Furch

Hazard to Others

Posts: 130

Registered: 8-10-2006

Member Is Offline

Mood: No Mood

|

|

Extraction problems.

Hello!

I have a problem. You see, I'm trying to perform a reductive amination with a ketone, using methylamine as amine source, and aluminum foil as the

reducing agent... However, when the reaction is complete, and it's time for the clean up, things get bad. Really really bad...

I evaoprate the solvent (IPA), dissolve the residue in 10% HCl till acidic, wash with DCM, then, as I add 10% NaOH to make the mixture basic, a white

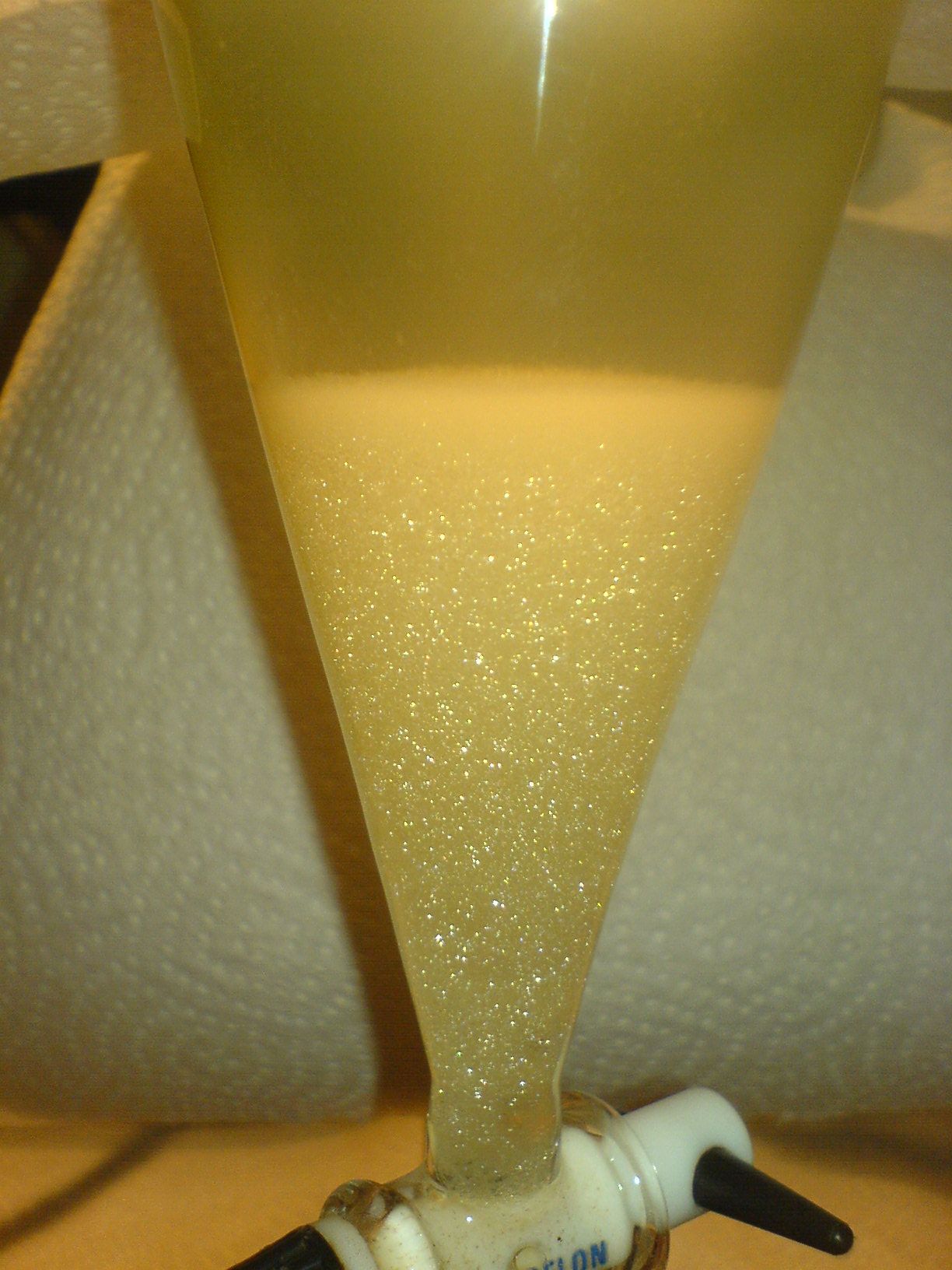

precipitate falls out in form of "clouds"... This is normal you say? Aye, me too... It's the freebase, right? Wrong. When I try to extract with DCM,

this is what happens (see attachment).

The DCM-layer won't clear up... It's full of bubbles! It's as if the DCM has an invisible film of something, prohibiting it to combine with the other

bubbles...

However, when I tap this "layer" off, and repeat the extraction a couple of times with DCM, I try to wash the DCM-layer with water, and this is what

happens.

Tiny bubbles of water stick to the glass walls of the separatory funnel... And it's impossible to distinguish where one layer starts and the other

ends because of a mountain of bubbles.

This problem haunts me. I know there is nothing wrong with my lab technique, as I performed this exact reaction a couple of years ago with great

success. I've tried everything, it seems... I've tried nitromethane as the methylamine source, different brands of aluminium foil, different batches

of ketone I've even gotten lab grade NaOH... But still this problem occurs.

I've also tried "salting out", and adding brine to make the bubbles go away, but without success...

I've tried ignoring this and gone on as if there WERE layers to deal with, and the best yield I've gotten when doing this has been around 5%.

The DCM I use has been recovered according to the procedure in Vogel's, so it definitely should not be the problem.

But what is? I'm desperate! And I'm running out of materials...

Please help, if you can.

Sincerely,

Furch

[Edited on 16-1-2007 by Furch]

|

|

|

Misanthropy

Hazard to Self

Posts: 69

Registered: 24-3-2005

Member Is Offline

Mood: Variable

|

|

I don't know, however it sure is pretty!

|

|

|

Chris The Great

Hazard to Others

Posts: 463

Registered: 29-10-2004

Location: Canada

Member Is Offline

Mood: No Mood

|

|

Your DCM could be impure... that's what I would venture as to your problem. Another possibility is to distill your product first, to seperate out

whatever is your problem.

If you dissolved your post-reaction sludge in acid, then the white stuff is aluminum hydroxide.

|

|

|

Organikum

resurrected

Posts: 2339

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

Filtration through a mixture of fine glasswool/cotton might be a solution.

|

|

|

Furch

Hazard to Others

Posts: 130

Registered: 8-10-2006

Member Is Offline

Mood: No Mood

|

|

Thanks for the replies, Chris and Organikum.

Organikum, aye, that would probably be a good solution if it was a standard emulsion... But the problem here is a little more complex, it seems.

Chris, I haven't thought of that. Idiot me. Of course, I should've extracted the post reaction mixture with DCM BEFORE dissolving it in acid... That

way any aluminum hydroxide will be left behind in the water phase...

But still it's funny, because I extracted the freebase with multiple portions of boiling IPA. I.e. the very majority of the Al(OH)3 should've been

excluded in those extractions... IIRC, Al(OH)3 isn't very soluble in IPA at all.

Well, I'll have to save this batch by neutralizing the whole mess (washes, extracts etc.) and distilling it as is.

Thanks again!

- Furch

[Edited on 16-1-2007 by Furch]

P.s. Take a look at the picture, and see the tiny bubbles clinging to the glass in the DCM phase... Also, in the center and upper part of the DCM

phase, an inverted "mountain" of bubbles has formed and won't go away on standing. I'm about to go insane just by looking at those things.

[Edited on 16-1-2007 by Furch]

|

|

|

Shaddy

Harmless

Posts: 11

Registered: 22-6-2006

Location: out and about

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Furch

Hello!

I have a problem. |

1. Nice photo.

2. You will never get good phase separation DCM and basic aqueous phase. Aluminium hydroxide may be also the problem in your case, but it`s not

presented on the photo.

3. It means: You should extract it 4-5 times with DCM and then wash combined organic phases with brine. Every time you need to separate organic layer

without "bubles". You should get at least half of promised yield with this procedure.

4. May be it will be easier to use Et2O or TBME in this case. But it`s up to you.

|

|

|

Furch

Hazard to Others

Posts: 130

Registered: 8-10-2006

Member Is Offline

Mood: No Mood

|

|

Thank you, Shaddy!

I decided to try an experiment, to determine the cause of the emulsion... I dissolved some aluminum foil in HCl (aq), then made basic with NaOH, and

then added some DCM... Guess what? See the attached photo.

Upon further invesitgation of Al(OH)3, the Merck says it's used in the making of gels and emulsions(!!!).

Clearly, I shouldn't have made the post reaction mess acidic in the first place, but rather extract immediately with non-polar and take it from there.

Let this be a warning to everyone - always remove Al(OH)3 before trying to extract with your non-polar solvent!

Also, I decided to combine all the washes and the mother portion post IPA extraction, and distill everything and see what comes out.

Thanks for the replies people! I hereby declare this thread closed, and the mystery solved.

- Furch

[Edited on 16-1-2007 by Furch]

|

|

|

chemrox

International Hazard

Posts: 2961

Registered: 18-1-2007

Location: UTM

Member Is Offline

Mood: LaGrangian

|

|

DCM emulsion

I've had many frustrating hours trying to clear up DCM emulsions with little success. How about using acetone, THF, hexane or ether (depending on

polarity of product)?

Water is the main culprit but I'm wondering if fine particulate matter contributes to it. I was extracting a grass and gave up on DCM for this

reason.

|

|

|

unionised

International Hazard

Posts: 5128

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

I usually find that adding a drop or 2 of methanol to the "bubbles" with a long thin pipette works.

|

|

|

Flip

Hazard to Others

Posts: 116

Registered: 7-12-2005

Member Is Offline

Mood: No Mood

|

|

Aluminum hydroxide is amphoteric, and has a wide variety of anionic and cationic species, differing in coordination and/or hydration. The equilibrium

of these species is determined by the pH in solution.

pH 1-6 = water soluble species predominate

6-8 = optimal

9+ = water soluble species predominate

The problem here is might be a correlation between the acidic solution and equilibria toward reactive and polymeric ions, which could bind the

solution, the other solutes, and the other Al species - making emulsions such a pain.

Or wait, what about aluminum chloride hydroxide complexes in various states of dissociation and interaction accounting for these observations?

As an aside, you could also modify your procedure to first wash with aq. NaOH, then boil off some the alcohol volume extract with a non-polar and work

from there. Brine can battle aqueous emulsions, and agitation from anything that vibrates seems to speed things along.

[Edited on 1/20/07 by Flip]

|

|

|

chemrox

International Hazard

Posts: 2961

Registered: 18-1-2007

Location: UTM

Member Is Offline

Mood: LaGrangian

|

|

24/40 or fight!

Maybe we can get you out of this and you can help with my problem..

Anyway, I think an approach that could work would be getting your product ino a higher boiling solvent while you leave the DCM behind.

For example, ad zylene and distill the DCM out from under. Use reduced pressure if you can but DCM boils around

40 degC.

I hope this works. It'd a damned shame to get through all the difficult stuff and end up fucked by the sep funnel.

Expensive too, I bet )^; congrats on the other steps

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Aluminium hydroxide dissolves to form the aluminate if you add even more NaOH. This might be an option. Try it out with a small amount of the aqueous

phase.

It might also be possible to dissolve the Al(OH)3 by complexation with fluoride, though i don't know if the complex is still stable in basic solution.

Take a small amount of the aqueous phase and add KF or NaF solution, and see if it clears up.

Addition of fluoride is a method to facilitate phase separation in nitroglycerine production. The NG droplets are sometimes surrounded by a little

silicic acid and therefore coagulate only difficultly in the diluted spent nitrating acid. Adding a very small amount of NaF immediately resolves this

problem.

[Edited on 20-1-2007 by garage chemist]

|

|

|

bio2

Hazard to Others

Posts: 447

Registered: 15-1-2005

Member Is Offline

Mood: No Mood

|

|

......Aluminium hydroxide dissolves to form the aluminate if you add even more NaOH...........

This will definitly dissolve the Al hydroxide but it may take

6-9g NaOH per gram of Aluminum.

|

|

|

Isomeric_Fred

Harmless

Posts: 31

Registered: 25-6-2006

Member Is Offline

Mood: curious

|

|

we would like to contribute our 2 cents.

first of all, better to make reaction in ethanol in our experience.

then instead of filtering/evaporating it, simply add KOH till all Al is on the bottom and a nice blob. then decant ethanol, add more ethanol, heat

again with swirling, and decant again. repeat 1-2 more times, then evaporate ethanol and workup as usual.

this is ala osmium (osmiums variation on al/hg, found on rhodium site). works extremely well, avoids problematic Al sludge, and gives very nice

yields...

hope this helps......

|

|

|

Furch

Hazard to Others

Posts: 130

Registered: 8-10-2006

Member Is Offline

Mood: No Mood

|

|

Thanks a lot all... I was pretty sure the problem was worked out, though I haven't given it another try just yet.

Isomeric fred, that's exactly what I did, you see. I used Osmium's variation of this reaction, however I used IPA instead of EtOH, and Osmium mentions

in his writeup that IPA works well, if not better (in my opinion a LOT better), but it's more expensive.

Why do I think that IPA is better? Because it has a greater tendency to form layers with aqueous salt solutions, also it won't bring as many inorganic

salts into the alcoholic layer...

Anyway, I believ the problem I encountered can be avoided simply by not making the residue goo post alcohol extraction acidic, but rather extract

directly with DCM and take it from there. Osmium's writeup suggests that you make the whole thing acidic post alcoholic extraction, and this is the

fatal flaw of that writeup, in my humble opinion.

I also believe the problem can be avoided with the procedure some people suggested above, by adding a lot more NaOH... Though I'd prefer to just

extract the post alcohol extraction mixture with DCM.

Thanks a lot!

- Furch

[Edited on 20-1-2007 by Furch]

|

|

|

Boomer

Hazard to Others

Posts: 190

Registered: 11-11-2005

Member Is Offline

Mood: No Mood

|

|

There are two "Osmium-procedures" in the Rhodium archieve. The second is called "Osmium/BrightStar...Amination" and uses NO acid after extraction, it

goes like this:

Short Form:

mixed 66.8g MeAm.Hcl in 67g dH2O

mixed 39.6g NaOH in 119g dH2O, cooled in ice bath

mixed 423mL MeOH, 26.1g Al foil, 140mg HgCl2 in RBF

slowly poured NaOH solution into MeAm solution, then added to RBF

added ketone to RBF

refluxed with mixing until slowed down and temp started dropping, then added heat to keep at ~65°C

strained unreacted foil

basified with KOH solution (230g 85% KOH, 469g dH2O)

extracted 1x 500mL, 1x 200mL toluene

washed toluene 3x 700mL dH2O, 1x 700mL brine

dried 10 minutes in 40g MgSO4

gassed and vacuum filtered 5x, cleaned in boiling acetone, vacuum filtered, dried

yield 50.99g

And later in the text:

Once the reaction is deemed finished, (...) strain/filter out any unreacted foil chunks. .... The mixture was slowly basified by pouring the KOH

solution into reaction contents, and was stirred on a stirrer for about 10 minutes. Some bubbling was observed as any remaining foil was reduced. The

mixture was extracted with 1x 500mL, 1x 200mL fresh toluene by pouring the toluene into the beaker and continuing stirring. After separating the

extractions were combined. ... The combined toluene extracts were washed .... The toluene was dried in 40g dried MgSO4 for 10 minutes. The toluene was

then gassed, ...

I remember an Al/Hg from my past where the sludge was left to settle, the IPA decanted (I forgot but this was probably repeated at least twice), then

mostly evaporated, basified and extracted with ether. This was not a drug synth btw, and used only 10 mmol substrate. Without decanting, I had had

similar problems, only instead of bubbles there was cloudy slime, which did not separate in a week even with lots of additional solvent and brine.

|

|

|

Isomeric_Fred

Harmless

Posts: 31

Registered: 25-6-2006

Member Is Offline

Mood: curious

|

|

look Furch, you said -

"I have a problem. You see, I'm trying to perform a reductive amination with a ketone, using methylamine as amine source, and aluminum foil as the

reducing agent... However, when the reaction is complete, and it's time for the clean up, things get bad. Really really bad...

I evaoprate the solvent (IPA), dissolve the residue in 10% HCl till acidic, wash with DCM, then, as I add 10% NaOH to make the mixture basic, a white

precipitate falls out in form of "clouds"... This is normal you say? Aye, me too... It's the freebase, right? Wrong. When I try to extract with DCM,

this is what happens"

which means u didnt follow it exactly...

what you should have done, is dissolve the ketone in alcohol of choice, start amalgamation in alcohol of choice with minimal amount of Al, when starts

refluxing you add the amine in one portions, then drip in the ketone slowly over time, while refluxing

30 minutes after all Al has dissolved, u add slowly alkali base of choice, till there forms a semi solid lump on the bottom and alcohol clears up.

then decant alcohol, add more, heat, stir, add abit more koh, and decant alcohol again, and repeat 1-2 more times, and combine all alcohol pulls.

test for ph making sure its above ph 12. then distill away the alcohol, collect it and keep it cause it has your starting alkylamine in it. once u get

a residue on the bottom and no alcohol is present u let cool, add non polar of choice (toluene is good for it), wash with water, brine. then add acid,

wash with non polar, discard it, and then again base, extract with toluene, add hcl solution, and startheating till it hits 110-115 deg.

then u cool it down in the freezer and salts comes out.

rextalize and viola!

|

|

|

Furch

Hazard to Others

Posts: 130

Registered: 8-10-2006

Member Is Offline

Mood: No Mood

|

|

In the text I have, that is not the procedure.

In the text I have, it is described, by Osmium, that the post reaction and EtOH/IPA extracts residue is dissolved in acid and washed with non-polar.

That was what I did, and that is what is wrong with that procedure.

Next time I will dissolve the residue in non-polar and wash it with water instead, which is what I've concluded above.

Thank you.

- Furch

|

|

|