| Pages:

1

2

3

4

5 |

markgollum

Hazard to Self

Posts: 53

Registered: 21-2-2004

Member Is Offline

Mood: No Mood

|

|

I have made enough fairly pure benzamide by the benzoic acid > methylbenzoate > benzamide route for several experiments.

But I am uncertain how to proceed with the hoffman rearraingment even several hours at the university library came up empty as to how exactly it is

done.

This what I did.

First I made 295g of benzoic acid from sodium benzoate and HCl.

Next I made the methyl benzoate as per the procedure on frogfot's page.

67.66 g of benzoic acid was added to 227.25mL MeOH and ~8ml 90% H2SO4 in a glass pressure vessel. (Not necessary just seemed convenient)

The mixture was kept at 50-62C for 6 hours, left overnight at room temp.

The next day I filtered the contents (a fair bit of a fine white pecipitate formed right at the beginning when the chemicals were first mixed) added a

bit more H2SO4 > more whit ppt, refiltered, then transfered to an erlenmeyer and refuxed for an hour.

Next the MeOH was distilled off and the residue was poured into water with lots of NaHCO3 to neutralize the acid and washed with more water.

Yield was poor ~42mL of methyl benzoate. ( The white ppt was NaHSO4 from some sodium benzoate in the benzoic acid)

Next the 42mL of methyl benzoate was added to a 150mL glass pressure vessel containing 40mL of selfmade ammonia water (not saturated but NH3 gas would

not dissolve rapidly enough to prevent the bubbles from reaching the surface) 55mL of MeOH was added and more ammonia gas was bubbled in for about

30min, (at one point I became impatient and increased the gas flow to much resulting in the eruption spilling ~20mL of solution) the pressure vessel

was closed and kept at room temp for 2 weeks.

(two layers, top one water and methanol, bottom the majority of the methyl benzoate)

At the end of the 2 weeks during which I would often shake the vessel to form an emulsion, only about 1/3 of the methyl benzoate had reacted so I

decided to warm the flask to speed things along.

I made a "warm box" by suspending some nichrome wire and pushing a thermometer through the lid of a styrofoam box I had received some glassware from

Ebay in.

After 2.5 days at 50-65C the methyl benzoate layer had completely dissapeared and the solution had become clear.

On cooling to RT a mass of white crystals precipated.

The methanol and ammonia were boiled off and the I recrystalized the benzamide from water.

The resulting crystals smelled strongly of methyl benzoate and would turn into an oil at about 80C, so I decided to boil the crude benzamide in 6% HCl

IIRC (might have been 4%) to preferentially hydrolyse the ester.

The solution was boiled gently for about an hour, left overnight, neutralized with the exact amount of NaOH necessary, heated and cooled to redissolve

and reprecipitate the crystals, filtered, then the crystals were rinsed with cold water, dryed, and weighed.

A sample was taken to the Uni and its melting point was taken.

Final results 11.2g of benzamide melting point 126C literature 132C (not bad considering the principal impurity is a liquid)

[Edited on 17-12-2006 by markgollum]

[Edited on 17-12-2006 by markgollum]

[Edited on 17-12-2006 by markgollum]

[Edited on 17-12-2006 by markgollum]

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by markgollum

The resulting crystals smelled strongly of methyl benzoate and would turn into an oil at about 80C, so I decided to boil the crude benzamide in 6% HCl

to preferentially hydrolyse the ester.

The solution was boiled gently for about an hour, left overnight, neutralized with the exact amount of NaOH necessary, heated and cooled to redissolve

and reprecipitate the crystals, filtered, then the crystals were rinsed with cold water, dryed, and weighed.

A sample was taken to the Uni and its melting point was taken.

Final results 11.2g of benzamide melting point 126C literature 132C (not bad considering the principal impurity is a liquid)

[Edited on 17-12-2006 by markgollum]

[Edited on 17-12-2006 by markgollum] |

NO! Why did you boil the amide in HCl? Thats a sure way to hydrolyze it! This explains the bad yield.

You could have steamdistilled the methyl benzoate from the aqueous solution (benzamide is very soluble at 100°C) of the amide, that would have been a

correct procedure. After cooling, you would have obtained recrystallized benzamide which can then be freed from benzoic acid residues by treatment

with ammonia solution.

[Edited on 17-12-2006 by garage chemist]

|

|

|

markgollum

Hazard to Self

Posts: 53

Registered: 21-2-2004

Member Is Offline

Mood: No Mood

|

|

I know that acids and bases hydrolyse amides ,

however all the textbooks I read claim that a prolonged reflux with acid is necessary and that the preferred method to hydrolyse an amide is to boil

with 30% NaOH.

Besides if I had hydrolysed a large amount of the amide, I think I would have noticed the low solubility benzoic acid precipitating.

|

|

|

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by garage chemist

Hmm, the orgsyn prep looks interesting- but the use of an organic solvent makes the procedure more time- consuming and more expensive. I think I'll

stay with the urea melt method. |

The method at Orgsyn is for the amines coupling with carboxylic acids and is useless for the direct preparation of N-unsubstituted amides or amides of

lower boiling amines. Only its theoretical principle was taken for the amide formation with urea - that is the boric acid catalysis. Otherwise, with

urea the active reagent in the carboxylic acid activation and amidation is presumed to be the ammonium cyanate (NH4OCN) that forms in equilibrium at

elevated temperatures (I don't remember where I read this anymore). But anyway the H3PO4 or H3BO3 both activate the acid themselves as well as

increase the concentration of free cyanic acid that is also able to activate the carboxylic acid for the reaction with ammonia/urea.

According to Synthetic Organic Chemistry (Wagner&Zook, 1953) the following paper should contain the preparation of benzamide with urea (if I

understood it well): Cherbuliez and Landolt, Helvetica Chimica Acta 29 (1946) 1438.

| Quote: | | NO! Why did you boil the amide in HCl? Thats a sure way to hydrolyze it! This explains the bad yield. |

No way would 1h of boiling in 6% harm much the benzamide. Amides are nearly as easy to hydrolyze when compared to esters.

…there is a human touch of the cultist “believer” in every theorist that he must struggle against as being

unworthy of the scientist. Some of the greatest men of science have publicly repudiated a theory which earlier they hotly defended. In this lies their

scientific temper, not in the scientific defense of the theory. - Weston La Barre (Ghost Dance, 1972)

Read the The ScienceMadness Guidelines!

|

|

|

Pabpa

Harmless

Posts: 11

Registered: 27-11-2006

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by garage chemist

Would you give us a report of the synthesis, e.g. the used amounts of reactants, what you have done exactly etc...? Just like I did with my report of

the benzamide synthesis above. That would be nice.

|

I'll scale it up and give a description next year. I'd like to use calcium hypochlorite because it's less expensive.

|

|

|

dr. nick

Hazard to Self

Posts: 94

Registered: 20-6-2004

Location: Doh!land

Member Is Offline

Mood: yes

|

|

after mixing the ammonia- and water washed product of the given procedure (urea+benzoic acid) with some chlor bleach solution i got a brown liquid

which smell somehow reminds me of "garlic breath" with a somehow alcoholic by-taste ... how would you describe the smell of aniline?

darn, i really could use a small amount of it to be able to compare.

[Edited on 24-12-2006 by dr. nick]

[Edited on 24-12-2006 by dr. nick]

[Edited on 24-12-2006 by dr. nick]

of course you can well i couldn\'t before

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Aniline smells unpleasant, though not fishy as one might expect.

The smell is weak and yes, "bad breath" is somewhat fitting as a description.

But the smell is in no way useful as an indicator of its presence! You need to isolate it and charaterize its properties (e.g. derivatization as the

acetanilide and recording the melting point of this)!

How have you isolated the benzamide product? Dissolved in hot water, adding ammonia and letting cool to crystallize like I have done?

And did you add some extra NaOH to your bleach like it is necessary for a hofmann degradation?

BTW, I recently made a benzamide batch using 15g each of benzoic acid and urea, and 5 drops H3PO4. I have crystallized it by now, what remains to be

done is filtering, washing and drying. I will report the yield.

[Edited on 25-12-2006 by garage chemist]

|

|

|

dr. nick

Hazard to Self

Posts: 94

Registered: 20-6-2004

Location: Doh!land

Member Is Offline

Mood: yes

|

|

| Quote: | | And did you add some extra NaOH to your bleach like it is necessary for a hofmann degradation? |

Ah, i knew

i missed something - been thinking about it, but not under the same point of view - and as it was already pretty basic i didn't add extra NaOH.

How much/to what ph should the NaOH be added?

At the moment i'm just adding a little HCL to get the solution to neutral/slightly sour ph to try and see if i'd get some anilin.hcl maybe ... I don't

see any other way to get the anilin out of the watery solution ...

It was a very small amount this time, will start another run with more next time.

You used Benzoic Acid:Urea 1:1? To compensate the loss of sublimating Benzoic Acid?

Good idea, i guess - will do it that way, too!

[Edited on 25-12-2006 by dr. nick]

of course you can well i couldn\'t before

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

Is aniline suddenly hard to buy? If so it's a good thing I have a lot of it on hand. If you work with it much keep an eye on your fingernails and

peek in the mirror once in a while. Dark blue lips and/or a blue band on your nails is a Bad Sign that you have over exposed yourself.

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Calculate the stochiometry of the hoffmann and add enough NaOH for the solution to still be strongly basic after reaction.

| Quote: | | At the moment i'm just adding a little HCL to get the solution to neutral/slightly sour ph to try and see if i'd get some anilin.hcl maybe ... I don't

see any other way to get the anilin out of the watery solution ... |

Oh man!  Are you sure you should make any aniline if you are that ignorant of

its properties? Are you sure you should make any aniline if you are that ignorant of

its properties?

Aniline-HCl is SOLUBLE in water, just as ANY amine hydrochloride/other mineral acid salt!

Anline is isolated by making the reaction mix BASIC and steamdistilling the aniline out of the solution.

The distillate is extracted with ether or DCM, the organic phase dried with Na2SO4 and the solvent distilled away to leave the aniline.

You could even directly extract the basified reaction mix with solvent, although the product will be less pure.

|

|

|

dr. nick

Hazard to Self

Posts: 94

Registered: 20-6-2004

Location: Doh!land

Member Is Offline

Mood: yes

|

|

i am aware of that.

when the water is evaporated the salt (if there is any) should be left, right?

so come down again, please, 'k?

btw.: thanks for the steamdistilling hint, also good to know a simple a/b would work also.

[Edited on 25-12-2006 by dr. nick]

of course you can well i couldn\'t before

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

But with evaporation you have all the sodium salts in there as well. It simply is not a valid procedure.

Normal distillation of the basified reaction mix should do the same as steamdistillation, I think you might even see aniline oil drops in the first

distillate.

I have isolated toluidine from a nitrotoluene reduction by normal distillation of the aqueous mix, so it should work just as well with aniline.

BTW, I got 12,8g benzamide from the 15g benzoic acid.

I also did another batch with 20g benzoic acid (1h 30min at 180-185°C), which yielded 17g benzamide!

This works very good. Lets hope that the benzonitrile production works as well. I have yet to synthesize the benzyltriethylammonium chloride as a

catalyst for the reaction of benzamide with thionyl chloride.

However, the melting point of the benzamide is consistently too low (around 118°C, while it should be from 124-128°C). Recrystallization is

obviously required for obtaining a pure product.

I'll see what yields of benzonitrile I will get from the crude product.

|

|

|

dr. nick

Hazard to Self

Posts: 94

Registered: 20-6-2004

Location: Doh!land

Member Is Offline

Mood: yes

|

|

i see.

thanks, you're very helpful!

In case one has (not in this case) pure aniline.hcl - what are the visual (sensual) properties of it? i don't have a merck index (mac here), is there

something equivalent to it?

Just out of interest: Benzonitrile - Phenylcyanide, what could it be used for?

please be indulgent with me, i'm no complete idiot (i guess), i simply do not have much chemical literacy, so i'm tinkering around with the equivalent

of an adult chem experimentation kit, trying to learn something the interesting way. i think i know enough (i hope) on safety, but that's it.

thanks!

[Edited on 26-12-2006 by dr. nick]

of course you can well i couldn\'t before

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Aniline is not stored as the HCl salt. Contrary to aliphatic amines, which do not store well as the freebase (CO2 uptake from the air) aniline is a

weak base which does not take up CO2 at all and stores fine as the freebase. Also, the aniline has a much smaller storage volume than its

hydrochloride.

I also think that the hydrochloride is strongly hygroscopic, although I am not sure of that. But there must be a reason why aniline is never handled

as its salt and always as the oil.

It is clear what you have to do: basify your reaction mix and distill off about half of its volume. Extract the distillate with ether or DCM, dry the

extract with Na2SO4 and evaporate the solvent.

Benzonitrile can be reacted with grignard reagents to form an imine complex which is hydrolyzed to the phenylketone on heating with aqueous acid. For

example, the reaction of ethylmagnesium bromide with benzonitrile would afford propiophenone after workup and hydrolysis.

And as you might know the reagent ethyl bromide is very easily made from ethanol and HBr. Only the grignard formation might be difficult without the

proper drying agents for making absolute ether.

|

|

|

dr. nick

Hazard to Self

Posts: 94

Registered: 20-6-2004

Location: Doh!land

Member Is Offline

Mood: yes

|

|

Thank you,

this should help a lot!

btw: wether there is some aminobenzen in my product or not, after evaporating the water there is a dark brown sludge left on the bottom of the vessel

with plaques of whiteish crystalline matter within - to me that looks promising, even if don't want the hcl either. Next runs will take place after

method described above!

Hm, not bad - propiophenon ... there was something i can't remember yet, got to look it up, didn't it have to do something with phenylmagnesium

bromide ... ? well, probably another story.

of course you can well i couldn\'t before

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Full benzamide synthesis documentation with pictures and writeup is now available here:

http://www.versuchschemie.de/htopic,8165,.html

[Edited on 2-1-2007 by garage chemist]

|

|

|

smuv

National Hazard

Posts: 842

Registered: 2-5-2007

Member Is Offline

Mood: Jingoistic

|

|

Benzoate --> Benzoic acid --> Benzamide --> Aniline

So I made some aniline this weekend. Everything was a little rushed forcing me to make some stupid mistakes, but all in all it went pretty well.

Sorry for some crappy pictures.

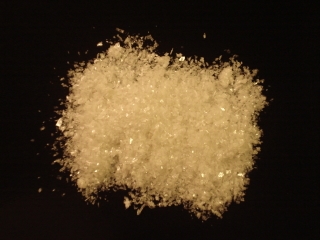

Benzoic acid

160.2g Potassium benzoate

~300mL Water

170mL 20.2% Hydrochloric acid

Potassium benzoate was added to the beaker followed by ~300mL water. The mixture was stirred and heated until homogeneous. Next, the hydrochloric

acid was added in two portions and the precipitate was recovered via vacuum filtration; some distilled water was used to complete the transfer.

A portion of this crude product was recrystallized (probably was unnecessary as benzoate was a high grade and HCl was previously distilled). I

accomplished this by dissolving as much crude benzoic acid as I could into 900mL of 90c distilled water, then increasing the temp to 100c and quickly

vac filtering. The filtrate was allowed to slowly cool to room temp and then was placed in the freezer. Crystals were recovered via vac filtration

and the filter cake was dried in the filter funnel.

Benzamide

40g Benzoic acid

59g Urea (3 eq)

3g boric acid (15 mol %)

The benzoic acid, urea and boric acid were added to a 250mL filter flask and everything was mixed until quasi-homogonous. A thermometer adapter was

jerry rigged out of a piece of damp paper towel and into this a thermometer was placed with its bulb submersed in the powdered mixture. To the

sidearm of the flask a piece of surgical tubing was affixed, the other end of the tubing was placed just above a beaker of water which was covered

with a damp paper towel. The filter flask was placed in an oil bath and heated for ~3h at 170-180c; I want to note that heat up took about 30-40

minutes because my hotplate is pretty weak (anyone else think their Nuova is a little sissy when it comes to heat?). Evolution of gas began around

110c and became progressively more vigorous with increasing temperature. Every 10min or so, the thermometer was used to tap any sublimate off the

side of the flask (most of it seemed to be ammonium carbonate). The hose on the sidearm was functional, but not as expected; ammonium carbonate would

just fill the tubing and hang out there. Every hour I removed the tube and washed it out with water. This setup worked pretty well to contain the

smell of ammonia, which could only be detected when cleaning the sidearm tube or removing the thermo adapter to kick off the sublimate. Towards the

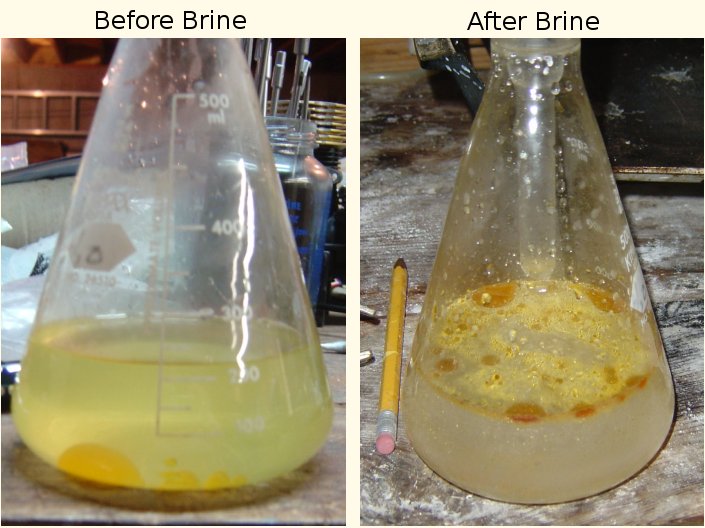

end of the 3h the bubbling waned and some suspended solids were noted in the melt. After 3 hours at 170-180c the melt was poured slowly into a beaker

filled with 400mL sodium bicarbonate solution, some more water was used to complete the transfer. Next, more bicarbonate was added followed by enough

NaOH to make solution strongly basic to pH test paper. The solution was stirred for a while; it had a spicy cinnamon like smell (benzonitrile, I

presume). The whole mess was vacuum filtered, dried in the funnel and allowed to stand overnight. Mass of ultra-crude product, 35.6g.

Next, I took two grab samples and tried to get a mp, both were super high; it looks like my initial workup kind of sucked. I ground the product in a

mortar and pestle and divided it into two portions to search for a suitable workup. I took one portion and added it to ~100ml denatured alcohol and

heated the mixture to boiling with some vigorous swirling. I allowed the solution to cool to room temp (to hopefully precip everything but the

benzamide). After cooling, the mix was vac filtered and filter cake was washed with some alcohol. The filtrate was placed in a casserole dish and

most of the ethanol was evaporated, some nice plates precipitated out on cooling. The mp of this product was 119-120c, the low melting point is

presumably due to a benzonitrile impurity (although crystals were odorless). This product was deemed pure enough, so the same workup was performed on

the other half of crude product. Both crystal crops were combined giving 16.5g of benzamide or a 41.6% yield.

(The reagents)

(The reaction, about halfway through. No thats not motor oil!)

(Basic solution used to remove reaction junk from melt, my problem child)

(product precipitated from ethanol)

(ghetto melting point apparatus)

Aniline

33g NaOH

330mL Water

10.5g TCCA (containing few percent CuSO4)

16.5g Benzamide

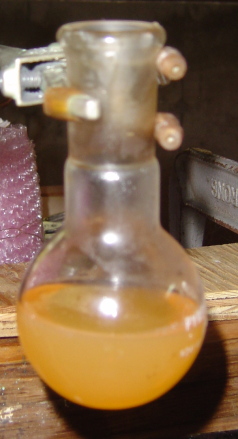

A 10% sodium hydroxide solution was prepared, it was chilled slightly (~15c) and added to a 500mL Erlenmeyer flask. A stir bar was added followed by

the TCCA (it contained a few percent CuSO4). Immediately after addition the solution took a peculiar red black tinge which could not be explained by

cupric hydroxide floc. All the TCCA dissolved with a very minimal amount of gas evolution and warming. Next the benzamide was added and the solution

was stirred until most of it dissolved (~10 min). The solution darkened over the ten minutes to a turbid white-yellow and finally an opaque maroon.

Everything was setup for reflux and the solution was slowly heated (over the course of ~20 min) to 60c and maintained at 60-65c for 20 minutes. The

temp was pretty easy to maintain by lifting the flask off of the hotplate to moderate temp. After this heating, the apparatus was setup for simple

distillation, an Erlenmeyer flask was a bad choice for this, and half way through I switched to a 1000mL fb flask. At first the distillate was a

milky white but with time a faint yellow orange distillate began coming over. After about 250mL was distilled, I halted the operation to go sleep.

The distillation was not complete though as the distillate coming over was still strongly basic to universal test paper. The steam distillate was

saturated with NaCl and extracted 3x with ~30mL DCM. The extracts were dried over calcium chloride, vac filtered and filter cake washed with DCM.

The solvent was evaporated off on a water bath. The last traces of DCM and moisture were removed by briefly heating the aniline just to boiling over

a free flame. The final mass of crude aniline was 10.9g or an 86.6% yield. I wish I had time to distill this product, but I simply did not and will

not for a long time.

(Solution after stirring for 20 minutes)

(steam distillation setup, before replacing Erlenmeyer with FB flask)

(receiver before ugly yellow stuff started coming over)

(aniline's density is so close to that of water, it sinks in distilled water, but floats in brine)

(pooled extracts)

(aniline ready to be re-distilled)

Improvements, questions, discussion

Benzamide

What the hell did I do wrong?

I would have followed garage_chemist’s workup but I didn’t have any surfactant free ammonia on hand. I thought a strongly basic solution would

remove most of urea’s decomposition products, no? I had planned to take the crude crystals and extract them with boiling heptane but I didn’t

have the time to distill some heptane. Although GC’s workup was much easier I think mine worked ok, can anyone see any problems with it that would

have killed my yields?

This reaction is driven forward by the loss of ammonium carbonate, could my somewhat closed apparatus have something to do with my crappy yields?

Aniline

I was surprised that the steam distillate came over colored, is this normal?

I had never done a steam distillation before, was testing the distillate as it came over with pH paper a good metric to judge the progress of the

distillation or would I have read strongly basic forever due to traces of aniline coming over?

I think I could get by using less sodium hydroxide; I just took the Organicum procedure and replaced Chlorine with TCCA. In the future I think I will

strongly chill the sodium hydroxide solution before adding TCCA.

Sorry to be so long winded, I just want to catalog everything as accurately as possible so others can repeat and provide comments about my procedures.

"Titanium tetrachloride…You sly temptress." --Walter Bishop

|

|

|

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

Excellent work! Thanks for sharing.

Comments:

About benzamide preparation... The unreacted benzoic acid is not the main problem, so you primary focusing on its removal may have not been the

optimal choice. Among the side products of the reaction there are plenty of urea decomposition products (biuret, cianuric acid and its amides...). I

would suggest to rather attempt recrystallizing the whole mess in toluene (or xylene) to remove these insoluble and high melting side products. This

will also remove the unreacted benzoic as long as there is not much left. If the melting point is still not optimal, you can then recrystallize again,

but this time from water. A double recrystallization using solvents of opposite polarity (when possible) gives the best purity (ethanol dissolves too

much benzamide at RT and is perhaps not the best choice). Also, it is possible that the reaction is over already in one hour and using longer times

just creates more biuret and other crap increasing losses in the work up.

About the Hoffman rearrangement... Nice. The critique is about using CaCl2 for drying the extract. You should know that CaCl2 is incompatible with

amines and alcohols, complexing with them. Rather use Na2SO4 or MgSO4 next time. Also, it would be nice if you could make a TLC of the aniline to see

if it is clean from chloroanilines which can also come over with steam. Or at least measure its bp. I would not worry too much about your aniline not

being colourless, but still the information about its actual purity would be good.

…there is a human touch of the cultist “believer” in every theorist that he must struggle against as being

unworthy of the scientist. Some of the greatest men of science have publicly repudiated a theory which earlier they hotly defended. In this lies their

scientific temper, not in the scientific defense of the theory. - Weston La Barre (Ghost Dance, 1972)

Read the The ScienceMadness Guidelines!

|

|

|

smuv

National Hazard

Posts: 842

Registered: 2-5-2007

Member Is Offline

Mood: Jingoistic

|

|

Thanks for the critique

benzamide: I agree, ethanol was a sub optimal solvent, it is just what I pure on hand. I will probably follow up on this in the future (when I have

time in my lab). I want to clarify, I didn't really recrystallize from ethanol, I drove off like 90% of the solvent and let it cool; while some

pretty chunks formed it wasn't a true recrystallization. I did this as you can expect to minimize the loss of benzamide with this sub optimal

solvent.

Aniline: About the desiccant, wow! I know this and just totally overlooked it; thanks for pointing it out! About purity, I would very much have

liked to further characterize the product but I just didnt have time over my short Columbus day vacation.

I would like to repeat this process in the future and hopefully optimize it, as I think it could be modified to painlessly make large quantities of

aniline, very useful for the amateur chemist. Unfortunately I attend a university far from my home lab which means during the semester I have little

time to focus on this hobby. This is why everything was rushed and my aniline was not further characterized.

"Titanium tetrachloride…You sly temptress." --Walter Bishop

|

|

|

Jor

National Hazard

Posts: 950

Registered: 21-11-2007

Member Is Offline

Mood: No Mood

|

|

Why did you talk about yourself as 'swim' and 'he' in the first post?

Ive read it before, and all the guys on drugsforums use it, they call theirselves SWIM. Why?

|

|

|

smuv

National Hazard

Posts: 842

Registered: 2-5-2007

Member Is Offline

Mood: Jingoistic

|

|

Someone who isn't me.

It is a stupid way to avoid self incrimination.

In the future, ask stuff like this in the proper forum or do a google search so threads don't get side-tracked.

That being said, I have no idea why someone would want to remain anonymous while making aniline. What are you going to do with it, go make

psychedelic dyes?

"Titanium tetrachloride…You sly temptress." --Walter Bishop

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Beautifull work! Thank you very much for sharing!

I've not much to add, maybe that KOH or K2CO3 are evry well suite dfor drying amines.

The fact that your amine came out colored during the steam distn doesn't necessarily means that it is heavily contaminated. Commercial aniline turns

yellow after a while exposed to light in any case, and the impurities are very colored, so that very little casues quite some discoloration. I'm sure

a quick fractionnation will remove them. I would suggest keeping your distille dproduct in a amber bottle, away from light and heat.

It's a real pleasure to read such reports. Thank you again for your time in posting this!

\"You can battle with a demon, you can embrace a demon; what the hell can you do with a fucking spiritual computer?\"

-Alice Parr

|

|

|

smuv

National Hazard

Posts: 842

Registered: 2-5-2007

Member Is Offline

Mood: Jingoistic

|

|

Thank you for the kind words.

Speaking of purity, if I require very pure aniline, can I achieve this by directly distilling my product or should I employ other means of

purification as well? I assume fractional distillation is the way to go, can I do this with minimal product decomposition without hassling with a

vacuum distillation?

"Titanium tetrachloride…You sly temptress." --Walter Bishop

|

|

|

jarynth

Hazard to Self

Posts: 76

Registered: 12-8-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by smuv

I was surprised that the steam distillate came over colored, is this normal? |

Don't confuse distillation with discoloration. It does purify your product, but even tiny impurities can give it a strong coloration. Many freshly

made, colorless aromatic compounds turn darker when exposed to light, air, etc. Some volatiles already have a color of their own, e.g. the essential

oil of cinnamon bark.

|

|

|

Ullmann

Hazard to Self

Posts: 51

Registered: 22-12-2004

Member Is Offline

Mood: No Mood

|

|

Good Work!

Best way to purify aniline is distillation in vacuo IMHO....

|

|

|

| Pages:

1

2

3

4

5 |