Chem Science

Hazard to Others

Posts: 123

Registered: 30-7-2018

Location: Argentina

Member Is Offline

|

|

Mono-Nitration of Phenol [Tarr Elimination Method]

INTRODUCTION:

Nitration of phenol to make 2-Nitrophenol and 4-Nitrophenol is a reasonably common amateur synthesis. However when i was considering the synthesis of

4-Nitrophenol i did expecto low yield and hard work by tarr. NileRed's Video on the topic made me expect just 1.82g of 4-Nitrophenol from 21.8g of phenol. These is just not good, as phenol for me is

expensive.

However i need 4-Nitrophenol as im actually working on the synthesis of paracetamol from aspirin as NileRed for my Channel in spanish. So i got to

work on it.

On the present publication i will inform on my procedure for the elimination of the tarr produced on the nitration for easy workup.

Also i will report on other alternative synthesis attempts on the search of a better 4-Nitrophenol yield.

Nitration of Phenol with tarr elimination.

Nitration Solution:

14,6g of Sodium Nitrate was dissolved in 54g of 30% [m/m] sulfuric acid with stirring. These solution was then cooled to 10ºC

Phenol Melting:

9.1g of phenol were mixed with 2mL of water and heated slightly with stirring to dissolve and generate an eutectic mixt

Nitration:

The phenol-water mixture is added to a dropping funnel, and suspenden on top of the nitration mixture, the reaction is controlled by a thermometer and

done on an ice bath. The phenol is added drop by drop to the stirred nitration mixture, controlling the temperature so that it doesn't go above 20ºC.

After the phenol is added the mixture is left to stirr at room temperature overnight.

The next morning, to the reaction mixture, 20g of sodium hydroxide were added slowly to basify the mixture, keeping the temperature below 50ºC.

After all sodium hydroxide is added, to the reaction mixture a 10-15% solution of hydrogen peroxide is added slowly until oxygen liberation is

observed, in my case i used 30mL at 40ºC approx., On these step the black solution is lighten slightly, once oxygen liberation is observed, the

solution is left to stirr for 30min to 1hr at 40-50ºC.

The mixture is filtered and the filter washed with warm water to transfer all soluble compounds.

The filtrate is accidified to a pH of 2 approx. Here the nitrophenols precipitate with almos no tarr [Chemical Satisfaction here].

The solution is brought up to 500mL in volume and subjected to simple distillation to separate the 2-Nitrophenol.

Once no yellow condensate is observed on the condenser, and the condenser is clean, the distillation is stoped.

The hot mixture in the distilling flask is filtered while hot and left to cool, and the 2-Nitrophenol distillate is also cooled

The 2-Nitrophenol is filtered, dried and stored.

The 4-Nitrophenol may contain sodium sulfate, so it needs to be purified by dissolving in ethanol, mixing with water, evaporated to a low volume and

cooled to crystalized.

Final yield is:

2-Nitrophenol: 3.7g [27,5%]

4-Nitrophenol: 2.2g [16,4%]

Phenol Nitration Mixture

Nitration Mixture Basified

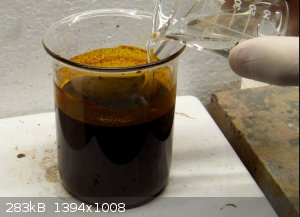

Adittion of Hydrogen Peroxide

Filtration of Mixture after tarr elimination

Nitration Reaction with tarr eliminated [basic]

![Nitration Reaction with tarr eliminated [basic].jpg - 216kB](https://www.sciencemadness.org/whisper/files.php?pid=677426&aid=95096)

Nitration Reaction with tarr eliminated [Acidic]

![Nitration Reaction with tarr eliminated [Acidic].jpg - 151kB](https://www.sciencemadness.org/whisper/files.php?pid=677426&aid=95098)

2-Nitrophenol and 4-Nitrophenol Samples

4-Nitrophenol once 2-Nitrophenol was steam distilled

Crude 4-Nitrophenol

Final Samples

Alternative Phenol Nitration

I came across a paper An Efficient and Regioselective Nitration of Phenols Using NH4NO3, KHSO4 where there's reported up to 60% yield on 4-Nitrophenol, and reasonably

simple and accessible. So i gave it a try.

Procedure:

In a 100mL Erlenmeyer flask, 5g pf phenol were added, along with 6.4g of cupric nitrate hydrate, 7g of sodium bisulfate monohydrate and 60mL of

acetonitrile.

The mixture is set to reflux for 6hs, evolution of NO2 gas is observed

After Reflux the mixture is poured to 300mL of water, and distilled to recover 2-Nitrophenol, and the 4-nitrophenol was recovered by filtration after

cooling the distilling solution.

Yields were:

1.3g of 2-Nitrophenol [17,5%]

1.1g of 4-Nitrophenol [14,8%]

However, a second attempt of these same reaction yielded no nitrophenols.

Unfortunately i was so exhausted by nitrophenol synthesis at this point i loss my report on these reaction, so ... sorry for that

Inspiration for these experiment's

On the procedure to make picric acid from phenol i came across these story that on the beginning, the nitration was done without the final heating

that the modern procedure recoments, so less yields were obtained.

While performing my nitration experiments to make mono-nitrophenols i observed that on the tip of the dropping funnel, the phenol turned black, these

made me think, meaby some Phenol reacts with NO2 gas, or NO and O2 , and makes some Nitroso-phenol or something like it. So i thought maybe if i can

help oxidized any side product of the nitration i can eliminate the tarr these black thing makes, similar to finishing the oxidation on the picric

acid synthesis. These gave the bases of the experiment's i did to come up with these procedure.

I did think on the possibility of making 5-Nitrosalicylic acid aand decarboxylate it. However i did not go far with these out. Some recommendations i

can give is to use diluted nitration mixture, here are some of my attempts

Reaction A

Salicylic Acid: 10g

HNO3 [70%]: 10mL

Water: 50mL

Very violent reaction.

Reaction B

Salicylic Acid: 10g

HNO3 [70%]: 10mL

H2SO4 [30% m/m]: 10mL

Water: 500mL

Yield: 4.5g mp: 220-230ºC

Conclusion

Although the nitration of phenol still gives low yields, even with these alternative, these procedure is a more workup friendly way to make it, i

think these information can give some insight on what is the reason of the tarr formation.

Notice that i used 9.1g of phenol, and obtained 2.2g of 4-Nitrophenol. If i have used the 21.8g NileRed use, i can expect 5.2g of 4-Nitrophenol,

instead of the 1.82g NileRed obtained.

I'm working on a spanish video of these procedure, and when it's done i will add a link.

Thank's for your time

[Edited on 9-10-2022 by Chem Science]

|

|

|

Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Well done! The tar was very annoying when I did the nitration of phenol. I see that you developed the tar elimination method by yourself, bravo!

I succeeded in improving of the color of p-nitrophenol by final crystallization from 0,5% Na bisulfite, I found that in some patent. My product was

similar color as your and the bisulfite method improved it to white. Even small quantities of oxidation impurities strongly discolor the product.

The biggest problem of p-isomer was oiling out from water solution during crystallization so I had to use diluted solution, not saturated at 100 C - I

still do not know whether the oiling out in my case was due to impurities or whether it is common behavior of the para isomer when the water solution

is too much concentrated.

https://www.sciencemadness.org/whisper/viewthread.php?tid=15...

I see you are focused on paracetamol, then the higher yield method for you could be via p-nitrosophenol

[Edited on 9-10-2022 by Fery]

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

@Chem Science, thankyou for posting this very interesting piece of work, your o-nitrophenol look pretty good (the yellow product) but the

p-nitrophenol is rather brown so probably still contains some tar. Do you think it would be worthwhile to try maintaining a lower temperature during

nitration, say <0 C, to reduce tar formation and increase yield accordingly?

The paper you posted contains some interesting nitrating mixtures for the more reactive phenols too. Thanks for this too.

|

|

|

Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Boffis, its color is not white, but traces of impurities are able to discolor it heavily. They are perhaps some oxidative side products like quinones.

Boiling with activated charcoal did not improve the color in my case, but it did by 1 crystallization from 0,5% water solution of Na bisulfite and in

my case it had to be done from not too much concentrated solution. When cooling too much concentrated solution the product first always oiled out and

only below some magic temperature when the concentration in water phase was lower than some magic threshold only then crystals start to appear.

Because also solubility in very cold solution is not low enough, in my experiment it looked like from 2 grams impure crystals I got 1 g of purified

crystals and 1 g stayed dissolved in the mother liquor. It's worth trying to reuse the mother liquor by adding there 1 g of impure crystals and repeat

the cycle as wasting 50% of the compound dissolved in mother liquor is too much by my opinion.

|

|

|

Chem Science

Hazard to Others

Posts: 123

Registered: 30-7-2018

Location: Argentina

Member Is Offline

|

|

@Fery

Thanks for the comments  I might try your recrystallization, thanks for that I might try your recrystallization, thanks for that

@Boddis

It's always and honor to report my experiments to my fellow Chemists

I did try to do a very temperature controlled nitration at T<10ºC but never subzero. Something i did try, is to add a Nitrogen Oxide scavenger.

Some experiments:

NITRATION OF PHENOL WITH NO2 SCAVENGER:

_50g H2SO4 (30% m/m)

_H2O2 [20.4M] 5mL

_HNO3 [68%] 8mL

_Phenol 10g + 2.2mL H2O

At 10ºC the mixture showed no reaction. Heating above room temperature for 2hr gave a dark red solution and separated in 2 phases.

Distillation of these yielded no 2-Nitrophenol.

NITRATION OF SALICYLIC ACID WITH NO2 SCAVENGER:

_Salicylic acid 10g

_Urea 6.5g

_HNO3 (68%) 10mL

_H2O 500 mL

_H2SO4 (30% m/m) 30mL

Even at 100ºC for 2hr no reaction was observed

Im not shure what to conclude from these experiments, but i think something funny is going on with the Peroxide tarr elimination.

|

|

|

Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Small amount of NOx could probably improve reaction speed? For some nitrations there is recommended to add a little of NaNO2 or use part of wasted

nitration acid from previous nitration.

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Hi Chem Science, In the nitration of salicylic acid in the presence of urea is that water figure correct ie 500ml? If so then you are working way too

dilute. Having already dilute the sulphuric acid you don't need any water. The use of H2O2 with nitric acid is problematic too, my experience is that

it simply oxidises stuff.

I am translating an old German paper on the nitration of salicylic acid where they use cold 98% nitric acid! They then describe the separation of the

mononitrosalicylic acids from the dinitro acid, dinitrophenols and picric acid, the yield of mononitro acids is only 40%. I have a couple of other

papers/patents on this mononitration that I am looking at. It appears that salicylic acid is less prone to oxidation than phenol but its tendency to

polynitrate or decarboxylate causes problems.

|

|

|

Chem Science

Hazard to Others

Posts: 123

Registered: 30-7-2018

Location: Argentina

Member Is Offline

|

|

@Boffis

Remember that i did a nitration with relatively concentrated sulfuric and nitric acid but it was too violent ! On the conditions mentioned before, in

500mL of water i got a yield of 31%.

If you have links to the patents and papers it would be nice

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

That 98% nitric acid will be interesting.

My first reaction in my youth was nitrating (well, attempting) salycilic acid with 68% nitric acid.

No matter how carefully I wanted to go it always ended in a foamy-bubbly runaway.

It always decarboxylated at first, then at one point in the mixture (250 ml Erlenmeyer flasks were used) I could detect a small yellow spot, which

turned quickly rust-colored and the runaway (with NOx evolving) started.  It

was not explosive but always foamed out of the flask. Geez! I still have a few grams of recrystallized product from one of those reactions (from 30+

years ago)! I think it is o-nitro-phenol but I had no means of characterising it in those days. Maybe now. It

was not explosive but always foamed out of the flask. Geez! I still have a few grams of recrystallized product from one of those reactions (from 30+

years ago)! I think it is o-nitro-phenol but I had no means of characterising it in those days. Maybe now.

|

|

|

kmno4

International Hazard

Posts: 1503

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

Mechanism of nitration of phenol is not similar to nitration of benzene or toluene. It turns out that HNO2 is a catalyst in nitration

of PhOH. Besides, proportion of o-/p- derivatives strongly depends on HNO2 concentration, temperature and solvent used.

Some speculations in literture give p-nitrosophenol as primary product of nitration (or rather nitrosation) of PhOH, being further oxidized to

p-nitrophenol.

The key factors to avoid formation of tarry material is to keep temperature of reaction as low as possible, with good mixing. Even local overheating,

caused by too fast rate of addiction of reagents is harmful.

What surprises me in preparations given in many books (Vogel, etc....) - phenol (its solution) is always added (slowly) to some nitration mixture.

It would be much better to add the nitration mixture (slowly) to the phenol solution, at least in theory. But no procedure I know exploits such

reagents addition. I wonder why - serious problems with mixing of such semi-solid mass or what ?

Слава Україні !

Героям слава !

|

|

|

Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Hi kmno4 and thanks for more information, that explains a lot.

The phenol mixture added to nitration acid is usually something like 90 g of phenol + 10 g H2O so it is a solution of water in phenol which is

miscible and liquid, but if you add more water it is immiscible and becomes miscible again when the concentration of phenol is very low so it is a

solution of phenol in water (less than 10 g of phenol + 90 g H2O). The second choice (diluted phenol in water) is inconvenient for nitration as that

would introduce a lot of water and would make nitration acid too diluted.

|

|

|