Chemetix

Hazard to Others

Posts: 376

Registered: 23-9-2016

Location: Oztrayleeyah

Member Is Offline

Mood: Wavering between lucidity and madness

|

|

Knowing when to anneal glass: Checking for stress and avoiding cracking

Quote: Originally posted by macckone  | Annealing is critical.

And a propane only torch will work for small work and not well for that if using borosilicate.

For larger work you really need propane/oxygen so you can use a diffuse flame as Tsjerk suggested.

If you don't have a proper annealing oven you may want to use soft soda-lime glass.

An oven on high heat (500+) is sufficient to anneal small items of soft glass.

You cannot do a full anneal but it works better than nothing.

It isn't perfect but it is going to be better than unannealed borosilicate. |

Soda glass is terrible for working without annealing with a kiln. It will more than likely crack just heating it up. Since the aim is to produce a

small piece of crude apparatus, borosilicate is going to the best option to use. It will tolerate more abuse than soda.

Annealing, vs flame annealing?

Even in the glassblowing world there are constant battles over the nature of annealing and whether something must be annealed. The Purists will always

say you must anneal, always. Taking it to 565C for 10-15 minutes then cooling at no less than 300C per hour until 200C. Then it can come back to room

temperature at whatever speed it wants to.

In the scientific world we often use glass that has residual stress in it and it's perfectly fine. Glass to metal seals or even glass that transitions

from one type to another will always have stress in it.

You have to understand that there are certain ranges of stress to both the magnitude of the stress and its geometry that make it either acceptable or

not in the application. So I'm going to show some stresses in borosilicate glass and make some points about the different situations.

I've used a computer monitor and placed a polycarbonate sheet over it then used a polarizing film in from of my phone camera to get these shots.

Lets look at an item the OP is trying to produce by themselves with a small propane air jet torch. A small retort. Basically a sphere on a tube.

So there are a few coloured bands on the stem where there is some residual stress but otherwise the sphere is basically stress free. There sphere was

formed and a crude flame annealing was done. Those bands are relatively wide and the contrast between the colours isn't very high, all indicators that

the stress levels are low. The sphere is about 30mm diameter on a 10mm tube. Could you bend the neck and make a small retort and even use it? My guess

is yes. You wouldn't try to boil something like sulphuric acid where the risk of cracking with something that dangerous in it could occur. But water

or other low boiling solvents. Sure!

Below is an example where low stress is in a position where the geometry of the stress matters.

This is on a piece of 20 mm dia tube, and although the bands aren't particularly tight the angle makes the forces unlikely to be tolerated by the

glass when heated, the stress bands are making differences in the concentration of stress. At the top and bottom of the tube the stress is sort of

concentrated at where it is almost pinched by the angle as it wraps around the tube. At least in the first image the bands are geometrically

symmetrical. In this example there was no flame annealing, it was heated on one side more than another with a propane air flame to where it could be

bent slowly.

Both these examples are fairly light walled glass that is easy to flame anneal. When you start making more complex shapes and using thicker glass the

stress is much higher and so your flame annealing needs to be done with more attention to detail.

The next image is a 45mm tube with a 5 mm wall that has no flame annealing. It was a piece that had the end melted and pulled off. It was left to air

cool with no care to prevent cracking.

You can see the bands are tight and bright. There's large stress in this piece and it's only luck that it hasn't cracked. It might never crack or it

could start at any minute. But either way I doubt I could try to warm this up in a flame without it developing a crack. Putting it in a kiln and going

through an annealing cycle is the only way to get rid of the stress in this piece.

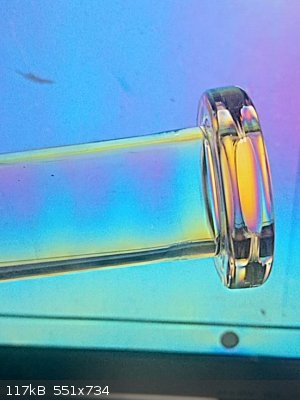

The next piece is an example of how a complex shape with thick glass has to be flame annealed and cooled slowly using a soft flame to ensure it will

survive after being formed.

The flange is 44mm dia and 10mm thick, it's on a 28 mm tube with a 2mm wall. This sort of shape with a thick right angle would not survive being

cooled down like the last piece. So in this case being careful with the rate of heating and cooling after a proper flame annealing treatment has left

only very slight stress in the glass. It will survive being reworked and added to a large flask as a flange port, then the whole item will be

annealed.

But the fact it was flame annealed to allow it to survive being made is testament to how annealing with a flame is to be done properly, if I didn't

know just what size and shape of flame to use I wouldn't have been able to make this item. I also use a bunsen burner to control the rate of cooling.

The points to be made here is that stress in glass has a range to it. Knowing when it's going to be important and when it's not important as the

situation dictates is a skill developed with some experience. By properly flame annealing you reduce the chance of the piece cracking before you can

see the stress using polarized light. And you might have made something will have some stress but not large enough and not in a position where it's

going to matter.

When you do start to want to produce more complex items then get a kiln and properly anneal at 565C.

|

|

|

Texium

|

Thread Moved

11-9-2021 at 07:44 |

Texium

|

Thread Topped

11-9-2021 at 07:44 |

Mateo_swe

National Hazard

Posts: 548

Registered: 24-8-2019

Location: Within EU

Member Is Offline

|

|

I have several times broken fritted filter funnels when cleaning them.

Sometimes not even hitting them, just by the temperature change.

I suspect they arent annealed correctly as i bought cheap china boro glassware on Ebay.

I have a ongoing project where i will build a hi-temp oven from heat resistant bricks and Kanthal resistance wire.

It would be controlled by either a microcontroller or an advanced temp. controller so ramp times can be set.

Could i put suspected weak glassware with internal stresses in the oven and anneal and make the glassware stronger?

The parameters below are from the top post.

Also, would i have to adjust the parameters depending on glass thickness?

Taking it to 565C for 10-15 minutes then cooling at no less than 300C per hour until 200C. Then it can come back to room temperature at whatever speed

it wants to.

[Edited on 2024-6-7 by Mateo_swe]

|

|

|

RedDwarf

Hazard to Others

Posts: 167

Registered: 16-2-2019

Location: UK (North West)

Member Is Offline

Mood: Variable

|

|

"then cooling at no less than 300C per hour until 200C"

I read this in both Chemetix and Mateo's posts - do you really mean "less", I was expecting there to be a maximum cooling rate not a minimum, and if

it is a minimum cooling rate, what is the reason for it?

|

|

|