kmno4

International Hazard

Posts: 1496

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

Acetone condensation with KOH - some experimental results. Isophorone

Part I

INTRODUCTION

Because I had a 1-liter bottle of very old ( more then 20 years....) acetone and slightly less old KOH (looking normally, not covered with carbonate),

I decided to repeat some experimets with aldol (base catalyzed) condensation of acetone. Such experiments were abandoned long time ago but not

forgotten. It is known that this reaction may give many products, the most known are: diacetone alcohol (DAA), mesityl oxide (MO), phorone (PH), a-

and b-isophorone (IPH and bIPH), xylitones (XYL), mesitylene (MES)... and many more condensation products of these substances with acetone (AC) and

themselves. The "end product" is a resin (RES). Depending on conditions, this resin is a mixture of polycondesates of linear structure or cyclic. For

amateur, it is useless junk and its formation should be reduced as much as possible.

In industry, aldol condensation of acetone is performed at ~3 MPa/250 C and low concentration of KOH water solution, in continous way. Under these

conditions, reaction takes single seconds and main product is IPH (~70% yield).

Of course, it is not easy to make it at home... And, as everybody knows, it is rather hard to obtain anything interesting from acetone and KOH (or

NaOH) just by mixing them. Reddish liquid is formed and there is no literature directions about what to do with it.

Several old publications (years 18xx) mention procedures for IPH preparation from AC and CaO, solutions of sodium ethanolate, KOH... etc. In almost

all cases no yields are given and/or experimental details are missing.

After reexamination of my earlier experiments and additional literature research, it turn out that it is possible to obtain defined products under

some experimental conditions, namely low conversion of AC. In another case, large part of early formed useful products is converted into XYL and RES.

My exeperiments were performed with AC and solid KOH only, without any cosolvent, because amateur chemistry should be as cheap and simple as possible

- it is the starting point.

Used KOH is of standard purity - it means that pure KOH content is ~90 %, the rest is mostly H2O. Carbonate is not harmful in small amounts. All

important remarks to the condition and results will be given in brackets and expanded in the end. It is assumed that the structures of all mentioned

compounds are known and basic chemistry of aldol condensation of AC is also known to the interested.

Because of low conversion, the best results are obtained working with rather large amounts of AC and with re-use of formed co-product (MO).

GENERAL REMARKS_1

With proportion 100g AC / 6g KOH, the main products of the reacion are MO and IPH in proportions 1:1,5 - 1:2 with large recovery of AC. XYL and RES

are always formed, with amounts depending on AC/KOH ratio. The smaller the ratio eg. 100/12, the more useless polycondensates are formed, making

seperation of IPH more difficult and lowering the total yield. Used KOH acts as catalyst for the condensation and - at the same time - as dehydrating

agent. Earlier experiments were started with even smaller AC/KOH ratios, but it gave large amounts of yellow-brown oils, containing small amount of

IPH and reddish resin (but intesively yellow when diluted in organic solvents). Because I see no use for MO (at present), after separation it is added

to the recovered AC for another preparation. In this way, the yield of IPH increases to more than 50% (total for three passes).

Example experiment.

200 g of dry (1) AC is poured into a glass bottle and 12 g of powdered (2) KOH is added. Stirring bar is also placed inside the bottle and the bottle

is closed firmly with the cap. The mixture is getting warm practically at once, becomes yellow and red during few minutes. The bottle is placed on

magnetic stirrer plate and stirring is started. It is important to keep temp. of the bottle above r.t., at ~30 C or so. The heat generated by reaction

at the beginning is enough for several hours, later external heating is needed. In my case, heat generated by the stirrer itself is used for heating

the bottle, by covering the botle with larger glass jar. It gives "free" heating during whole needed period.

During first hours, some mysterious sediment/suspenstion is formed (apart KOH suspension), but during next hours of stirring it slowly disappears. The

mixture becomes deeply red (yellow in large dilution), with particles of KOH floating around (mainly close to the bottom). Slowly, very slowly, KOH

starts to dissolve in water formed during condensations. To dissolve it completely, about 24 h of stirring at elevated temp.is needed (3). At the end

of this time, only liquid phases are present: 30-40 % water solution (heavy) of KOH and deeply red (but transparent) AC solution of various products

(light). From time to time it is checked if all solid KOH dissapears. When it is done, these phases are separated and the KOH solution is rejected (it

contains almost nothing but KOH and H2O). It sould be performed then the mixture is still warm, to prevent sudden "freezing" of KOH solution on

cooling in your separation device ( unfortunately it happened...).

That is why another way of separation is more prefered. The bottle is cooled to about 10 C (or below) - it causes crystallization of KOH hydrates as

uniform mass on the bottom. The AC layer is then poured off. Some very small (fraction of cm3) amount of liquid KOH solution is usually present on the

solid and it should be also removed (but it is not very important).

To the red AC solution, 3-4 droplets of 75% H3PO4 (it was at hand) are added (to remove any KOH and stop further condensations) and set for simple

distillation.

Heating is on, the mixture starts to boil and the distillate is collected until temp. reaches ~85 C in the head. About 140-160 g of liquid is

collected (4), being impure AC (containing some MO and H2O).

At this point, separation of reminder was conducted exploiting formation of water azeotropes.

It was done in two ways: with simple and fractional(5) distillation. Of course, the second way is better.

So, to the reminder in a flask water is added and the mixure is distilled again.....

GENERAL REMARKS_2

MO forms H2O azeotrope with b.p. ~91 C

All these: DAA, PH, IPH also form H2O azeotropes, but with b.p. ~99 C

AC gives no azeotrope

MES - lack of informations

Separation of DAA, PH and IPH would be impossible in this way, but fortunately DAA and PH (and MES) are not detected at all as product of condensation

under given conditions. This knowledge comes from (many) earlier experiments, including distillations of raw IPH at atm. press. There is small

fraction collected up to ~150 C, then there is fast increase in temp. above ~210 C, when main fraction of IPH starts to collect. Between 150 C and 210

C practically nothing distills. DAA is highly unstable under condensation conditions, giving back AC or dehydrating to MO. Question of PH is more

complicated, but if it is really formed, its amount is very small, undetectable at "home level".

.....The biphasic mixure starts to boil, first droplets of distillate form at ~80 C. It contains AC, MO and H2O. The tepmerature in the head rises

slowly, the distillate becomes also biphasis. At ~89 C starts to distill impure (AC) MO azeotrope and it is collected separately. This MO fraction is

collected until ~97 C, then reciver is again changed. Collected MO-H2O mixture is NaCl saturated and water solution is rejected. The impure, wet MO is

used for another preparation, or can be kept for pure MO isolation (it was not done, as given earlier). Prepared MO is colorless liquid with awfull,

nauseating odor, resembling everything and nothing. About 15-20g of such MO is obtained (4).

The distillation is continued, collecting fraction 97-99 C. It takes some longer time, the product is a mixture of MO and IPH with H2O. Its amount

depends on quality of distillation, bacuse separation of the azeotropes and H2O is very imperfect in this case. This distillate is kept, without

liquids separation. When temperature reaches 99 C (or at least 98,5 C), reciver is changed and mixture of IPH and H2O is collected, however it still

contains small amount of MO....

GENERAL REMARKS_3

IPH-H2O azeotrope (b.p. 99,6 c) contains ~16 % of IPH. Solubility of IPH in H2O is ~1,4%, H2O in IPH is ~4%. Because large amount of water is

distilled off, water phases should not be rejected because it contains some IPH. It is definitely some complication, but it can be bypassed (at least

partly).

end of Part I, the rest is in preparation (with few pictures).

ps. Sorry for so many words, but I would like to avoid any doubts and generating too many questions

Слава Україні !

Героям слава !

|

|

|

Fery

International Hazard

Posts: 1015

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Well done!

I wanted to perform the reaction using CaC2 but not yet time.

https://pubs.rsc.org/en/content/articlehtml/2018/ra/c8ra0596...

Attachment: C8RA05965A.pdf (835kB)

This file has been downloaded 214 times

You can also react diacetone alcohol with urea into keto pyrimidine

https://patents.google.com/patent/US2782197A/en

Attachment: US2782197.pdf (363kB)

This file has been downloaded 229 times

|

|

|

kmno4

International Hazard

Posts: 1496

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

Part II

... First ~25 cm3 of distillate is set aside - it contains the rest of MO, with IPH and H2O.

About 100 cm3 of water is then collected, with pale yellow-green nicely smelling IPH upper layer.

The amount of wet IPH should be 11-13 g and it is separated. Water phase, containing ~1,4 g of IPH is returned to the destillation flask and distilled

again. Another ~100 cm3 of H2O is collected, but with amount of IPH smaller than earlier, rougly 5-8 g. Water is separated and again returned to the

same flask. From now, ~25 cm3 portions of distillate are collected and mass ratio of organic phase to water phase of each sample is calculated.

Distillation is stopped, when the ratio drops below 5/100. When distillation is continued, slighly more IPH is obtained but with XYL, slowly

distilling with

steam. The color of organic distillate changes then to more yellow, odor becomes not IPH like, its density drops, temperature in the head reaches 100

C. Total amount of obtained wet, crude IPH is ~25-30 g (4). The organic reminder in a flask contain only XYL and RES - nothing interesting to do

with it. To remove H2O from prepared IPH, CaCl2 is used in portions: 1-2 g is added first, when CaCl2 dissolves completely, its layer (bottom) is

pipeted out and another potrion is added, until IPH becomes dry.This IPH is not very pure, it still contains some MO and XYL (and - possibly - PH).

But for experiments with decarboxylation of a-aminoacids, it is perfect.

GENERAL REMARKS_4

It was experimentally checked, that distillation of this IPH under normal pressure always leads to partial decomposition (polymerization, oxidation

?). Brightly colored IPH gives only slightly brighter distillate, but high-boiling residue in distillation flask is rather large, sometimes more than

30% of starting crude IPH and has yellow-brown color. When the distilled IPH is redistilled, it happens again - large amount of brownish oily residue

is formed. It was very dissapointing, so such distillation was no more tried. Some old german article says that IPH (called there "isoacetophoron"),

at reduced pressure (89°C/10 mm or 100°C/17 mm) can be distilled many times, without any decomposition. However, in my hands, long-lasting (>12h)

heating of IPH and H2O also gives some residue, bul in small amount (<5%) and this time it has nicely looking orange-red color.

... The procedure given above is the first run/pass. Besides the IPH, a lot of impure AC, MO, intermediate distillates and water fractions (containing

IPH) are left.

The best way of utilization of these fractions is performing another run.Obtained AC fraction (140-160 g), MO fraction (15-20) g) and intermediate

fraction 80-89 C (few grams) are combined into one. It is then dried roughly with CaCl2 to remove most of water ( most of CaCl2 may be dissolved,

giving easy to separate layer on the bottom). It is then almost ready to use (1) substrate for another condensation with KOH. Amount of KOH is

calculated as for pure AC. This mixture gives slightly better amount of IPH. There is no MO accumulation in another MO fraction (the more of it is

present at the start, the more is used up). Time of KOH dissolving is practically the same (24h), under similar conditions. Further procedure is as

above. After AC distilling off, to the residue is added ~25 cm3 MO-IPH-water intermediate fraction (saved earlier), all waters from IPH separation,

enough fresh water for another azeotrope distillation... and so on.

This is all about simple distillation method. From 200 g of starting AC, after 3 passes, about 50-60 g of "decarboxylation grade" IPH can be obtained,

about 80-90 g of AC and ~10 g of MO are recovered.

Short description of fractional distillation/separation.

Product of condensation (with H3PO4 added) is placed in some larger RBF and water is added, at least in equal amount. The biphasic mixture is then

fractionally distilled. AC comes first in range 58-60 C, then some small fraction (mainly AC) is collected in 60-90 C. MO azeotrope is collected in

range 90-95 C. It is completely colorless and biphasic (about 50/50 by volume) fraction. Then fraction 95-99 C, containing MO,IPH and H2O (and,

possibly, also other substances) is collected. It is also biphasic, with yellow-green organic phase, with lager amount of water (colorless).When temp.

crosses 99 C, IPH azeotrope is collected in the same way as in simple distillation case (with returning water phase to RBF.. etc). Obtained IPH looks

like some vegetable oil (canola... etc) and has rather pleasant peppermint-camphor-hay odor. After CaCl2 drying, its density corresponds rather well

to literature value. Initial azeotropic IPH-H2O fractions have compositions very close to

literature value. As IPH is exhusted from RBF, ratio IPH/H2O in distillates gradually increases, but it is the same IPH as in earler fractions (the

same color, odour, density). Just b.p. of azeotrope IPH-H2O is very, very close to b.p. of water itself and separation in column is not good.

Distillation is stopped, when IPH/H2O ratio reaches value given earlier. However, in this case the ratio can be lowered and few grams more of IPH can

be obtained.

Some modifications of the procedure are possible, for example:

Post-condensation mixture (from 200 g of AC) is distilled without column, but only AC fraction is collected, the MO-IPH-XYL-RES residue is kept. The

AC fraction is dried and reacted with KOH. Only AC is removed, as above, the residue is combined with the residue obtained earlier. Combined residues

are distilled with column, collecting everything below 95 C and obtained distillates (mainly MO) are salted out (NaCl), combined with AC recovered

from the 2nd run and reacted with KOH - this is the last, 3rd run. Post-condensation mixture from this run is added directly to the residues without

MO, water added and then fractionally distilled. If properly performed, given procedure saves some time and it is possible to exploit RBF with smaller

volume.

Of course, one can do only one condensation with >200 g of AC and obtain the same amount of IPH as in case of multi-run reaction. But it this case,

also rather large amount of MO is obtained (after water azotrope separation, drying and distillation) as co-product.

end of Part II - the last part is coming soon

Слава Україні !

Героям слава !

|

|

|

kmno4

International Hazard

Posts: 1496

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

... and the last part

Remarks/comments

(1) When fresh AC is used (p.a. or better grade), no additional drying is required. Reaction with KOH starts pactically at once, the mixture becomes

yellow and red in less than 1 minute.

When AC is of worse quality, or comes from recovery, it may contain some larger amounts of water.

Larger water content dramatically slows down the reaction rate, beacuse hydration of KOH is faster than AC condensation. KOH particles are then

covered with concentrated KOH solution, become sticky and proper stirring is highly problematic. The mixture gains some coloration in > 1 h and

total time of condensation may be longer than 48 h. The best method of drying AC for our purpose is using... KOH as drying agent, for example:

100 g of wet AC is placed in some Erlenmeyer flask and 1-2 g of KOH is added (flakes, without grinding). Dipole is inserted and AC with KOH is stirred

at high speed on mag. stirrer. From time to time, the flask is controled if there is any larger amount of liqid KOH solution on the bottom. If yes -

it is pipeted out and stirring is continued. Of course, when whole solid KOH dissapeared completely, additional 1-2 g is added again. When

concentration of water drops below some level, condensation of AC is started. It is indicated by appearing yellow coloration of AC - it may take 5

minutes or 60 minutes, depending on water concentration at the start. Stirring is then stopped and the yellow AC is carefully poured off - it is ready

for condensation.

(2) Orginal KOH was in form of flakes. Needed amount is placed in some mortar and grinded into small pieces (<1 mm) or just powdered. There is no

need to make perfect dust, 2-3 minutes of grinding is OK. WARNING: use goggle or some glasses during this operation, powdered KOH may be dangearous to

everything on your face, including same face

(3) About 30-35 C is good

(4) Concrete value depends on exeperimental conditions, work up, patience and your skills

(5) Vigreux, 40 cm long, ~3 cm diam.

Basically, that is all I wanted to share. IPH is not expensive industrial product, but preparing it from cheap AC and KOH gives much more fun than

buying a bottle of IPH  . For smaller amounts, the method given above offers IPH

much cheaper than commercial e.g. 50 ml sample. . For smaller amounts, the method given above offers IPH

much cheaper than commercial e.g. 50 ml sample.

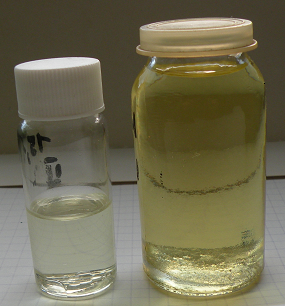

Some picture were taken, but they are not very interesting.

A sample of of IPH separated after azeotropic distillation (on the left) and a sample distilled earlier IPH under normal pressure. I have impression,

that this distilled IPH became more colored on standing. Anyway, distillation with water gives slightly purer product. However, in several recently

read papers, the authors use (re)distilled IPH at around 212-215 C.

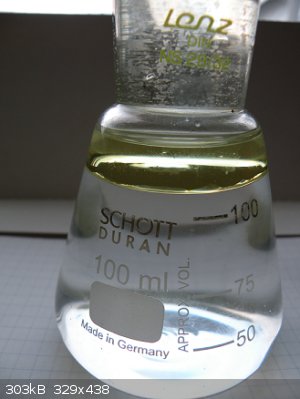

Another boring picture: a sample of azeotropic distillate (fractional). Simple measurements show, that its composition closely corresponds to

literature value.

And the last one: a gallery of samples and a residue.

They were collected with more or less equal amounts of water (5 x ~50 ml and 2 x ~25 ml, from left), to check if it is uniform product (by density

measurements). The first sample (not shown - no color and appearance difference with the others), gave slightly less density (the most possibly MO

traces) than next 6 ones, with practically constant density. The last sample has again sligtly less density, because of XYL content. The orange-red

liquid is mentioned earlier post-distillation residue. It has not very pleasant odor, not IPH like.

Слава Україні !

Героям слава !

|

|

|

dicyanin

Hazard to Self

Posts: 57

Registered: 29-3-2020

Location: Europe

Member Is Offline

Mood: inquisitive

|

|

my results

Reading up on isophorone it appears to be choice catalyst material in the decarboxylation of α-amino acids, as a cyclohexenone derivative

that is unsubstituted in the ortho-positions so from a steric point of view unhindered (compared to natural occurring derivatives like carvone and

pulegone commonly used for that purpose by amateur experimenters). For this a crude product of technical purity should suffice, so this makes kmno4's

procedure quite attractive. Here is what I made of it:

Experimental

18 g anhydrous KOH flakes were ground with mortal and pestle and added to 300 ml acetone in a capped 1 L Schott-Duran bottle. Magnetic stirbar was

added, the bottle wrapped in insulation foam and good stirring was started. In a few minutes an exothermic reaction was noted and the acetone turned

orange-red. After 4 hours of stirring the hotplate was turned on on the lowest setting (<50°C), at that point the solution had turned dark red. It

was stirred for an additional 4 hours, after which all solid KOH had dissolved and a small bottom aqueous layer had formed. The solution was decanted

into a separatory funnel when still warm, taking care to remove a small amount of tar that had formed, the bottom aqueous base layer was drained off

and the red solution was transferred to a 1 liter roundbottom flask.

The smell of the red acetone solution had a sickly sweet note, pleasant at first but soon becoming somewhat nauseating.

To the stirring solution was added 6 drops of 75% phosphoric acid, and the flask was set up for distillation. Acetone started distilling over at

56°C, everything was collected up to 65°C. About 200 ml acetone was added back to the Schott bottle while the red oily residue in the roundbottom

flask was set aside for later.

To the Schott bottle was added dry acetone up to the 800 ml mark, followed by 48 g ground KOH (anhydrous flakes). The capped bottle was placed in a

warm water bath (40-50°C) on a hotplate/magnetic stirrer and the mixture was stirred for 20 hours, after which all solid KOH had gone in solution,

forming a bottom aqueous layer, which was drained off using a separatory funnel, and the top acetone solution was placed in the roundbottom flask, 16

drops 75% H3PO4 were added with stirring and the whole was set up for distillation. ~400 ml acetone were collected at 56-58°C.

The flask was cooled to 40°C and 400 ml distilled water was added. A black oil layer separated and floated on top. The mixture was set up for

distillation, the distillate up to 85°C was collected. A second fraction was collected between 89-96°C containing mostly the sickly smelling mesityl

oxide-water azeotrope. From 97°C-100°C our product started coming over together with water, the smell is minty and not unpleasant.

The emulsion in the receiving flask was saturated with table salt, the organic layer taken up in methyl tert-butyl ether, the aqueous phase extracted

with 30 ml MTBE. Pooled organics dried over MgSO4 and solvent evaporated.

Water was added to the distilling flask, and the mixture was distilled until the black oily top layer in the distilling flask had mostly disappeared.

Distillate is each time saturated with salt, extracted with MTBE, organic layer dried over MgSO4, ether evaporated.

Total yield: about 40 ml minty-smelling yellow oil

Some tarry residu is left in the distilling flask which is best cleaned with fresh acetone.

sic transit gloria mundi

|

|

|

dicyanin

Hazard to Self

Posts: 57

Registered: 29-3-2020

Location: Europe

Member Is Offline

Mood: inquisitive

|

|

TLC

TLC solvent was methylene chloride

1, 2, 3, 4 stands for the first 10 ml collected, second, third and last 10 ml fraction from above experiment

It is surprisingly hard to find TLC data on acetone condensation products.

I suspect the most prominent streaks to be isophorone isomers and the spot above it to be mesityl oxide? There's an additional unknown spot present in

the first and last samples.

sic transit gloria mundi

|

|

|

kmno4

International Hazard

Posts: 1496

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

I noticed rather low yield of your IPH, taking into account amount of used AC.

Unfortunately, reaction AC with KOH is controlled by too many parameters: purity of reagents, AC:KOH ratio, temperature and time of reaction. Also

speed of stirring is important and it should be high (to avoid accumulation of products on KOH surface).

Elevated temperature is generaly harmful for IPH yield, just too many isoXYL and resin are formed. At lower temperatures (around 0 C), MO formation is

predominant. Separation of MO and IPH is easier than separation of isoXYL and IPH. Besides, MO can be reused, isoXYL and resin are useless.

Interesting is also slight change in color (but easily seen) and small sediment formation when post-condensation organic liquid is treated with H3PO4

(or similar, not very strong acid). This step is very important, traces of any alkali must be removed from the mixure before distillation. In another

case, large amount of polymeric, tarry material is obtained, the yield of IPH is reduced.

H3PO4 is too weak acid to cause some larger condensation, even during distillation of the mixture.

Prepared IPH is surely better than 90%, at least I think so, but it does not freeze even far below 0 C. Most possibly, depression in m.p. caused by

impurities is large. Overcooling is rather ruled out, but who knows.... Removing of beta-IPH, always formed by-product in small amount, is practically

impossible, using such simple methods as above.

The only examples of TLC of similar mixtures I have seen, were performed with DNP derivatives and n-hexane-ether solvent system (80/20 v/v).

[Edited on 12-4-2024 by kmno4]

Слава Україні !

Героям слава !

|

|

|

|