| Pages:

1

..

5

6

7

8

9

..

14 |

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

Wow, coincidently I am in the process of making a fume hood as well, it is rather small just 7" square by 13" tall, but it is big enough to

fit over a simple setup emitting bad fumes. Powered by an old computer fan(30W) that takes 115 volts...rather monster for a computer fan. It is just

something that can be placed over whatever is emiting fumes to draw them outside. I am aware that this fan will die soon from corossive vapours, but

they are free(seems everyone in my family has a couple...), so it is not too difficult to replace one. Due to the layout of my backyard my neighbours

can see everything unless I am under a tree, so work outside in the past has been risky durning the day, or done late at night.

The 'glass' of the hood is lucite...does not really matter but it sounds impressive.

Impressive ordenblitz...and that hood is in your house? Nice.

[Edited on 19-7-2005 by rogue chemist]

|

|

|

ordenblitz

Hazard to Others

Posts: 259

Registered: 18-7-2004

Location: Northwest

Member Is Offline

Mood: Bohr'd

|

|

Lets try this again.

rogue chemist.. No it's not in my house.

Taking a second look at the monster distillation can for benzene, I decided to scale the quantity back and shorten the time. I put 1100g of my 2/1

sodium benzoate/calcium hydroxide mix (about 30% of the original load) into the can. This filled it roughly 1.3 inches. I wanted a thin layer this

time. I then connected the condenser and fired up the burner. In 30 minutes the distillate stopped coming over and I had 210ml of product.

http://img217.imageshack.us/img217/7693/2107ud.jpg

Not bad for 40 minutes of work. Next I decided to try sodalime to see if the lower melting point would hasten the reaction or increase the yield. So

to 1100g of the mix I added 200ml 40% NaOH solution, mixed thoroughly and added to my can. I turned on the flames and in less then 20 minutes it was

all over. This time I had 200ml of liquid goodies. So, faster yes but slightly poorer yield.

http://img217.imageshack.us/img217/7641/2000kh.jpg

While the can is still hot I open it up and hit it with the hose and the thermal shock breaks the clinker into a thousand pieces and I simply dump out

the chunks, load her up and off we go again. A day of this and quite a bit of benzene could be had. Geez.. I don't even know what I am going to

do with this benzene and here I am making liters of it.

I have run this now about 4 times and I think the can should last quite a while. The only thing I need to replace is the cap seals, which I cut out of

high temp silicone.

It is interesting to note that the faster you push this reaction the redder the product gets. Compared to my first batch it looks a deep red. The only

difference between the first run and the second was load in the can and how fast I heated it up. The final test will be when it's distilled and

the tally taken. I assume that I made a bit more biphenyl by pressing it hard. I will sort out the final count and post.

[Edited on 28-7-2005 by ordenblitz]

|

|

|

Eclectic

National Hazard

Posts: 899

Registered: 14-11-2004

Member Is Offline

Mood: Obsessive

|

|

Steam dealkation of toluene...

http://www.sriconsulting.com/PEP/Reports/Phase_IX/RW09-15/RW...

Hot tube, some kind of catalyst, maybe vanadium or molybdenum...

[Edited on 28-7-2005 by Eclectic]

|

|

|

ordenblitz

Hazard to Others

Posts: 259

Registered: 18-7-2004

Location: Northwest

Member Is Offline

Mood: Bohr'd

|

|

All the batches are now finished and from 2500gm/1250gm, sodium benzoate/calcium hydroxide and some time I have about 1.4 liters of benzene. Not too

bad at all. I managed to save the unreacted material from my first run and add it to subsequent runs. As long as I keep the load in the can at about

1000 grams, I get very good yields.

http://img54.imageshack.us/img54/5143/benzdist0py.jpg

I distilled the darker batches and the lighter yellow ones separately. While the distillate from the faster hotter runs is more toward the red/orange,

it results in less solid matter (biphenyl etc) remaining after the finish distillation. So I say, hotter and faster is better.

http://img54.imageshack.us/img54/5373/benz6oo.jpg

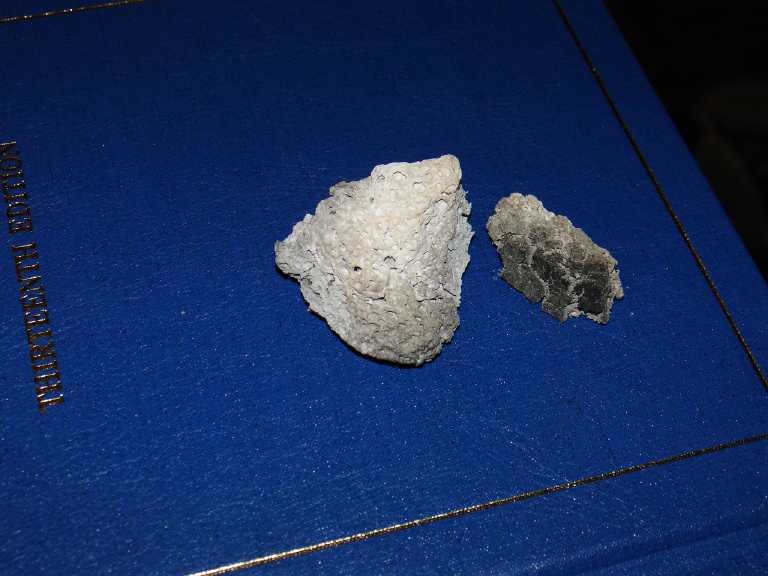

I got a picture of the clinker that I broke out of the can. It is very light and porous looking a lot like lava rock or pumice. One other interesting

thing is that it is very hard after coming out of the can but upon exposure to the air for a day it completely disintegrates into dust. So to make

cleanup easy after a run, just let your vessel sit open for a while and dump out the powder.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

This is an old thread but I have some recent contributions, and questions. I need about 50 mL of benzene so am making it by decarboxylation of Na

benzoate using NaOH according to a procedure in my 1960 lab manual. Since I'm using a 25mm x 200mm test tube I find that to optimize heat transfer

to maximize yield (60-70%) it's best to use 1/2 batches. This only gives me about 5mL per heat. So it is a labor of love to get my 50 mL.

C6H5CO-ONa + NaOH + heat --> C6H6 + Na2CO3

Here's a picture of the business end. This is an early picture and shows a full batch in the tube - it's too much. From the rubber stopper a 5mm

glass tube leads to my gg thermometer adapter fitted to a condenser. I pour the heat to this using my propane fired bunsen burner until the dry

powder fuses. This causes generation of benzene plus an orange chemical dissolved in the benzene. There has been previous speculation that this is

biphenyl; but is that orange? Also there is this curious looking "smoke" that is generated and goes down the condenser before the benzene comes over.

Now what the hell is that?  Before I'm done the residue left in the tube is

black. So I'm carbonizing some of the benzene and/or the generated Na2CO3? Today for the first time I saw a green tint to the powder as it was

heated. I think this is most likely a Ni or Cu compound coming in as an artifact from the kitchen spoon I use in making up the powder matrix. So it

is very interesting and I thought some members would also find it so. I'll post a 2nd picture showing the receiving pot with the orange colored

benzene. Before I'm done the residue left in the tube is

black. So I'm carbonizing some of the benzene and/or the generated Na2CO3? Today for the first time I saw a green tint to the powder as it was

heated. I think this is most likely a Ni or Cu compound coming in as an artifact from the kitchen spoon I use in making up the powder matrix. So it

is very interesting and I thought some members would also find it so. I'll post a 2nd picture showing the receiving pot with the orange colored

benzene.

Oops: I need to crop these photos first so will send them next post (sorry).

[Edited on 27-1-2006 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Benzene making, 1st picture:

<img src="http://www.scimad.org/scipics2/Na_Benzoate_+_NaOH%20_2).JPG" width="800" />

<!-- bfesser_edit_tag -->[<a href="u2u.php?action=send&username=bfesser">bfesser</a>: reduced

image size(s); hosted image(s) at scimad.org/scipics2/]

[Edited on 12.12.13 by bfesser]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Benzene making, 2nd picture:

<img src="http://www.scimad.org/scipics2/benzene_receiving_flask_(2).JPG" width="800" />

<!-- bfesser_edit_tag -->[<a href="u2u.php?action=send&username=bfesser">bfesser</a>: reduced

image size(s); hosted image(s) at scimad.org/scipics2/]

[Edited on 12.12.13 by bfesser]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

ordenblitz

Hazard to Others

Posts: 259

Registered: 18-7-2004

Location: Northwest

Member Is Offline

Mood: Bohr'd

|

|

Magpie said:

There has been previous speculation that this is biphenyl; but is that orange?

The FTIR thinks it is.

Would you call that speculation?

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Nope. That's good enough for me.  It's just when I looked in my CRC no color

was given for biphenyl. Thanks for the confirmation. It's just when I looked in my CRC no color

was given for biphenyl. Thanks for the confirmation.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

mantis

Harmless

Posts: 38

Registered: 17-7-2005

Member Is Offline

Mood: No Mood

|

|

What about phenol?

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

The yellow color is from polymerized gunk (tar- like substances), as biphenyl is actually colorless.

The reaction is not clean at all and produces a small amount of random organic stuff. But simple distillation gets rid of this and pure benzene can be

isolated.

Another approach to benzene manufacture:

I hope to get some anhydrous AlCl3 soon (I placed an order) and want to try the "disproportionative dealkylation" (I made up that word) of toluene.

2 C6H5-CH3 ----(AlCl3)----> C6H6 + C6H4(CH3)2

Toluene is converted into Benzene and Xylene. The equilibrium is shifted to the right side by constantly removing the formed benzene by slow

distillation of the reaction mix through a column.

I'l report my findngs, and I'll also try what influence the amount of AlCl3 has on the benzene yield.

[Edited on 27-1-2006 by garage chemist]

|

|

|

mantis

Harmless

Posts: 38

Registered: 17-7-2005

Member Is Offline

Mood: No Mood

|

|

I heard about the dehydrogenation of cyclohexan or cyclohexen, with metallic palladium as catalyst. Has anyone ever tried this?

|

|

|

BromicAcid

International Hazard

Posts: 3253

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

One day while reading through "Technical Bulletin Reaction Solvent Dimethyl Sulfoxide" I ran across some entries on pages 51-52 regarding the use of

DMSO as a reaction solvent for decarboxylation reactions giving high yields of product and thought, "Hey... I can get sodium benzoate... add a little

HCl and get some benzoic acid, add to DMSO, and distill off the benzene.." Today I got to the last step of that series of events.

For completeness here is a general outline of the conversion of sodium benzoate to benzoic acid.

Dissolve 230 grams sodium benzoate in 375 ml H2O to give a clear solution

Filtered it because there was some insoluble particulate

Added 50 ml concentrated HCl more was necessary but the solution at this point was too thick to stir

Filter and wash the precipitate with copious amounts of water

An additional 150 ml of the HCl was added

Precipitate filtered, sodium chloride noticed as a contaminate in this batch so additional washing was preformed

Combined filter cakes were allowed to air dry for three days and crushed

Total yield was roughly 92% (176 grams)

Ta dah! Benzoic acid, be wary of the dust from it, it's terrible on the lungs.

So, 100 grams of benzoic acid was placed into a 1L 2-neck FB flask and 70 ml of DMSO was also added. The benzoic acid proved to be fairly soluble in

the DMSO and a nice mostly liquid solution was obtained on stirring. A stopper was placed in the second neck of the flask and the main neck was

connected to a still head, Liebig condenser, vacuum adaptor, and finally to a 250 ml Erlenmeyer.

The solution was heated and subjected to magnetic stirring. Initially a whiteness appeared on the inside of the flask leading me to believe some

substantial sublimation was due to occur but this did not appear to be the case. The mixture continued to heat and small droplets started to condense

in the upper walls of the flask. Finally the liquid hit the still head and the temperature was anything but steady, going between 50 C and 85 C up

and down, up and down. Strange.... Some distillate started to come over after some time and a smell was noted.

The smell was like the lingering taste that becomes apparent after getting DMSO on the skin. It was fairly pungent and sulfurous, unlike

H<sub>2</sub>S though so I felt a little safer. Still, it was annoying and troublesome. At any given time I could put my finger over the

vacuum adaptor at the end of the distillation apparatus and pressure would build up fast, indicating at least to me that a gas was being generated

(CO<sub>2</sub> assuming things were going right) Because of this smell and the slow rate of distillation though (by this time the still

head had leveled out near 80C) I opted to add some water to the mixture.

Hold it! Water? Why water you ask? Well, the information in the DMSO technical bulletin lead me to believe water could be helpful in this reaction,

some of the decarboxylations occurring in 70% DMSO with 30% water (it is also noted the NaCl is beneficial to some decarboxylations but I didn't

pursue this path). A second reason was that water and benzene form an azeotrope, and I was hoping to take advantage of that to help strip the benzene

out of the solution. So I decided to add 40 ml of water to the mixture. I opened the second neck of the flask and added 10 ml. A strong gas

evolution was noted, very strong that blew out gasses almost, I assumed this is because the mixture was much hotter then the boiling point of the

water. The gasses were very sulfurous and they burned my eyes badly despite the goggles. I felt like an idiot.

Remaining water was added in a second aliquot. This did not generate the intense gas evolution as previously noted. Immediately after the stopper

was replaced water began to very quickly distill over. The rate of distillation was very rapid. I continued heating and distilling for nearly an

hour and according to the side of my receiving flask all the water had distilled over. The still head had remained just below 100C the whole time so

I don't think much benzene came over with the water, the water was a milky color. An organic layer was floating on top of the water though. I am not

sure if this was carried over by the water, but I think the bulk of it came from the initial distillation without the water.

I have yet to analyze this organic component but I believe it to be benzene based on its boiling point (from before I added the water) coupled with

the fact that it is insoluble in water whereas if it were DMSO that had steam distilled it would have dissolved in the water. I would like to repeat

this process with a short path distillation and more time using no water as I did appear to be getting results, however slowly. In complete contrast

to my short path idea, I additionally think a reflux condenser would be most useful in this case to prevent DMSO from making its way over to the

receiving flask.

The whole reason behind this little excursion (considering that I have plenty of benzene) was just to see if this process could give better yields of

benzene as opposed to the dry distillation process. Additionally this process can use simple glassware as opposed to steel works (however I do prefer

steel tubes, they're cheaper and more abundant). I will attempt this process again in the future, if it works then it would be a continuous use for

DMSO as it would merely act as a reaction solvent, more benzoic acid added continuously, the only chemical consumed being the ever cheap HCl.

If anyone has any thoughts on this burning acrid gas coming out of the solution when I added water of the gas that failed to condense that managed to

sneak its scent out I would be glad to hear them.

[Edited on 3/1/2006 by BromicAcid]

|

|

|

budullewraagh

Hazard to Others

Posts: 168

Registered: 1-8-2004

Location: new york

Member Is Offline

Mood: Aliphatic

|

|

the gas was probably DMSO, considering the fact that it penetrated your goggles and burned your eyes and smelled sulfurous.

|

|

|

BromicAcid

International Hazard

Posts: 3253

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

I doubt the gas was DMSO as it was for all intents completely different in terms of smell and burning sensation. From the DMSO Technical Bulletin I

found the following entry that might explain what the smell was I noted in my decarboxylation of benzoic acid with DMSO experiment:

| Quote: | | Chemically, DMSO is stable above 100 C in alkaline, acidic or neutral conditions. Prolonged refluxing at atmospheric pressure will cause slow

decomposition of DMSO. If this occurs, it can be readily detected by the odor of trace amounts of methyl mercaptan and bis(methylthio)methane.

|

Although it didn't smell like the stuff that they add to propane to make it smell. It burned more then that. A possibility though.

|

|

|

bio2

Hazard to Others

Posts: 447

Registered: 15-1-2005

Member Is Offline

Mood: No Mood

|

|

.... I additionally think a reflux condenser would be most useful in this case to prevent DMSO from making its way over to the receiving

flask.........

You could put the still head on a short reflux condensor kept

a little above the boiling point of benzene to condense the DMSO that tries to carry over or heat tape a claisen.

This would also help prevent the benzene from refluxing.

|

|

|

hinz

Hazard to Others

Posts: 200

Registered: 29-10-2004

Member Is Offline

Mood: No Mood

|

|

I've tried to decarboxyate sodium terephthalate, with miserable yield. The sodium terephthalate was made by dissolving PET-bottles in a hot/boiling

saturated aqueous NaOH solution, it went quite fast if the solution was hot enough.

I went on with heating of the solution for a few hours, then I added more NaOH and poured the viscous mass in a retort, about 300g.

http://pic20.picturetrail.com/VOL1206/4241286/13306106/20633...

This retort was heated by a wooden fire in the chimney outside the house. Note the clear liquid in the glass bottle isn't benzene, it's water mixed

with ethylene glycol, the solvent and product of PET hydrolysis.

The yield was extremly bad, the only product I've got is this 1-2ml floating on top of the aqueous layer in this test-tube. It's red like the benzene

obtained by others here, it burns with a grimy oxygen deficent flame and it smells like an aromatic compound. Close to this is the porous material,

mostly Na2CO3 I broke ourt of the steel tube.

http://pic20.picturetrail.com/VOL1206/4241286/13306106/20633...

The strange thing I observed when heating the tube beyoint the point the water/EG came over, was a white smoke or mist in a flammable gas. This stuff

can be seen above the water in the glass bottle. It's strange because I don't understant to which flammable gas sodium terephthalate could be

decompose without loosing a carbon atom or (nearly impossible) forming acetylene. But the porous material doesn't contain any free carbon.

Any possible reactions as explanation for this phenomenon?

BTW, Where/ as what does the remaining sodium benzoate end up in this reaction: 7 gm. NaOH + 25 gm. C7H5NaO2 = 7ml C6H6? Maybe by destilling as free

acid, but this in improbable due the alkaline conditions, maybe oxidised... .

|

|

|

chromium

Hazard to Others

Posts: 284

Registered: 27-6-2005

Member Is Offline

Mood: reactive

|

|

I do not know how much ethylene glycol was in water layer but mix of water and EG can probably dissolve some benzene. This might explain low yield.

I did some fast calculation with sodium terephthalate and benzene formulas and it seems that 100% yield would be aproximately 1/3 of mass of dry

sodium terephthalate.

If i had suitable retort i would like to try just heating pieces of PET with NaOH and no water at all. This could give mix of benzene and ethylene

glycol.

When all think alike, then no one is thinking. - Walter Lippmann

|

|

|

roamingnome

Hazard to Others

Posts: 363

Registered: 9-9-2006

Member Is Offline

Mood: No Mood

|

|

this has been a interesting thread to catch up on and

it seems that ORGANIKUM is defintaly the benzoate master here. Ill certainly save benzoate if i run into a sack of it, but

acetylene condensation needs to be figured out now...

i wonder if cyrogenic josseling of the gas might click them together with the right magic wand waving on the side

Russian Chemical Bulletin

Issue Volume 5, Number 12 / December, 1956

C14-labeled benzene was synthesized by the condensation of acetylene-C14 diluted with steam at 740°, the time of contact being 3.5 seconds. The yield

of benzene-C14 was 30% on the amount of active carbon taken.

the yield of just benzene without regard for labels might be higher.... any acetlyene condensators out there?

The Nobel Laureate Gustaf Dalén was blinded by an acetylene explosion. bummer

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by Organikum

Disproportionation of toluene or xylene using the Radzivanovskii* in-situ AlCl3 catalyst works and yields about 30% benzene from toluene.

*This catalyst is usually prepared by venting dry HCl gas into benzene/Al. Here the Al can be added to the toluene directly, foil works.

HCl is vented in for several hours then the benzene is distilled off continously. |

And further ....

| Quote: | Originally posted by Organikum

The Radzivankovskii catalyst is somehow tricky it seems. It takes a long time until the reaction HCl/Al kicks in. The addition of AlCl3 or SnCl4 so

avail should help.

Other salts will be tried soon.

Amalgamation of a small amount of the Al works well (no poisonous Hg-salts required, just add some Hg to a piece Al-foil...).

Alternativly some AlCl3 may be prepared with Al in DCM or perchlorethylene and chlorine. This can be used to kickstart the HCl/Al reaction....

No problem, I prefer Cl2 over HCl-gas anytime  |

What about using aluminum amalgam in isopropanol to produce benzene from paradichlorobenzene moth crystals ?

This might even work concurrently with the toluene disproportionation , if the paradichorobenzene were dissolved in toluene ,

as the reaction mixture would be

anhydrous from the formation of aluminum isopropoxide ,

and AlCl3 would also be formed in situ .

PS: If a 500 pixel image width limitation is enforced ,

the text formatting will not be trashed by the pictures

which members post here .

[Edited on 28-4-2007 by Rosco Bodine]

|

|

|

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

Isopropanol is an alcohol and as such it quenches AlCl3.

Where did you hear that aluminium amalgam in isopropanol reduces p-dichlorobenzene to benzene?

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Actually I never heard of it , and never tried it ,

it just seemed like a plausible result to me .

I know paradichlorobenzene may be almost

paraffinic in its unreactivity , but it isn't teflon .

Suppose you (partially) neutralize aluminum isopropoxide

with (anhydrous , nascent ) HCl , if not AlCl3 is what will be in solution as the result .....then what will be ?

Under anhydrous condition , I just don't see the chlorohydrate being likely , but I am not certain .

There would definitely be a tug of war for any

potential water or hydroxyl fragment

Update:

I found an old post where aluminum amalgam has already been tried and didn't react .....so it is pretty certain

that it would take some really extreme conditions of

temperature and pressure to get any reaction to proceed

involving the chlorines of paradichlorobenzene .

See bottom post page 3 by Polverone .

http://www.sciencemadness.org/talk/viewthread.php?tid=916&am...

[Edited on 26-4-2007 by Rosco Bodine]

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

p-dichlorobenzene + AlCl3 gives mostly a mix of the dichlorobenzene isomers, the chlorines seem happy to hop about on the ring but don't like to jump

rings. Careful fractionation of the mix might be able to remove benzene, I've not tried that as several reports stated no ring jumping for Cl although

Br has been stated to ring jump.

If the mixed dichlorobenzene isomers are cooled so the much of the para isomer freezes out, the ramaing mix is a useful not-too-reactive solvent.

|

|

|

BromicAcid

International Hazard

Posts: 3253

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

I'm pretty sure this has been mentioned before but your attempts remind me of using magnesium and isopropanol to give benzene from chlorobenzene, as

shown in:

Organic Syntheses, Coll. Vol. 5, p.998 (1973); Vol. 47, p.103 (1967).

|

|

|

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

Direct link would be: Reduction of organic halides. Chlorobenzene to benzene.

But I don't think aluminium amalgam would do that. I know it can't do that in the presence of water, but I doubt anhydrous conditions would make much

difference. Mg can insert in the Ar-Cl bond but I never saw an equivalent electron transfer from Al to aromatic halides. Even zinc would have more

chances of working.

Rosco, AlCl3 is a very strong acid and as such will complex even with such weak bases as water or alcohols. It coordinates with the oxygen's lone

electron pair just like other acids do (just like H<sup>+</sup>, for example). Like any acid/base reaction this complex is also

equilibrium:

R-OH + AlCl<sub>3</sub> <=> [R-O-AlCl<sub>3</sub>]<sup>-</sup> + H<sup>+</sup> <=>

R-O-AlCl<sub>2</sub> + HCl

When you want AlCl3 to efficiently catalyze FC reactions, then the solvent must never be more nucleophilic or basic than substrate is.

[Edited on by Nicodem]

|

|

|

| Pages:

1

..

5

6

7

8

9

..

14 |