blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Potassium Alum Synthesis from Scrap Aluminium without Sulphuric Acid

I’ve in the past prepared alum from scrap Al by dissolution into sulphuric acid with subsequent addition of K2SO4, or by

dissolving the Al into KOH and then neutralising the potassium aluminate with H2SO4. In both cases chilling then yields the

crystals, Recrystallization from hot solution improves purity. I made near-kg quantities like that.

Due to EU-led restrictions many of us are now w/o sulphuric acid, so I’ve developed a method that doesn’t use that acid.

My first port of call was sodium bisulphate (NaHSO4) but even a 50 w% solution didn’t dissolve the Al at any appreciable rate.

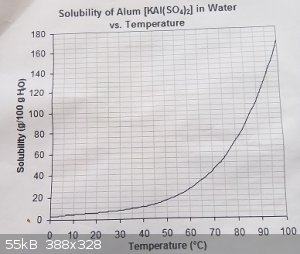

The following method was then tested at the level of 1 g Al, with success. It’s based on the fact that KCl is much more soluble near 0 C than alum

(which is near insoluble in the cold)

KCl by contrast, is still soluble by 28 g/100 ml at 0 C (Wikipedia)

5 simple steps:

1. Dissolve scrap Al into conc. HCl with a 20 % stoichiometric excess

For my second test I used 5.0 g Al and 55 ml 10.2 M HCl. The reaction is very exothermic (mainly due to the high solvation enthalpy of

Al3+), so to avoid the acid to boil off too much, add the metal in about 5 portions, dissolving the first one completely before adding the

second, etc. In addition, cover the beaker with a watch glass.

Near the end, simmer the solution a few minutes to dissolve any remaining stubborn bits of metal.

4. Addition of K2SO4

Add DIW up to a total volume of 280 mL and take the solution up to 70 C. Gradually add 65 g of K2SO4 and take the solution back

up to about 70 C, keep stirring and heating until all K2SO4 is fully dissolved.

Transfer to a flexible receptacle like PP beaker and allow to cool to RT, then store overnight close to 0 C.

Collect the crystals of crude alum.

5. Recrystallization

Add the same weight of DIW to the collected crystals and heat to near 100 C with constant stirring, until the alum is fully dissolved. Transfer to a

flexible receptacle like PP beaker and allow to cool to RT, then store overnight close to 0 C.

Collect the crystals of recrystallized alum.

I obtained 65 g of product, a yield of 74 %.

The overall reaction is:

Al(s) + 3 HCl(aq) +2K2SO4(aq) + 12 H2O --> KAl(SO4)2.12H2O(s) + 3 KCl(aq) + 3/2

H2(g)

6. Analysis (upcoming)

In the next few days I’ll determine density and the aluminium content of the product.

[Edited on 1-3-2023 by blogfast25]

|

|

|

Parakeet

Hazard to Self

Posts: 73

Registered: 22-12-2022

Location: Japan

Member Is Offline

Mood: V (V)

|

|

Sounds like a very interesting procedure.

Do you think that sodium bisulfate + chloride salt will work? It should produce HCl in situ.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Parakeet  | Sounds like a very interesting procedure.

Do you think that sodium bisulfate + chloride salt will work? It should produce HCl in situ. |

Thanks!

I don't think adding, say KCl, will meaningfully increase the dissociation of the bisulphate. But increasing ionic strength will increase dissociation

a little (increased activity coefficient)

Worth evaluating though.

|

|

|

Fery

International Hazard

Posts: 1000

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

H2SO4: pKa1 < 0; pKa2 = 1.92

when dissolving Al in H2SO4 the concentration of H3O+ which reacts with Al is more than 100 times higher (from the first dissociation step pKa1) than

when using NaHSO4 where only the second dissociation occurs (pKa2).

You need as high H3O+ concentration as possible to dissolve Al. That explains why the dissolution in NaHSO4 was so slow. But this is only my

theoretical guessing. Good that you did real experiment!!!

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

And you are correct. With bisulphate the dissolution of Al is impractically slow (but not zero either) I didn't expect dissolution as fast as with

H2SO4, just not quite as slow.

[Edited on 2-3-2023 by blogfast25]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

The picnometer density came out at 1.76, close to the value of 1.75 listed.

The complexometric determination of Al by back titration of Na2EDTA with Zn standard against ErioC Black T. That gave an Al content of

5.3 w%. The theoretical value based on formula masses is 5.7 w%. I believe that discrepancy may be due to poor drying: alum is hard to dry w/o weight

loss.

Another alum making experiment revealed that my kitchen foil contains silicon, whereas takeaway food trays does not.

Kitchen foil, when dissolved in HCl shows a brown insoluble residue (that filters off easily):

It reacts with vigour with hot 25 % NaOH but doesn’t dissolve completely: a lighter brown residue remains and it isn’t Fe(OH)3

Silicon is of course a common alloying element for aluminium.

[Edited on 12-3-2023 by blogfast25]

|

|

|