| Pages:

1

..

12

13

14

15

16

..

68 |

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Here's a thought . Some of the bearing metal alloys

like Babbitt might be useful for casting liners . Some of the alloys could have the right combination of properties to give good performance and they

are low melting and

easily cast to form precision parts directly from the mold .

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

| Quote: | Originally posted by enhzflep

Well, here's the extent of my failures thus far. They're all 0.3/0.4mm with the exception of the one on the right which, was 1mm. My feeling is that

the failures are caused by incorrect technique and are excacerbated by insufficient friction, resulting in slipage between liner and mandrel(s). I

could always chuck a piece of bussines card on either side of the liner for that extra grip.

Any thoughts nitro? |

It surely is starting to look like a liner!  I think you are almost there...The

technique is mastered quick enough and is not really the cause of the failures. I also had a lot of trouble with "liner grip", which usually results

in tearing of the metal... I think you are almost there...The

technique is mastered quick enough and is not really the cause of the failures. I also had a lot of trouble with "liner grip", which usually results

in tearing of the metal...

Your biggest problem is the mandrel grip, and there is a very simple way to solve it. Just use smaller diameter circles in the beginning! Larger

circles can be done, but you really have to start in the middle, and work carefully through to the sides. With a large circle, the work arm, and thus

force, when pressed on the sides becomes larger than the grip of the mandrel can handle and it tends to slip or tear the metal...(been there  ) There is a minimal, "grip surface" to "metal circle diameter" ratio so to say that

allows good spinning... ) There is a minimal, "grip surface" to "metal circle diameter" ratio so to say that

allows good spinning...

Another very important thing is the mandrel-contramandrel fitting. When you firmly press your sheet metal between the mandrel and contramandrel, and

then get it out, there should be no vissible rings of excessive pressure be vissible, especially at the sides. This is where the metal is pressed too

thin, and eventually tears. The mandrel and contramandrel should fit together in a way that the pressure becomes evenly distributed over the entire

surface area of the fitting...

You can use sanding paper or a vile to make a more smoothly curved mandrel and contramandrel fitting...

And last, the steeper the angle of what you want to spin, the more chance at tearing. This is no problem if you have mastered spinning better, but

when I started, I did 60 deg. first with good results...

If you do want to make liners with 40 deg. then you just have to make sure that you don't thin the metal to a too great extend at the middle of the

circle, as this causes tearing. This is very simply overcome by:

1 Once the middle of the circle becomes attached to the

mandrel, don't work on the middle of the circle anymore!

2 For every few strokes from the middle to the sides, make a rowing sweep from the sides to the middle. By doing this

you bring extra metal towards the point which is streched

most (the middle), and prevents tearing...

[Edited on 3-5-2006 by nitro-genes]

|

|

|

Boomer

Hazard to Others

Posts: 190

Registered: 11-11-2005

Member Is Offline

Mood: No Mood

|

|

Microtek wrote: "The transmission velocity of the shock wave in air is equal to the speed of sound in air; ca 330 m/s. It is likely that a simple air

filled cavity would act like a shock tube ( much like the NONEL system ) to conduct a flamefront at ca 2000 m/s."

I don't think the shock will be limited to 330 m/s, since the air in front of the shock wave gets compressed (and therefore heated). My *guess* would

be 1500 m/s like the 'air gap speed' used to calculate a mixtures VoD below TMD.

Air or styrofoam will make no difference. Other inert stuff gets up to 6 km/s (from memory - there's a table e.g. in Cooper), but this is not what we

want (too thick lens needed).

Explosive lenses? This gets more and more professional me thinks....

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

| Quote: | Originally posted by Rosco Bodine

Here's a thought . Some of the bearing metal alloys

like Babbitt might be useful for casting liners . Some of the alloys could have the right combination of properties to give good performance and they

are low melting and

easily cast to form precision parts directly from the mold . |

US3255659 has some very interesting proposals in which the casting is made via powdered material - in an pressed mold format! Thus one could used most

any material in which is available in powdered form. From the patent the use of nickel powder had been quite successful and the mold easy to produce

in most any home workshop environment. The availablity of nickel, tin, copper and moly is easily found on the mil-surplus market (got about 40lbs

mixed samples for a few dollars of >325 mesh)

One issue I had found with spinning is the shape-tool end; it needs to be very smooth and rounded. My attempts were via a wood lathe and I used a

blunted chisel. The smoother I made it the better. I buffed the tip to a glass-like knob and found that spinning was much easier. But the adhestion of

the material to the bearing surface / mandel as pointed out previously WAS a problem. The best method I found was posted here; the use of a nut/bolt

arrangment central to the work. I may try some copper this weekend as I feel much more comfortable now after messing with it for a dozen time or so.

The alternative of forming via sheet metal has been less than clean geometrically but it DOES work. The energetic material however becomes more and

more a significant issue in what I have seen and that factor has promise the more varied attempts I see.

|

|

|

Microtek

National Hazard

Posts: 872

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

I don't think there is much mass transport through the shock front, so I don't think there will be any noticeable compression of the air in front of

the shock wave. At least, not by the shock wave in the air. Anyway, as long as the speed is significantly below that of the VOD of

the explosive, that is all that matters.

I've seen a high speed xray video of such a charge going off, and it detonates as if there is no propagation through the cavity.

|

|

|

panoptic

Harmless

Posts: 10

Registered: 3-5-2006

Member Is Offline

Mood: No Mood

|

|

And thus they stumbled upon the channel effect...

To be fair, the channel effect will have a run up distance and a critical diameter (may not happen in large diameter cavities).

If you wanted to further decrease the density of a plastic wave shaper, possibly microspheres could be used.

I hope someone will eventually be able to reproduce the Zukas book.

[Edited on 3-5-2006 by panoptic]

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

| Quote: | Originally posted by NBK

Since when does 6 lines = 17 lines? Please point out the error in this math.

|

It counts as 17 in the quote box here. Even six you must admit is disproportionate and still makes the point.

The letter count is roughly 48 to 440, just as significant FYI.

| Quote: | | I certainly don't expect people to trip over themselves to welcome me here, but I'd also expect people to acknowledge that I'm not some n00b idiot

who's got nothing to add to the discussion, either. |

Heh, well, the very nature of this quoted statement suggests that you very much so do want us to roll out the red carpet and bow down for your

entrance. Not good form for anyone, I'm afraid.

Also, I count 19 lines on the subject in your reply, consistent with your other reply. I would observe you have a definite fixation on this, hmm?

| Quote: | Research by the Buerau of Mines showed that rough sand-cast iron liners, cleaned of sprue and other such gross remenants of casting by simple fileing,

penetrated to near-similiar depths as machined liners.

The difference was in uniformity of the hole profile, with the rough liners creating 'pocked' holes, compared to the typically smooth holes made by

highly symetrical liners. |

Ah, good to know. Liners may be far cheaper and easier than thought, then

Tim

|

|

|

panoptic

Harmless

Posts: 10

Registered: 3-5-2006

Member Is Offline

Mood: No Mood

|

|

Peripheral initation of SCs is as I understand it to reduce the required explosive mass (the shock is spherical initially in a 'normal' SC) as well as

to cause a quicker collapse by having the wave front sweep over the liner during a shorter time span (not to mention the direction of the shock wave).

BTW, spun formed liners may supposedly generate rotating jets due to stress in the metal.

[Edited on 5-5-2006 by panoptic]

|

|

|

Polverone

Now celebrating 21 years of madness

Posts: 3186

Registered: 19-5-2002

Location: The Sunny Pacific Northwest

Member Is Offline

Mood: Waiting for spring

|

|

TAKE FURTHER VERBAL SQUABBLING TO EMAIL OR U2U

This thread is about shaped charges.

PGP Key and corresponding e-mail address

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

These are really incredible pictures! May I ask where you copied them from?

| Quote: | Originally posted by panoptic

BTW, spunn formed liners may supposedly generate rotating jets due to stress in the metal.

[Edited on 3-5-2006 by panoptic] |

I've read this before... Only axial rotations, no horizontal drift I believe. Do you also know what it exactly implicates for liner collaps and

performance? Quite amazing that with these incredible pressures and stresses, the small amount of internal stress in the liner can still have such an

effect on the jet...

[Edited on 3-5-2006 by nitro-genes]

|

|

|

a_bab

Hazard to Others

Posts: 458

Registered: 15-9-2002

Member Is Offline

Mood: Angry !!!!!111111...2?!

|

|

On the pictures subject, do you have the rest of them showing the full jet formed?

These are X-ray pictures obviously. You can see the progress of the detonation from the blasting cap to the charge. Nice indeed...

|

|

|

panoptic

Harmless

Posts: 10

Registered: 3-5-2006

Member Is Offline

Mood: No Mood

|

|

Here.

There is a wealth of information on the subject around, on the net, via accademic databases, in governmental databases, in patents, you name it.

Find a few documents, learn the terminology, find others by it.

BTW, I don't think it is x-ray (you see the expanding gases), I think it is cross sections and a high speed camera (possibly a linear charge).

Somone mentioned large casted liners, this is a spun cast copper liner with 0.7 m charge diameter (think military industrial complex, earth

penetrators).

(Sorry to clutter the thread with images)

[Edited on 5-5-2006 by panoptic]

Attachment: SC.pdf (750kB)

This file has been downloaded 3344 times

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

| Quote: | Originally posted by nitro-genes

These are really incredible pictures! May I ask where you copied them from?

|

The reference to Zukas book is the Fundementals of Shaped Charges.... it was available through the author who is a member of the ISEE and a working

professor at a university (in the mid-west I think). The thing is out of print now. Not even ISEE's Blaster's Library has it anymore (I think the

original source). It wasn't cheap. From the author it was $75. If you can find a copy even for more it may be worth it as it was a seminal work on

this issue.

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Yeah, would really like to have FoSC too... Axt is one of the proud owners of the book. Too bad about his strict policy concerning the scanning of

books. I mean, it is out of print and only 407 pages to scan, come on...

In an attempt to save explosive material, I tried to make a beehive charge from some pvc tubing, a plastic coffeespoon and the remaining PETN/Pib

(about 18 grams). I aligned every component as precise as I could, but it was still a failure... Only 3.8 cm penetration this time, and a very messy

entrance hole. I didn't even bother to post the pictures of the result, if anyone would like to see them, I might reconsider.

Anyways, this was the setup that was used:

The difficulty might not even be avoiding a miss-alignement of some sort, filling the charge correctly was just very diffcult as one might imagine. I

decided to fill the conical part of the plastic spoon and the part with the liner seperately and then glue them together. This made it very likely

that some airpockets remained where the two pieces were pressed together. Also, the conical coffeespoon part was very fexible, and thus not very

precise...

It's is quite a job I would say too make a perfect beehive charge, not to mention a charge containing a well functioning waveshaper lens. I still have

some NM left, so I might try a liquid type of HE (PLX) for this kind of experiments...

Ahh, well... At least the movieclip attached is somewhat entertaining.

If you look at the three frames that captured the actual detonation in the movieclip, I think you can see a assymetry in the upgoing sparks caused by

the jet at the right side.

[Edited on 5-5-2006 by nitro-genes]

Attachment: 25mm Beehive shaped charge compressed.avi (934kB)

This file has been downloaded 2041 times

|

|

|

NBK

Harmless

Posts: 7

Registered: 22-4-2006

Member Is Offline

Mood: No Mood

|

|

Go to this thread where you'll find a working Rapidshare download link and password for the PDF copy of FoSC that I scanned.

Thanks go to Axt for refusing to share, for otherwise I never would have bothered with it myself.

While the file has 'Excerpts' in the title, it's actually the entire useable contents of the book. The pages that I didn't scan were all computer code

for modeling, using hardware and programs that is either obsolete, or classified.

Polverone, if you want to add it to the SM library, go ahead. Just credit the source like the others.

Friends come and go, but enemies last a lifetime.

My PGP Key Fingerprint: 2453 AA75 C64D B418 7D36 FD45 E42D AF70 23A3 E16E

|

|

|

Deceitful_Frank

Hazard to Self

Posts: 82

Registered: 5-11-2005

Member Is Offline

Mood: Pensive

|

|

Nice little clip there nitro... I grabbed a couple of frames myself though I resisted the urge to post them up on this thread. The brightly lit ones

expecially impressive. That camcoder of yours must have some lens to close down quick enough to give such detail in the action AND the path, fence

bushes etc.

I'm presently looking for a camcorder myself. May I ask what make and model you use?

Anyway back to the topic!

You say that you had difficuly aligning the boat-tailing cone and this might have caused the assynetry in the detonation. IMHO it would be no harder

to align a central detonator than a central cone section. More likely the problem was in the filling of the charge.

Getting two sections perfectly full and gluing them together without air bubbles is nigh on impossble and with a device this small, all it would take

would be a small void on one side to slow the detonation wave and cause the cone to collapse unevenly.

As you appear to state... precision is critical

Thinking of using a liquid explosive... totally biased but you know what my favourite!

If you are making SCs more than 3-4cm diameter you might consider a 38:62 by mass blend of EGDN and NM. thats a 1:4 molar ratio.

This is balanced for CO and H20, has excellent gas output, density 1.26, 6600 m/s and at 145 kbar, 3/4 the detonation pressure of pure EGDN... but you

get 2.5 times as much!

Needs abit more of a kick in the ass to get it going than pure nitric ester but I believe the high amount of NM makes it bery resistant to LVD. Tested

100 grmas in 3.3cm diamter and when it goes... it REALLY goes!

Sure... lets see those damage pix.... and you gotta post that second lit frame too!

[Edited on 5-5-2006 by Deceitful_Frank]

[Edited on 5-5-2006 by Deceitful_Frank]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Here are the results:

The first picture from the left to the right is the entryhole in the first block of steel, 2.5 cm thick. In the bottom left corner a very strange

copper coloured spot can be seen, without any penetration.

The second picture is the exithole of the same block. Underneath I placed the 5 cm steel block that I used earlier, to get a total of 7.5 cm of steel

thickness.

What appeared most odd to me was that the exithole in the first block is about 8 mm in diameter, but the entryhole of the second block is only 3,5 mm!

The penetration hole through the 2,5 cm steel block had a very smooth

appearance though... The penetration hole through the 2,5 cm steel block had a very smooth

appearance though...

The two blocks were seperated only by a small piece of some kind of ceramic, about 2 mm thick, to make the two blocks level. I can't believe this can

be the cause of the sudden drop in hole diameter between the two blocks. Also note the strange copper stains surrounding the entry in the second

block...What has happened here?!

The two steel types were very much alike...

The movie was made with a digital camera, the canon powershot 540a. It can make 640 * 480 movies @ 30 fps or 320 * 240 @ 60 fps with 4 times optical

zoom. The images are great, but the sound is not very good, since it has a very small microphone. The deep lows are therefore enot very well

recorded...

[Edited on 5-5-2006 by nitro-genes]

|

|

|

enhzflep

Hazard to Others

Posts: 217

Registered: 9-4-2006

Member Is Offline

Mood: No Mood

|

|

Nice pics, as always nitro.

The spot in the first image has the same appearance as many of my failed attempts. Given the fact that I was mostly using hmtd, I always had a much

lower Vdet and pressure. I notice opposite this spot that there appears to be some 'ripples' for want of a better word. I speculate that it could in

fact be the location of carrot imapact. Did you find it this time?

You don't mention if the hole was covered by the ceramic, or if it was used as a shim. In either case without clamping the whole assembly together,

you are liable to suffer a huge preesure loss once the first block has been breeched.

In refference to the staining surrounding the 2nd entry hole - Notice that 'flaps' surrounding the exit hole have not just bent back to be

perpendicular to the face. They have in fact, continued to bend somewhat due to their momentum. This effect may well be enough to create a vacuum

stong enough to de-focus the jet, resulting in (a) the surrounding copper spray, (b)The pitted appearance of entry hole #2 and (c) the marked decrease

from ~8 to ~2.5 mm in hole diam, as the outer 'sheath' of the jet was whisked away.

Deceitful_Frank - The JVC Everio MG-50 is a pretty good camera. 720x576 @ 25fps(Pal) 29.997fps(NTSC) (interlaced, so there's 1/2 a frame 50 or 60

times a sec), 15x optical zoom, f1.2 lens , 48khz dolby sound, shutter speed to

1/4000 sec, etc, etc. Looks and sounds just the like the real thing. , 48khz dolby sound, shutter speed to

1/4000 sec, etc, etc. Looks and sounds just the like the real thing.

Depends on what (else)exactly you want the camera for.

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

| Quote: | Originally posted by nitro-genes

Here are the results:

Also note the strange copper stains surrounding the entry in the second block...What has happened here?!

The two steel types were very much alike...

|

It's hard to tell via pictures even good ones.....could that be the plug smear?

Your pics of explos show a black smoke, etc. (OB -) Have you been consistent, using the same explos material?

|

|

|

enhzflep

Hazard to Others

Posts: 217

Registered: 9-4-2006

Member Is Offline

Mood: No Mood

|

|

Fundamentals of Shaped Charges

| Quote: | Originally posted by NBK

Go to this thread where you'll find a working Rapidshare download link and password for the PDF copy of FoSC that I scanned.

|

For those of you unable to access the above link, here it is again

address: http://rapidshare.de/files/11491938/Excerpts_from_Fundamenta...

rar password: "http://www.roguesci.org"

Jerzy Urban ..... .....

-------------------------------------------------------------------------------------------------------------------------------------------

Who is Jerzy Urban?

|

|

|

enhzflep

Hazard to Others

Posts: 217

Registered: 9-4-2006

Member Is Offline

Mood: No Mood

|

|

Liner production

Was reading through some of the Los Alamos stuff today and came across what appears to be a magnificent description of the way to go about creating SC

liners.

Had pondered the idea of using my old 5ton kick-press (hydraulic rocket press would be fine too) for punching out liners, but was somewhat unsure of

how to go about designing the tools..... UNTIL I came across a declassified doc from the 70s that some of you may have seen before.

After wading through the copious refferences to cross-milling and micro-crystalline structure analysis, of the roughly 4mm thick

tantalum liners, the 17page document seems to boil down to

about 3 pages of what seems to be quite a good text. liners, the 17page document seems to boil down to

about 3 pages of what seems to be quite a good text.

It seems that once one has passed through the stage of tool development, that a liner may be produced in as little as 2-3mins, with no annealing and

virtually none, if any machining.

Even then, the toughest part for me would be the calculations and finalization of tool dimesnsions, once they were determined, tool manufacture would

be really quite quick and or cheap.

Having just dusted off my press and sourced some steel plate and bar, just thought I'd ask if anybody else has contemplated or utilized this method?

[Edited on 10-5-2006 by enhzflep]

Attachment: Punch Forming of Truncated cones.pdf (72kB)

This file has been downloaded 4110 times

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Drop forging would work nicely too , just heat the

disc shaped slug up to a plastic free forming

temperature and quickly transfer it to the forming die and

whack it with the drop hammer . Depending on

the number of forming strikes and the cooldown of

the part , the final blows can even work harden

the finished part .

|

|

|

enhzflep

Hazard to Others

Posts: 217

Registered: 9-4-2006

Member Is Offline

Mood: No Mood

|

|

The drop-forging method would also be very nice IMHO. With a potential of

reducing the number of job-specific tools needed for production. Not to mention

that pressing a button sure beats the hell out of swinging a fly-press, kicking a

kick-press, or smacking a tool (and trying to keep the bastard straight)with a hammer. This would be a much better way to go about producing liners.

That said, my aim is to do it as much as possible on a homework-shop scale.

In that case, removing the need to handle hot blanks would be nice, as would

doing without a drop-press. Sure, it's a few more tools to machine/pay to have

machined, but in my case - without free access to a drop-press, a greater number

of forming tools is the cheaper option for me. I.e couple a bucks for more steel,

+ $0 tool production, since I machine them all myself downstairs.

However, work hardening of the final part would be performed in either case,

with a corresponding increase in penetration...

|

|

|

enhzflep

Hazard to Others

Posts: 217

Registered: 9-4-2006

Member Is Offline

Mood: No Mood

|

|

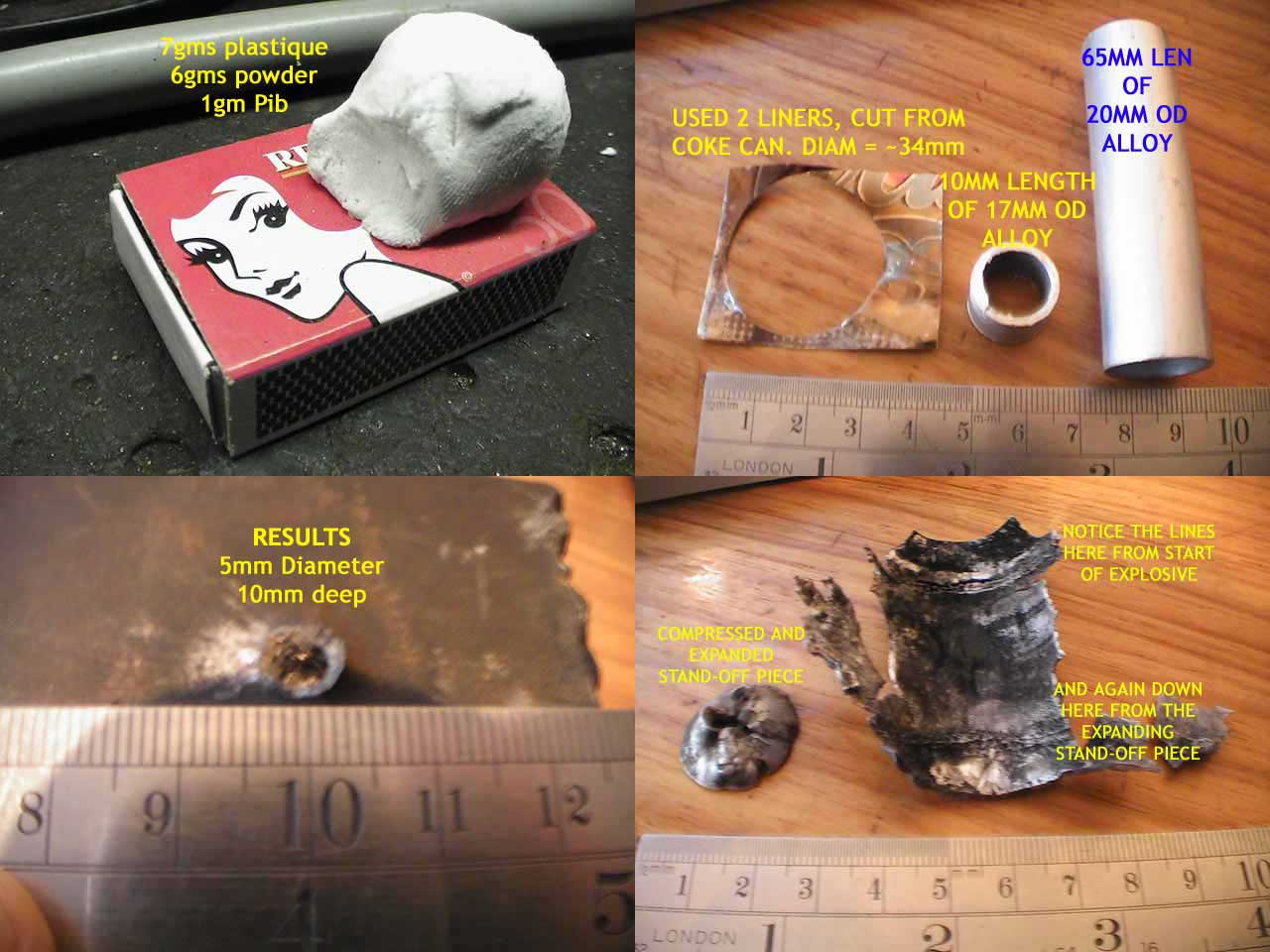

Effects of Plasticizing

Did another test last nite, involving the effects of plasticizing a

relatively low density powder. Typically, it's hard to get my

flavour of the month to much more than about 0.8g/cc. With a

TMD of around 1.56g/cc, I just had to be losing some

oomph, albeit for the sake of safety.

Having extracted some Pib(?) from Blu-Tak, I went about

plasticizing some HMTD. Managed to make about 7gms the first

time around, just using the HMTD that had stuck to the paper

toweling used to dry it after production.

Dissolved the sticky stuff (Pib?) from blu-tak with Shellite,

allowed all solids to settle, before eyedropper-ing about 3gms

of the resultant clear liquid into the HMTD, allowing to dry until

it weighed around 7gms, and smelled more like blue-tak than

shellite.

Upon a rough calculation of the new density, I was pleased to

find it was somewhere around 1.3! Not quite TMD, but one hell

of a lot closer than is feasible/safe to press it to dry.

First round saw me placing 7gms into a SC (as illustrated

below) and once again firing into 10mm hard-steel. I almost got

right through. I did however notice that the hole didn't taper in

diameter towards the bottom, as has been the case in previous

trials. The ground shock was also distinctly sharper and of less

duration.

Second round saw me placing a 3-4gm lump onto concrete

with no container, and the absolute smallest detonator I could

make. Think chinese firecracker fuse, with 1.5cm hmtd at one

end, initiated by a speck of Double salts at the black-powder

/Hmtd junction. This was then dipped twice in NC

laquer to exclude air and twisted tightly while drying, to a

diameter of 60thou - 1.5mm. 4 of them will fit inside a standard

'BIC crystal' ballpoint pen with the inards removed.

Ha. removed a triangular piece of concrete 2inches on each side

about 1/2 inch deep...

Now the thing that especially amazed me was: HMTD has a

really bad OB. Yet the +ive effect on VDet far outweighed the

-ve effect on OB. Light output was also reduced. But noise was

definitely better. Weird stuff.

So, 7gms of this, with a worse OB than straight Hmtd, and only

6 "active" grams in it was able to do greater damage - and more safely

to my steel plate than 7-8g straight. Makes the idea of using

copper liners with it seem feasible.........(+dirt cheap)

Note in the pictures that the Stand-off/liner retaining ring has

been crushed by the force on the colapsing cone. Makes one

think twice about just gluing the cone in place.

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

| Quote: | Originally posted by enhzflep

Having just dusted off my press and sourced some steel plate and bar, just thought I'd ask if anybody else has contemplated or utilized this method?

|

YES. I have thought of utilizing the copper end caps of copper home-utility pipe. The issue is how to create a series of levels or other progressive

stages in the hammer-forging process. We have all seen the stamping method of forming. It is used in cap production as well. The best of two worlds

would be met if one could stamp / forge a basic cone and then utilize a lathe to smoothe the form; taking care to aniel or in some way alter the

crystaline structure of the metal during this process. I was out of town on business and now that I am back I will attempt to play with this concept.

It appears to be workable via a wooden cone templet w/ differing levels.

One of the best methods of Plasticizing I have seen was created via the solvent of the base-plasticizing material. Let's say it's etoh: that was

used....the solvent was initially poured into a beaker along with a greater percentage of HE and -then- the plastic was added bit by bit to that

solvent, utilizing a teflon spatual to gently disolve the plastic through a figure eight pattern of movement. The order of addition was important as

it allowed the creation of a totally saturated plasticizing component which held more HE than simple addition of HE to plastic, etc. This then yielded

a PBX which was like the commercial in most respects. The result from that effort fit within a mold of the SC that was extremely effective when

compared to a simple press-fit of HE. In fact the PBX could be molded by hand to such a shape that it proformed a cutting action in and of itself on

concrete which astounded the observer.

[Edited on 15-5-2006 by quicksilver]

|

|

|

| Pages:

1

..

12

13

14

15

16

..

68 |