Delta-R

Harmless

Posts: 16

Registered: 6-5-2018

Member Is Offline

|

|

Novel Nitrocellulose Preparation?

Can’t find any record of this preparation method in the literature anywhere but it yields highly nitrated itrocellulose at room temp, and better

yet, entirely as a byproduct of Fuming Nitric acid distillation - that is to say, if you’re going to be making fuming nitric acid anyway, this seems

like a possible way to harness the vapors that would otherwise go into a scrubber

Essentially the set up is a simple short vacuum distillation apparatus, with a stoichiometric ratio of Concentrated Nitric acid or a Nitrate salt plus

concentrated sulfuric acid in the distilling flask. The receiving flask is a 2 neck round bottom submerged in an ice bath, into which a thermometer

adapter is placed holding a glass tube which narrows down to a capillary. During distillation, a steady supply of dry ozone is passed through it,

bubbling up through the distillate, converting NO2 into nitric and nitrous acids. Attached to the vacuum takeoff on the receiving end is a tube

exiting into a cylinder packed with cellulose/cotton which all gases most pass through to exit - a disposable 50cc syringe minus the plunger works

well.

When the distillation is complete, the cotton is removed - Washing and drying steps are substantially the same as in the typical method of preparing

nitrocellulose. A highly nitrated cellulose is the end result, along with a clear fuming nitric acid, free of NO2 (although not quite WFNA however, as

it does contain a few percent H2O).

I’ve tried a few variations with no noticeable differences, including cranking the temperature up and doing a quick and dirty distillation, turning

the temperature way down and doing a very very slow distillation with lots of ice cooling, kno3, NaNO3, HNO3 - all yielded a pretty similar result.

Obviously it’s not groundbreaking research or something that will change the way home chemists make nitrocellulose but I thought it was interesting

nonetheless. What do you guys think?

|

|

|

Sulaiman

International Hazard

Posts: 3723

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

I think that you need a scrubber after your scrubber/converter.

For the cellulose-to-nitrocellulose reaction to go to completion you must inevitably have some of the gasses un-reacted hence escaping,

or have some cellulose not fully nitrated.

Also, I have not so far considered O3 as a simple gas to generate or manage.

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

Johnny Cappone

Hazard to Self

Posts: 74

Registered: 10-12-2020

Location: Brazil

Member Is Offline

|

|

It is one more possible route for this compound.

However, I believe that it has little or no applicability in amateur chemistry (even if some of us are experienced chemists with extremely

well-equipped laboratories).

Nitrocellulose was and still as my favorite EM, it is a great possibility to carry out your first organic nitration and to obtain a material of

properties well studied for the last 150 years. Boiled battery acid, saltpeter and cotton previously boiled in caustic soda solution. There is simply

no way to be simpler than that. I really don't see how anyone would want to complicate this, with the use of ozone and a not exactly trivial glassware

setup.

|

|

|

Delta-R

Harmless

Posts: 16

Registered: 6-5-2018

Member Is Offline

|

|

@Sulaiman- you’re correct, there is unreacted NO2(N2O2? HNO3? HNO2? O3?) making it all the way out the other end. The solution I came up with is to

make the cylinder into a sort of modified inverted funnel trap - the exit facing down into a small beaker which is sat in a salted ice bath at the

back of the fume hood. The vapors condense quickly and do a good job trapping anything that gets past — it produces ~30 mL of a yellow liquid per

~200ml RFNA. It looks nearly identical to the RFNA in the collection flask but interestingly enough, a quick latex glove test shows they’re very

different - almost no reaction aside from slight discoloration even after a milliliter or two compared to 1-2 drops of the RFNA in the collection

flask being enough to produce a rapid ignition.

@Johnny Cappone - completely agree yes the goal is making Nitrocellulose, then this is a completely over the top and needlessly complicated set up,

and like I said, I obviously couldn’t see anyone using this method instead of the normal Methods. I just thought it was interesting because I

haven’t seen it mentioned in any literature end it produces an extremely highly nitrated product. When fully dry, they produce some of the most

violent deflagration of any Nitrocellulose I’ve seen.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1411

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

In amateur practice, the second stage nitrocellulose is much more used, ie with a nitrogen content of 12.2 - 12.6 N. Especially as a binder and

sensitizer. Usually in the range of 1 - 10%. Which can be commercially available and stabilized.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Delta-R

Harmless

Posts: 16

Registered: 6-5-2018

Member Is Offline

|

|

Agreed - the samples that were left for the whole distillation were very highly nitrated - they do not dissolve in acetone, just leaving a clumpy,

fibrous mass, and they VIOLENTLY ignite and disappear with no ash whatsoever. However it seems you can tune the nitrogen content by reaction time, as

with standard procedures - if left in around an hour, you get a nice, fully acetone soluble product that still burns quite rapidly and completely.

Side question- I was just exploring this a bit more and walked away for a few minutes only to come back with a collection flask full of white

precipitate. My first thought was sodium nitrate boiled over but nothing in the condenser or any other glassware. I also noticed this in the

condensate collecting from the exit of the cylinder. The solution was cold. When I added H2O, I got rapid bubbling and NO2 production, everything

quickly dissolved and the resulting liquid was heavily acidic. I also noticed this only forms in nearly anhydrous conditions and won’t form in less

concentrated distillates AND when it’s present, no amount of ozone will clear the RFNA up, however when diluted, o3 clears it up rapidly. Is it safe

to assume this is N2O5/nitrogen pentoxide being created by interaction of ozone on NO2/N2O4?

|

|

|

B(a)P

International Hazard

Posts: 1139

Registered: 29-9-2019

Member Is Offline

Mood: Festive

|

|

Quote: Originally posted by Delta-R  | | Agreed - the samples that were left for the whole distillation were very highly nitrated - they do not dissolve in acetone, just leaving a clumpy,

fibrous mass, and they VIOLENTLY ignite and disappear with no ash whatsoever. |

Doesn't highly nitrated cellulose dissolve in acetone?

|

|

|

Johnny Cappone

Hazard to Self

Posts: 74

Registered: 10-12-2020

Location: Brazil

Member Is Offline

|

|

Quote: Originally posted by B(a)P  | Quote: Originally posted by Delta-R  | | Agreed - the samples that were left for the whole distillation were very highly nitrated - they do not dissolve in acetone, just leaving a clumpy,

fibrous mass, and they VIOLENTLY ignite and disappear with no ash whatsoever. |

Doesn't highly nitrated cellulose dissolve in acetone? |

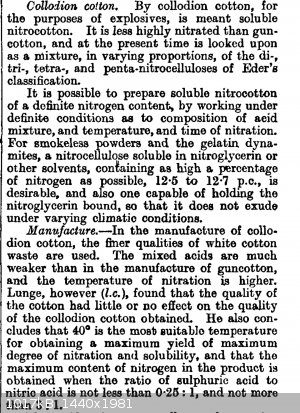

See the attached image. "A Dictionary of Applied Chemistry Volume II", 1919, page 461. This encyclopedia devotes a lot of space to the properties of

nitrocellulose (and it is a very pleasant reading about how chemistry was done on a laboratory and industrial scale at the beginning of the last

century. It contains many routes and information on numerous useful compounds)

|

|

|

B(a)P

International Hazard

Posts: 1139

Registered: 29-9-2019

Member Is Offline

Mood: Festive

|

|

Quote: Originally posted by Johnny Cappone  |

See the attached image. "A Dictionary of Applied Chemistry Volume II", 1919, page 461. This encyclopedia devotes a lot of space to the properties of

nitrocellulose (and it is a very pleasant reading about how chemistry was done on a laboratory and industrial scale at the beginning of the last

century. It contains many routes and information on numerous useful compounds)

|

I didn't see a reference to acetone solubility in that clip? Thanks for the pointer though, I will check that text out.

Nitrocellulose Industry, Worden, 1911 (in the SM library) indicates that di, tri, tetra and penta nitrocellulose are all soluble in acetone.

|

|

|

Johnny Cappone

Hazard to Self

Posts: 74

Registered: 10-12-2020

Location: Brazil

Member Is Offline

|

|

I came across a text in this same book ("A Dictionary of Applied Chemistry, Volume II) that spoke exactly about the solubility of nitrocellulose due

to the nitrogen content, I just couldn't find it.

Delta-R's report when saying that "[...]the samples that were left for the whole distillation were very highly nitrated - they do not dissolve in

acetone, just leaving a clumpy, fibrous mass[...]" seems to be compatible with what I have already read in the literature, the fact that a given mass

of nitrocellulose is usually composed of several esters, and that even when there is a predominance of one (higher nitration) or another (lower

nitration), traces of the esters at the other end are expected to still be present.

That is, even a low nitrogen nitrocellulose, purposely made this way to favor its solubility (as described in the image I provided in the previous

post) will still contain some highly nitrated cellulose, as well as in a highly nitrated cellulose like the one prepared by Delta-R there is still

some percentage of the ester with low nitrogen content, which would explain the formation of the sticky and spongy mixture, although the bulk of the

compound has not dissolved

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1411

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Nitrocellulose with a nitrogen content of 12.2 - 12.6% nitrogen forms with acetone in a ratio of 1:10 to form a liquid consistency as a varnish. 13%

forms (1:10) a liquid as thick as honey. 14% nitrogen and higher (1:10) will form a gel, or something like pudding. Acetone with a water content of

11% has the highest ability to dissolve nitrocellulose.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|