| Pages:

1

..

9

10

11

12

13

..

17 |

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Σldritch  |

.........

I doubt you will get much other than ammonia similar to how you will not get alcohols from clemmensen reduction; the reactant is bonded to the metal

surface until it has picked up hydrogen on all its bonds to the metal so the reaction will not stop at nitrite very often.

|

I believe based on your comment is that it is necessary to have some excess in nitrate, at least the required amount of say NaOH, and less than

indicated amount of Aluminum, plus some oxygen. The complete dissolution of the metal surface by the NaOH is likely needed. If not, likely reaction

with water on the aluminum could lead to further reduction:

3 [ H2O = H+ + OH- ]

Al + 3 OH- → Al(OH)3 + 3 e-

3 e- + 3 H+ = 3 .H

.H + NO3- = OH- + .NO2

2 .NO2. + H2O = HNO2 + HNO3

.H + NO2- = OH- + .NO

.......

Physical removal of undissolved aluminum metal (actually Al foil, an alloy, with Fe,..., which could act as a galvanic couple producing reducing e- )

may be needed, else Al sitting in a slow reaction with water, or per other reactions, may be an issue. Aqueous nitrite are photoactive producing

hydroxyl radicals, which could lower yield with time, so avoid prolonged light exposure.

[Edited on 4-10-2017 by AJKOER]

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

OK, I ran an experiment per my reaction (actually, cited in the literature under alkaline conditions, see, for example, [EDIT] "Nitrate Removal from

Ground Water: A Review", by Archna, et al., E-Journal of Chemistry, 2012, 9(4), 1667-1675), link: https://www.google.com/url?sa=t&source=web&rct=j&... ):

2 Al + 3 NO3- + 3 H2O -- 6OH- --> 2 Al(OH)3 + 3 NO2-

I dissolved 7 g of KNO3 in 12O cc of distilled water. I added 1.4 g of aluminum foil (a sheet of 14 cm x 23 cm). Used an excess of NaOH (5 cc).

([EDIT] As a old prior source spoke of a pH around 9.0, a better procedure may be to add the stoichiometric dose of NaOH over divided doses, with

stirring and stopping before if all the aluminum is dissolved). All the aluminum dissolved. Left a fine black suspension of which I was able to filter

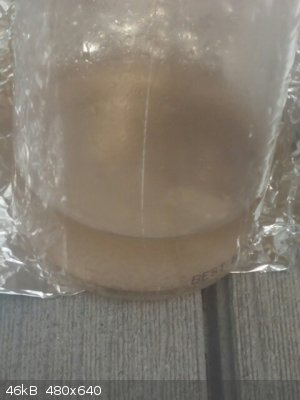

most out of the very alkaline solution. See picture of pre-filtered solution below:

Added the hopefully now nitrite rich mix with added sea salt to 97% ethanol ([EDIT] Ever Clear, not Evergreen), and currently awaiting sunlight to

breakdown the alcohol (smell change) via photolysis of aqueous nitrite/sea salt (reference: please see http://onlinelibrary.wiley.com/doi/10.1029/JC086iC04p03173/a...). Not a classic test for nitrite, but it is one of my intended uses (for

photolysis).

[Edited on 5-10-2017 by AJKOER]

[Edited on 6-10-2017 by AJKOER]

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Photolysis run:

|

|

|

Melgar

Anti-Spam Agent

Posts: 2004

Registered: 23-2-2010

Location: Connecticut

Member Is Offline

Mood: Estrified

|

|

Quote: Originally posted by AJKOER  | OK, I ran an experiment per my reaction (actually, cited in the literature under alkaline conditions, see, for example,

file:///home/chronos/u-6092dab7e8781d5c630e3fdaff87bc2dff6db2e0/Downloads/154616.pdf ):

2 Al + 3 NO3- + 3 H2O -- 6OH- --> 2 Al(OH)3 + 3 NO2- |

Have you realized that that's a link to a file on your local computer? It seems to indicate that you have a Unix-like filesystem, and that your

username (or the system name) is "chronos". Possibly on a public computer, since your files are in a folder with what appears to be an MD5 hash in

the username, and may be a way of allowing guest users to save files locally.

Quote: Originally posted by AJKOER  | I dissolved 7 g of KNO3 in 12O cc of distilled water. I added 1.4 g of aluminum foil (a sheet of 14 cm x 23 cm). Used an excess of NaOH (5 cc). All

the aluminum dissolved. Left a fine black suspension of which I was able to filter most out of the very alkaline solution. See picture of pre-filtered

solution below:

Added the hopefully now nitrite rich mix with added sea salt to 97% ethanol (Evergreen), and currently awaiting sunlight to breakdown the alcohol

(smell change) via photolysis of aqueous nitrite/sea salt (reference: please see http://onlinelibrary.wiley.com/doi/10.1029/JC086iC04p03173/a...).] |

Evergreen? You sure you don't mean "Everclear"? Maybe it's time to get some sleep now, eh?

The first step in the process of learning something is admitting that you don't know it already.

I'm givin' the spam shields max power at full warp, but they just dinna have the power! We're gonna have to evacuate to new forum software!

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

or stop taste testing the ever clear for potency!

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Melgar:

Fixed the link on another machine and inserted article title.

Thanks. I was using an alternate computer (Acer Chrome book). Apparently, just copying the url as displayed on that machine for certain links (like to

locally stored downloaded files) is problematic for the other computers. Lots of new things with the Chrome book computer got to get acquainted with,

but it does have a low price, large screen and even HMDI ports to play online movies onto big screen TVs,...... Recommend it for word processing (talk

and it enters your text fairly accurately based on context), research,..., but not for anything like online games and such.

I don't drink the alcohol, else I would at least known what to call it if I have to buy more!

Cheers!

[Edited on 6-10-2017 by AJKOER]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

NaNO2 can be bought very cheaply at Ace hardware where salts are used to brine salmon eggs.

[Edited on 7-10-2017 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Pure KNO3 is sold as stump remover aid in stores with home garden sections (Home Depot,...).

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Updated picture following photolysis in sunlight for 6 hours:

The reaction mix is now more intensely colored (resembling olive oil) together with a diminished smell from the former strong scent of the EverClear.

Some photochemical reaction, in alkaline conditions, has apparently occurred, which may be supportive of the claim of the initial nitrite presence

given the short time frame of treament. The latter with sea salt, alcohol and distilled water in the presence of strong sunlight, may have produced

hydroxyl radicals, as would be expected per my prior cited source, thereby further producing new products. Definitely, no smell of NH3.

[Edited on 7-10-2017 by AJKOER]

|

|

|

Σldritch

Hazard to Others

Posts: 309

Registered: 22-3-2016

Member Is Offline

Mood: No Mood

|

|

Tried preparing Isopropyl nitrite from the nitrite i made. Yield was 30%.

|

|

|

Melgar

Anti-Spam Agent

Posts: 2004

Registered: 23-2-2010

Location: Connecticut

Member Is Offline

Mood: Estrified

|

|

Nitrates and nitro groups are rarely very active at all toward reduction in strongly alkaline solutions. I'm pretty sure that a H+ ion would be

necessary for reducing NO3-, and those are hard to come by in a solution that alkaline. Not to mention, aluminum would be acting as an acid, and

forming aluminate salts with your alkalis. I think that in the reaction you cited, what must be happening is that eventually aluminum neutralizes the

pH, at which point it may be possible for it to reduce nitrates selectively, since the aluminum/aluminate would be able to buffer the pH.

But since your solution was strongly alkaline, I'd expect that you still have nitrates, rather than nitrites. You can always test by adding a strong

acid and checking for brown fumes, which would mean nitrite. I suspect you don't actually have any though.

The first step in the process of learning something is admitting that you don't know it already.

I'm givin' the spam shields max power at full warp, but they just dinna have the power! We're gonna have to evacuate to new forum software!

|

|

|

Rhodanide

Hazard to Others

Posts: 348

Registered: 23-7-2015

Location: The 80s

Member Is Offline

Mood: That retro aesthetic

|

|

RIGHT?!

I can buy NaNO2 by the POUND, but NaNO3 is IMPOSSIBLE to find!!! Or any Nitrate for that matter, besides

NH4NO3 from instant cold packs.

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

My claimed alteration of NH3 generation is cited as likely correct (see reaction 1.6 below). Here is an extract from a source, page 1.12, "Mitigation

of Hydrogen Gas Generation from the Reaction of Water with Uranium Metal in K Basin Sludge", by SI Sinkov, et al, January 2010, to quote:

"2 Al + 2 NaOH + 6 H2O → 2 NaAl(OH)4 + 3 H2

The evolution of H2 was moderated by the addition of NaNO3 to the cladding removal solution to form ammonia. The chemical reduction of

the nitrate to ammonia occurs by the following stoichiometry:

8 Al + 5 NaOH + 3 NaNO3 + 18 H2O → 8 NaAl(OH)4 + 3 NH3 Reaction 1.5

With higher sodium nitrate concentrations, ammonia decreases and NaNO2 is favored:

2 Al + 2 NaOH + 3 NaNO3 + 3 H2O → 2 NaAl(OH)4 + 3 NaNO2 Reaction 1.6

Systematic study of the effects of NaOH concentration and the NaNO3:Al ratio were undertaken to optimize the cladding removal process to

minimize H2 release and decrease the unwanted production of NH3 (Gresky 1952). The reactions showed reasonable adherence to

stoichiometry, as the NaNO3:Al ratio was varied, particularly at lower ratios. However, as shown in Figure 1.4, the release of NH3

could not be completely supplanted by NaNO2, even at high NaNO3:Al mole ratios.

Testing also showed that NaNO3 concentrations above ~1 M (85 g NaNO3/liter) had little further effect in decreasing the H2 yield

(Figure 1.5). At high NaNO3 concentrations, the H2 yield was ~2 mL of gas (~8.3×10-5 moles) per gram (3.7×10-2 moles) of aluminum

or 2.2×10-3 moles of H2 per mole of Al. This is about 0.15% of the 1.5 moles H2 per mole of Al yield that would have occurred

in nitrate-free alkaline solution or an attenuation factor of 1/0.0015 (~670).

.......

The joint evolutions of H2 and NH3 were found to be at a practical minimum under plant conditions when the nitrate and aluminum mole

quantities were nearly equal (Gresky 1952):

20 Al + 17 NaOH + 21 NaNO3 + 36 H2O → 20 NaAl(OH)4 + 18 NaNO2 + 3 NH3 Reaction 1.7"

Source link: http://r.search.yahoo.com/_ylt=A0LEV1L8gNxZJTAA.mnBGOd_;_ylu...

Note, my prior work above suggested a reaction of:

2 Al + 3 NO3- + 3 H2O -- 6OH- --> 2 Al(OH)3 + 3 NO2-

As compared to:

2 Al + 2 NaOH + 3 NaNO3 + 3 H2O → 2 NaAl(OH)4 + 3 NaNO2 Reaction 1.6"

[Edit] I have happily surprised that my reaction mechanics, attributed to likes of Mg, Al and Zn, apparently apply also to uranium, to quote from the

same source, page 1.2:

"Uranium metal is highly electropositive, reacting with water to produce hydrogen radicals (H·) and UO2. The reactive hydrogen radicals

can combine to form H2:

U + 2 H2O → UO2 + 4 H· → UO2 + 2 H2 Reaction 1.1

The H2 dissolves in water and, upon water saturation, forms bubbles that are released into the gas phase.

The hydrogen radicals or H2 also can react with uranium metal to form UH3:

U + 3H· (or 1.5 H2) → UH3 Reaction 1.2

The UH3 then can react with water to liberate hydrogen radicals or H2:

UH3 + 2 H2O → UO2 + 7 H· (or 3.5 H2) Reaction 1.3 "

[Edited on 12-10-2017 by AJKOER]

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Melgar  |

......

Nitrates and nitro groups are rarely very active at all toward reduction in strongly alkaline solutions. I'm pretty sure that a H+ ion would be

necessary for reducing NO3-, and those are hard to come by in a solution that alkaline. Not to mention, aluminum would be acting as an acid, and

forming aluminate salts with your alkalis. I think that in the reaction you cited, what must be happening is that eventually aluminum neutralizes the

pH, at which point it may be possible for it to reduce nitrates selectively, since the aluminum/aluminate would be able to buffer the pH.

But since your solution was strongly alkaline, I'd expect that you still have nitrates, rather than nitrites. You can always test by adding a strong

acid and checking for brown fumes, which would mean nitrite. I suspect you don't actually have any though. |

As I noted previously on page 1 of this thread, "possible reaction in the presence of nitrate, with either prehydrated or totally solvated electrons,

being reported as readily scavenged by nitrate:

e(p)-/e(aq)- + NO3- + H2O -> NO2 + 2 OH- (Source: see eq. (5) in JAERI-Conf 95-003, "5. 6 Radiolysis of Concentrated Nitric Acid Solutions R.

Nagaishi" by P.Y. Jiang, et al, link: https://www.google.com/url?sa=t&source=web&rct=j&... )"

which would seem to suggest a possible shift to say partially solvated electrons in place of .H in less acidic conditions as a path to aqueous NO2

(and some NO2- + NO3- therefrom).

My rough recollection of the literature was that the vigor of Al/NaOH reaction was possibly a factor in the effectiveness of any reductive process.

This could imply that oxygen from air or dissolved in solution could be entering the reaction and producing the superoxide radical anion (or just

referred to as superoxide), via:

e(p) + O2 = .O2-

Given the apparent affinity of superoxide with nitric oxide to form peroxonitrite in alkaline aqueous solution (see, for example, "Reaction of

superoxide with nitric oxide to form peroxonitrite in alkaline aqueous solution", Inorganic Chemistry (ACS Publications),

pubs.acs.org/doi/abs/10.1021/ic00216a003, by NV Blough (1985), http://pubs.acs.org/doi/abs/10.1021/ic00216a003 ), a further reaction may be occurring with the stable NO2 radical also, which I would state as:

.O2- + .NO2 = O2 + NO2- (Source: "Table 1: Initial Concentrations for three scenarios under polluted continental (urban), unpolluted continental

remote)", R48 at

http://www.google.com/url?sa=t&rct=j&q=e(p)-%2B%20NO3-%20%2B%20H2O%20%3D%20NO2-%20%2B%202%20OH-&source=web&cd=17&ved=0ahUKEwj_js-k

nvHWAhUC4SYKHaP0Cr04ChAWCC0wBg&url=http%3A%2F%2Fprojects.tropos.de%2Fcapram%2Fcapram23.pdf&usg=AOvVaw1t2DhghrOHnYru_phBHNYk )

The net of the last three reactions could then be:

2 e(p)- + NO3- + H2O -- O2 -> NO2- + 2 OH-

which I have also seen reported in the literature (it is also a cited half cell reaction, see, for example, http://www.google.com/url?sa=t&rct=j&q=e-%20%2B%20NO... ).

In any event, the formation of a reductive species (.H or e-(p) ) appears to occur at both low and high pH.

[Edited on 15-10-2017 by AJKOER]

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Some interesting observations from this 1921 paper (please ignore the theory), "THE MECHANISM OF REDUCTION OF NITRATES AND NITRITES IN PROCESSES OF

ASSIMILATION.", by OSKAR BAUDISCH, 1921, link: http://www.google.com/url?sa=t&rct=j&q=THE%20MECHANI... . Some interesting comments to quote:

"This dissociation of nitrate into oxygen and nitrite can also be brought about by means of metallic iron as well as under the influence of the energy

of light. If a neutral oxygen-free solution of potassium nitrate be shaken in a vacuum with active iron prepared by reduction with hydrogen, the

supernatant liquor obtained after the iron powder has been allowed to settle will give every reaction applicable for the detection of nitrous acid. In

other words, metallic iron will easily reduce potassium nitrate to potassium nitrite in the cold in the absence of every trace of oxvgen, .."

My take on using a boiled aqueous nitrate solution (removing oxygen) to which is added fresh iron filings in an a sealed O2 free vessel, as a possible

path to nitrite:

2 [ H2O = H+ + OH- ]

Fe + 2 OH- → Fe(OH)2 + 2 e-

2 [ e- + H+ = .H ]

2 [ .H + NO3- = OH- + .NO2 ]

2 NO2. + H2O = 2 H+ + NO2- + NO3-

Adding reactions:

Fe + 3 H2O + 2 NO3- → Fe(OH)2 + NO2- + NO3- + 2 H2O

Upon cancelling, my estimate of the overall slow net reaction is (which implies equal moles of iron metal powder and an available nitrate):

Fe + H2O + NO3- → Fe(OH)2 + NO2-

Note, avoid an excess of iron metal and water as:

.H + NO2- = OH- + .NO

......

[Edit] In fact, a source notes the following:

"Nitrate reduction can be induced under basic pH according to the following reaction10:

3NO3- + 8Fe (OH)2 + 6H2O → NH3 + 8Fe(OH)3 + OH-

Experimental results showed that a Fe: NO3- ratio of about 15: 1 was required in the presence of copper catalyst for the reaction

to proceed"

Source: "Nitrate Removal from Ground Water: A Review", by Archna, et al., E-Journal of Chemistry, 2012, 9(4), 1667-1675), link: https://www.google.com/url?sa=t&source=web&rct=j&...

A problematic side reaction is possibly the formation of hydrogen gas (which also suggests employing an expandable vessel to avoid spillage):

.H + .H = H2 (g)

Use of a Magnetizer may likely accelerate the reaction also (see https://www.sciencemadness.org/whisper/viewthread.php?tid=77...).

[Edited on 14-10-2017 by AJKOER]

|

|

|

Σldritch

Hazard to Others

Posts: 309

Registered: 22-3-2016

Member Is Offline

Mood: No Mood

|

|

1. Metal powders are hard to make and/or expensive.

2. The reactions requires an excess of nitrate which...

3. is hard to separate and...

4. produces lots of byproducts such as...

4. nitric oxide produced by the reaction of ferrous with nitrates/nitrites and ammonia. (http://pubs.acs.org/doi/abs/10.1021/ja01331a020?journalCode=...)

The carbohydrate-nitrate-base route was at least well established and used industrially for quantitative nitrite production. It really seems like the

best route to make nitrite to me unless you just want to have fun with the metal reduction.

If you want really pure nitrite i think converting it to an alkyl nitrite and hydrolysing it will do it.

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Σldritch  | 1. Metal powders are hard to make and/or expensive.

2. The reactions requires an excess of nitrate which...

3. is hard to separate and...

4. produces lots of byproducts such as...

4. nitric oxide produced by the reaction of ferrous with nitrates/nitrites and ammonia. (http://pubs.acs.org/doi/abs/10.1021/ja01331a020?journalCode=...)

The carbohydrate-nitrate-base route was at least well established and used industrially for quantitative nitrite production. It really seems like the

best route to make nitrite to me unless you just want to have fun with the metal reduction.

If you want really pure nitrite i think converting it to an alkyl nitrite and hydrolysing it will do it. |

In my opinion, none of your cited points are valid for the claimed oxygen-free iron metal approach (granted, to be verified and not likely very large

scale as keeping oxygen free is likely increasingly difficult upon scaling up).

1. I have prepared iron filings for experiments in under 5 minutes with a medium sized file acting on a cast iron rode.

2. My indicated net reaction indicates just 1 mole of nitrate to produce 1 mole of nitrite.

3. Fe(OH)2 is not soluble in near neutral conditions, so no separation issue.

4. No byproducts except perhaps a very small amount of H2 or NH3.

5. Normally, per your link, the reaction of a ferrous salt in highly acidic (not neutral conditions) acting on nitrate can lead to NO. Also, using a

very high (15:1) Fe to NO3- ratio along with a copper catalyst (as I noted above in a reference) may enable reduction to ammonia. The latter reference

applies to commercial nitrate removal from ground water.

---------------------------------------------------------

[Edit] My speculation as to why air/oxygen is such a problem, even in trace amounts, with respect to the Iron metal/H2O/Nitrate process:

First, we want H+ + e- = .H to take place.

But, O2 can steal the the e- forming the superoxide radical anion, .O2-, resulting in the loss of one potential .H

Also, the .O2- + .H = HO2- , resulting in the loss of an existing .H (source: see

https://images.search.yahoo.com/search/images;_ylt=AwrBT89Dq... ).

Also, in the presence of CO2 in air, creating soluble ferrous bicarbonate, we could have Fe(ll) + O2 = Fe(lll) + .O2- , which is the so called metal

auto oxidation reaction, regenerating the superoxide to remove another .H

And finally, Fe(lll) + HO2- = Fe(ll) + H+ + .O2- (pH >4.8), which recycles any soluble ferric to ferrous (and also creates another superoxide),

thereby resulting in a cyclic chain reaction consuming any created .H (or e-) reducing radicals.

[Edited on 15-10-2017 by AJKOER]

|

|

|

unionised

International Hazard

Posts: 5126

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Melgar  |

Nitrates and nitro groups are rarely very active at all toward reduction in strongly alkaline solutions. I'm pretty sure that a H+ ion would be

necessary for reducing NO3-, and those are hard to come by in a solution that alkaline. Not to mention, aluminum would be acting as an acid, and

forming aluminate salts with your alkalis. |

Nonsense.

https://en.wikipedia.org/wiki/Devarda%27s_alloy

|

|

|

Fantasma4500

International Hazard

Posts: 1681

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

iron oxalate, very low solubility in water, as oxalic acid is a strong acid pretty much any soluble iron salt you can find of iron will precipitate

iron oxalate when mixing up solutions of oxalic acid and iron salt, its easily purified by decantation, barely takes minutes to settle, its

decomposition point is around the temperature of melting point for sodium nitrate

mix the two and heat up, nanoiron will form, along with a bit of carbonate and hydroxide of iron oxides, the nanoiron should react so vigously that

you wouldnt need to heat the mixture very forcibly, likely it would act slightly pyrotechnic even supplying itself with energy, in theory this works,

in practice i have zero experience yet

starting materials are relatively easy to get around, procedure should be simple and isolation of reaction products should also be quite doable

sodium nitrite is sparingly soluble in ethanol, cant find much about sodium nitrates solubility in ethanol however, this may be exploitable.

sodium nitrate is insoluble in acetone, nitrite in acetone? i'd test solubilities out in common solvents but some very organized thieves got this idea

that sodium nitrite is super valuable in producing explosives so they had to my neat little bottle of well labeled sodium nitrite.

barium nitrate-nitrite could be a plausible way to get rid of nitrate, although it comes close to solubility different of sodium nitrate-nitrite, ~5g

Ba(NO3)2 vs 50g Ba(NO2)2 100mL @0*C

what using FeOx could offer would be a quite clean process without hazardous lead fumes, possibly some carbon monoxide and some iron, but likely

dodging the brutal mess of charcoal, for dealing with alkali carbonate i'd suggest reacting the mess with HCl as NaCl has only a few grammes of

solubility difference from 0-100*C making it ideal for fractional crystallization

on a sidenote IPN is quite worthy for FAE

|

|

|

GrayGhost-

Hazard to Self

Posts: 61

Registered: 31-10-2017

Location: Argentina

Member Is Offline

Mood: No Mood

|

|

I used Al flakes ( used to applied to face ) + potassium nitrate both dry, and firing. I was obtain many smoke and scrap.

|

|

|

Master of the Elements

Harmless

Posts: 4

Registered: 10-1-2018

Member Is Offline

Mood: No Mood

|

|

It is sold at some sporting goods shops as a bait preservative, usually right next to the borax and sodium sulfite.

|

|

|

Fantasma4500

International Hazard

Posts: 1681

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

alright. i think ive just came across the ultimate preparation of nitrite, works with sodium nitrite. ive just tested it using dilute H2SO4 and a bit

of the suspected material with a bit of iron sulfate solution. immediate black precipitate

its ridiculously simple: NaNO3 decomposes into mainly NaNO2 at temp of 300-500*C. a hotplate can easily reach glowing red hot temperatures, my

infrared thermometer said hotplate was 450*C hot but having worked with steel i'd say easily 600*C

shortly after it melted an aroma of pyrotechnics was present, possibly from some NOx, i wouldnt call it NO2 however, Na2O was mentioned as one minor

decomposition product in a study about it.

i reacted the finished product with H2SO4 and a bit of copper, around 10mL H2O to 1mL conc H2SO4, faint bubbling, no visible NO2

it was heated for something past 30 minutes in a small stainless steel tray, covered with aluminium foil

the aluminium foil was attacked by something, seemed very fragile but mostly intact, once it has been heated for a while the pyrotechnic smell is no

longer present and this could be a hint at the reaction being mostly over

once the thing finished crackling a solid mass could be broken apart and chipped out

essentially you may be left with a bit of impurities, mostly NaNO3, but relatively pure from something as lazy as throwing it on a hotplate

i didnt measure out exact amounts before and after, finished product was quite dense, but the stainless steel appears to have been darkened greatly,

most likely from either NOx or oxygen along with intense heating, nice matt dark.

low viscocity NaNO2 + ~800*C hotplate https://i.gyazo.com/bf38097573567358c1d5f48eb38b0934.jpg

i can see NaNO3 is insoluble in acetone, but i cant find anything on NaNO2, so for purification it may be easier to do it with potassium nitrate, as

theres major difference in potassium nitrite/nitrate solubility in water, KNO2 is also soluble in ethanol where KNO3 isnt really.

tl;dr thermal decomposition of NO3 = NO2, KNO2 can be extracted with ethanol, KNO3 cant

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

When using KNO3 in place of NaNO3 in the OP reaction consisting of a nitrate, a base, and starch(in this case, potato or corn starch powder), is there

a risk of forming cyanides?

I ask this because of this article in SM wiki:

http://www.sciencemadness.org/smwiki/index.php/Potassium_nit...

| Quote: |

A less known reaction is the synthesis of potassium cyanide, by reacting a mixture of potassium nitrate and charcoal in a cast iron bowl, in an inert

atmosphere to prevent combustion or oxidation to potassium cyanate:

2 KNO3 + 7 C → KCN + KCNO + 5 CO[2]

If you attempt to try this reaction, AVOID ADDING ACID TO THE RESULTED SLAG AS IT WILL GIVE OFF HYDROGEN CYANIDE GAS WHICH CAN BE DEADLY (see the

Sciencemadness thread below).

|

This is, because I don't have Na but K nitrate, and in theory, upon forming, potassium and sodium ions should precipitate sodium carbonate and

potassium nitrate out easily when recrystallizing, and leave potassium nitrite in solution, because it has by far the highest solubility, hence the

purification should be more convenient than with Na.

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

I performed a test with this. I ground up 100g of KNO3, 48g of NaOH and 20g of potato starch and placed the mix in steel pot and placed a steel plate

as a lid. I heated it slowly with gas burner, and it started to buff up, smoke, and then a controlled reaction kicked in and it appeared to be burning

for several seconds, generating white smoke, and then it stopped and ceased totally. I let it cool, and yellow rock hard mass was formed with slight

greenish tint, not sure if it was from the red impurity of KNO3.

I dissolved it with 100mL of boiling water and added a little, but part was left undissolved. I filtered it clear, orange liquid, and cooled it. KNO3

and apparently what is Na2CO3 crystallized out. I concentrated the liquid by heating, and white mass what is likely Na2CO3 crashed out. I plan to

process it further by cooling it down to 0 and see if it solidifies completely, and if, add just a bit to extract the KNO2, and eventually dry it in

desiccator.

What I was afraid if this reaction could have generated any cyanides, according to my previous post. I haven't smelled any almonds, but if I try to

sniff it too much, I begin to imagine that I notice a trace of it, but this happens every time. I suppose it should be detectable, unless there's that

genetic thing? I smell normal and bitter almonds(BzH), though.

|

|

|

Σldritch

Hazard to Others

Posts: 309

Registered: 22-3-2016

Member Is Offline

Mood: No Mood

|

|

Nice to see someone actually giving this a try! Some this i learned while doing this when making nitrite for azide (which worked further proving this

synthesis works):

1. The smell is from some volatile carbon compound presumably formed from the starch. You get it from pyrolysing starch too, which is probably the

source. It can not be cyanide because we use oxidizer in a huge excess and knowing the smell of cyanide i can say this is not it though i can see the

similarity. I like to clean up the filtrate with activated carbon, it gets rid of the smell and most of the color (it is slightly yellow as a solid).

2. I strongly recommend using Potassium Nitrate and Calcium Hydroxide or something equivalent such as Calcium Nitrate and Potassium Hydroxide to get

good separation. While you might be able to get out Sodium Carbonate easily with just sodium you can not separate the Sodium Nitrate and Nitrite.

There tends to be a lot of nitrate left over, which is worth saving. Mixing in potassium might improve it but at the cost of carbonate separation.

3. Crude yield tends to be 10% with mixing Calcium Nitrate and Potassium Nitrate lazily. Grinding does not seem to improve it much. Crude yield is 30%

when dissolving the salts and then mixing and boiling it down until ignition. Takes more time but the better yield is absolutely worth it. Obviously

use metal container for this.

4. When doing it as suggested in (3). Do not use starch, use sucrose or you will have a horrible, caustic, goopy mess to work with.

[Edited on 5-11-2020 by Σldritch]

|

|

|

| Pages:

1

..

9

10

11

12

13

..

17 |

|