CycloRook

Hazard to Self

Posts: 89

Registered: 2-4-2018

Member Is Offline

Mood: No Mood

|

|

Choosing reflux condensers ?

Does anyone have a system for choosing reflux condensers ?

I'm assuming their is a rule for type of solvent volume being refluxed etc.

How to ensure you don't overwhelm the condenser.

Thanks

|

|

|

crow6283

Hazard to Self

Posts: 60

Registered: 14-1-2018

Member Is Offline

Mood: No Mood

|

|

Well the general rule is simply the more volatile, lower the boiling point, the more efficient a condenser is needed. Lower boiling point solvents

like DCM, diethyl ether, even methanol I use a dimroth/coil type condenser. Most anything else a Liebig. For the really low boiling ones I often use

a cooler with plenty of ice in it and a pump for circulation rather than going from the tap - unless it’s winter.

Maybe there is some rule or chart out there but to me it came from experience (failure or two) and then adjusting as you go.

Better safe than sorry though, right ? When in doubt I go for a more efficient condenser.

|

|

|

Llamamide

Harmless

Posts: 2

Registered: 30-4-2019

Location: Germany

Member Is Offline

|

|

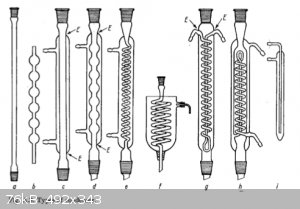

Organicum; Practical Handbook of Organic Chemistry, 1st English ed.; Becker, H., Ed.; Addison-Wesley Pub. Co: Reading, Mass, 1973.

| Quote: |

air condenser (a). Because of the low cooling effect of the air, (a) can be used only for high-boiling substances with boiling points

over 150°C. It is sometimes used as a reflux condenser in the form of a "vertical tube", but is not very efficient for this purpose because laminar

flow prevails and the substance easily "breaks through". The modification (b) is more suitable as a reflux condenser, and is used particularly in

semimicro preparations where, because of the small amounts of heat to be removed, air cooling is frequently sufficient even with low-boiling materials

(where necessary, the condenser may also be wrapped with moistened filter paper or a damp cloth). With rates of distillation that are not too high,

(a) can also be used from about 150°C as a product cooler for high-boiling substances.

Liebig condenser (c) is used mainly as a product condenser (up to about 160°C). The cooling medium is flowing water up to about

120°C and stationary water from 120-160°C. Because of the small cooling surface and the laminar flow, the Liebig condenser is not very effective as

a reflux condenser and can be used only for relatively high-boiling substances (b.p. > 100°C).

bulb condenser (d) is used only as a reflux condenser. Because of the bulbs the vapour flow becomes turbulent and the cooling effect

is considerably better than that of the Liebig condenser. Since atmospheric humidity deposits on the outer wall (see above), the positions of sealing

are again points of danger.

Narrow coil condensers (e) should never be used as reflux condensers, because the condensate cannot flow away satisfactorily in the

narrow coil and is often thrown out of the top of the condenser, which may give rise to accidents. In the vertically descending position, however, the

coil condenser is an outstanding product condenser and is used particularly for low-boiling substances.

Städeler condenser (f), the cooling vessel of which can be charged with mixtures of ice and common salt, carbon dioxide and acetone,

etc., so that even very low-boiling substances can be condensed in this way.

Dimroth condenser (g) is a reflux condenser with an intensive action. If the relatively large amounts of distillate which adhere to

the cooling coil can be discarded, it can also be used as a product condenser. The points of sealing (E) are outside the zone with a high temperature

gradient, so that the condenser can be used without special precautions up to 160°C.

jacketed coil condenser (h) is a combination of the Liebig condenser and the Dimroth condenser. Since the cooling effect is very

good, low-boiling solvents (e.g. ether) cannot easily escape.

Suspended condensers, cold fingers (i): this special form of reflux condenser can be hung loose in a reflux apparatus and is

particularly useful in semimicro apparatus.

|

Some interesting-to-know parts omitted for better readability. The book is available for free downloads at various places in the internet  I haven't read Vogel's, but I'd assume it would have a similar part about laboratory

glassware and how to use it? Textbook knowledge is not all bad! I haven't read Vogel's, but I'd assume it would have a similar part about laboratory

glassware and how to use it? Textbook knowledge is not all bad!

In terms of not overloading your condenser: do not apply excessive heat and keep runaway reactions under control by cooling or not letting them happen

in the first place. Also be resourceful and learn to do chemistry on the smallest scale possible. Prevents and contains a lot of nastiness.

[Edited on 10-1-2022 by Llamamide]

|

|

|

teodor

National Hazard

Posts: 876

Registered: 28-6-2019

Location: Heerenveen

Member Is Offline

|

|

I used a Dumroth condenser (Duran, with tap water) for temperatures up to 213C. To check the effectiveness I count how many turns of the spiral are

fogged up. Based on this I can say it is not effective for diethyl ether but is quite effective for methanol and everything with a higher boiling

point. For reflux (unlike high-speed distillation), I don't need a big amount of vapors passing into the condenser so I can always regulate my

heating. When I see the visible puffs of vapor coming inside the condenser that means it is already being pushed a bit.

|

|

|

dawt

Hazard to Self

Posts: 74

Registered: 9-5-2016

Location: EU

Member Is Offline

Mood: fluorescent

|

|

I really just use three condensers - a 30 cm Dimroth for reflux, a 40 cm Liebig (actually more of a West condenser) for Distillations and a 20 cm

intensive condenser for anything involving DCM or ether (plus a bunch of ice in my water). For small scale anything I also have a 20 cm Liebig in

NS14. This has basically worked for me since forever, never had issues with that system.

|

|

|

CycloRook

Hazard to Self

Posts: 89

Registered: 2-4-2018

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by dawt  | | I really just use three condensers - a 30 cm Dimroth for reflux, a 40 cm Liebig (actually more of a West condenser) for Distillations and a 20 cm

intensive condenser for anything involving DCM or ether (plus a bunch of ice in my water). For small scale anything I also have a 20 cm Liebig in

NS14. This has basically worked for me since forever, never had issues with that system. |

what is an

intensive condenser ?

Do you have a picture? I think DCM and Ether are probably the most volatile substances one would encounter for a reflux.

|

|

|

Llamamide

Harmless

Posts: 2

Registered: 30-4-2019

Location: Germany

Member Is Offline

|

|

h) is an "Intensivkühler"

|

|

|

Mateo_swe

National Hazard

Posts: 541

Registered: 24-8-2019

Location: Within EU

Member Is Offline

|

|

So a intensive condenser is a jacketed reflux condenser (ie. an ordinary reflux condenser(g) with an outer jacket cooling also the outer surface.

I have a double jackeded condenser (liebig condenser with extra outer jacket), this variant is also quite common and quite effective.

|

|

|

SWIM

National Hazard

Posts: 970

Registered: 3-9-2017

Member Is Offline

|

|

I don't think the term intensive condenser is used much in English though.

Don't recall what is used though. I'd just list them as "coil and tube condenser".

The Stadeler condenser is good for low boiling solvents but a pain to clean. (and needs recharging)

For Low boiling stuff I usually use a Dewar condenser with ice/salt if I'll be around to keep an eye on it.

An insulated lid fabricated to fit the top makes the coolant last a bit longer.

There's an awful lot of room for personal preference here

As long as it cools well enough and doesn't choke most things will work.

Ones that have their own little reservoir obviously need more watching than ones you pump water through, but are easier to use with low temperature

cooling mixtures.

(Pumping ice/salt through a Liebig or West condenser leads to an awful lot of condensation in humid climates unless you insulate them)

|

|

|

RustyShackleford

Hazard to Others

Posts: 200

Registered: 10-12-2020

Location: Northern Europe

Member Is Offline

|

|

a while back i did some calculations while distilling a large amount of toluene and acetone.

From my estimations and calculations, my 300mm 24/40 alihn condenser (effectivly ~350mm liebig) can handle 300W of condensation at a temperature

difference of 80C. With some simplifications and completely ignoring pump throughput (which should be far above distillate, so doesnt rly matter),

that gives

Q=10.7 * L * dT

(L=condenser length in meters, dT = temperature difference between vapor and condenser water)

ofc youd have to figure out the Q value yourself, which depends on the vapor flowrate, but if you just want a rough guess then ~50% of the hotplate

power if its around 100C vapor, 80% if its around 40C.

|

|

|