Johnny Cappone

Hazard to Self

Posts: 74

Registered: 10-12-2020

Location: Brazil

Member Is Offline

|

|

How to remove these incrustations? Cleaning a GPU heatsink

I know many of us around here have other hobbies and probably some of you are also interested in computers. Normally I would post this on a hardware

forum, but my question here has more to do with chemistry.

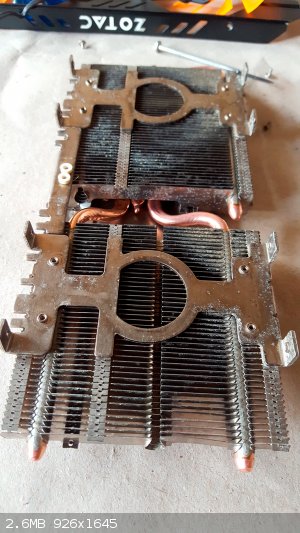

I recently purchased a used graphics card from Aliexpress. Its heat sink, the part responsible for removing heat from the chip and transferring it to

the circulating air, has some incrustations of unknown origin that I believe is negatively interfering with heat transfer as the board has unusually

high temperatures.

First I tried a vinegar bath for an hour, brushing the sink fins with a soft bristle brush. This brought back the shine of the copper heatpipes, as

expected, leaving behind a slightly greenish copper acetate solution resulting from vinegar's attack on the oxide that coated the metal. However, both

the oxide layer of the fins and the incrustations still there.

These fins are usually made of aluminum, but some appear to be given an additional metallic coating (chrome? nickel?) to make them look shiny. Does

anyone have any idea what these incrustations might be, what metal is covering the aluminum fins and how to remove the oxide without damaging them?

I have some ideas of what might work, but decided it would be a good idea to check the board first.

Maybe diluted hydrochloric acid? It wouldn't attack copper (well, actually it would attack softly, as it should have some atmospheric air and hence

oxygen dissolved in it), but it would attack aluminum; nitric acid would attack copper in the heatpipes, and with sulfuric acid I'm not absolutely

sure what the effects would be.

Damn, it would be so easy if I knew exactly what these incrustations are made of. It's all about finding a solution that preferentially attacks them

and the oxide of the fins, leaving the entire piece with a shiny appearance again.

Anyone?

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

Aluminium is going to be difficult, whatever dissolves the oxide dissolves the aluminium faster. I think you can't do much more than scrub.

[Edited on 14-12-2021 by Tsjerk]

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2168

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

+1 tsjerk

There is no good way to clean aluminum other than a surfactant and scrubbing with a toothbrush.

|

|

|

Fulmen

International Hazard

Posts: 1725

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

It looks like corrosion damage to me. Abrasives or steel wire brushes should remove the bulk of it if you can get at it. 10% sodium hydroxide will

strip off any corrosion as well as the anodizing.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

Yes, and it will eat through the aluminium like a it's cotton candy. Probably before it does anything to the oxide.

|

|

|

yobbo II

National Hazard

Posts: 764

Registered: 28-3-2016

Member Is Offline

Mood: No Mood

|

|

Ultrasonic cleaner with added gentle abrasive (like sodium carbonate)?

|

|

|

Fulmen

International Hazard

Posts: 1725

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

@Tsjerk: Nonsense. It will corrode the metal slightly, but I've stripped anodizing many times without damaging the metal. We're talking a few 1/100mm

as long as you don't overdo it.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

Twospoons

International Hazard

Posts: 1326

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

The problem with any chemical cleaning method is that you are going to have to remove every trace of the cleaner from every crack, gap, joint or hole.

Otherwise you are just setting yourself up for a major corrosion problem long term.

Stick with water + abrasive.

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

Quote: Originally posted by Twospoons  | The problem with any chemical cleaning method is that you are going to have to remove every trace of the cleaner from every crack, gap, joint or hole.

Otherwise you are just setting yourself up for a major corrosion problem long term.

Stick with water + abrasive. |

The removal of the cleaner is not so much a problem when the object is not there anymore.

|

|

|

Fulmen

International Hazard

Posts: 1725

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

@Twospoons: Good point. Stripping the anodizing should be a last ditch effort for a number of reasons.

How about phosphoric acid?

We're not banging rocks together here. We know how to put a man back together.

|

|

|

Ubya

International Hazard

Posts: 1247

Registered: 23-11-2017

Location: Rome-Italy

Member Is Offline

Mood: I'm a maddo scientisto!!!

|

|

heatsink fins are made out of aluminium, and sometimes they get a coat of nickel/chromium to make them shine.

probably some scratching and some water/condensation caused that damage through galvanic corrosion, wet aluminium by itself wouldn't corrode that

much.

most acids/bases would dissolve the aluminium before or while attacking the oxydes/hydroxides.

usually to clean water damaged electronic boards the safest and most effective procedure is to scrub with 99% isopropyl alcohol and then put them in

an ultrasonic cleaner with alcohol and detergent (i think the detergent might be skipped).

The ultrasounds can remove all the loose/loose-ish flakes of corrosion.

if the protective metal layers have been damaged, new corrosion will form pretty easily even after this fix, so keeping everything dry will be

mandatory

---------------------------------------------------------------------

feel free to correct my grammar, or any mistakes i make

---------------------------------------------------------------------

|

|

|

Johnny Cappone

Hazard to Self

Posts: 74

Registered: 10-12-2020

Location: Brazil

Member Is Offline

|

|

Thank you all for the suggestions, guys.

@Fulmen, I found a video of a guy on YouTube successfully removing anodizing using a NaOH solution. It seems to be exactly what I'm looking for.

Contrary to what I thought, it looks like my heatsink fins weren't coated with another metal, but simply anodized. Perhaps removing the anodizing will

remove any foreign material encrustations that are trapped in it. So it will be the first method I will try. About the phosphoric acid, I have

sulfuric acid here, but I don't know if I can get my hands on some phosphate. Anyway, if nothing else works, I'll do a test run with H3PO4 in a small

area of the fins to see how things work.

@Yobbo II: unfortunately I don't have an ultrasonic cleaner. I've been in several other situations where owning one would be very useful, someday I'll

end up buying it.

@Twospoons, you have a valid point. But, given the good solubility of NaOH, I believe that repeated washings in tap water will do the job. This is an

especially difficult part to physically clean due to its large surface area (exactly what you would expect from a heatsink). I mean, dust and things

like that come off easily, but stickier dirt actually requires a more aggressive cleaning method. However, if the NaOH solution does not work, I will

try to scrub the part with an abrasive and brush. I don't know what it's called in the rest of the world, but around here we have something called

(literal translation) "polishing paste", you can find it in any supermarket and, as far as I know, it's used to polish metals. It would be incredibly

laborious to brush all the heatsink fins, but if the NaOH doesn't work or is too aggressive, I'll try this method. Would you suggest any specific

abrasive?

@Ubya, yeah. When i got this GPU I realized that at some point it must have operated in a really humid environment somewhere in China for the heatsink

metal to be so severely corroded in some areas. The board works, the chip is in good condition and the PCB looks practically new. Luckily (or bad

luck, when it comes to the heat and dry air most of the year) the place where I live has low levels of humidity most of the time. Actually, sometimes

the air gets so dry (10-12% humidity) that the National Weather Service needs to ask people to avoid outdoor sports and keep a humidifier running at

home. So once this issue is fixed, I don't think I'll have to worry about it again.

This is the video I found, he uses a NaOH solution and gets really good results: https://youtu.be/QQq5XhTH46E

|

|

|

andy1988

Hazard to Others

Posts: 135

Registered: 11-2-2018

Location: NW Americus ([i]in re[/i] Amerigo Vespucci)

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Johnny Cappone  | Normally I would post this on a hardware forum, but my question here has more to do with chemistry.

I recently purchased a used graphics card from Aliexpress. |

Brave.

Too often sellers on AliExpress sell things which should be recycled domestically. I've bought lots of things there. LiFePO4 batteries for example,

they all are marketed as Grade A (new), but in fact are all well-used and removed from EVs when no longer fit for use. Some sellers don't appear to

even bother testing for useless duds before shipping them. On the other hand I've bought used old notebook RAM, and a used HDD board there which I

couldn't find anywhere else.

Quote: Originally posted by Johnny Cappone  | | Its heat sink, the part responsible for removing heat from the chip and transferring it to the circulating air, has some incrustations of unknown

origin that I believe is negatively interfering with heat transfer as the board has unusually high temperatures. |

I'd seen crusty buildup on fins like that before, but not to that extent. Humidity makes sense. Never gave it much thought.

I personally don't think that the buildup matters. I'd wondered in the past on the possibility of poor heat pipe implementation by the manufacturer, but you're probably speaking of the heat production in terms of what you feel coming off of it, and

not pointing an IR camera at the board itself, so I don't think that the heat sink is a problem, as the heat coming off is a sign the heat sink is

working as intended!

The aluminum fins are there as a mass to transfer heat to the air. Mount a fan on it keeping in mind case air flow. I use wires from bread bags linked

together to strategically hang a couple fans in my case. Would make more sense to me than trying to renew those fins. But again, heat coming off means

it is working as intended in preventing the board from getting too hot (extending its life).

A problem in electronics is that dendrites may form, making undesired connections, excess heat is a consequence as the circuit draws more current.

Might be caused at the time of manufacture. Might be caused by an ESD event, e.g. not wearing ESD wrist protection when handling board, but the

problem won't be apparent until years later as the dendrites grow. The dendrites may grow, and draw more current. Eventually this likely culminates in

a failure, a bad burning odor emitted from the computer as things burn, and hopefully the power supply turning the system off, but is not always the

case, I've had a HDD board burn and smoke and computer didn't shut off. Stick to reputable manufacturers for better quality control, and buy a metal

ESD wrist strap with an alligator clamp to use when handling such electronics. And if you smell something burning then suspect something in the

computer, it took me a while to figure that out as it smoldered.

Also, the power electronics on the board may be relatively inefficient. Say, 65-72% of the electricity doing useful work, as opposed to say 92-95% in

premium modern expectations. Which may translate into a lot of Watts of heat. The inefficiency is heat energy, EM emissions, audible sounds (buzzing)

not contributing to useful work. Aging components may reduce efficiency. Could say more but this is all. Interesting stuff to think about.

[Edited on 17-12-2021 by andy1988]

|

|

|

Johnny Cappone

Hazard to Self

Posts: 74

Registered: 10-12-2020

Location: Brazil

Member Is Offline

|

|

Thanks for the notes, Andy.

I know. But the GPU market is crazy, man. Even in countries with a relatively prosperous economy and strong currency it hasn't been exactly easy to

get a good graphics card for a reasonable price. Around here, for someone with my socioeconomic profile, buying a used one is the only option.

Unfortunately, buying from a reputable local seller would cost twice as much.

| Quote: | | Too often sellers on AliExpress sell things which should be recycled domestically. I've bought lots of things there. LiFePO4 batteries for example,

they all are marketed as Grade A (new), but in fact are all well-used and removed from EVs when no longer fit for use. Some sellers don't appear to

even bother testing for useless duds before shipping them. |

That's really true. I've bought a lot of things on Aliexpress before, including second-hand goods, and they all worked quite satisfactorily given

their low cost. Yes, there are dishonest sellers there, and many. But if you know how to patiently search and read all the reviews made by other

buyers of the product you want, I would say that the chances of having a problem are greatly reduced. The GPU this heatsink belongs to also works and

I considered it a good purchase, I just think that keeping the heatsink as clean as possible is highly desirable both functionally and aesthetically.

| Quote: | | I personally don't think that the buildup matters. I'd wondered in the past on the possibility of poor heat pipe implementation by the manufacturer,

but you're probably speaking of the heat production in terms of what you feel coming off of it, and not pointing an IR camera at the board itself, so

I don't think that the heat sink is a problem, as the heat coming off is a sign the heat sink is working as intended! |

Damn, it's a GTX 760. A chip naturally hot as hell from birth. Zotac is a good manufacturer, but they simply designed a clearly inefficient heatsink

for this card. We're talking about a chip capable of dissipating up to 200W, just 3 tiny heatpipes unfortunately won't do the job. Also, I live in a

place where the average temperature is around 30-35 degrees Celsius, but for at least 3 months of the year we experience temperatures that can reach

41 degrees Celsius and stay there for weeks, briefly falling to 32-35c at night and rising again at sunrise. The weather here is terrible and any

air-cooled device will suffer a lot. I get the temperature of the GPU through 3 different software on my computer, so I can get a pretty accurate

reading. I can also feel the really hot air coming out of the heatsink so I know it's doing its job. As I said, I would just like to get that 5% more

heat dissipation efficiency that a properly clean heatsink might give me.

| Quote: | | The aluminum fins are there as a mass to transfer heat to the air. Mount a fan on it keeping in mind case air flow. I use wires from bread bags linked

together to strategically hang a couple fans in my case. Would make more sense to me than trying to renew those fins. But again, heat coming off means

it is working as intended in preventing the board from getting too hot (extending its life). |

Although my computer case is designed to accommodate the typical office setup and not a computer with high TDP components, I have made some

modifications to it that ensure good airflow to the internal components.

|

|

|