| Pages:

1

2

3

4 |

specialactivitieSK

Hazard to Self

Posts: 94

Registered: 21-10-2014

Member Is Offline

Mood: No Mood

|

|

By guanidine perchlorate, methanol is used.

|

|

|

Hey Buddy

Hazard to Others

Posts: 441

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Consolidated update

I've not been working on this as much as i'd like. I am still at the exploration of the simple displacement methods. I wanted to sum up findings:

-A dirty version of GlyClO4 can be prepared via reflux of stoich NH4ClO4 and glycine, or with added HCl.

-I haven't compared yields between the two. its unknown if any advantage is had by HCl.

-The product of the HCl route can be easily melted at low temp. I melted it at around 120 C which seemed like a good working temp. The original text

version of this material, prepared via HClO4, is reported to melt at 103 C.

-Both methods of producing the dirty version of this material result in a strange behavior: The material readily melts into a clear opaque castable

substrate that cures flat. BUT... If the material is left un-melted such as in a drying plate, it develops brown spots and the smell of caramelized

sugar. A sample made via HCl was left in the drying cabinet @ 60 C for two weeks and it developed this character. Another sample, prepared without

HCl, was stored in a sealed plastic container for several months and when it was opened, it exhibited both the sweet sugar smell and some browning.

The brown-tainted material does not melt at any useful temp up to 180 C. The material after browning is still hot water soluble, and the brown color

comes out into hot water and a solid material can be recovered leaving a brown water and white material. In the instance where I tried this to purify

it, I refluxed it again after separating the brown water, and ammonia did not evolve from reflux. Then I accidentally burned the sample and wasnt able

to continue recovery for checking explosive character.

Regarding explosive character of the dirty version of GlyClO4:

I used NAP to test all detonations of the material.

The brown version from the bottle (mentioned before, prepared without HCl), could be detonated but not melted. It can be detonated in small masses

like a primary explosive (>50 mg). I believe this is only possible due to the power of NAP.

--A fresh sample made with HCl was cast within 2 days of drying in a 1" diameter x 1.5" length. It was not hygroscopic.

That sample detonated entirely and I believe it is detonating at reduced velocity. I couldn't say for sure, but suspect it's detonating around

5-6km/s. That test's results are in the photos posted earlier.

I attempted to prepare a sample using Isopropanol solvent. Neither glycine nor ammonium perchlorate appeared to dissolve into boiling IPA. the IPA

sample was dried then refluxed again in water. Ammonia was evolved.

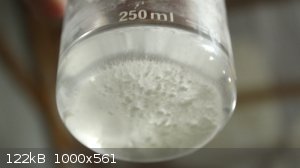

Reflux lasted 1 hour. The sample was cooled to room temperature and stayed dissolved in the water. While in liquid phase, and at RT, 90% IPA was added

to the sample.

White material precipitated. The beaker was left out overnight and resulted in two crystals. A long needle crystal which consolidated over the ptfe

stir bar, and large blocky square crystals which formed on the bottom of the beaker. The crystals were decanted and separated on a hot pan. The

crystals would not melt at 120 C.

Im not sure what any of this means, but I thought I would just describe this and maybe someone would get value out of it. I have no idea why the

material seems to behave unpredictably. My only guess is there are variable proportions of impurities at play here.

The next interest in this exploration is a pure HClO4 sample. Which probably should have been attempted first as control, but I was too fascinated at

the prospect of a material produced from OTC salts.

Currently building up HNO3 towards that.

Regardless, I think there is value to the dirty version because of its simple utility. It really casts nicely and would be an excellent cast substrate

for anything in that temp range. I regard its explosive character comparable to dinitrotoluene.

Does anyone know if nitrate esters can be safely carried in a perchlorate melt cast? I would like to try nitro guanidine and PETN in the dirty

version.

[Edited on 22-6-2023 by Hey Buddy]

|

|

|

MineMan

International Hazard

Posts: 1014

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

I can’t answer your other questions. I wish PHILOU was here too.

As for the melt cast. Can you try incorporating a few percent glass microballoons and or aluminum, should allow full VOD.

The displacement reaction from AP is obviously most interesting. Any other amino acids that might work as well? Citrulline?

Was really hoping this synth would be as easy as NAP? Is it possible to add aminoguanidine and use glycine as the ligand… such as glycine

aminoguanidine perchlorate. Probably not, as you need a heavy metal with a positive charge?

|

|

|

Hey Buddy

Hazard to Others

Posts: 441

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Quote: Originally posted by MineMan  |

The displacement reaction from AP is obviously most interesting. Any other amino acids that might work as well? Citrulline?

Was really hoping this synth would be as easy as NAP? Is it possible to add aminoguanidine and use glycine as the ligand… such as glycine

aminoguanidine perchlorate. Probably not, as you need a heavy metal with a positive charge? |

practically all the amino acids have ~decent explosive performance. There are several that are liquids that perhaps could be used as energetic

plasticizer in PBX. Of course that is out of scope for me for now. I am mostly focused around finding alternatives to TNT due to waste liquor of

aromatics, and finding a high performance filler to experiment with that would approximate or exceed RDX. Aspartic acid NO3 is 7.5km/s 22 GPa with an

mp of 98 C, but it has half the heat of formation as TNT, so it would probably be approximate to TNT in experimental performance. Still it is a

nitrate that could potentially overcome shortcomings of TNT and be compatible with nitrimine and nitrate fillers like carbohydrazide nitrate or ANQN.

IsoLeucine perchlorate would also be interesting because it has approximate heat of formation to TNT, but 25%+ GPa and an extra km/s. Its also mrlting

at mid 70 C. The biggest problem with that is availability of isoleucine. Aspartic acid is also somewhat more expensive as well. Glycine and lysine

are very inexpensive and easily available where as the others ive found are twice in cost.

I think the dirty version of GlyClO4 is almost as easy as NAP. It has to be cast right away after drying. It isnt tested if it is stable long term or

if it degrades in the cast state. the browning may be degradation of impurities. The actual HClO4 version may be more stable

.--For detonation, An energetic filler like PETN would definitely bump up the numbers quite a bit. ETN melt phase sensitivity is too bad, because it

would be ideal for this sort of purpose if it were safe.

--Regarding complexes, you can definitely make glycine perchlorate metal complexes. I have not experimented with aminoguanidine with glycine, but I

have done a little bit of guanidine/glycine. I have experimented with a Cu 1 variant and I moved on because I was looking for sensitive primary

explosives rather than secondary character explosives. That copper/clo4 complex from guanidine standalone was very simple, in my memory i think i used

sulphate as the copper source. It produced a green copper 1 complex that was insoluble and detonated on hammer stike a little less sensitive than

PETN. I was not looking for that kind of material at the time, but it is probably worth revisiting and also checking melt properties. It was a metal

complex of secondary explosive character. There are certainly possibilities in that realm of glycine, its just so many variables, it is a difficult

thing to decide which direction to explore. Once I have more experience with casting, I can begin doing a lot more comparison of actual work of

secondaries.

|

|

|

yobbo II

National Hazard

Posts: 765

Registered: 28-3-2016

Member Is Offline

Mood: No Mood

|

|

This sounds too easy to be usable.

Glycine Sulphate (which seems to exist) + Barium Perchlorate (or chlorate).

Barium Sulphate is totally insoluble. You are left with Glycine Perk. in solution.

Yob

|

|

|

Hey Buddy

Hazard to Others

Posts: 441

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Amino acid anecdote

I found this paper on the interaction of amino acids with ammonium nitrate. The purpose of the paper is phase stabilization of AN using amino acids.

It concludes that amino acids do stabilize AN. The relevent part is they determined that amino acids like glycine form GlyNO3 and Gly/AN complex under

heat and water. Other amino acids only form complexes without release of NH3.

There is really a lot of much deeper exploration warranted for amino acid energetics. I wonder if amino acid stabilized AN is still hygroscopic?

Attachment: amino acid NH4NO3 stabilization.pdf (1MB)

This file has been downloaded 264 times

|

|

|

Hey Buddy

Hazard to Others

Posts: 441

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Amino acid anecdote

I found this paper on the interaction of amino acids with ammonium nitrate. The purpose of the paper is phase stabilization of AN using amino acids.

It concludes that amino acids do stabilize AN. The relavent part is they determined that amino acids like glycine form GlyNO3 and Gly/AN complex under

heat and water. Other amino acids only form complexes without release of NH3.

There is really a lot of much deeper exploration warranted for amino acid energetics. I wonder if amino acid stabilized AN is still hygroscopic?

Attachment: amino acid NH4NO3 stabilization.pdf (1MB)

This file has been downloaded 238 times

Not sure why this posted twice?

[Edited on 24-6-2023 by Hey Buddy]

|

|

|

Microtek

National Hazard

Posts: 872

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

| Quote: |

The next interest in this exploration is a pure HClO4 sample. Which probably should have been attempted first as control, but I was too fascinated at

the prospect of a material produced from OTC salts. Currently building up HNO3 towards that. |

What is the purpose of HNO3 in the context of making HClO4?

|

|

|

Hey Buddy

Hazard to Others

Posts: 441

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

I was going to try this method

https://www.youtube.com/watch?v=rUFsvlsi08E

What do you recommend?

[Edited on 24-6-2023 by Hey Buddy]

|

|

|

Hey Buddy

Hazard to Others

Posts: 441

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Aspartic Acid Nitrate 151.11 g/mol

1.6g/cm3

-8.16 OB (CO)

98 C mp

22.9 GPa

7508 m/s

[insensitive bio energetics, zhang 2017]

This is the highest performing nitrate currently known of amino acids. It outperforms TNT theoretically and outperforms TNP in velocity, though not in

pressure. This material is reported to melt between the temp of TNT and TNP. This is the initial procedure I used in preparation. I'm just going to

dump all ionic amino acid experiments into this thread to keep them all together since they are somewhat similar.

43.4 g (29 ml) HNO3 (75%-99%)

70.6 g L-Aspartic Acid (.53 mol @ 133.103 g/mol)

60 ml dH2O

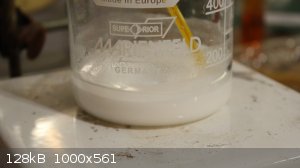

60 ml dH2O was added to a beaker (@ rt ~30 C), water was stirred as 70.6 g Aspartic Acid was added.

Asp conglomerates in a somewhat insoluble, self-clinging, white mass at the bottom of beaker. It can be stirred into the slurry but it quickly settles

back to the bottom as a thick mass.

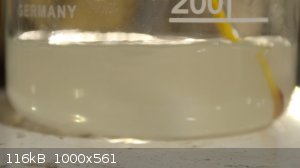

Nitric was added slowly. At 10ml addition of HNO3, the temperature of reaction increased 7 C and the mass concentration of aspartic acid changed as it

was converted to nitrate, dissolving into solution.

*60 ml H2O was probably too much H2O. two-thirds or even half is probably suitable, despite the insolubility of aspartic acid at first addition.

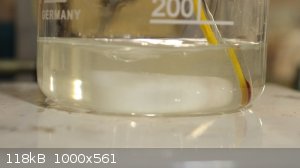

On complete addition of HNO3, temperature was 40 C. The reaction changed from thick and opaque to thin and clear like water within around 10 minutes.

The reaction was stirred ~15 minutes after complete addition of HNO3.

The viscosity of the finished nitrate product in this volume of water is a syrup, similar to mineral oil.

The finished product was poured out onto a pyrex pan and dried at 75 C.

I plan to test mp, castability, hygroscopicity, and perhaps some blasting in 1x1.5" pex as standalone and perhaps with some PETN and NQ. It is drying

now.

Please let me know if there is something youd be interested in testing in this material, and I will accomodate if in my ability. I originally planned

to compare to TNT, but I have run out and found I also have no toluene so if the material is good, I will direct compare to TNT and TNP later. This is

a small validation batch, so its limited to however much nitrate is made from 70 g Aspartic.

[Edited on 26-6-2023 by Hey Buddy]

[Edited on 26-6-2023 by Hey Buddy]

|

|

|

Hey Buddy

Hazard to Others

Posts: 441

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

It's now the next morning. Drying appears to have plateaued. It is now the consistency of melted hot glue. It is around 80-85 C, I'm hesitant to go

higher because I dont want to melt it. Any suggestions?

will try desiccator

[Edited on 26-6-2023 by Hey Buddy]

|

|

|

underground

National Hazard

Posts: 704

Registered: 10-10-2013

Location: Europe

Member Is Offline

|

|

Vacume desiccator would be ideal. Could you also give a try the perchlorate salt?

|

|

|

Hey Buddy

Hazard to Others

Posts: 441

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

I guess i should probably build a vacuum desiccator. I put it in a trashbag with a half pound of NaOH, hopefully that will work. I believe from the

paper, the perchlorate salt of aspartic acid is a liquid phase material with lower power than the nitrate. I will however attempt some perchloric acid

and treat the glycine. hopefully today. I fear if the AspNO3 cant be dried by heat, it may be hygroscopic? I was looking through the paper and I didnt

see anything about hygroscopicity. Maybe its some technical measurement reading in the paper that I'm unfamiliar with?.. they do use water evaporation

then vacuum desiccator though it says, so maybe its not hygroscopic and requires desiccation to dry?

[Edited on 26-6-2023 by Hey Buddy]

I found a vacuum pump and a vacuum desiccator in garage but i cant transfer the material from the pan because its too gummy. Pan is too big to fit. I

will just leave it in NaOH for now.

[Edited on 26-6-2023 by Hey Buddy]

|

|

|

underground

National Hazard

Posts: 704

Registered: 10-10-2013

Location: Europe

Member Is Offline

|

|

It reminds me the diaminourea nitrate. It was a PITA to crystalize out and it was very hydroscopic. You could try to add a solvent that it is not

soluble in to force it to crystalize out.

|

|

|

Hey Buddy

Hazard to Others

Posts: 441

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Good idea. That's a good thing to test anyways. I will scrape some and put it in desicator, try some in solvents and if nothing else, try to melt it

to release water. If all that failed it may just detonate anyways regardless of water. Then move on back to glycine.

I ordered some isoleucine which should make decent NO3 and ClO4 salts. Have yet to test lysine which is a complete unkown. Dont know if it will be

solid phase or not.

|

|

|

Microtek

National Hazard

Posts: 872

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

Regarding the perchloric acid, I have advocated the NaClO4 + concentrated HCl several times in the past here on SM:

| Quote: |

An easier way to perchloric acid is to use highly concentrated HCl (37-40 %) and NaClO4. In the mix, NaCl is practically insoluble (common ion

effect), so filtering off the NaCl will give you a mix of hydrochloric and perchloric acids. This can then be heated (or distilled) to drive off the

HCl. By heating the liquid to 135 C, the perchloric acid will be pure enough to not give a precipitate with AgNO3.

Problems with this method are:

- You need a acid resistant filter, preferably a fritted glass Büchner (or you can settle for decanting, but you will lose some acid)

- You really need a very highly concentrated hydrochloric acid or the solubility of NaCl will be appreciable

Advantages:

- If your NaClO4 contains some chlorate it will be destroyed

- You avoid high temperature distillation of HClO4 and all the dangers associated with that |

I'm attaching the paper with the method I used. If you only have NH4ClO4, you can easily convert it to NaClO4 by reacting with the stoichiometric

amount of NaOH, and heating to drive off the ammonia.

Attachment: HClO4 from NaClO4.pdf (377kB)

This file has been downloaded 246 times

|

|

|

Hey Buddy

Hazard to Others

Posts: 441

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Quote: Originally posted by Microtek  | Regarding the perchloric acid, I have advocated the NaClO4 + concentrated HCl several times in the past here on SM:

|

That looks like a good route

|

|

|

Hey Buddy

Hazard to Others

Posts: 441

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

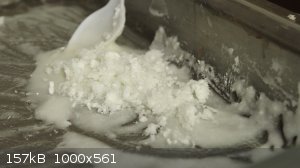

I've been playing with AspNO3 for the past day. Here are some findings...

Regarding AspNO3 itself:

This material is hygroscopic and water soluble. When dried, it is a semi-solid similar to a glassed soft-polymer like melted sucrose. It melts below

100 C as referenced in paper. In melt phase, it is thicker towards 100 C, perhaps like a melted sugar. It becomes thinner at higher temperatures like

melted butter.

I mistakenly used too much nitric acid because the concentration was unknown. During melt phase, a lot of what (I'm assuming) was excess HNO3/H2O was

vaporized into the air.

AspNO3 casts as a clear semi hard flat cast, similar to a soft epoxy. It is hygroscopic on the surface.

It is soluble in acetone, MeOH and IPA

Insoluble in nitromethane

It forms a milky solution and in acetone, falls out of solvent as a powder and when removed, quickly returns to goo. It possibly reacts with the

solvents changing its properties, like melting point and opacity.

Now the interesting part:

Melted AspNO3 plasticizes nitroguanidine. I cant tell you what the rate is, because I learned this in haphazard experimentation, not expecting it to

melt NQ. Not only does it melt NQ, it does so with impressive proportions of NQ. It seems endless. I stopped adding NQ because I simply didn't want to

use that much nitroguanidine stock.

The NQ is dissolving in AspNO3 presumably at or near max density. It is certainly the easiest way to achieve max density of NQ. Plasticized NQ is very

sticky while hot but cools in a few minutes to consistency remarkably similar to comp C4. It shapes and forms practically identically to C4 warmed to

body temperature. It has greater adhesive properties than C4, and easily bonds its surface to concrete, wood, metal and plastic. It can be molded into

shapes and can mold into thin sheets.

The NQ plastique has two components, the AspNO3 and the NQ plastique itself. The AspNO3 component appears to retain hygroscopicity at surface of

material and cast shape but the inner volume of material is unaffected. The NQ plastique can be exposed to water where the ASPNO3 in exposure to water

is dissolved, leaving the NQ at ultra high density which cures to a hard plastic like PVC. The plasticity of the NQ plastique (without additional

hydrophobic plasticizer) is moldable on exposure to atmospheric air for around 6 Hours. At 6 hours the plastic begins to set hard. I haven't tested if

it can be remelted yet.

FYI: Nitroguanidine has been underutilized due t its low density crystal form which really cant be overcome easily. High bulk density techniques are

used but are under performing. propyl nitroguanidine is another way to melt NQ but its not really feasible and I believe it loses some of the benefit

of NQ. The performance of NQ at high density is reported to be 8344 m/s Vd, 29GPa pressure @ 1.759 g/cc according to Koch.

[Edited on 27-6-2023 by Hey Buddy]

It's now been 9 hours since experimenting with the NQ plastique. It remelts after being rock hard like PVC. I would consider this material to be a

reversible thermo-curing NQ plastic. A sample was left in water over night. At first, the sample cured solid like a marble. Overnight the sample broke

apart and left presumably NQ at high density in the water. This may be a low-effort method of achieving high density NQ.

[Edited on 27-6-2023 by Hey Buddy]

|

|

|

Hey Buddy

Hazard to Others

Posts: 441

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

AspNO3 continued

The AspNO3 cast into a 1" body began to leak out of the bottom today as temperatures got into 90 F in garage. In my mind, there was no reason

therefore to attempt a detonation of that straight sample because anything that leaks at ambient temps isnt really a suitable material in stand alone

casting. I attempted to fire the unknown qty NQ/AspNO3 mix. It did not detonate on a 1g NAP cap. Thats business as usual for nitroguanidine. It

projected the material all over in small pieces.

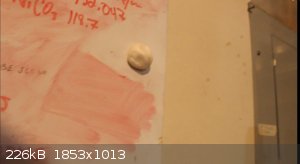

I then attempted a PETN pbx and recorded numbers this time. 13.44 g AspNO3 were melted at 110 C on a glass dish. 13.46 g PETN were slowly added and

carefully kneaded into melt. The entire mass appeared to melt in with the aspNO3. By the end of addition, consistency was like a dense dough. The

material stuck to the watch glass and a ball of 23.95 g was recovered from the melt. This is a plastique 50:50 w/w AspNO3/PETN. The material is very

much like C4 again, but you can feel it is less dense. Its pliability and rigidity attributes are quite similar to C4. It sets into hardening slower

than the NQ mix. I rolled it into a ball as well as I could and calipered the diameter (31.92 mm) and came to the density of 1.406 g/cc which is

somewhat low, presumably entrapped air and water. No degassing. C4 is at ~1.72 g/cc, for comparison. PETN should be 1.77 g/cc and the AspNO3 should be

1.60 g/cc. This PETN/AspNO3 should fire with less fuss than the NQ analogue.

Last image is high density NQ separated from water solution of the NQ plastic from earlier. This technique, melting NQ into a water soluble substrate,

then dissolving substrate, may be handy for high NQ density. More testing needed, but looks promising.

Aside from hygroscopicity, the quality of these plastics is quite good. The PETN version seems less attracting to water, but the NQ version wasn't

maxed out on w/w NQ, so it may actually work better. I made a sample of the NQ version and added a small amount of PETN as sensitizer to test as well.

If a low temp melting amino acid were found, without hygroscopicity, it could be very useful in a simple 2 part mix alone. Additives could improve

these I'd imagine, but for two simple components, energetic melt carrier and filler, they are quite good. I'm familiar with government contract

produced C4, and these two materials are pretty similar in handling. Which is interesting to me because they are so simple with no inerts, and were

randomly learned of.

[Edited on 28-6-2023 by Hey Buddy]

UPDATE:

These two comps have good handling properties for a few hours, but the hygroscopicity makes them practically unusable. The high density benefit effect

for nitroguanidine is interesting and the prospect of a two part energetic PBX is interesting. A non-hygroscopic amino acid salt would be much more

practical. Maybe even one that is lower performance but has the same material properties. I could not get either the 50% PETN nor the NQ/PETN to fire

on a cap. Or if they did it was partial and so-low power it was uneventful. Unsure if this is an effect of water absorption or the effect of

insensitivity of AspNO3. Will move on to proper attempt of glyClO4 now.

[Edited on 28-6-2023 by Hey Buddy]

|

|

|

Hey Buddy

Hazard to Others

Posts: 441

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

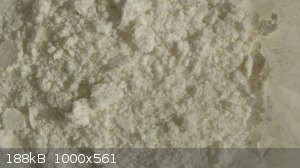

High Density Nitroguanidine

report for anyone interested:

I recovered NQ from one of the NQ/AspNO3 charges by simply soaking it overnight in water, then rinsing with water and drying on heat for 24 hours. I

believe all of the AspNO3 is dissolved in water. NQ is left behind. The density measured was 1.4 g/cc - 1.5 g/cc on the sample recovered. There could

be something unseen at play responsible for that reading, such as an unkown chemical reaction of the molecule, but assuming it is actually NQ, it's

higher than industry standard high bulk density NQ, which is .97 g/cc in strict cases. In broad application, high bulk density NQ is considered

>.81 g/cc. I give the range of 1.4 -1.5 g/cc to cover error. 1.4 g/cc is certainly attained by this material recovered out of AspNO3/NQ melt.

[Edited on 30-6-2023 by Hey Buddy]

Update on amino acid research:

I have still managed to somehow avoid preparing HClO4 again, things have been busy and hot. Ive ordered some isoleucine, will probably also attempt

citrulline and arginine. The Isoleucine is reported to make decent nitrate and perchlorate. Others are unkonwn. Goal is to find a <150 C mp, melt

cast with solid state performance higher than TNT, nonhygroscopic. Glycine nitrate makes a reported low-power explosive with a 150 C mp, which is

high. Since glycine is already at hands and glycine is common, I will knock out glycine next for hygroscopicity and mp check. Isoleucine, lysine,

arginine will all be checked for NO3 and ClO4. Im waiting on a storage bottle for HClO4...

[Edited on 1-7-2023 by Hey Buddy]

|

|

|

Microtek

National Hazard

Posts: 872

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

I can report that, from my own experiments, glycine perchlorate is quite hygroscopic. It does melt at a useable temp though. It would be very nice

indeed if we could find a cheap, ionic compound that could function as a carrier for melt cast formulations. In general, I think performance should be

tested on pressed powder charges rather than melt cast ones. Otherwise, it will be difficult to achieve full detonations of the highest velocity.

In my experience the number one obstacle is hygroscopicity. Practically all of the perchlorate salts of nitrogen containing bases I have tried have

shown a high degree of it.

|

|

|

Hey Buddy

Hazard to Others

Posts: 441

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

I thought so too, but was hoping a direct HClO4 would be less. Dang. Truth hurts.

Quote: Originally posted by Microtek  |

It does melt at a useable temp though. It would be very nice indeed if we could find a cheap, ionic compound that could function as a carrier for melt

cast formulations. |

IMO, more melt casts are crucial because a given explosive is always practically used in a carrier substrate or body of some sort. PBX, Cast, or det

cord etc. Powder is really only used in early rockets or detonators. Shock tube and det cord use powder but it's an isolated application, the tubing

itself lends its plasticity quality to the function of the powder. TNT has virtually no real alternative other than perhaps TNP if you discount its

>100 C mp.

Quote: Originally posted by Microtek  |

In general, I think performance should be tested on pressed powder charges rather than melt cast ones. Otherwise, it will be difficult to achieve full

detonations of the highest velocity. |

I agree with this, a melt cast only gets in the way comparing secondaries head to head. I have tried some melt casting of secondaries in the AspNO3,

but really its because one shot is enough to spot check the melt cast alone. After that, if it does/does not fire, it becomes a question of: "how

insensitive of a filler can this fire with?" / "How sensitive of a filler is needed to make it fire at all?" Those two questions were in my head when

filling with NQ / PETN.

In the AspNO3 case, it's practically unusable, so it doesn't really matter. Doesn't fire well at all. The only good resolution out of it was learning

of its plasticization ability, eliminating Aspartic acid from amino acid list, and the route to high density material. Not disappointing per se, but I

wasn't writing home about it.

Quote: Originally posted by Microtek  |

In my experience the number one obstacle is hygroscopicity. Practically all of the perchlorate salts of nitrogen containing bases I have tried have

shown a high degree of it. |

Agreed.-- Hygroscopicity is a show-stopper for secondaries. Water solubility is a much lesser detriment than hygroscopicity.

--What is it about a molecule or a complex, like for example, NAP. What makes it non-hygroscopic? Is it the metal? is it the guanidium group? Is

guanidium perchlorate hygroscopic? The amino acids seem like they are flexible enough to easily modify with complexation, if necessary. That is a lot

more time consuming in testing, so hopefully avoided. There are also several amino acids that contain guanidine groups, that might prospect better, if

that aspect is favorable to a non-hygroscopic NO3/ClO4. Arginine comes to mind. Citrulline has carbonyl which seems more likely to be hygroscopic. I

was disappointed by aspartic acid nitrate because I had hoped the nitrate would be less hygroscopic, but it was opposite.

|

|

|

underground

National Hazard

Posts: 704

Registered: 10-10-2013

Location: Europe

Member Is Offline

|

|

In my opinion a relatively cheap secondary with good performance is sentisized nitromethane. The main disadvantage obviously is that it is a liquid

and it has to be prepared few minutes before.

[Edited on 30-6-2023 by underground]

|

|

|

MineMan

International Hazard

Posts: 1014

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by underground  | | It reminds me the diaminourea nitrate. It was a PITA to crystalize out and it was very hydroscopic. You could try to add a solvent that it is not

soluble in to force it to crystalize out. |

Is that a solvable problem with the right equipment? I still can’t find an energetic as attractive?

|

|

|

Hey Buddy

Hazard to Others

Posts: 441

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

It appears glycine nitrate is hygroscopic as well. I've been drying a sample for 24 hours on heat...

Glycine is so inexpensive its probably the most realistic for the cast purpose. Maybe a complex is the way to go...so many combinations. endless... I

got the isoleucine but it has added sugars making it useless. I got lysine but they sent the HCl by mistake. Perhaps its a sign its time to take the

ANQN/TNT pill and get off these fancy fly by night amino acids.

GlyNO3 melts technically at reported mp but is workable around 170-180 C. It dissolves NQ but its composite isn't very dense. I'm melting in NQ to

these amino acids to inspect their melt character.

[Edited on 1-7-2023 by Hey Buddy]

It's now the next day, the NQ/GlyNO3 and straight GlyNO3 are definitely less hygroscopic than aspNO3 or NQ/NH4NO3 eutectic. Unfortunately, the mp of

glyNO3 makes it only useful for high temp explosives and it's also low power. If there is great variation in hygroscopicity in amino acid nitrates,

perhaps there is a low melt non hygroscopic amino acid ionic compound.

[Edited on 1-7-2023 by Hey Buddy]

|

|

|

| Pages:

1

2

3

4 |