CouchHatter

Hazard to Others

Posts: 152

Registered: 28-10-2017

Location: Oklahoma

Member Is Offline

Mood: 76 elements taken!

|

|

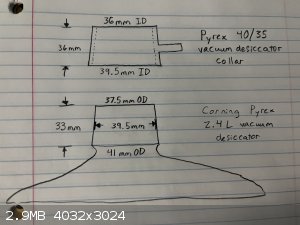

my rogue 40/35 ground glass joint

I thought I'd save money by buying a vacuum desiccator missing its collar (first mistake).

I sized the GG joint at 40/35, and bought the "proper" collar. Now, the M-F joints are not quite the same size; the collar only fits halfway down the

joint!

Would it be worth looking for another collar that is infinitesimally bigger yet ostensibly also 40/35? It seems like 1.5mm is out of tolerance

Or is there another GG joint configuration I overlooked?

I have in mind to modify what I have using elbow grease, but I have heard the troubles of sanding GG joints by hand. The collar is probably too

fragile to sand anyways.

Maybe heating the collar with a big torch and "re-mating" them would be better?

|

|

|

Chemetix

Hazard to Others

Posts: 376

Registered: 23-9-2016

Location: Oztrayleeyah

Member Is Offline

Mood: Wavering between lucidity and madness

|

|

I'd reckon your best bet will be get some #60 silicon carbide grit or similar, coarse but not too coarse. Add some water to the joint and dab some

grit on there. With some light force and lot's of rotation the grit wears down fairly quickly and so does the glass. So grind a bit, then lift very

slightly to allow the water tension to redistribute the grit and then rotate and grind once more. Keep doing this until the grit no longer feels like

it's grinding. Wash out the residue between the joints and start again until the depth has come down to something you're happy with. Being a 1:10

taper only a small amount of diameter change equals 10 times that amount in change in length. The grinding wont take long to come down in length

between the joints. The joints will no longer be interchangeable, they are now exclusively wed in tapered matrimony. But you have a joint that looks a

bit better.

To be very honest, the difference in length is hardly worth the effort, it should seal perfectly fine. That said, small imperfections like this have

made me waste hours of time getting something perfect so I know! The struggle is real.

|

|

|

Dr.Bob

International Hazard

Posts: 2758

Registered: 26-1-2011

Location: USA - NC

Member Is Offline

Mood: Mildly disgruntled scientist

|

|

Is the dessicator a Pyrex brand one or another brand (or none?) If so, then the Pyrex collar should work. I have fixed a few, and they are pretty

much interchangable. But if either part is not Pyrex brand, then you may have an issue. Your size is pretty common on eBay, but I am looking for a

55/38 sleeve, which is hard to find, apparently. Modifying the one you have may be very hard to do, but you may have no choice, if it doesn't match.

|

|

|

TLutman

Harmless

Posts: 26

Registered: 13-10-2019

Member Is Offline

|

|

You can go to most auto parts stores and get lapping compound. There is fine and course grit, and it is a greasy type compound.

I wouldn’t heat the collar and stick it on as you are most likely going to crack the collar when it cools

|

|

|

Sulaiman

International Hazard

Posts: 3730

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

Assuming that there is a hole in the side of the male joint it is necessary to grind one or both parts until the hole aligns with the hose connection

of the female joint.

If there is no hole then a different female part will be required.

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

CouchHatter

Hazard to Others

Posts: 152

Registered: 28-10-2017

Location: Oklahoma

Member Is Offline

Mood: 76 elements taken!

|

|

Thank you all, these are great suggestions. I will keep you appraised of the results.

The glass pieces are both Pyrex, although the desiccator says "Corning Pyrex" while the collar says "Pyrex", so they might be separated in age by some

decades.

My thoughts exactly, Dr. Bob; I don't really care to buy more Pyrex collars and have them fit the same. I'll at least break this one first, haha.

Sulaiman, each piece of glass has the proper hole in it; I realize I didn't include these on my drawing, but they're there, and correctly located. The

hole in the male side is enormous so they WILL line up, if only the collar would slide down further.

|

|

|

CouchHatter

Hazard to Others

Posts: 152

Registered: 28-10-2017

Location: Oklahoma

Member Is Offline

Mood: 76 elements taken!

|

|

I pronounce thee lid and collar! It took some elbow grease, and real grease, but now that it's all cleaned up, I couldn't be happier with the results.

Can hardly believe it only took an hour! Thanks for the great ideas everyone.

|

|

|

Dr.Bob

International Hazard

Posts: 2758

Registered: 26-1-2011

Location: USA - NC

Member Is Offline

Mood: Mildly disgruntled scientist

|

|

That is amazing, I have never tried to lap a joint like that, figured it would take a longer time. Great that it worked.

Glad that someone has had good luck with fiuxing glass. I have been a one person wrecking crew on addition funnels lately, broke 2 in 2 weeks, while

running a bunch of big LAH reductions. Fortunately now while adding the LAH, but after the reaction was done and I was trying to clean them.

|

|

|

Phosphor-ing

Hazard to Others

Posts: 248

Registered: 31-5-2006

Location: Deep South, USA

Member Is Offline

Mood: Inquisitive

|

|

Cleaning is where the vast majority of my breakage comes from (90%+)!

"The nine most terrifying words in the English language are: 'I'm from the government and I'm here to help.'" -Ronald Reagan

|

|

|