| Pages:

1

..

74

75

76

77

78

..

81 |

Dornier 335A

Hazard to Others

Posts: 231

Registered: 10-5-2013

Location: Northern Europe

Member Is Offline

Mood: No Mood

|

|

Neat, I wasn't aware of the backup. Especially since I never had time to reupload all of them myself. The descriptions are unfortunately long gone but

I'm happy to answer questions if you have any.

|

|

|

MineMan

International Hazard

Posts: 1034

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Dornier 335A  | | Neat, I wasn't aware of the backup. Especially since I never had time to reupload all of them myself. The descriptions are unfortunately long gone but

I'm happy to answer questions if you have any. |

Thanks man!

It’s a pleasure to still have you around  ) )

|

|

|

EF2000

Hazard to Others

Posts: 154

Registered: 10-5-2023

Location: The Steppes

Member Is Offline

Mood: Taste testing the Tonka fuel

|

|

Quote: Originally posted by Dornier 335A  | | Neat, I wasn't aware of the backup. Especially since I never had time to reupload all of them myself. The descriptions are unfortunately long gone but

I'm happy to answer questions if you have any. |

It's great that you're still around!

I'm mostly interested in your flash powders compositions. They are really otstanding! So, here's the first question: what is the "High Explosive Flash

Powder" (HE FP) from videos #2, #78 and #79? Is it some version of your mainstray super flash powder (Mg+NaNO3+C/FeCe/S...) or something else? If it really detonates,

I see a lot of potential uses for it. For example, annular charges in thermobaric warheads (pardon my militarism).

And the second question is about Golden and Crimson powders. Do they explode when heated in confinement, like whistle mix and yellow powder do?

|

|

|

yobbo II

National Hazard

Posts: 781

Registered: 28-3-2016

Member Is Offline

Mood: No Mood

|

|

I recognise the sounds of the birds chirriping in the background

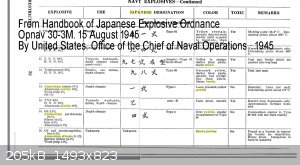

Regarding ammonium chlorate. It turnes up in a us navy book of wwI explosives

It was used as a booster mixed with something else. It must be an error. Will post table later.

Called brown powder used by the japanese .

Yob

[Edited on 14-7-2023 by yobbo II]

|

|

|

dettoo456

Hazard to Others

Posts: 261

Registered: 12-9-2021

Member Is Offline

|

|

It might just be an impurity in my 5-ATz or nitrite or H2SO4, but for some reason whenever I run a recryst on NaNTz in acetone, my stir bar and PTFE

stir rod always start to degrade and fall apart on contact with the hot NaNTz/acetone sol. I use acetone to extract NaNTz from a dry, crude rxn mix

containing Na sulfate and bisulfate with small amounts of sulfuric and nitrous acid left in. I then decant the acetone and let the NaNTz drop out.

Whenever the acetone and NaNTz mix together though, and come on contact with anything ptfe, they immediately cause the outer surface to slide off and

turn into a gummy, almost soluble (in acetone) blob. The PTFE slightly resembles styrene in gasoline - sticky and pliable but still with some definite

form. The reaction also occurs slightly during the 5-ATz nitrosation reaction in water, but to a much lesser degree and only when the mix is hot and

acid conc is high.

This issue with the teflon has happened to me multiple times and I can attest to the purity of the NaNTz - although I haven’t tried to see if the

same thing happens for other 5-NTz salts in any other solvents.

Has this ever happened to anyone else? Running energetic synths in non-glass/metallic vessels is really important and it’s annoying that this

incompatibility could pose a real issue.

|

|

|

B(a)P

International Hazard

Posts: 1139

Registered: 29-9-2019

Member Is Offline

Mood: Festive

|

|

Quote: Originally posted by dettoo456  | It might just be an impurity in my 5-ATz or nitrite or H2SO4, but for some reason whenever I run a recryst on NaNTz in acetone, my stir bar and PTFE

stir rod always start to degrade and fall apart on contact with the hot NaNTz/acetone sol. I use acetone to extract NaNTz from a dry, crude rxn mix

containing Na sulfate and bisulfate with small amounts of sulfuric and nitrous acid left in. I then decant the acetone and let the NaNTz drop out.

Whenever the acetone and NaNTz mix together though, and come on contact with anything ptfe, they immediately cause the outer surface to slide off and

turn into a gummy, almost soluble (in acetone) blob. The PTFE slightly resembles styrene in gasoline - sticky and pliable but still with some definite

form. The reaction also occurs slightly during the 5-ATz nitrosation reaction in water, but to a much lesser degree and only when the mix is hot and

acid conc is high.

This issue with the teflon has happened to me multiple times and I can attest to the purity of the NaNTz - although I haven’t tried to see if the

same thing happens for other 5-NTz salts in any other solvents.

Has this ever happened to anyone else? Running energetic synths in non-glass/metallic vessels is really important and it’s annoying that this

incompatibility could pose a real issue. |

I have never had nor heard of this issue before. Did all of your stir bars come from the same place? Was it a reputable source?

While I have not had hot acetone/NaNTz in contact with my stir bars, I have had hot acidic solutions of NaNTz in contact with my stir bars and I have

never noticed and degradation or discolouration.

|

|

|

dettoo456

Hazard to Others

Posts: 261

Registered: 12-9-2021

Member Is Offline

|

|

Yes the stir bars are PTFE and the degradation has happened with multiple bars from different sources (vwr, scilogex, and some old second-hand ones).

I’ll try to link a video showing it - the warped ptfe is much easier to scrape off the bar (even with a dull metal spatula) and has a springy,

elastic/plastic nature.

[Edited on 23-7-2023 by dettoo456]

[Edited on 23-7-2023 by dettoo456]

|

|

|

B(a)P

International Hazard

Posts: 1139

Registered: 29-9-2019

Member Is Offline

Mood: Festive

|

|

Quote: Originally posted by dettoo456  | Yes the stir bars are PTFE and the degradation has happened with multiple bars from different sources (vwr, scilogex, and some old second-hand ones).

I’ll try to link a video showing it - the warped ptfe is much easier to scrape off the bar (even with a dull metal spatula) and has a springy,

elastic/plastic nature.

[Edited on 23-7-2023 by dettoo456]

[Edited on 23-7-2023 by dettoo456] |

That is so strange. I have just checked all of my stir bars that may have been in acidic nitrotetrazole solutions and they all look in great

condition. I have also just checked all of the tetrazole references I have and I can't find mention of this issue observed by others. Looking forward

to hearing if anyone else has experienced/heard of this.

Edit - typo

[Edited on 23-7-2023 by B(a)P]

|

|

|

Rainwater

National Hazard

Posts: 991

Registered: 22-12-2021

Member Is Offline

Mood: Break'n glass & kick'n a's

|

|

Making sodium by the nerdrage process, its easy to tell when a stirbar is fake. I had a few simply dissolve and turn my reaction a rusty red. This

sounds similar.

"You can't do that" - challenge accepted

|

|

|

dettoo456

Hazard to Others

Posts: 261

Registered: 12-9-2021

Member Is Offline

|

|

Attachment: IMG_1524.mov (6.2MB)

This file has been downloaded 300 times

I had to cut up the video but hopefully this shows some of the properties of the stir bar. The NaNTz solution is orange/yellow but I know for sure

that is is pure - any other impurities I can’t deduce.

The PTFE shown is more springy/elastic than normal PTFE (which would usually break clean off of the bar when cut). Also, my dull spatula can’t dig

into clean PTFE; not in the case of this degraded PTFE though.

|

|

|

B(a)P

International Hazard

Posts: 1139

Registered: 29-9-2019

Member Is Offline

Mood: Festive

|

|

Quote: Originally posted by dettoo456  |

I had to cut up the video but hopefully this shows some of the properties of the stir bar. The NaNTz solution is orange/yellow but I know for sure

that is is pure - any other impurities I can’t deduce.

The PTFE shown is more springy/elastic than normal PTFE (which would usually break clean off of the bar when cut). Also, my dull spatula can’t dig

into clean PTFE; not in the case of this degraded PTFE though. |

Wow, you are right the PTFE is totally destroyed! How long and what was the sustained temperature that stir bar was in contact with the NaNTz

solution? Is there a chance your stir bars could have been damaged previously from some other experiment?

|

|

|

Dornier 335A

Hazard to Others

Posts: 231

Registered: 10-5-2013

Location: Northern Europe

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by EF2000  |

It's great that you're still around!

I'm mostly interested in your flash powders compositions. They are really otstanding! So, here's the first question: what is the "High Explosive Flash

Powder" (HE FP) from videos #2, #78 and #79? Is it some version of your mainstray super flash powder (Mg+NaNO3+C/FeCe/S...) or something else? If it really detonates,

I see a lot of potential uses for it. For example, annular charges in thermobaric warheads (pardon my militarism).

And the second question is about Golden and Crimson powders. Do they explode when heated in confinement, like whistle mix and yellow powder do?

|

It is a flash with two oxidizers and two fuels: sodium nitrate, potassium chlorate, ferrocerium, and red P. I think the ratio was 25/35/25/15.

Obviously quite sensitive, but its biggest problem is the ferrocerium which oxidizes in air. It won't detonate after only a few days. Later, I got

several simpler mixtures like Mg/NaNO3 to detonate by simply grinding the powders down to submicron sizes.

Golden/crimson powder is equivalent to black powder in almost every way (except hygroscopicity). The mixture ignites well below its melting point so

it doesn't behave like whistle mix or yellow powder.

|

|

|

EF2000

Hazard to Others

Posts: 154

Registered: 10-5-2023

Location: The Steppes

Member Is Offline

Mood: Taste testing the Tonka fuel

|

|

Quote: Originally posted by Dornier 335A  |

It is a flash with two oxidizers and two fuels: sodium nitrate, potassium chlorate, ferrocerium, and red P. I think the ratio was 25/35/25/15.

Obviously quite sensitive, but its biggest problem is the ferrocerium which oxidizes in air. It won't detonate after only a few days. Later, I got

several simpler mixtures like Mg/NaNO3 to detonate by simply grinding the powders down to submicron sizes. |

Thanks for the answers, much appreciated.

I had a suspicion that the first high explosive flash powder must have some serious drawbacks. "The first pancake is a lump" as they say in my

country. Since it's basically a mixture of Armstrong's Mixture and flash powder with air-sensitive fuel, any practical use is ruled out.

But Mg/NaNO3 flash powders are very promising. Especially if the extra fine Mg powder is somehow protected from air and moisture. Like

linseed oil coating or chromate passivation.

|

|

|

B(a)P

International Hazard

Posts: 1139

Registered: 29-9-2019

Member Is Offline

Mood: Festive

|

|

Quote: Originally posted by EF2000  |

But Mg/NaNO3 flash powders are very promising. Especially if the extra fine Mg powder is somehow protected from air and moisture. Like

linseed oil coating or chromate passivation. |

The sodium nitrate is what will need careful protection from moist air.

|

|

|

EF2000

Hazard to Others

Posts: 154

Registered: 10-5-2023

Location: The Steppes

Member Is Offline

Mood: Taste testing the Tonka fuel

|

|

Of course. Sodium nitrate needs to be protected from becoming moist. And magnesium needs to be protected from reacting with that moisture.

I don't know how to protect both in bulk powder form, but in plastic-binded composition it's easy. For example, silicone binders, used in Bulgarian

H-TBX and A-TBX, are both dry and water-proof.

|

|

|

OneEyedPyro

Hazard to Others

Posts: 280

Registered: 7-10-2015

Member Is Offline

Mood: No Mood

|

|

Does anyone know the maximum amount of PETN that can be dissolved in molten TNT? I did some digging but everything seems to refer to either a very low

percentage of PETN or a 50/50 mix. I think I recall seeing something from Urbanski or PowerLabs many years back saying that they were effectively

miscible, but I'm second guessing myself wondering if it wasn't in reference to ETN/TNT.

|

|

|

MineMan

International Hazard

Posts: 1034

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by OneEyedPyro  | | Does anyone know the maximum amount of PETN that can be dissolved in molten TNT? I did some digging but everything seems to refer to either a very low

percentage of PETN or a 50/50 mix. I think I recall seeing something from Urbanski or PowerLabs many years back saying that they were effectively

miscible, but I'm second guessing myself wondering if it wasn't in reference to ETN/TNT. |

Look up pentolite. Used in blasting boosters

|

|

|

OneEyedPyro

Hazard to Others

Posts: 280

Registered: 7-10-2015

Member Is Offline

Mood: No Mood

|

|

I have and found only info about common ratios used commercially. I've seen references that the Russians have used a mixture of 75/25 in grenades,

mortars, HE projectiles etc but that may just be a suspension of PETN like with Comp B using RDX rather than being fully molten.

|

|

|

MineMan

International Hazard

Posts: 1034

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by OneEyedPyro  |

I have and found only info about common ratios used commercially. I've seen references that the Russians have used a mixture of 75/25 in grenades,

mortars, HE projectiles etc but that may just be a suspension of PETN like with Comp B using RDX rather than being fully molten.

|

Well that works too. Even water can be used to increase the suspension of energetics and their power.

|

|

|

DennyDevHE77

Hazard to Others

Posts: 168

Registered: 15-9-2014

Member Is Offline

Mood: No Mood

|

|

7-14% PETN is dissolved in TNT, the rest will be already as an emulsion. At the same time, such an additive within the limits of solubility makes

molten TNT sensitive to primary means of initiation (capsule detonator No 8)

|

|

|

PLSHY

Hazard to Self

Posts: 96

Registered: 30-7-2023

Member Is Offline

|

|

Quote: Originally posted by OneEyedPyro  | | Does anyone know the maximum amount of PETN that can be dissolved in molten TNT? I did some digging but everything seems to refer to either a very low

percentage of PETN or a 50/50 mix. I think I recall seeing something from Urbanski or PowerLabs many years back saying that they were effectively

miscible, but I'm second guessing myself wondering if it wasn't in reference to ETN/TNT. |

86.5% tnt and 13.5%

petn form a low melting point eutectic with a melting point of 77 degrees Celsius 。When pentolite melts, it is a solid-liquid mixture, not a liquid.

And it has only one ratio, that is 50:50

[Edited on 3-11-2023 by PLSHY]

|

|

|

Bender84

Harmless

Posts: 32

Registered: 24-3-2016

Member Is Offline

Mood: No Mood

|

|

Hello everyone,

Has anyone ever come across any material on the flammability of nitroglycol or nitroglycerin vapors, or the sensitivity (and explosiveness) of these

substances' vapors to ESD, for example?

I have only found a study on the flammability of alkyl nitrates vapors (The Inflammation of Alkyl Nitrate Vapours and the Effect of Inert Diluents, by

P. Gray and A. D. Yoffe, Proceedings of the Royal Society of London. Series A, Mathematical and Physical Sciences, Vol. 200, No. 1060 (Dec. 22, 1949),

pp. 114-124). The authors does mention nitroglycerin vapors in the abstract (which, after all, have a relatively low vapor pressure), but there is no

further development of this topic in the text itself.

I would be grateful for pointing me to a source where I could find information on this subject (if such a source exists).

Best regards.

[Edited on 4-11-2023 by Bender84]

|

|

|

Microtek

National Hazard

Posts: 921

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

I would think that the vapor pressure of NG at least is too low to support combustion, though I haven't seen any papers discussing it.

|

|

|

knowledgevschaos

Harmless

Posts: 41

Registered: 9-8-2023

Location: Sci-Hub and the hardware store

Member Is Offline

Mood: Hungry for information

|

|

Hello everyone. This might sound like a dumb question, but why does iron spark on a grinder while aluminium, a more reactive metal, produces no

sparks? Thanks.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1447

Registered: 2-9-2014

Location: Tel Aviv University

Member Is Offline

Mood: old jew

|

|

Because aluminum has a much higher thermal conductivity than iron. Aluminum dissipates heat from the grinding area so quickly that this area does not

have time to heat up to an ignition temperature.

Development of primarily - secondary substances: CHP (2015) neutral CHP and Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024) Diper

60 (2025)

|

|

|

| Pages:

1

..

74

75

76

77

78

..

81 |