Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

mononitrophenols - nitration of phenol

Put 1,5 mol 30% HNO3 (I made it from 166 g of 57% HNO3 with density 1,3505 g/ml + 149 g H2O) into 1 L 2-neck RBF, add magnetic stirbar, dropping

funnel with pressure equalizing into one neck, thermometer into second neck, place the flask in ice-water bath onto a magnetic stirrer.

Liquefy 1 mol = 94,1 g of phenol with 20 ml water in 200 ml beaker (heat the reagent vessel with phenol above 41 C, pour the desired amount of phenol

from it into the beaker while weighing the beaker until reached the desired weight, add warm water, mix) and pour it into the dropping funnel. Attach

a hose to the hose connector of the dropping funnel to lead NOx gases out of the building or put the apparatus into fumehood.

Start stirring the 30% HNO3 and drop phenol into the reaction mixture at such a rate that the T is kept below 20 C (the reaction is exothermic, the

nitration itself and oxidative sidereactions). Even the first drop of phenol changes the color in the reaction mixture to yellow, further drops to

dark brown and soon the color becomes very dark. The phenol addition lasted for 2 hour. Then stir for extra 1 hour at T 20 C. I approximate the NOx

gas evolved at a scale 1-2 L.

Transfer into separatory funnel, separate bottom tar oily very viscous phase into a beaker (its volume is approx 100 ml), discard upper layer phase

(maybe it could be done in a less messy way by cooling to 0 C or even below 0 to such T where diluted acid still does not freeze but the thick oil

solidifies and then just pour out the waste HNO3). It is almost impossible to see the border of the 2 phases, but after the lower viscous phase

drained then the upper layer starts to flow more readily due to its much lower viscosity so you notice it when watching the stem of the separatory

funnel and when it drops out of the funnel it also creates eyes on the surface of already drained bottom oily layer. Washed 3 times with 250 ml ice

cold water, keeping bottom dark oily layer and discarding upper H2O layer. It is necessary to get rid of nitric acid.

Put the oil into 2 L RBF, add 1 L hot H2O, boiling chips, attach Liebig condenser with as much wide inner tube as you have. Start distilling.

2-nitrophenol creates intramolecular H bridges between -OH and -NO2 so its solubility in water is very low and its volatility by steam distillation is

high unlike 4-nitrophenol where the bridges are intermolecular. Water with o-nitrophenol distills, m.p. of the o-nitrophenol 44-45 C so it is better

to use warm water in condenser circulation, otherwise the product solidifies in the condenser - do not allow to obturate the condenser !!! Watch the

condenser carefully and if the obturation portend, stop the water circulation flow (it is good to do it every 10-15 minutes anyway) and allow the

steam to heat the condenser and melt the o-nitrophenol so it slides down to the receiver. Do not use take-off vacuum adapter with flask as a receiver

(adapter has a tube which is cold and too narrow), use a beaker instead so the condensate drops from the condenser directly into the beaker and you

have a good view into the inner tube of the condenser through its output end. It is also better to circulate the cooling water only so slowly that the

product is still melted in the beginning parts of the condenser. After more than 500 ml of condensate collected, decant the water and return it back

into the distillation flask and continue second round. Now after collecting 50 ml the amount of o-nitrophenol was significantly lower than in first

round, the condenser was cleaned by stopping circulation and allowing the small amount of 2-nitrophenol to melt and slide out of the condenser. Then

water circulation resumed and in 50 ml distillate only very little of 2-nitrophenol, condenser flushed by steam after stopping circulation, then

circulation resumed and no yellow solid product anymore, only yellowish drops of water without solidified 2-nitrophenol so the distillation finished.

Yellow solid 2-nitrophenol was crushed to smaller pieces and air dried. Do not dry it for too long, it seems to slowly sublime !!! Better to dry it in

a dessicator over CaCl2.

Yield 38,3 g. It has quite interesting scent.

4-nitrophenol.

Adjust the volume in distillation flask to 1 L, add 25 ml 35% HCl, heat upto boil to extract p-nitrophenol from the tar at the bottom of the flask.

When it starts to boil, turn the heating off, let to settle for 5 minutes (so the droplets of tar sink and coalesce with the tar at the bottom),

decant the solution into 2 L tall beaker carefully, so the tar stays in the distillation flask (use a lamp to shine through the flask to see the tar

at the bottom).

Everytime after heating to boil (to extract p-nitrophenol from the tar) allow it to somewhat cool down so the tar settles to the bottom, only then

decant into the tall beaker.

Filtering the hot solution with tar through filter paper to get rid of tar does not help, the filtrate is liquid just dark colored and on cooling down

the dark oil separates from the formerly clear liquid and the water phase becomes less dark. The solution of 4-nitrophenol on cooling just separates

into 2 phases: upper phase H2O saturated with 4-nitrophenol, bottom phase 4-nitrophenol saturated with H2O.

Cooling the solution was done by putting tall beaker into shallow cold water bath where only low part of the beaker submersed into the cooling water,

so the bottom phase solidified as first and only then crystallization started at some point when upper layer is further cooled down. Then put the

beaker into fridge (4 C) overnight.

You'll end up with a beaker in which there is solid dark thin bottom layer (few mm), then half of the beaker filled with nice needle shaped crystals

in mostly vertical position and upper half just mother liquor.

Return the mother liquor back into the flask by carefully decanting as much of it as possible, then carefully scrape the needle shaped crystals with

thick glass rod (it works very well) and store them for further purification and then break the low dark crystalline solid mass into pieces and return

them back into the flask (formerly liquid 4-nitrophenol phase saturared with H2O which later solidified).

This was repeated few times. The reason why not to use fresh clean water and returning dirty mother liquor back into the flask is due to the

significant solubility of 4-nitrophenol in water so the reason is to reduce product loses at the cost of some purity degradation.

The 4th cycle of extraction yielded only little of crystals.

15 g of black hard tar was discarded from the flask at the end (without any sign of crystals, just glass like black substance).

So the extraction was performed 4 times with 1 L of H2O + 25 ml 35% HCl, the mother liquor reused from the first extraction till the last 4th

extraction.

The formerly 1 L mother liquor (now little less volume due to loses on crystals) was kept as it was expected to contain maybe upto 10 g of the

4-nitrophenol (solubility at 15 C is 11 g / 1 L, at 4 C it is less but no info in literature).

The 4-nitrophenol needle-shaped crystals were recrystallized using 2 beakers and 500 ml 1% HCl (500 ml H2O + 10 ml 35% HCl) - but now the extraction

of the product was by warming only upto 50-60 C (not to the boil, it was possible to touch by hand, no thermometer used), decanting from first into

second beaker, cooling the bottom of the second beaker in shallow cold water bath, further cooling down to 4 C in a fridge for half a day, pouring the

mother liquor back into the first beaker with dirty product, scraping crystals from the second beaker, returning a little of solid mass from the

bottom of second beaker into first beaker. Again reusing the mother liquor due to significant solubility of the product in the water. Total 4

extractions+crystallizations performed, at the end only few grams of dark crystalline solid stayed in the bottom of second beaker which was extracted

again using the same cycle (5th cycle) and after drying it yielded 1,9 g of of crystals (5th cycle) with darker color than the main crop (cycles 1-4).

The first 4 crystallizations yielded 25,0 g of 4-nitrophenol after air drying it on filter paper. The formerly 500 ml of mother liquor was kept too.

The 1000 ml mother liquor from the first series of extractions kept aside was now extracted with 2x 100 ml of ethylacetate (second approach would be

to let it to evaporate and crystallize), ethylacetate layers were separated, added together, air evaporated outside during 3 days (some smell of

acetic acid due to hydrolysis of the ester observed) and the solid dark product was once recrystallized using the 500 ml mother liquor from the second

series of extractions. It yielded 6,6 g of 4-nitrophenol of poorer quality - visible as darker color than the main crop.

So the total yield of 4-nitrophenol was 33,5 grams of which 25,0 g the main crop and the 1,9 g + 6,6 g crops much darker crystals with lower purity.

The recrystallization from water acidified with HCl seems not to be the right way how to achieve good purity of the product but is capable to separate

the product from tar. Perhaps toluene could be used for further recrystallization or another solvent. One method uses diluted NaHSO3 solution for

recrystallization. There is a problem in alfa and beta modifications of crystals, one of them is not stable and light changes their color to red,

there is some temperature point where these 2 modifications wrap on crystallization.

The glass was cleared with diluted solution of NaOH.

Photos will follow in the second post. The third post will contain a lot of information I collected.

|

|

|

Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

apparatus: 1 L 2-neck RBF with 1,5 mol 30% HNO3, magnetic stirbar, thermometer with long stem, dropping funnel with phenol (only half of phenol due to

its insufficient volume only 50 ml, the second half of the phenol on the right side in the beaker), bath with water-ice, magnetic stirrer

first drop of phenol into diluted HNO3

NOx gases evolved so I connected the hose connector of dropping funnel to a hose to lead the gases outside of the building (total volume of gases

evolved during the whole nitration approximated to 1-2 liters)

washing the nitrophenols (bottom layer), this is the last washing where the upper water layer is not dark so the border of the 2 layers is well

visible, but when separating the nitrophenol from the waste nitric acid the border is not visible due to very dark color of the waste nitric acid (but

they have very different viscosities though)

draining the nitrophenols into RBF for steam distillation separation

steam distillation, watch the condenser and do not allow it to clog

if using cold water for circulation, turn it off every 10-15 minutes so the 2-nitrophenol melts and slides down to the beaker

after distilling off 500 ml of water from formerly 1 L water charged in the flask, the distillation was interrupted, water from beaker decanted and

returned back to the flask to continue the steam distillation (if I knew that it was almost done I would just further continue to distill more 150 ml

of distillate)

steam distillation done, no solid 2-nitrophenol in the condenser anymore (totally 650 ml of water distilled so far)

2-nitrophenol crushed to smaller pieces and air dried, it seems to slowly sublime, perhaps better to dry it in desiccator

crystals of 4-nitrophenol

crystals of 4-nitrophenol with lower purity and smaller amount on following cycles of extraction/crystallization

crystals of 4-nitrophenol with lowest purity and smallest amount on the last extraction/crystallization cycle

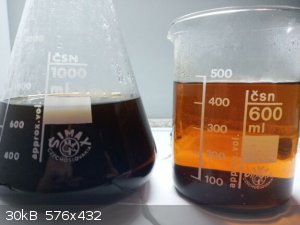

comparison of mother liquor which stayed after the first round of extraction/crystallization (left side, formerly 1 L volume somewhat reduced due to

loses on crystalls and evaporation on boiling) and solution in the second cycles of extractions/crystallizations (500 ml, right side, second round,

first extraction/crystallization, currently it is still warm and saturated with 4-nitrophenol - upper layer, the bottom layer is 4-nitrophenol

saturated with water, this is state before crystallization, it is going to be decanted into an empty beaker to let it to crystallize)

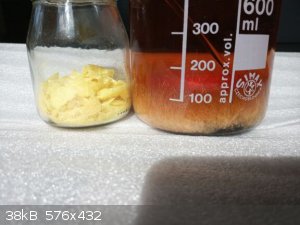

comparison of colors of solid 2-nitrophenol (yellow on the left side) and color of 4-nitrophenol (right side, there is still some solidified black

4-nitrophenol which was formerly liquid phase of 4-nitrophenol+H2O which later solidified on the bottom on cooling, then needle-shaped crystalls of

4-nitrophenol which are going to be collected, then mother liquor above them)

|

|

|

Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

now the complete mess of all info in case somebody wants to find something useful there

sidgwick1915.pdf

https://sci-hub.tw/https://doi.org/10.1039/CT9150701202

duff1929.pdf

https://doi.org/10.1039/JR9290002789

https://pubs.rsc.org/is/content/articlepdf/1929/jr/jr9290002...

https://sci-hub.tw/https://doi.org/10.1039/JR9290002789

97.png

https://books.google.cz/books?id=SPxbxns2NKMC&pg=SL3-PA9...

http://myweb.liu.edu/~nmatsuna/che122/exp19.pdf

hart1910.pdf

https://sci-hub.tw/https://pubs.acs.org/doi/pdf/10.1021/ja01...

https://www.oc-praktikum.de/nop/en/instructions/pdf/5001_en....

https://webcache.googleusercontent.com/search?q=cache:Za8LQu...

Attachment: 5001_en.pdf (212kB)

This file has been downloaded 494 times

Attachment: exp19.pdf (68kB)

This file has been downloaded 505 times

Attachment: hart1910.pdf (145kB)

This file has been downloaded 387 times

Attachment: prepchem.com_4-nitrophenol.zip (36kB)

This file has been downloaded 390 times

Attachment: duff1929.pdf (395kB)

This file has been downloaded 453 times

Attachment: p-nitrophenol_color_change.pdf (411kB)

This file has been downloaded 438 times

Attachment: sidgwick1915.pdf (630kB)

This file has been downloaded 447 times

Attachment: US3933929.pdf (445kB)

This file has been downloaded 397 times

https://onlinelibrary.wiley.com/doi/abs/10.1002/047084289X.r...

Purification: recystallization from toluene gives the metastable

α-form if performed at>63 ◦C; the β-form is obtained as yellow

prisms at <63 â—¦C.

Handling, Storage, and Precautions: the α-form is light stable,

whereas the yellow β-form gradually turns red in light. Moderately toxic by inhalation and skin absorption.

% of 4-nitrophenol in its saturated toluene solution:

https://sci-hub.tw/https://doi.org/10.1039/CT9150701202

sidgwick1915.pdf

5,60 % 62,4 C

6,54 % 66,3 C

9,99 % 72,2 C

14,22 % 77,1 C

22,41 % 82,6 C

26,40 % 84,5 C

34,67 % 87,7 C

44,45 % 90,0 C

49,96 % 91,0 C

61,50 % 93,8 C

68,69 % 95,8 C

79,80 % 100,2 C

89,98 % 105,4 C

100,00 % 113,8 C (m.p. of the 4-nitrophenol)

in the above pdf you can also find solubility of nitrophenols in water and solubility of water in 4-nitrophenol

duff1929.pdf

https://doi.org/10.1039/JR9290002789

https://pubs.rsc.org/is/content/articlepdf/1929/jr/jr9290002...

https://sci-hub.tw/https://doi.org/10.1039/JR9290002789

https://sci-hub.tw/https://pubs.rsc.org/en/content/articlela...

page 158

186. (( Note on EL colour change in P-paranitrophenol brought about

pNitropheno1 yields two modifications which have been examined

crystallographically by the author (Zeitsch. Kryst. Min., 1907, 44,

159). The two modifications possess great similarity in the values

of their prism angles; that they are quite distinct, however, follows

from the observed transformation of one into the other on heating

under the microscope. The transition temperature, if one really

exists, has not been accurately determined, but the author’s

observations would seem to point to a temperature of 63 C, for a

saturated toluene solution yields crystals of either modification

according as the temperature is above or below 63 C. That modification

which appears at high temperatures will henceforth be termed

α the other β.

The α-modification is almmt colourless, being of a very pale

lemon-yellow tint. The β-modification, on the other hand, is of a

pronounced yellow colour; but on allowing it to remain for some

time the crystals were found tlo acquire gradually a red tinge on

the surface. The α-crystals, on the other hand, preserved their

original tint.

Experiments were theref ore made under varying conditions, and

it was soon found that the red coloration appears only when the

crystals are exposed to sunlight. The brighter the light the quicker

is the change; in dull weather crystals may be exposed for many

days without any appreciable change, whilst on a bright day the

red coloration is apparent after an hour or so. Absolutely no

change takes place if the crystal be kept in the dark. A tube

which has been kept wrapped up in black paper presents no trace

of chmge, even after a lapse of seven years.

It was at first thought that the coloration might possibly be due

to the formation of an ammonium salt. That this is not the case

is proved by the fact that the change proceeds in a desiccator over

sulphuric acid, and again when the desiccator is filled with hydrogen

or carbon dioxide. The change, although quickly enough detected

by the eye, must in reality be a very slow process, since crystals

after some months’ exposure still present a yellow nucleus, and it

is likely that the red material acts as a protection against further

change by absorbing the aictinic rays.

It b very remarkable that the a-modification is wholly unactedon.

Of this there can be no doubt, as the following will show.

Solutions in water at the ordinary temperature yield crystals, the

great majority of which are those of the P-modification, but, in

addition, some crystals of the a-modification also appear. Owing

to the similarity in habit, it is often impossible without an

actual measurement on the goniometer to distinguish between

crystals of the two modifications. The whole of one crop thus

obtained was collected into a tube, and exposed to sunlight for

some time; all the crystals with the exception of two turned red

after a few hours. The action was allowed to proceed for a few

months; but even after this prolonged treatment the two crystals

still failed to show the slightest trace of change. They were there

fore taken out, and measured on the goniometer, and proved to be

crystals of the a-modification. A few of the red crystals selected

at random proved on measurement to be those of the P-modification.

Commercial p-nitrophenol consists of a mixture of both kinds of

crystals, and on examination it will generally be found that some

are red whilst others are not. The former are those of the

&modification.

Cases of colour change have previously been observed, but as far

as the author is aware, no case has previously been discovered in

which the change is restricted to one crystalline modification. At

prAsent the usually accepted view with regard to polymorphous

modifications is that the difference in crystalline form is not due

to a difference in the chemical molecule, but rather in the different

mode of packing of the molecules. The above remarkable difference

of behaviour, however, of the two ‘‘ polymorphous †modifications of

pnitrophenol would seem to argue for a difference in chemical

structure; it is difEcult to see how a mere difference in the

arrangement of the same chemical molecules should render one

crystal structure immune to the action of actinic rays. It is

therefore suggested that the chemical structures of the a- and

R-modifications of p-nitroghenol ar0 different.

https://patents.google.com/patent/US3933929A/en

In a purification process for p-nitrophenol obtained by nitration of phenol, separation of crude nitrophenols, steam distillation to remove

o-nitrophenol, and cooling the broth obtained when it contains more than 0.5% sodium bisulphite and is at pH 5.4 to 6.4 to deposit crystals of

p-nitrophenol, an improvement consists in stirring the crystals with water at 55°-85°C to give a mixture containing 10-40% excess of

p-nitrophenol over the solubility at that temperature, separating the upper layer of p-nitrophenol in water obtained, cooling it to 40°-50°C and

separating the layer of water in p-nitrophenol, cooling the latter to below 30°C and collecting the crystals deposited.

https://patentimages.storage.googleapis.com/df/ee/5e/f89d095...

https://chemistry.stackexchange.com/questions/13589/solubili...

3

p-Nitrophenol is actually modestly soluble in water at neutral pH (16 g/l at 25 °C) because of its weak acidity (pKa=7.16 at 22 °C) and the

formation of intermolecular hydrogen bonds between the phenolic OH group and water molecules. The latter would also explain why the compound dissolves

in diluted HClaq despite being protonated at lower pH values. The importance of intermolecular hydrogen bonds is also demonstrated by the

significantly lower solubility of the ortho isomer, which forms intramolecular hydrogen bonds and therefore appears to be less polar to the solvent

(source):

enter image description here

In basic solutions, p-nitrophenol is deprotonated to p-nitrophenolate. The anion is stabilized by delocalization of the negative charge into the

benzene ring and the electron-withdrawing nitro group (only two of the possible resonance structures are shown):

https://en.wikipedia.org/wiki/4-Nitrophenol

4-Nitrophenol

Melting point 113 to 114 °C (235 to 237 °F; 386 to 387 K)

Boiling point 279 °C (534 °F; 552 K)

Solubility in water

10 g/L (15 °C)

11.6 g/L (20 °C)

16 g/L (25 °C)

https://en.wikipedia.org/wiki/Nitrophenol

o-Nitrophenol (2-nitrophenol; OH and NO2 groups are neighboring; CAS number: 88-75-5), a yellow crystalline solid (m.p. 46 °C).

https://www.prepchem.com/synthesis-of-4-nitrophenol/

A mixture of 94 grams of phenol and 20 ml. water is added dropwise to a obtained solution containing of 150 grams of sodium nitrate dissolved in 400

ml. water and 250 grams of concentrated sulfuric acid. Good stirring is maintained during the addition, and the temperature is kept below 20°C.

Stirring is continued for 2 hours. The mother liquor is poured off from the tarry mixture of nitrophenols, and the tar is melted with 500 ml. water

with the addition of enough chalk to make the mixture neutral to litmus. The wash water is poured off and the washing repeated. The crude ortho and

para nitrophenols, freed from nitric acid, are subjected to steam distillation, using a condenser with a wide tube. About 40 grams of pure

o-nitrophenol distills over. The residue in the distillation flask is cooled and filtered after standing for 24 hours. The precipitate is boiled with

1 liter of 2% hydrochloric acid and filtered through a fluted filter. The pure p-nitrophenol crystallizes from the filtrate in nearly white, long

needles. The extraction can be repeated if necessary. The yield is about 40 grams each of the ortho-nitrophenol and para-nitrophenol isomers. It is

bad practice to treat the crude nitrophenols with sodium hydroxide, as called for in some procedures, because the sodium hydroxide has an immediate

resinifying action.

Physical Constants

Compound Mol. Wt (g/mol) Density

(g/mL)

b.p. (°C) m.p. (°C)

Phenol 94.11 1.071 182 40-42

Nitric acid 63.01 1.490 - -

p-Nitrophenol 139.11 1.270 279 113-115

o-Nitrophenol 139.11 1.495 214-215 44-45

Procedure:

Slowly add 10 mL concentrated nitric acid to 35 mL water in a 250 mL round

bottom flask using your medicine dropper. Insert your thermometer into the small neck,

using the red neoprene thermometer adapter to hold it securely.

Prepare an ice bath. The stockroom will provide pre-measured portions of phenol

(8.0 g) in 2 mL of water. Be careful to not get the phenol on your skin. It is a mild

irritant. It is advisable to wear disposable gloves for this experiment. They are provided

by the stockroom.

Add the phenol slowly in 1 mL portions (15-20 drops) to the nitric acid solution.

Maintain the temperature between 45-50°C. As you add each portion, swirl the flask to

ensure thorough mixing. The reaction is exothermic and you will need the ice bath for

cooling the reaction mixture. When all the phenol has been added, rinse the test tube

with 1 mL of water and add this rinse to the reaction mixture if needed. Allow the

reaction mixture to stand for 10 minutes. The reaction mixture becomes very dark.

After 10 minutes, pour the dark, oily mixture into a separatory funnel. You want

to separate the oily layer that is on the bottom. Drain this into your 500 mL round bottom

flask. Sometimes it is very difficult to see where the bottom layer ends. You can drain

off a small portion and then add 10-15 mL water and swirl the separatory funnel. Drain

off a small portion of the oily solution and add 10 mL additional water. Usually at this

point it is possible to see a clear separation between the two layers.

This is a convenient place to stop if you are out of time. Usually this experiment

takes more than one laboratory period to complete.

Add 200 mL of water to the 500 mL flask and mark the total volume with a

marking pen on the outside of the flask. Set-up your apparatus for a simple distillation,

using 2 ground glass stoppers in the two extra joints of the three-necked round bottom,

the three-way adapter with your thermometer adapter (ground glass + rubber adapter) and

thermometer, your condensing column with water hoses, your vacuum adaptor and 400

mL beaker as the receiving flask (see Figure 3.3 for reference but note that you are using

the 500 mL 3-necked flask and you can use a Bunsen burner as a heat source if you

want).

Add 50 mL additional water and begin distilling. You will see a yellow liquid

coming over along with the water. This is ortho-nitrophenol. You must be careful

because it can solidify in the condensing column and block the column. YOU DO NOT

WANT TO HEAT A CLOSED SYSTEM!!! Usually it is necessary to turn off the cold

water going to the condensing column at some point so that the solid ortho-nitrophenol

can melt and slide down into your receiving flask. When this happens, turn the water

back on. Otherwise you will start to see steam coming out of your vacuum adaptor.

If the total volume in your distilling flask falls below the 200 mL mark, then turn

off the heat, add 20-30 mL more water and continue your distillation until no more

yellow oil comes over. The yellow oil will solidify. Collect it by filtration, grind it with

a mortar and pestle and let it dry. Obtain the weight and calculate the percent yield as if

the theoretical yield were 100% ortho. Take the melting point.

To isolate the para- isomer, adjust the volume of the residual liquids in the

distilling flask to a total of 200 mL. You may need to remove more water by distillation

or to add more water. Add 0.5 g of decolorizing charcoal to the residual liquid and reheat

to boiling for one minute. Filter into your 400 mL beaker using a coarse fluted filter

paper and your stemless funnel. You want to work as quickly as possible so that the solid

para-nitrophenol does not solidify/crystallize on the filter paper. All you are trying to

remove at this point is the charcoal. Many types of colored impurities will adhere to the

charcoal and be removed by filtration.

Once you have filtered off the charcoal, cool the 400 mL flask as rapidly as

possible in order to obtain crystals. Sometimes this can be tricky. Collect the crystals by

suction filtration, dry them, get the weight and melting point and calculate the percent

yield of each product.

You can easily remove the oily residue on your glassware using dilute sodium

hydroxide solution.

Remove any larger pieces of the tar-like residue using your spatula,

then add a few mL of dilute NaOH and swirl the flask, using your brush. Flush with

clean water. Please leave your glassware CLEAN when you check out of the lab.

https://shodhganga.inflibnet.ac.in/bitstream/10603/133545/11...

https://sci-hub.tw/https://pubs.acs.org/doi/pdf/10.1021/ja01...

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

Hi Fery, thanks for the detailed description! I might found your preparation useful. :-)

What is "quite interesting scent" regarding o-nitrophenol? Could you compare it to something? How would you describe it if it was possible?

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Nice work Fery and a really comprehensive write-up. I have often looked at this preparation and shied away from it because of the black tar. Though

just lately I have made a lot a tars of different coloures  . .

|

|

|

Cou

National Hazard

Posts: 958

Registered: 16-5-2013

Member Is Offline

Mood: Mad Scientist

|

|

epic x)

|

|

|

Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Boffis, yes this is the most messy nitration I have ever done. The nitration itself was OK, just the workup was very dirty and very slow (> 1

week). The slowness and the biggest problem - the crystallization of the para isomer (only http://myweb.liu.edu/~nmatsuna/che122/exp19.pdf

mentions laconic that the crystallization could be tricky, nothing else in any other sources about the difficulties, I had to research what the hell

happened and found answer in almost 100 years old documents which were hard to obtain). The para I obtained is not completely colorless... but one of

the 2 crystalline forms of para isomer changes color under light from colorless to red. Anyway the purity still OK for further syntheses, but there is

not too much to be done with it - reduction to p-aminophenol, reaction with monochloroacetic acid in alkaline environment to produce

p-nitroaryloxyacetic acid. Both orto and para could be used as acidobasic indicators. Orto has interesting scent and beautiful yellow color. In

alkaline their color intensity is devilishly saturated, even trace concentrations yellow, low concentrations already very dark. Para could be

researched for the 2 crystalline modifications, IIRC the temp 63 C (it is exactly in the sources I posted) is an edge where the crystallization of the

2 forms wraps. One of the crystalline form is light stable, the other one changes color to red on exposure to light (it is visible at some pictures I

posted, there where is red color + sunlight + shade). Really a lot of interesting surprises and challenges, definitely worth to be tried. I'm very

happy that I tried it, in most practical chemistry documents the synthesis and workup seems to be flawless, but the workup isn't, especially for the

para isomer. I still have 2 L of that "strange" 57% HNO3 (density 1,35) which is good for nitration of compounds easy to be nitrated like phenol and

naphtalene (I managed to use only 500 ml of it during past 20 years, so it was formerly 2,5 L). I have enough of common 65% in stock (density 1,4), I

just wanted to use that 57% for something.

[Edited on 5-6-2020 by Fery]

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Have you thought of trying the nitrosation route? I read somewhere that simple phenolic nitro compounds can sometime be preared by nitrosating the

phenol with sodium nitrite and any mineral acid followed by oxidation with 50% or "dilute" nitric acid. This method when applied to phenol results in

almost exclusively the para isomer. I have also seen a similar prep on o-cresol to give 2-methyl-4-nitrophenol but p-cresol does not react. This might

allow you to use up some of your lower strength nitric acid (or you could just add more conc sulphuric acid soak up the excess water!).

I think you are right about this being one of those preparations you do to improve your manipulation skills in the lab rather than to prepare the

compounds.

|

|

|

Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

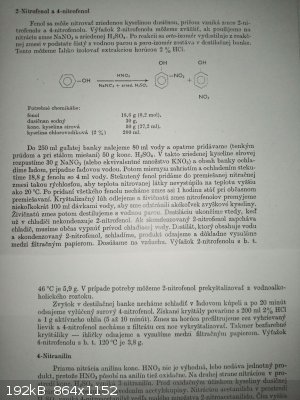

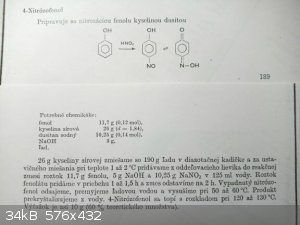

Boffis, cool idea. I think I'll manage to prepare the 4-nitrosophenol, I found this synthesis few pages later than the phenol nitration (picture

attached, sorry it is written in my language, if someone interested I can translate into English). Then oxidation using 50% HNO3 (not included in my

book).

Btw some NOx gases produced during the nitration of phenol which could catalyze this way into para position.

[Edited on 5-6-2020 by Fery]

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Hi Fery, I've found the nitro via nitroso-o-cresol. Check out pages 16 and 54, its in two separate preps in the attached book (I think this was

downloaded from the SM library. This oxidation used ferricyanide but I am sure I have seen one via nitric acid but thinking about it it may be for

dinitrosoresorcinol but I have papers for this. I'll dig them out if you would like to see them.

Attachment: 1B Advanced laboratory manual of organic chemistry M Heidelberger.pdf (934kB)

This file has been downloaded 443 times

|

|

|

Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Hi Boffis, thank you very much for the manual, I'll study it.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Maybe that's why the 1937 Gattermann crystallizes it as the sodium salt.

Quote: Originally posted by Boffis  | | I read somewhere that simple phenolic nitro compounds can sometime be preared by nitrosating the phenol with sodium nitrite and any mineral acid

followed by oxidation with 50% or "dilute" nitric acid. |

Another application of nitrite + sulfuric acid is to aniline, see e.g. Systematic Org Chem (where it's also used on salicylic acid, which is less

interesting).

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

@S.C. Wack; Thats an interesting route from aniline, I have not heard of this route before and thats an interesting book too.

@Fery; also check out Urbanski vol 1 p536-540 ish details are for resorcinol to 2,4-dinitroresorcinol but this is the nitric acid oxidation of a

nitroso compound.

I presume I downloaded both of these books from the SM liberary, if not they are widely mirrored.

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Found it! sort of..

In the Urbanski reference above at the bottom of page 475 it states that p-nitrophenol can be prepared by the oxidation of nitrosophenol with dilute

nitric acid but does not give a reference.

But check out the patent US 3933926, it used 26% nitric acid.

Attachment: Preparation of nitrophenols via nitroso compound oxidation US 3933926.pdf (685kB)

This file has been downloaded 415 times

|

|

|

Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Boffis, interesting... for those who need only 4-nitrophenol this is the best route!

|

|

|

Methyl.Magic

Hazard to Others

Posts: 139

Registered: 14-5-2007

Member Is Offline

Mood: No Mood

|

|

Really nice work with picture ! I really liked the isomer seperation , it is not so common: nowadays people uses indirect ways to have the correct

isomer. Or they simply bought them  That is ufortunatly what I do... That is ufortunatly what I do...

|

|

|

Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Hi Methyl.Magic, steam distillation is my favorite separation method. Due to intramolecular H-bound the ortho isomer is almost insoluble in water, has

low b.p. and distills well with steam. The para isomer forms intermolecular H bounds thus is better soluble in water, has higher b.p. and its

concentration in steam is very low and stays dissolved after steam condenses (solubility approx 10-15 g per 1 liter at 15-25 C). The ortho obtained by

steam distillation is really very pure. The pain is to purify the para isomer (problems described during crystallization, color change because of

light sensitivity etc).

In fact, what motivated me to perform this synthesis was something meant as a joke during the time of coronavirus lockdown. In my country, antifever

drug paracetamol was sold out during first 2 weeks and then all pharmacies usually exposed a big paper in their entrance doors that paracetamol is

unavailable. But 1 pharmacy in this difficult situation showed a sense of humor and posted on their internet pages that they do not have paracetamol,

but there is a method how to prepare it - nitration of phenol, separation the para-nitrophenol, reduction to para aminophenol, acylation with acetic

anhydride into acetaminophen (paracetamol). The lockdown is luckily gone, such drug with the acetaminophen was produced in enough quantities in few

weeks by another pharma company under different product name, and the cool idea of phenol nitration persisted in my mind, so I tried it.

|

|

|

Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

The 8,5 g of dirtiest last crop of 4-nitrophenol was recrystalled this way:

3,0 g dissolved in 50 ml hot toluene in 100 ml Erlenmayer flask, let to sit for few seconds and decanted into clean flask where allowed to slowly cool

down to room temperature

after cooling down it was decanted into dirty flask (only 40 ml now) and 3,0 g of dirty 4-nitrophenol added, heated until it dissolved (a lot of dark

tar stayed sticked at the bottom) and after few seconds decanted into second flask with purer product and allowed to slowly cool down to room

temperature

then decanted into first dirty flask (now only 30 ml of mother liquor) to which was added 10 ml of toluene to have total volume of 40 ml and last 2,5

g of dirty product, heated until dissolved, let to settle oily drops for few seconds and then decanted into second flask where allowed to cool down

that way most of the dark tar removed

25 ml of fresh toluene added into second flask so total volume 75 ml now, heated until everything dissolved and allowed to cool to room temperature

very slowly (thermally insulated)

it was NOT processed at once (8,5 g dirty 4-nitrophenol + 75 ml of toluene) but in 3 batches (3,0 g + 3,0 g + 2,5 g) because tar dissolves better in

solution richer on 4-nitrophenol and in 3 batches the concentration of 4-nitrophenol was always lower than in 1 batch (8,5 g nitrophenol + 75 ml

toluene) so the tar separated better (stayed sticked on the bottom of flask so it was easy to decant) - the same as with water purification (extracted

5 times not with boiling water where solubility of 4-nitrophenol higher together with higher solubility of the tar, but with water 50-70 C warm in

which 4-nitrophenol less soluble so the tar)

yield 7,8 g

the edge where the crystalline forms sensitive and insensitive to light wraps is 63 C, at that temperature the toluene solution of 4-nitrophenol is

approx 5 %, so the crystallization started from approx 10% solution at higher temperature to yield a mixture of both crystalline forms, in the picture

there are red crystals (photosensitive) which crystallized below the edge temperature and pale yellowish crystals which crystallized above the edge

temperature

I would like to try the 0,5% bisulphite pH 5,4-6,4 water purification method as the last idea with this preparation.

|

|

|

fdnjj6

Banned by request

Posts: 114

Registered: 20-2-2019

Member Is Offline

Mood: Pissed

|

|

Do you happen to know how to do this with toluene? I need mononitrotoluene and can't for the love of my life figure out how to make it using the

dilute (probably 40-50% HNO3) nitric acid or from sulfuric acid and a nitrate salt.

|

|

|

Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Hi fdnjj6, be patient, I'll synthesize mononitrotoluenes soon (perhaps in 1 year at most) to synthesize 2 and 4-amminobenzoic acids from it.

When you have such almost concentrated HNO3, you can use it with sulfuric acid. Concentrate sulfuric acid with boiling until it starts to decompose to

SO3, then you have 98% H2SO4 and mix with your HNO3 and then you can nitrate toluene. The pain is to seprate mononitrotoluenes, but when the final

goal are amminobenzoic acids, perhaps the orto could be steam distilled and para remains in distillation flask, but that I must try to figure out, it

is just my idea (the same as orto mononitrophenol is volatile with steam due to intramolecular H bridge I expect the same with orto amminobenzoic

acid).

|

|

|

fdnjj6

Banned by request

Posts: 114

Registered: 20-2-2019

Member Is Offline

Mood: Pissed

|

|

Quote: Originally posted by Fery  | Hi fdnjj6, be patient, I'll synthesize mononitrotoluenes soon (perhaps in 1 year at most) to synthesize 2 and 4-amminobenzoic acids from it.

When you have such almost concentrated HNO3, you can use it with sulfuric acid. Concentrate sulfuric acid with boiling until it starts to decompose to

SO3, then you have 98% H2SO4 and mix with your HNO3 and then you can nitrate toluene. The pain is to seprate mononitrotoluenes, but when the final

goal are amminobenzoic acids, perhaps the orto could be steam distilled and para remains in distillation flask, but that I must try to figure out, it

is just my idea (the same as orto mononitrophenol is volatile with steam due to intramolecular H bridge I expect the same with orto amminobenzoic

acid). |

I figured it out. Forgot you even responded. The nitration worked but the isomer separation requires a lab freezer to cool slowly and form larger

crystals as well as a vacuum pump that you don't care for. It ate away at mine and so I couldn't use it. 500mg yield from a theoretical 20 grams.

There goes benzocaine.

|

|

|

Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

0,5% Na bisulphite adjusted to pH 5,4-6,4 (I checked with digital pH meter) water purification method improved color of p-nitrophenol to white. Again,

it must be crystallized from not too much concentrated solution (otherwise oiling out, most of product then solidifies at bottom and only a little of

crystals adhering to it raising upwards). Dilution approximately such that half of the p-nitrophenol crystallizes and half stays in the mother liquor,

then adding impure p-nitrophenol into mother liquor and repeating. Pure crystals are obtained only after crystals sucked on sinter and washed with a

little of ice cold water on the filter. The washing merged with mother liquor. I did it at small scale only as an attempt which could fail (but it

didn't and revealed as viable) so 1 g crystallized and 1 g stayed in solution, then for every step I added 1 g of impure p-nitrophenol and repeated

the cycle.

|

|

|

|