Keras

National Hazard

Posts: 929

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

Notes on p-Toluenesulphonic acid → p-Cresol

So attempted the transformation above.

First step is to neutralise p-Tosyl acid into sodium p-Tosylate. Easily peasy, used ¼ mole (~ 50 g) of p-Tosyl acid. 100 mL seems to be enough to

dissolve it. Just drop in the right amount of sodium hydroxide. Boil the solution. Get Na p-Tosylate.

Next step is caustic fusion with potassium hydroxide. That’s where it gets critical. There is information available, but it is not really detailed

as to how run the reaction. I mixed KOH and Na p-Tosylate in a stainless steel pot and put it on a gas burner. My reference says ½ hour at 360 °C

when the molar ratio of KOH to Na p-Tosylate is 2.5:1 should result in 70% yield.

Not really what I got. It seems KOH must be fused first and only then p-Tosylate added piecemeal. Why? Because p-Tosylate will darken and get tarry as

the crucible heats. TBH, it was only when I got at the end of the half-hour that the mix began to liquify, and it was already very brown, almost black

because of what I assume p-Tosylate decomposition. I stopped there lest I got only charred products. Apparently, nothing takes place before the mix is

liquid, so this first try resulted in an infinitesimal yield.

There is a characteristic smell of phenol escaping from the pot, though.

The cake is cooled, transferred to a beaker of water, neutralised with HCl to revert any super-soluble p-cresolate to less but still soluble p-cresol,

filtered. I got only tarry residues on the frit, so I attempted a liquid-liquid extraction with toluene, followed by boiling away the toluene with

added chips of activated charcoal. It wasn't completely unsuccessful, as I was left with a small amount of a dark brown liquid which strongly smells

like phenol, so it is definitely there, and in principle, this is working (needless to say, the result is so impure it didn't solidify as it should

have).

I have one question, though. Reaction is supposed to be conducted at 360 °C but p-cresol b.p. is lower, 200 °C. Unless by using a distillation

apparatus – which, by the way, the authors in the paper I quoted didn't seem to do – how can the yield be significant?

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

About the question: the phenol also forms a sodium/potassium salt which doesn't boil. Did you acidify the product?

|

|

|

Keras

National Hazard

Posts: 929

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

Quote: Originally posted by Tsjerk  | | About the question: the phenol also forms a sodium/potassium salt which doesn't boil. Did you acidify the product? |

Yes I did. At least, I neutralised the excess of potash using HCl until the pH was neutral. I reasoned that going further would serve no purpose,

since the pKa of cresol is around 10, like phenol's. Maybe I should’ve gone all the way to pH ~ 2.

Cresol is surprisingly soluble in water, like 2 g / 100 mL, which can seem really little (and is markedly less than phenol), but since I had 600 mL of

water, that makes an appreciable 12 g.

I perused the paper I had and found out I overlooked the passage describing the experimental conditions. Indeed, Na p-Tosylate must be added to the

already molten potash. Will do that next time.

|

|

|

Keras

National Hazard

Posts: 929

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

So, I’m back with this thread.

I retried today this experiment on the back of an enveloppe. I also wanted to verify that NaOH can be used, since some sources claim that NaOH without

extra KOH won’t react.

To be honest, the starting material is NOT TsOH but TsNa, so the first step is to dissolve TsOH in water, neutralise it with sodium hydroxide, and

boil the water off to get solid TsNa. TsNa is well behaved, it will form a nice free flowing powder, very few clumping after evaporating the last

traces of water.

So, I decided to use 50 mmol of TsNa (~ 9.7 g). Since the paper I have indicates that the best yields are obtained when NaOH is in a 2.5::1 excess

ratio, I put 5 g (125 mmol) of NaOH in a crucible, and the crucible in a heating mantle which was set for 400 °C (taking into account that the

crucible didn't touch the mantle, I had to make allowances for reduced thermal efficiency). When the sodium hydroxide was melted, I added the TsNa in

four portions. The crucible was capped and the mix stirred every ten minutes, for a total duration of 35 mn. After the last addition of TsNa, the

mixture is pasty, but not solid, it’s quite easy to stir. It was a bit frothy at 10 minutes, but whatever gaseous emission happened rapidly

subsided. Some vapours of TsNa or cresol escaped each time the crucible was uncapped, but it was really manageable (it doesn’t fume like crazy).

After 20 minutes, the mixture began to darken, and it was quite dark at 30 and 35 min when I turned the heating mantle off and let everything cool.

Once cold, the mixture is a dark solid, but doesn’t really stick to the walls of crucible too much, so it’s easy to scrape off. It is very soluble

in water, so the best way to remove it is probably to simply add water in the crucible and stir until everything has dissolved.

The dark solution thus obtained was acidified with HCl. There is, at start, a huge bubbling of what appears to be SO₂, so there has definitely be

formation of sodium sulphite. Judging by the quantity of HCl I had to add to neutralise the solution, there was quite a bit of it, which is a good

sign. At the end, I was left with a dark brown solution full of small particles (precipitate of cresol)? Unfortunately, I had no equipment to either

filter or distill, so after having smelt a strong (but not unpleasant to me) smell of phenol (which p-cresol is supposed to smell), I simply discarded

the solution :/

To wrap up, caustic fusion of TsNa with NaOH to form cresol seems to work. I’m going to repeat the experiment Saturday in my lab, and will try to

get a decent product out of it.

|

|

|

Texium

Administrator

Posts: 4618

Registered: 11-1-2014

Location: Salt Lake City

Member Is Offline

Mood: PhD candidate!

|

|

Nice. Minor critique though: you should write TsONa or NaOTs, not TsNa, cause Ts means tosyl, not tosylate. And why did you throw out the crude

solution? Seems like a waste when that could have instead been combined with the crude from your next run.

|

|

|

Keras

National Hazard

Posts: 929

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

Quote: Originally posted by Texium  | | Nice. Minor critique though: you should write TsONa or NaOTs, not TsNa, cause Ts means tosyl, not tosylate. And why did you throw out the crude

solution? Seems like a waste when that could have instead been combined with the crude from your next run. |

Err… Your definitely right, somehow I had imagined that with neutralisation the whole -OH group was taken off :p :p Talk about being dense.

You’re right (again!). I should’ve kept it. As a matter of fact, I botched the end. I waited a while for the particles to settle down and then I

intended to get rid of the supernatant water, but I tilted the beaker too much and a lot went down the drain before I even realised it did. After

that, I was left with a thin layer mostly black tar (with a strong odour of phenol) that I tried to recrystallise. I heated the beaker up to 50 °C

and then let it cool, and indeed I got a few crystals of a whitish substance floating on the tar. But there was only milligrams of it, so I poured

everything to the bin. It was just a proof of concept, so to speak.

This weekend, I’ll steam distill the result, since apparently cresol can be steam distilled out of solution.

[Edited on 6-4-2023 by Keras]

|

|

|

Keras

National Hazard

Posts: 929

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

So, third time is a charm, so they say.

Starting materials : ~ 19 g of TsONa ( ← This time I got it right :p) = 100 mmol

~ 14 g of KOH representing 250 mmol, that is a 2.5::1 excess over TsONa, which is apparently the ratio that maximises the yield.

KOH is loaded in a small earthenware crucible (50 mL), but a larger one in metal would probably be better suited (I’m actually waiting for a 75 mL

one in stainless steel). The crucible is capped and put into a heating mantle which is set for 400 °C (given that the crucible doesn’t fit exactly

the walls of the heating mantle). To maximise the heat efficiency, the heating mantle is covered with aluminium foil.

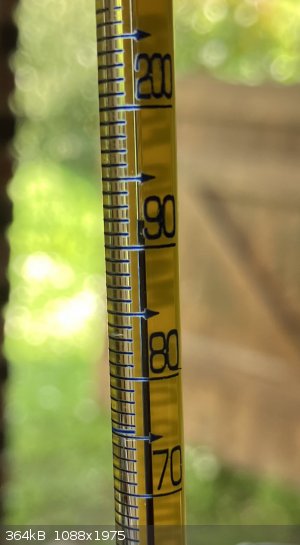

When KOH has all melted, the temperature is sampled using an infrared thermometer and found around 320 °C. At this point, TsONa is added in small

portion with ⅔ min between each addition to allow for the mixture to regain its fluidity. After the final addition, a timer is set to 30 min.

After a few minutes, a characteristic sizzle is heard and the mixture begins to froth. I’m not sure what gas is released. Possibly this is the water

contained in the KOH crystals, though no water wisps escape. At this point, the crucible must be open every two to three minutes and the mixture

stirred (which result in instant collapse of the frothing matter). The colour, initially yellow/orange, progressively darkens as the reaction

progresses.

After about 20 minutes, the frothing dies down and quickly after the mixture turns blackish. At that point, when the lid is open, white vapours of

what I assume is boiling cresol escape. The quantity of released vapours increases with time.

At 30 min, the mixture has definitely assumed a pitch black colour and is more fluid than it is before. The heating is stopped, the crucible is

removed and the mixture is transferred while hot to a stainless steel cup (ashtray like) and left to cool. Meanwhile 120 mL of water is heated to

boiling. When the mixture has cooled enough, the hot water is added to the stainless steel cup in two portions and the solution is transferred to a

beaker. Normally, all the mixture dissolves. Even the tar seems water soluble, which eases up later cleaning of the crucible (no organic solvant

needed, soap works well with a light abrasive sponge).

The pH is tested and found (of course) to be very alkaline (≥ 14). 23% hydrochloric acid is added until the pH turns neutral. At this time, nothing

much happens. HCl continues to be added piecemeal, resulting in bubbling and release of sulphur dioxide (from decomposition of the sulphurous acid

created along with KCl and NaCl). Addition of HCl is stopped when this bubbling dies down.

The resulting solution, which is now strongly acidic, is transferred to a 250 mL round bottom flask and set for steam distillation (don’t forget the

boiling chips, it bumps a lot).

The first drops of water collected are undoubtedly milky and soon seen to be yellowish. When enough has passed, the liquid collected separates into a

yellow lower organic layer covered in milky water. All along, sulphur dioxide escapes, so it is important to work outside or in a well ventilated

area.

The steam distillation is stopped when the drops of water collected are clear, containing no more cresol.

Owning to the slight difference in density between cresol (d = 1.03) and water (d = 1), the cloudy water does not readily separate. I had to put the

solution to rest overnight to get a clear separation of both phases. The upper aqueous layer, still a bit cloudy, is saturated with table salt and

transferred to a sep funnel and the lower layer, with as few as possible of remaining water, is put aside.

The aqueous layer is extracted three times with 10 mL of toluene. The third extraction results in a perfectly clear aqueous layer. The toluene

fractions are collected and combined with the yellow organic layer from the steam distillation. The aqueous layer is discarded, and the organic layer

returned to the round bottom flask for another distillation.

This second distillation conducted around 150 °C results first in the azeotrope water/toluene passing through at around 78/80 °C, followed by the

rest of the toluene at around 110 °C. Using excess toluene over water allows for the compound to be dried off during the distillation (no CaCl step

is needed). Once the 30 mL of toluene have been recovered, the distillation is stopped, and the liquid still present in the flask is transferred to a

small beaker (unfortunately, I had an insulation problem with my heating mantle at this point that made the RCD go off).

The toluene/water mix collected clears up with a few minutes, resulting in two very nice phases. I saved the toluene fraction for further use as

entrainer. Salt crystals stick to the RBF walls, part from the initial HCl addition and most from the saturation step.

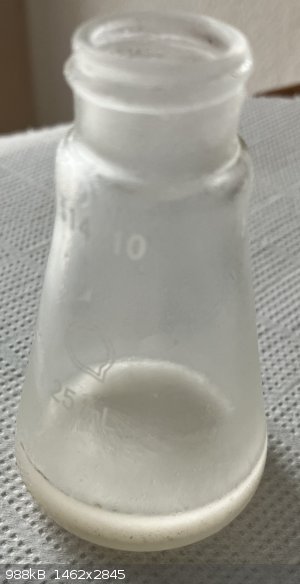

The (what I assume to be) liquid p-cresol collected from the RBF weighs 7.6 g, which, given that M ~ 108 g/mol, translates to around 70 mmol or 70%

yield, which is not bad given the published figures. However, although it has a smell strongly redolent of phenol, the product is (slightly?) impure:

it is not yellow but somewhat creamy in colour, and doesn’t crystallise at 35 °C as expected. In fact, I had to put it in the freezer to have it

solidify, and when taken back to room temperature, it quickly remelted. So a further distillation, possibly under reduced pressure, should be

attempted, if I can fix my heating mantle.

I will post some pictures tomorrow.

|

|

|

Keras

National Hazard

Posts: 929

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

Further follow-up.

I redistilled the result yesterday. Except for a tiny forerun corresponding to a very small amount of water, most of the product passed as a clear

liquid at 192 °C. I was left with a minute amount of tar in the flask.

Few problems though:

1. 192 °C is not the expected temperature for p-cresol but o-cresol.

2. The product won’t cristallise at r.t. as expected.

So either p-cresol shows significant supercooling, or it is not what it is expected to be (maybe a mix between o- and p-cresols?)

|

|

|

ErgoloidMesylate

Banned

Posts: 89

Registered: 8-8-2022

Location: Norad

Member Is Offline

Mood: Freedom of thought is priceless - You can't afford it

|

|

Quote: Originally posted by Keras  | So, third time is a charm, so they say.

When KOH has all melted, the temperature is sampled using an infrared thermometer and found around 320 °C. At this point, TsONa is added in small

portion with ⅔ min between each addition to allow for the mixture to regain its fluidity. After the final addition, a timer is set to 30 min.

After a few minutes, a characteristic sizzle is heard and the mixture begins to froth. I’m not sure what gas is released. Possibly this is the water

contained in the KOH crystals, though no water wisps escape. At this point, the crucible must be open every two to three minutes and the mixture

stirred (which result in instant collapse of the frothing matter). The colour, initially yellow/orange, progressively darkens as the reaction

progresses.

After about 20 minutes, the frothing dies down and quickly after the mixture turns blackish. At that point, when the lid is open, white vapours of

what I assume is boiling cresol escape. The quantity of released vapours increases with time.

I will post some pictures tomorrow.

|

Some old 1800s style chemistry.

This source says your gas is hydrogen:

http://www.orgsyn.org/demo.aspx?prep=CV1P0175

They presume they started with the correct isomers.

Cannula transfer and cannula filtering is used for lysergic synth Compressed air and remove co2

|

|

|

ErgoloidMesylate

Banned

Posts: 89

Registered: 8-8-2022

Location: Norad

Member Is Offline

Mood: Freedom of thought is priceless - You can't afford it

|

|

Quote: Originally posted by Texium  | | Nice. Minor critique though: you should write TsONa or NaOTs, not TsNa, cause Ts means tosyl, not tosylate. And why did you throw out the crude

solution? Seems like a waste when that could have instead been combined with the crude from your next run. |

Looks like this guy did some experiments on this topic:

http://www.sciencemadness.org/talk/viewthread.php?tid=15522#...

He got some of his equipment from "Dr" Bob (the guy who makes a ton of typos) but he doesn't seem to post here or make videos anymore.

Cannula transfer and cannula filtering is used for lysergic synth Compressed air and remove co2

|

|

|

clearly_not_atara

International Hazard

Posts: 2799

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

The balanced reaction does evolve hydrogen:

PhSO3Na + 2 KOH >> KSO3Na + PhOK + H2

EDIT: no lol, idkwtf

[Edited on 9-5-2023 by clearly_not_atara]

|

|

|

Keras

National Hazard

Posts: 929

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

You’re missing an oxygen atom on the right, if I’m not mistaken.

|

|

|

Keras

National Hazard

Posts: 929

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

You mean synthesising p-toluene sulphonic acid? Nurdrage has a video on this, it is fairly easy to do given you have a Dean-Stark apparatus available.

Separating o- from p- isomers is probably a bit more tricky, though. He didn't attempted it.

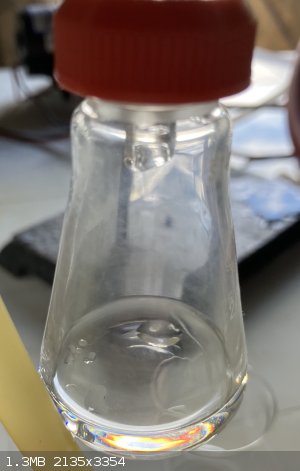

But that’s irrelevant to me since I started from commercial p-TsOH (cheap, because TsOH is used for saccharin synthesis). It was slightly rosy,

which I attribute to Fe³⁺ contamination. Matter of fact, when neutralising the acid with lye, past the neutral point I got a small amount of red

flakes with I think is ferric hydroxide that was filtered out, living a clear solution (see picture below, the colour difference between the funnel

and the erlenmeyer is quite dramatic. The purple colour is caused by micrograms of phenolphtalein I added to aid in the neutralisation).

|

|

|

clearly_not_atara

International Hazard

Posts: 2799

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

You're not.

By the Pourbaix diagram, sulfite is unstable. Maybe that's where the hydrogen comes from? What a strange phenomenon.

|

|

|

Keras

National Hazard

Posts: 929

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

There’s definitely sulphite in the final product, since SO₂ escapes during neutralisation and steam distillation.

Your equation clearly shows that water is produced, so that would explain the frothing, IMHO.

Now, why is there hydrogen emitted at the end? Probably some sort of further attack of molten KOH (in excess) on the final product?

|

|

|

ErgoloidMesylate

Banned

Posts: 89

Registered: 8-8-2022

Location: Norad

Member Is Offline

Mood: Freedom of thought is priceless - You can't afford it

|

|

If you are going to use stuff from industry sources, have you looked at the p-toluidine synthesis? I think it could be useful if you want to take a

look.

I think it uses sodium nitrite and urea.

Cannula transfer and cannula filtering is used for lysergic synth Compressed air and remove co2

|

|

|

ErgoloidMesylate

Banned

Posts: 89

Registered: 8-8-2022

Location: Norad

Member Is Offline

Mood: Freedom of thought is priceless - You can't afford it

|

|

Quote: Originally posted by ErgoloidMesylate  |

If you are going to use stuff from industry sources, have you looked at the p-toluidine synthesis? I think it could be useful if you want to take a

look.

I think it uses sodium nitrite and urea. |

Just ignore the brominated portion for example:

http://orgsyn.org/demo.aspx?prep=CV3P0130

Cannula transfer and cannula filtering is used for lysergic synth Compressed air and remove co2

|

|

|

Keras

National Hazard

Posts: 929

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

Quote: Originally posted by ErgoloidMesylate  |

If you are going to use stuff from industry sources, have you looked at the p-toluidine synthesis? I think it could be useful if you want to take a

look.

I think it uses sodium nitrite and urea. |

Will definitely have a look, but my final goal is not p-toluidine, but anisaldehyde (p-cresol → p-methoxytoluene → p-methoxybenzaldehyde).

|

|

|

ErgoloidMesylate

Banned

Posts: 89

Registered: 8-8-2022

Location: Norad

Member Is Offline

Mood: Freedom of thought is priceless - You can't afford it

|

|

Quote: Originally posted by Keras  | Quote: Originally posted by ErgoloidMesylate  |

If you are going to use stuff from industry sources, have you looked at the p-toluidine synthesis? I think it could be useful if you want to take a

look.

I think it uses sodium nitrite and urea. |

Will definitely have a look, but my final goal is not p-toluidine

|

No shit, that would be the starting precursor, are you less than bright?

Most would try for 3,4,5 methoxy aldehyde, but i digress.

Note to you personally: being brainless won't benefit yourself.

Cannula transfer and cannula filtering is used for lysergic synth Compressed air and remove co2

|

|

|

Keras

National Hazard

Posts: 929

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

Lol, right. But p-toluidine to anisaldehyde???

| Quote: |

Note to you personally: being brainless won't benefit yourself. |

I try to cope with the few neurones I’m left with :p

[Edited on 10-5-2023 by Keras]

|

|

|

ErgoloidMesylate

Banned

Posts: 89

Registered: 8-8-2022

Location: Norad

Member Is Offline

Mood: Freedom of thought is priceless - You can't afford it

|

|

http://orgsyn.org/demo.aspx?prep=CV3P0130

Are you going to use the cobalt method at that point?

https://drive.google.com/file/d/1xGiV4FJO_pWh3gYv8fQwa4AED-j...

[Edited on 10-5-2023 by ErgoloidMesylate]

Cannula transfer and cannula filtering is used for lysergic synth Compressed air and remove co2

|

|

|

Keras

National Hazard

Posts: 929

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

I mean, yes, I could start from p-toluidine, diazotise it and hydrolise it to p-cresol, but I don’t see the point. Either I start from

p-toluenesulphonic acid which is cheap and of which I have a couple hundred grams, or I buy p-cresol directly. :p

I had forgotten about that cobalt method, although I've recently bought some cobalt chloride. I was planning to use the Étard reaction with chromyl

chloride to oxide the methyl group to aldehyde. Also, the methylation of the hydroxy group I intended to carry out with dimethylcarbonate and cesium

carbonate as a base (this, apparently, yields a quantitative amount of 4-methoxytoluene after four hours of refluxing, and doesn’t need any dubious

methylating agent such as methyl iodide). Thanks for reminding me about the cobalt way. I need to buy an oxygen bottle, but that’s cheap, too.

[Edited on 11-5-2023 by Keras]

|

|

|

ErgoloidMesylate

Banned

Posts: 89

Registered: 8-8-2022

Location: Norad

Member Is Offline

Mood: Freedom of thought is priceless - You can't afford it

|

|

Quote: Originally posted by Keras  |

I mean, yes, I could start from p-toluidine, diazotise it and hydrolise it to p-cresol, but I don’t see the point. |

It avoids the excessively caustic route is the point, plus seems like a somewhat better procedure in my opinion.

Cannula transfer and cannula filtering is used for lysergic synth Compressed air and remove co2

|

|

|

Keras

National Hazard

Posts: 929

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

It is certainly less caustic. The procedure with KOH is fairly straightforward, though, and spares sodium nitrite which is hard to come by these days.

Apparently p-toluidine is restricted in the EU for w/e reason, so impossible to source.

Thanks a bunch again for shaking my memory about that cobalt thing, though. I was wondering these days why I had bought it in the first place! :p

|

|

|