International Hazard

Posts: 1681

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

as for testing nitrite, the best shot ive found at it so far is to first up take an amount of sodium nitrite and dissolve in water, then dilute that

down until it with 20% H2SO4 and FeSO4 doesnt bubble

i took 1g NaNO2 and added to 100mL water, 1mL of this was reacted with 1mL 20% H2SO4 / FeSO4

this solution is 1% NaNO2 or 1000ppm NaNO2

however it doesnt really form visible bubbles- so 1% NaNO2 is around the cutting line for bubbles to be seen

so if you take 1g of sample NaNO2 and dilute that down until you hit the point where it stops bubbling when reacted with the nitrite test- or maybe go

by how far it has to go before the solution stops being transparent- this will however depend on how much solution you have

best bet to eliminate the carbonate would be to use Ca(OH)2

it can end up forming some alkali hydroxide and that can then end up reacting with CO2 in the air to yet again form carbonate.

edit: using flour/Ca(OH)2/KNO3 i just had a minor breakthrough, hoping to write out something useful soon on getting quite pure nitrite and a

collection of methods ive attempted.

[Edited on 14-3-2022 by Antiswat]

|

|

|

Keras

National Hazard

Posts: 895

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

Reading this thread, I was wondering if potassium nitrate could be reduced to potassium nitrite using a mild reducing agent such as sodium

thiosulphate.

So, not taking care to weight/measure anything, I dissolved a bit of potassium nitrate in water (less than a gram of KNO₃ into 10 ml of distilled

water), then added some crystals of sodium thiosulphate. I was hoping to see either a cloud of colloidal sulphur form, but nothing happened.

I put the beaker in the fridge, and when it was cold I added a dozen drops of HCl in the hope of seeing the blue tinge of nitrous acid. However, the

solution turned cloudy with sulphur, so definitely sodium thiosulphate was oxidised at this point. Since I couldn't see any blue colour (in any case,

the nitrous acid would've been far too dilute), I added a few drops of benzyl alcohol (that’s all I had at hand) in the hope that it would be

nitrated by the acid.

So here I am: the upper solution is almost clear. All the colloidal sulphur has fallen to the bottom of the beaker at this point. At the bottom, I

also have a ‘pearl’ of benzyl alcohol, which is partly covered by something yellow. Is it sulphur trapped at the interface between the two

liquids? Is it nitrobenzyl alcohol? I have no clue.

|

|

|

unionised

International Hazard

Posts: 5126

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

"Thiosulfates are stable only in neutral or alkaline solutions, but not in acidic solutions, due to disproportionation to sulfite and sulfur, the

sulfite being dehydrated to sulfur dioxide:

S

2O2−

3 + 2 H+ → SO2 + "S" + H2O"

From

https://en.wikipedia.org/wiki/Thiosulfate

So there's no evidence of an oxidation.

|

|

|

Keras

National Hazard

Posts: 895

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

Ah, thanks, I didn't know that (I didn't even bother to check on Wikipedia). So you’re right. It’s just thiosulphate disproportionating. Some

stronger reductant might be in order. I suppose triphenylphosphine would work, but it’s not cheap. Sodium dithionite?

|

|

|

clearly_not_atara

International Hazard

Posts: 2787

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

You might want to check the electrode potentials. I suspect that reducing nitrate to nitrite without overreduction to NO/N2O is not so easy. Nitrite

is only stable in alkali, nitrate ion is not very reactive, so you have a catch-22 situation.

Maybe rextalizng kno3 is a more worthwhile endeavor? Chlorate is an unwelcome guest.

|

|

|

Fantasma4500

International Hazard

Posts: 1681

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

@keras

dithionite is very difficult to handle

as for electroreduction its done with pure platinum (deposited platinum doesnt work well for some reason, it has to be solid) and the

concentrations/amperage is very low

quite impractical. if you wanna use electricity just get a high voltage powersupply and do oswald, add in airpump and blow it directly into NaOH

solution, this will acquire you half and half nitrate/nitrite however.

ELECTROREDUCTION

THE PRODUCTION OF NITEITE FROM NITRATE.

The reduction of nitrate to nitrite can be accomplished satisfactorily, and the process is the subject of a recent patent.1

It has been shown (Miiller and "Weber)2 that in a divided cell, smooth platinum or copper cathodes reduce nitrate to nitrite and ammonia, but

platinised platinum gives much ammonia and little nitrite. A spongy copper or silver cathode was found to give the best results. With a current

density of 0.25 amps, per dm3 and a concentration of 2.3 grams of sodium nitrate per litre, a current efficiency of 90 per cent, was obtained. The

current efficiency with an amalgamated copper cathode was found to diminish when 50 per cent, of the nitrate had been changed.

Considerable care is evidently needed to prevent the formation of ammonia, since it has been shown by W. H. Easton3

|

|

|

Keras

National Hazard

Posts: 895

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

How so?

Does copper work? Between solid platinum and ‘spongy’ copper, I doubt anyone would hesitate.

|

|

|

Keras

National Hazard

Posts: 895

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

Still, I’m surprised that the sodium dithionite method doesn’t work. If I follow the CRC Handbook, we have:

NO₃⁻ + H₂O + 2 e⁻ ⇋ NO₂⁻ + 2 OH⁻ e = 0.01 V

2 SO₃⁻ + 2 H₂O + 2 e⁻ ⇋ S₂O₄²⁻ + 4 OH⁻ e = -1.12 V

So logically, this reaction:

NO₃⁻ + 2 OH⁻ + S₂O₄²⁻ → NO₂⁻ + 2 SO₃⁻

should have e = 1.13 V, which is a pretty high K and should be almost quantitative, no?

[Edited on 16-3-2022 by Keras]

|

|

|

Fantasma4500

International Hazard

Posts: 1681

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

@keras iirc chemplayer had a video on it, its on bitchute

he mentions that it heats up with contact with air because its so strongly reductive that it exothermically reacts with oxygen in air

i would consider anything towards P2O5 difficult to handle.

one other problem is that nitrite can also react so you dont want it to be too powerful

im hearing lead is really great for this reaction as it stops at nitrite- my experiences with it is that its very tedious to be stirring

ive tried with sawdust from bandsaw and in wide excess it gives some success, maybe coffeegrinding it would give better results, otherwise metal

workshops usually have a beltgrinder, they have a collection tray underneath where one may find mainly steel dust with some Fe3O4- Fe3O4 reacts very

fast with HCl so a quick minute rinse in warm HCl should do- decantation and flushing with EtOH would yield a great reagent

CaSO3 is listed as typical reagent for this reaction, i tried with calcium sulfamate but that didnt do much in my attempt

sulfite is doable as you may simply dump SO2 from a sulfur candle into Ca(OH)2- which should be doable from CaCl2 and NaOH, CaCl2 is commonly sold as

air dessicant granules

|

|

|

Keras

National Hazard

Posts: 895

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

Alright, I tried potassium nitrate + sodium hydroxide + sodium thiosulphate.

There’s a slight cloud forming when you combine potassium nitrate and sodium hydroxide in solution, but it clears up almost immediately.

So far, I’m faced with nothing much to report. Pretty everything has dissolved, and I didn't notice anything special happening. The reaction,

however, should be undetectable with the naked eye.

What is the best way to know if nitrite has really formed? A test that would evidence nitrites and not nitrates. Evaporate the solution and examine

the salts? Try to acidify it to form nitrous acid? Anything else?

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Nitrite can be determined quantitatively by titration of a solution with permanganate in warm dilute sulfuric acid: 2KMnO4 + 5KNO2 + 3H2SO4 ->

5KNO3 + 3H2O + 2MnSO4 + K2SO4

[Edited on 17-3-2022 by S.C. Wack]

|

|

|

Keras

National Hazard

Posts: 895

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

Thanks!

I put my hands on Vogel's Qualitative Inorganic Analysis, and there’s at least two experiments I could follow with what I have at home: the

HCl method to produce the blue nitrous acid, and oxidation of KI.

Your method is also mentioned in there.

|

|

|

Fantasma4500

International Hazard

Posts: 1681

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

i would suggest adding in an alcohol to absorb the NOx- rather have a bit of vasodilation than NOx.

i came across sodium dithionite- OTC. i wasnt yet aware that this is OTC so ill be trying to see if this does something interesting for nitrite

any other interesting methods are welcome.

|

|

|

Lionel Spanner

Hazard to Others

Posts: 168

Registered: 14-12-2021

Location: near Barnsley, UK

Member Is Offline

|

|

I may well be very late to the party, but has anyone tried the method described in US patent 729,515, namely heating sodium nitrate with calcium

hydroxide and graphite, giving sodium nitrite, calcium carbonate, and water vapour?

The author reported that repeating the process a second time reduced any unreacted nitrate to negligible quantities.

Attachment: US792515.pdf (139kB)

This file has been downloaded 350 times

|

|

|

BAV Chem

Harmless

Posts: 28

Registered: 9-5-2021

Location: In the middle of nowhere

Member Is Offline

Mood: Thoroughly confused

|

|

Quote: Originally posted by Lionel Spanner  | I may well be very late to the party, but has anyone tried the method described in US patent 729,515, namely heating sodium nitrate with calcium

hydroxide and graphite, giving sodium nitrite, calcium carbonate, and water vapour?

The author reported that repeating the process a second time reduced any unreacted nitrate to negligible quantities. |

This looks like another very doable variation of this process as the reaction with normal charcoal is too exothermic, leading to a lot of

decomposition.

On another note, what is the calcium hydroxide even there for in this reaction?

Some include it while others leave it out completely. I had some success with starch and no hydroxide and got a 30% yield (see a few posts above).

[Edited on 18-3-2022 by BAV Chem]

|

|

|

| Pages:

1

..

10

11

12

13

14

..

17 |