XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

Purifying Canadian tire Heptane

Pics will follow

Back story. (Skip if here just for the procedure porn)

Some friends where staying here and asked if they could grow pot, since it is legal I said go ahead, sadly they fell victim to a scam and moved back

home, leaving me with 4 plants that serve very little use to me, but 3 survived! Which brings us to why I need the Heptane

Objective:

Purify the Heptane then use to extract pot, then separate the components

Heptane Purification

Acid wash with clean distilled H2SO4 in aliquots till no change is observed on standing for 12H, then wash with 10% carbonate with a final distilled

water wash. followed by fractional distillation over sodium

Procedural reference

purification of laboratory chemicals 6e (elsevier, 2009)

Page: 156, bottom paragraph

1: Can of Emzone non chlorinated break cleaner was purchased from Canadian tire and placed int he freezer. After a couple hours this can was punctured

and drained into a 500ml RBF this was filled to maximum volume.

After being allowed to warm to room temp and degas a 10ml aliquot of H2SO4 was added and swirled, this rapidly took on a rust brown colour, and in

difficulties handling it was transferred to a 500ml sep funnel.

2: The first 10ml of spent acid was collected and a new aliquot of Distilled H2SO4 was added, this was shaken several times with about a minute

separation and shaken vigorously for 30 seconds and for several times with venting 1.5m of shaking with a vent every 30 seconds, then allowed to rest

5m apx)

3: By the third aliquot it was noted the acid no longer took on a brown colour but more of a burned look but mostly clear, this is where I am at the

time of writing this, when I continue on it will be the 4th aliquot of acid, if this remains clear I will then proceed to the 10% bicarb washes washes

and then final rinse

[Edited on 8-10-2021 by XeonTheMGPony]

|

|

|

Molybdenumb

Harmless

Posts: 2

Registered: 27-9-2021

Location: Eastern USA

Member Is Offline

Mood: Dunning-Kruger

|

|

I would think heptane is not the best solvent for extraction from biomass. In our lab, we have a customer who actually uses chloroform for the

initial extraction. We have ran HPLC on the biomass after the extraction and it was very efficient. They then use heptane to recrystallize the

concentrate they get from the extraction. Not really giving advice on how to proceed, rather just supplying some context.

[Edited on 8-10-2021 by Molybdenumb]

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2168

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

most of the extraction done here in colorado uses butane.

ethanol is probably the best solvent for thc given the high solubility.

the advantage of butane is it is a vapor at STP so it leaves a very dry product.

The stuff for lighters has a mercaptan that is fairly easy to remove but they sell it without odorant as well.

|

|

|

Amos

International Hazard

Posts: 1406

Registered: 25-3-2014

Location: Yes

Member Is Offline

Mood: No

|

|

The main reason alkanes like butane are preferred is because they extract far less of the polar compounds in the plant matter that present issues with

taste, color, clarity, and melting point. You can almost strictly target the very hydrophobic cannabinoids and flavorful terpenes with them as your

solvent. There are still waxes and some resinoids but these are much simpler to winterize out. Alkane solvents also have much lower viscosity than

polar solvents which might aid their ability to flow in and out of plant tissue to a greater and faster degree, but I am only suggesting that and

haven't heard that from an academic.

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

I was considering chloroform as well, but it seemed most things pointed to Heptane/Pentane/Hexane range as the best

Some noted the chloroform took a lot of waxes with it vs the Alkanes. So I'll see soon enough

they have favourable BP's and I can easily dial in ideal bp via vacuum. will try both eventually, as I loath open loop processes that flood the area

in flammable gasses

4th aliquot and still discolouring but much less so.

|

|

|

unionised

International Hazard

Posts: 5128

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by macckone  | most of the extraction done here in colorado uses butane.

ethanol is probably the best solvent for thc given the high solubility.

the advantage of butane is it is a vapor at STP so it leaves a very dry product.

The stuff for lighters has a mercaptan that is fairly easy to remove but they sell it without odorant as well. |

The "it's the best solvent" isn't right, what you want is the most selective solvent, and that's not ethanol.

Ethanol dissolves too much of the stuff you don't want.

I haven't noticed any odourant in any butane or "petrol" lighter fluid I have bought.

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

6 Aliquot of acid remained clear whilst stirred over night, an Acid Permanganate in water solution was prepared, this was then added to the 500ml

sepritory funnel and shaken for 2 minutes with a venting at the end of each 30 seconds of shaking. No colour change was noted.

Next phase will be the water washings first two being alkaline carbonate (Na2CO3 @ 10%) then a final washings with 3 aliquots of D-H2O, at which point

it will be dried with Magnesium Sulphate, anhydrate.

Then it will be allowed to contact some freshly recharged SilicaGell in the sep funnel for 5m then transferred to the distillation flask

Completion of this step it will then be distilled over sodium wire, at which point it will be ready for use for the extraction.

A note on handling:

During transfer I noticed it would surficate and pour off the bottom of the beaker even when using a rod to assist, it is very obnoxious on handling

due to this, I would recommend any intending to do the same avoid the use of beakers in favour of flasks & Sep funnels if at all possible due to

the way it will pour every where (I should have taken the hint when it did this pouring it out the can!)

1 Can will be slightly over 500Ml I estimate by the end of this due to handling losses and contaminant removal it will be at 500ml at the dot

[Edited on 9-10-2021 by XeonTheMGPony]

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

You could have a look at how toluene is cleaned with sulfuric acid, this is done by refluxing. I don't think cleaning works better with clean sulfuric

acid, so you could just use one aliquot of acid and prolonged standing or refluxing. No need to use multiple aliquots.

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

all depends on the target purity, my target is for very high purity other wise I wouldn't have bothered with it other then dumping from the can. there

is a very good reason why you use multiple smaller charges Vs one big one.

Each charge, removes and dilutes any contaminant, more effectively and efficiently, and as the old saying goes, crap in, crap out.

Since I intend to use this on a "consumable" product I will ensure it is as pure as one can, even if it means a drawn out tedious procedure.

|

|

|

unionised

International Hazard

Posts: 5128

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

Not according to my copy of Vogel.

Just shaking in a sep funnel is good enough.

Above 30C it starts to react.

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

With toluene, I used reflux as the procedure seems to take a long time, maybe the color gets darker after the extraction of the contaminants already

took place, but it keeps darkening for hours at reflux.

Quote: Originally posted by XeonTheMGPony  |

Each charge, removes and dilutes any contaminant, more effectively and efficiently, and as the old saying goes, crap in, crap out.

|

How do you know? This is how extraction works, but do you know this is an extraction? I think the contaminants actually react with acid, in which case

it doesn't matter how often you replace the acid and the time and temperature are far more important.

I really think you get a cleaner product when you raise the temperature. Sure you can replace the acid a couple of times, but you would have to cool

and heat a couple times as well when doing this at reflux.

Edit: it would be a simple test though; let the heptane/acid stand for a longer time, and see if the second aliquot gets the same color as when you

let the first stand for a shorter time.

[Edited on 9-10-2021 by Tsjerk]

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Quote: Originally posted by Tsjerk  | | With toluene, I used reflux as the procedure seems to take a long time, maybe the color gets darker after the extraction of the contaminants already

took place, but it keeps darkening for hours at reflux. |

I suppose there is an amount of water where toluene can in fact be refluxed with sulfuric acid without making toluenesulfonic acid. What exactly that

is IDK.

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

Yes, the procedure produces toluenesulfonic acid as a side product, which is a nice to have. The reaction is quite slow though, there always was a

sulfuric acid layer even after several hours of reflux.

When I needed clean toluene I distilled the toluene from the reaction mix after separation of the dark colored acid. To isolate the TsOH I added some

water to the flask to crystallize the TsOH as monohydrate

When I needed TsOH as catalyst in toluene I either refluxed for an amount of time before separation of dark acid, or I used clean toluene with the

TsOH.H2O and took the water off with a Dean Stark.

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

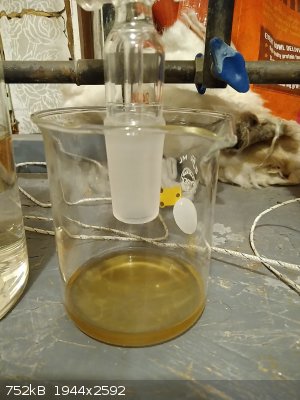

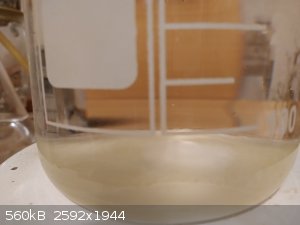

First picture is after first shaking sequence.

This is the second sequence

Third, be for, after

Here it is on the 6th aliquot stirring over night:

You can see it is no longer going brown orangish but rather simply a milky fogged look, at this point I move to the Acidified permanganate wash.

After left standing after several 30 second shakes no colour change observed thus it was given a rinse with distilled water after draining the

permanganate layer.

The combined Acid washes:

I didn't bother to photo the final rinse and neutralization washes as they where nothing to note, it was then dried and set up for distillation.

[Edited on 10-10-2021 by XeonTheMGPony]

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

This will be the Distilation post:

1 gram apx of sodium was cut and cleaned then put through a garlic press to make sodium wire (or as it turned out as sodium pellets and a funky

moulded sheet)

This was then charged into a 500ml flask (On hind site this was a very risky proposition, one good bump and would been catastrophic) Thankfully it was

a very stable well behaved distillation, befor hand the sodium was allowed to react under stirring for the day until it remained shinny.

First addition with some gentle warming

On stirring

The camera didn't catch it as well as I hoped but you can clearly see shinny spots IRL

Distilling into a bottle, I used the heads to clean the bottle

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

The Vacuum pump and controller

I went full scale hack more for it lol but it turned out rather nice looking and the controller proved to be nice and smooth at rpm control.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

There seems to be something in there that they're not telling you about.

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

Nice to see some photos!

@S.C. Wack: It is super technical grade, probably some sulfur containing stuff, some oxidizable crap and some more reducible crap, no idea what those

would be. The cleaning probably does a good job getting everything out that could react with your product.

Still, just saying, I think you could do this in a single reflux in an hour, after which you drain the acid, add the permanganate, drain, wash and

distill straight from sodium.

[Edited on 10-10-2021 by Tsjerk]

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

out of all the procedures I reviewed non said to do that, no offence but I will stick with the recommended procedure!

You can deff tell from the smell it is different, fresh from the can it has a sharp distinct smell all most alcoholic in a sense.

Now it is a much toned down soft scent of hydrocarbon.

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

Did the people recommending this procedure do any GC or MS on the "heptane"? I don't think so. The procedure is probably fine, but If I were so keen

on delivering a clean product as you are I wouldn't use cheap technical crap that turns brown with acid, reduces permanganate, and oxidized sodium

like your solvent does.Or if I would I would do it in less time you are doing it in.

|

|

|