neptunium

National Hazard

Posts: 990

Registered: 12-12-2011

Location: between Uranium and Plutonium

Member Is Offline

|

|

disolving carbon

Does anyone here know of a way to fully dissolve carbon (graphite form) ?

I am not talking about removing graphite burn stain or finely divided powder suspension in a liquid. I mean fully dissolving it like table salt in

water ? or rather sugar ... I thought about carbon disulfide possibly ? anything else?

The goal is to bypass the tedious, long and error prone process for preparing sample for carbon dating . Which by the way must mix with a toluene

based scintillation solvent... any idea?

https://www.youtube.com/watch?v=qvi83-PTDN8

|

|

|

DraconicAcid

International Hazard

Posts: 4355

Registered: 1-2-2013

Location: The tiniest college campus ever....

Member Is Offline

Mood: Semi-victorious.

|

|

I don't think carbon dissolves in much other than molten iron. Definitely not toluene or carbon disulphide.

Please remember: "Filtrate" is not a verb.

Write up your lab reports the way your instructor wants them, not the way your ex-instructor wants them.

|

|

|

Texium

Administrator

Posts: 4618

Registered: 11-1-2014

Location: Salt Lake City

Member Is Offline

Mood: PhD candidate!

|

|

Piranha solution or chromic acid are all that come to mind for me, though those would likely damage your sample.

|

|

|

Bedlasky

International Hazard

Posts: 1241

Registered: 15-4-2019

Location: Period 5, group 6

Member Is Offline

Mood: Volatile

|

|

Quote: Originally posted by Texium  | | Piranha solution or chromic acid are all that come to mind for me, though those would likely damage your sample. |

Concentrated nitric acid should also work (in theory). But I never tried that. Fenton should also oxidize it to CO2.

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2168

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

Chlorosulphonic acid is the only solvent other than iron.

https://www.nature.com/articles/nnano.2010.86

|

|

|

MichaelBijanAfghani

Harmless

Posts: 19

Registered: 15-11-2021

Member Is Offline

|

|

Quote: Originally posted by Texium  | | Piranha solution or chromic acid are all that come to mind for me, though those would likely damage your sample. |

Maybe You could bubble the outgoing carbon dioxide into water to make carbonic acid, then add sodium hydroxide to get sodium carbonate.

|

|

|

Bedlasky

International Hazard

Posts: 1241

Registered: 15-4-2019

Location: Period 5, group 6

Member Is Offline

Mood: Volatile

|

|

It would be better CO2 directly to NaOH solution. If you bubble CO2 just to the water, some will escape to the air.

|

|

|

unionised

International Hazard

Posts: 5128

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

Do you know what form the 14C is in?

I seem to recall that it is made by irradiating nitrogen with neutrons or something.

If I was doing that, I'd use a nitrate salt to hold the nitrogen in place in the reactor and then precipitate the carbonate that's formed with

calcium or some such. (You would need a carrier).

In that case, the answer to your question might be that you can dissolve it in vinegar.

|

|

|

neptunium

National Hazard

Posts: 990

Registered: 12-12-2011

Location: between Uranium and Plutonium

Member Is Offline

|

|

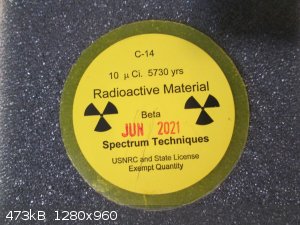

I realize now that the picture is a bit misleading... the carbon in the source is on a waxy substance i had no trouble dissolving in toluene for my

reference 14C.

I am currently measuring unknown samples (video) by first heating in absence of oxygen to make it a chunk of charcoal. this is then burned in oxygen

and the CO2 produced bubbles in a concentrated solution of LiOH which rapidly precipitate as lithium carbonate. this Li2CO3 can be somewhat dissolved

in my scintillation cocktail for counting but this is not an ideal process.

A better way would be to add dropwise a dilute solution of HCl in a vacuum to recover the clean CO2, react it with Lithium metal to get the carbide

which releases acetylene when dropped in water. this C2H2 can be heated in a steel catalyst to cycle into benzene .

That carbon rich benzene is then weighted and dissolved in the scintillation cocktail for counting .

So clearly the sample is completely destroyed in the process which is fine . But this is a high waste generating process with many opportunity for

contamination and I wanted to come up with a better/easier way to prepare samples from graphite to a carbon liquid easily dissolved in the

scintillation cocktail (mostly made of toluene BTW).

The best way I came up with was to react the charcoal directly with sulfur at high temp and distill away the CS2 .

Molten Iron is out of the question for obvious reason

I do not believe HNO3 would do much at all but it`s worth trying

I also heard about hot concentrated sulfuric acid and this is also worth trying (although probably also very inefficient)

Chlorosulphonic acid is the one that keeps coming back in many articles, I`d like to try it out but obtaining it may be a challenge ...

Thank you all or your contribution I do appreciate it !

|

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

The conversion of CO/CO2 and H2 to methanol is performed catalytically on a large scale, if you're trying to perform a gas-to-liquid hydrocarbon-type

reaction. It would probably be difficult to do on a lab scale and not very efficient though. Good luck.

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2168

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

chlorosulphonic acid requires either fuming oleum or phosphorus pentachloride to make.

Assuming you are starting with an organic mixture, a better method may be to use caro's acid aka piranha solution.

This will convert the carbon directly to CO2 without the carbonization step.

Then capture in lithium carbonate solution.

This eliminates one step.

The fewer steps the less room for loss or contamination.

|

|

|

unionised

International Hazard

Posts: 5128

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

I think the yield of the acetylene to benzene reaction is poor, with lots of by products.

On the other hand, acetylene is probably reasonably soluble in toluene.

How about reaction of CO2 with a Grignard , for example phenylmagnesium bromide to make benzoic acid?

The old school approach was to mix the sample with excess copper oxide and then heat it to convert all the carbon present to CO2.

No need for an intermediate charcoal step (with possible losses).

I think the apparatus was a flow of nitrogen through a a hard glass tube with copper oxide to oxidise the organics to CO2 H2O etc, then copper

turnings to reduce any NOx to N2 Then silver to remove halogens and finally phosphoric acid to remove most of the water.

After that you have pretty clean CO2 in N2

|

|

|

neptunium

National Hazard

Posts: 990

Registered: 12-12-2011

Location: between Uranium and Plutonium

Member Is Offline

|

|

Quote: Originally posted by macckone  |

Assuming you are starting with an organic mixture, a better method may be to use caro's acid aka piranha solution.

This will convert the carbon directly to CO2 without the carbonization step.

Then capture in lithium carbonate solution.

This eliminates one step.

The fewer steps the less room for loss or contamination. |

I like that... the loss aren`t important . a few milligram suffice and there is usually plenty of sample available . Contamination on the other hand

IS a big issue and eliminating a step is a huge benefit!

[Edited on 7-1-2022 by neptunium]

|

|

|

neptunium

National Hazard

Posts: 990

Registered: 12-12-2011

Location: between Uranium and Plutonium

Member Is Offline

|

|

Quote: Originally posted by unionised  | I think the yield of the acetylene to benzene reaction is poor, with lots of by products.

On the other hand, acetylene is probably reasonably soluble in toluene.

How about reaction of CO2 with a Grignard , for example phenylmagnesium bromide to make benzoic acid?

The old school approach was to mix the sample with excess copper oxide and then heat it to convert all the carbon present to CO2.

No need for an intermediate charcoal step (with possible losses).

I think the apparatus was a flow of nitrogen through a a hard glass tube with copper oxide to oxidise the organics to CO2 H2O etc, then copper

turnings to reduce any NOx to N2 Then silver to remove halogens and finally phosphoric acid to remove most of the water.

After that you have pretty clean CO2 in N2

|

That sounds good but the introduction of Phenylmagnesium is the source of contamination since it already contain carbon . Even as a petroleum

byproduct there is no way to get reliable result not knowing the history of the chemical. Nitrogen is a much better option than burning charcoal in

O2 I agree !

|

|

|