| Pages:

1

..

10

11

12

13

14

..

68 |

Chris The Great

Hazard to Others

Posts: 463

Registered: 29-10-2004

Location: Canada

Member Is Offline

Mood: No Mood

|

|

I'd say your main problem was your cap as you described, even with the much reduced standoff you would still get some penetration if the

charge fired properly. The lack of headroom is probably the main thing, even 0.25g of poor quality HMTD should have gotten at least a decent

detonation from the EGDN.

Also, make 100% sure that the cap is aligned perfectly with the rest of the charge, otherwise you end up with a nice big failure like me

|

|

|

Deceitful_Frank

Hazard to Self

Posts: 82

Registered: 5-11-2005

Member Is Offline

Mood: Pensive

|

|

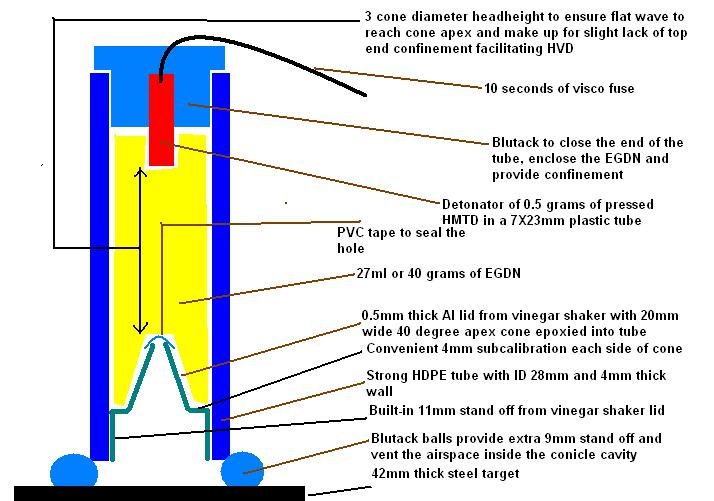

My second attempt.

Ok heres number two...

As you can see it has a better design.

Should be firing it within the next 3-4 so days.

Any thoughts or questions welcome

[Edited on 24-4-2006 by Deceitful_Frank]

[Edited on 24-4-2006 by Deceitful_Frank]

[Edited on 24-4-2006 by Deceitful_Frank]

|

|

|

enhzflep

Hazard to Others

Posts: 217

Registered: 9-4-2006

Member Is Offline

Mood: No Mood

|

|

Frank: Frank:

Ah-hah! Looks like a nice improvement. I too tried unsuccessfully many times using an external stand-off. It was not until i used an internal one

that i achieved any appreciable damage to the target.

However, i made the mistake of changing two variables at the one time. Namely the internal stand-off, in addition to the liner angle and mass.(Both

heavier and smaller included angle)

Interestingly - using a Blasting Jelly with a 1gm HMTD cap made of metal(Al) I was able to cause much less penetration (~1mm) than with 3/4 the amount

of HMTD, initiated with just 0.4gm HMTD placed in a flimsy drinking straw(~10mm penetration). In each case the detonator did not penetrate the charge,

but merely sat on top of the middle of it.

I too have more tests in mind(today). And will post the pics, and vids when done. They won't sound as good as yours since i will be testing under

40-50cm earth. Btw - How much do you reckon that steel thing weighed? It looks massive - and to see it jump about like that....

Once again - nice work.

|

|

|

enhzflep

Hazard to Others

Posts: 217

Registered: 9-4-2006

Member Is Offline

Mood: No Mood

|

|

Hmm,

I guess you do get what you pay for right?

Tried for many hours to spin a cone from both 0.3mm and 1.0mm

copper sheet and failed miserably. So, I tried a charge using a copper cone, the same as in a previous post I made. The only difference was that I

ignored 2 basic rules.

Firstly - the cone was rather thicker than it should have been. It was two layers of 0.25mm copper - instead of 3 layers of 0.1mm aluminium.

Secondly - the stand-off was only 0.25 Charge Diams, rather than the 1.5 I have used previously.

Result?

Frankly quite crap. I got at most 1-1.5mm penetration. This was even less than i got by using just 1gm in a 9mm tube with an internal stand-off of

10mm.(About 6mm penetration)

Calculating for the 1/7th penetration using 5 times the impulse I reckon that this was only 1/35th as efficient as my previously posted vid.

In short - obey established design rules and don't get sloppy. Oh well hope it gives somebody a laugh.

Attachment: Failure.wmv (889kB)

This file has been downloaded 1691 times

|

|

|

enhzflep

Hazard to Others

Posts: 217

Registered: 9-4-2006

Member Is Offline

Mood: No Mood

|

|

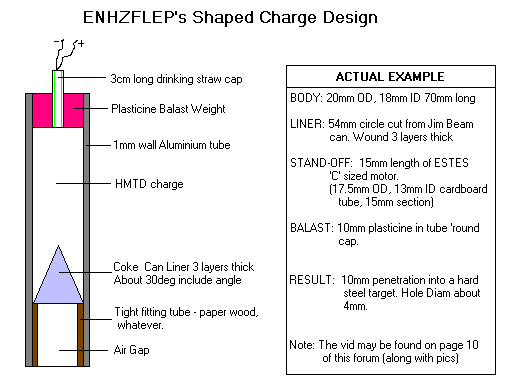

Those design rules i spoke of just above.

Like many things are best described with a picture.

enjoy enjoy

|

|

|

Deceitful_Frank

Hazard to Self

Posts: 82

Registered: 5-11-2005

Member Is Offline

Mood: Pensive

|

|

Thanks for your comments enhzflep

Yes, my second charge deffinately has the edge on build quality and design. I had cut an inch off the top of the tube to reduse its length and was

considering reattatching this to the bottom end where I had already glued in the Al vinegar shaker lid but my cheap hacksaw had resuced the cut edges

to a burred mess and the whole deal would not have been stable... scrapped that idea in favour of a few balls of blutack to increase the standoff to

1CD.

As for changing variables, my first attempt was such a pitiful failure I'm willing to try anything at this early stage!

As for your blasting gel/HMTD connundrum... 1g HMTD AL tube versus 0,4g HMTD plastic drinking straw? and HMTD versus BG? hmmmm, confusing. The only

sence I can make of this one is that NG containing gels at small diameters may well be LESS effective than HMTD! Remember that detonation pressure is

proportional to the SQUARE of the VoD. IIRC at small diameters NG or non-milky (containing no air occlusions) BG can go at a mediocre <2000m/s! If

pressed well, crystaline HMTD is very likely to go at its full 5000m/s so far as I'm aware.

LOL yes! I saw that too. Sadly on closer inspection you can see that its the camera that moves due to the shockwave. That steel must weigh well over a

tonne and I cant move it an inch by hand. I think its very unlikely that the downward force from 17ml EGDN could bounce it off its support.

Nice informative vid there!

Hey dont knock it too much... atleast you had SOME penetration though I spose the disappointment has more to do with the hours spent spinning the

cone.

Personally I've decided that I'm not going to bother making my own cones at this stage as it would involve too much time and effort. If I stuble

accross a prefabricated cone then I investigate a tube to fit around it.

Firstly I think that you got the cone thickness pretty good on as taking the 3-4% rule, for a 12mm CD this would give 0.36-0.48mm.

The standoff was indeed very short and wouldnt have allowed the jet to elongate and accelerate. Saying that you wouldnt want it to long either as

copper spray is even more useless against steel!

Lastly I noticed that you had you tube 3/4' full. It looks to me like its 10mm ID and about 80mm long so we can approximate the capacity as 62ml...

hmmm. surely the HMTD couldnt have been that un-dence?

Either way HMTD even at it MAXIMUM pressed density is only gonna give you approx 60kbar detonation pressure at BEST. EGDN gives nearly 200 and ANNM

around 110. Clearly there are better and indeed safer choices of maincharge for your experiments :

[Edited on 25-4-2006 by Deceitful_Frank]

|

|

|

Boomer

Hazard to Others

Posts: 190

Registered: 11-11-2005

Member Is Offline

Mood: No Mood

|

|

5 km/s for HMTD? In you wet dreams unless you press it in a hydraulic press, with heavy steel support around the pipe! I bet with hand pressing you

were at density 0.5 or lower, with det pressure of a mere 15 kbar. Thats about the *static* pressure of many HEs!

Using a vice (and NO HMTD!), I found that between 5 and 10 kPSI the pipe will expand/deform already. And this results in only 70-80% TMD (theoretical

maximum density = crystal density). For 90-95% TMD you need 30000+ PSI = hydraulics or a BIG vice for a small charge. Go calculate the volume and

weight before/after filling.

This is why a cast or plastic (or liquid) filler is best for home brew. The military has the pressing equipment needed, we dont. BTW I bet you had LVD

in the EGDN, hence no jet hole. Try a better cap next time, say 1g of something FAST (PETN/MHN) below the HMTD.

And no more primary main charges please! I want to hear more from you

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

| Quote: | Originally posted by Boomer

This is why a cast or plastic (or liquid) filler is best for home brew. The military has the pressing equipment needed, we dont. BTW I bet you had LVD

in the EGDN, hence no jet hole. Try a better cap next time, say 1g of something FAST (PETN/MHN) below the HMTD.

And no more primary main charges please! I want to hear more from you

|

I would have to agree that the filler is not only a safety issue but perhaps a serious stumbling block to effective penitration. The Los Alamos

material has been the source I have most depended upon for information outside the experiences of others and it seems that in their tests they demand

fillers that mantain high brisance via their composition and the use of plastics. A very simple and extremely effective (cheap too) plastic is ETN and

Styrene Butadiene. This in a 90:10 ratio is virtually the same feel and proformance as PETN / RDX - Styrene Butadiene. Absolutly no bubbles, fantastic

brisence, and safety. Essentially the same as a commercial product. Styrene Butadiene -=IS=- what has been used time and again in commercial plastics.

It molds so easily around the cone and interior, receiving the cap in a stable manner that consistency is maintained and one can concentrate on the

design element exclusivly!

|

|

|

enhzflep

Hazard to Others

Posts: 217

Registered: 9-4-2006

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Boomer

And no more primary main charges please! I want to hear more from you

|

Okay, okay. Point taken.

This will be the last one I post (& do with a primary  ) )

Its the smallest (and safest with this choice of filler) that i can do.

I usually make caps with more. I reckon that this had ~0.4-0.6gm of HMTD. Initiation was via a graphite powder slurry over the end of two exposed

wires (Hit with 320volts)

Btw - anybody had any luck obtaining erythritol in aus of late? apparently the TGA (therapeutic goods administration) has new

regulations which prevent the release of information on how to obtain it (according to www.hillsideherbal.com.au)

|

|

|

enhzflep

Hazard to Others

Posts: 217

Registered: 9-4-2006

Member Is Offline

Mood: No Mood

|

|

Failed  Attachment from above post. Attachment from above post.

Attachment: MicroSC.wmv (841kB)

This file has been downloaded 1707 times

|

|

|

enhzflep

Hazard to Others

Posts: 217

Registered: 9-4-2006

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Boomer

I bet with hand pressing you were at density 0.5 or lower, with det pressure of a mere 15 kbar. Thats about the *static* pressure of many HEs!

|

I take it you've not read pg 451 of COPAE?

Well here's an extract:

| Quote: |

Taylor and Rinkenbach found its true density (20°/20°) to be 1.57, its apparent density after being placed in a tube and tapped 0.66, and its

density after being compressed in a detonator capsule under a pressure of 2500 pounds per square inch only 0.91

It is not dead-pressed by a pressure of 11,000 pounds per square inch. |

Now then, 2500PSI = 1125kg square inch

or 1125kg for 6.45 square cm

Working on an column of 5.5mm diam

5.5mm diam = 0.238 square cm

(0.238/6.45) = 0.0368 (3.68% of a square inch)

so, 0.0368 * 1125kg = 41kg

Now, considering that i pressed at 20kg, i fail to see how this could even be guestimated at a density of 0.5 g/cc?

|

|

|

Chris The Great

Hazard to Others

Posts: 463

Registered: 29-10-2004

Location: Canada

Member Is Offline

Mood: No Mood

|

|

His point was that you aren't going to get near the expected 5100m/s detonation rate HMTD can get, which you had assumed you would.

For a main explosive that is a little easier than quickslivers great plastic explosive, I'd recommend (bias! bias! It is my favourite explosive)

methyl nitrate. The disadvantages are the high volatibility (bp ~65*C), the fact it causes nitro headaches, and the fact it is a very, very good

solvent. So you need to add it to the SC on site or you risk it eating through any plastic or glue. It is also a very low viscosity, it likes to get

out of what you put it in! I did find a polyethylene pop bottle to work great for transportation to the blast site, non-shattering and easy to pour

it out of. It is also EXTREMELY flammable.

The advantages are lower sensitivity than EGDN, incredibly easy synthesis, liquid, high detonation rate (8000m/s), a high detonation pressure (based

on compression tests, I estimate about 350kbar, higher than RDX! Which seems reasonable, since it is more brisant than RDX), very small critical

diamter (should get a high VoD even in a 10mm diameter metal tube) and extremely easy initiation, even a very weak cap with cause a high velocity

detonation.

|

|

|

enhzflep

Hazard to Others

Posts: 217

Registered: 9-4-2006

Member Is Offline

Mood: No Mood

|

|

Hmmmm, sounds good. I don't get nitro-headaches, so that's no issue. Yeah about that post. I apologize for the tone of it, and understood his point

(never mind the fact that i never expected anywhere near that VDet from HMTD. Just that that's what it's max is. 'twas actually frank that pointed out

the vdet.) I also much preffer more exotic things that HMTD, however with virtually no H2SO4 at the moment, my aim has simply been to improve the

design as much as possible using ultra cheap and nasty construction techniques. - it's just that this crap is all i have that goes bang at the moment.

I mean I do have about 4-4.2L left of 50% H2O2 and around 1.5 kg Hexamine just sitting about.

Spose i could always get some hobby fuel, then use the methanol for MethylNitrate and the Nitromethane for ANNM. Now that could be a good use of

chems. Only 5-10% useless oil in each purchase

I guess next experiment will be with the geometry and construction technique i have - but filled with a cast AN/HDN mix. Could be somewhat more

interesting and safe. After all this is just a hobby that i use to wind-down after work  that no-ones paying me for and actually costs money. that no-ones paying me for and actually costs money.

Oh, Chris btw - reviewed the last U2U i sent you. That big mess of stars was supposed to be a huge smilie ('case you wondered)

Finally - Managed to locate the cone used in the vid titled "Failure.wmv" check it out. The jet was retarded shamefully by the total lack of

stand-off.

|

|

|

Deceitful_Frank

Hazard to Self

Posts: 82

Registered: 5-11-2005

Member Is Offline

Mood: Pensive

|

|

Good stuff guys and yes it was I that assumed you could get full velocity from HMTD by hand pressing. Maybe I was typing with a little overenthusiasm

but boomer was right, even if he did labour his point abit

I'd just like to contadict Chrises third paragraph where he describes a few properties of his favourite explosive, methyl nitrate.

I've yet to synthesise MN but I as far as I was aware its MORE sensitive than EGDN. I'm not going to quote sourses and I may well be wrong but

whatever! This is just the opinion that I've gathered. Whether Chris can quote sources, or has used EGDN and can give a more reliable opinion than

me... I dont know.

Secondly, 8000m/s? this seems a little exaggerated to me. I thought urbanski and federoff quoted around 6800 as a maximum, to me this is far more

likely given its relatively low (1.21g/cm^3) density.

Maybe it can be over driven in extreme confinement with an 80 gram TNP cap like EGDN?! This is hardly practical if we are going to make use of is tiny

critical diameter for small and relatively safe experiments.

As for the matter of detonation pressure... 350Kbar... no way!

Using a well recognised formula to approximate detonation pressure for CHNO explosives with "normal" detonation products:

(VoD in m/s)^2 X Density in g/cm^2 X 2.5

-------------------------------------------------------------------

1,000,000

This gives a goood approximation of 140 kbar! Compare this to HIGHLY pressed RDX 340, EGDN 195, ANNM up to 110, HMTD up to 60 and pure NG... if you

are VERY VERY lucky, encase in steel with 3cm diameter and a strong cap, 235

Sure, on paper MN is great but lets not allow our emotions cloud the facts

enhzflep, nice pic of the recovered liner. Must be quite satisfying to see liner callapse for yourself in practice... reassures you that you are

deffinately on the right track!

[Edited on 26-4-2006 by Deceitful_Frank]

|

|

|

Chris The Great

Hazard to Others

Posts: 463

Registered: 29-10-2004

Location: Canada

Member Is Offline

Mood: No Mood

|

|

For the sensitivity, Urbanski gave 40cm vs 25cm for EGDN. Or it was PATR, one of the two. I have not been able to detonate mine with a hammer blow

on an anvil, even when soaked into paper. Seems pretty insensitive to me. I've seen some sources say otherwise, but they weren't as reputable as

Urbanski, so...

The formula is based on averaged the results, while it is accurate for most explosives, it doesn't work very well on methyl nitrate, as evidenced by

the fact it gives max at 6800m/s, while MeN has been measured at 8000m/s. Check PATR 2700. Urbanski gives the 8000 figure as well. I've seen some

conflict in the smaller diameter figures for it between Urbanski and COPAE, they both list the same source but have different measurements. Still,

those don't give the max, which is said to be 8000.

The 350kbar figure was from extrapolating the block compression figures for MeN, PETN, TNT, TNB and then based on the detonation pressures of those

(at the densities at which the tests where done), I got 360, 355, and 342kbar respectively for MeN. Since the plate dent test is pretty much a det

pressure test the result will be far more accurate than that of an empyrical formula. Sure, it won't be precise but the literally astounding brisance

test values for it make me think it is really in that range.

PATR 2700 gives 240% TNT for the plate cutting test and 185% TNT for the plate dent test, and 8000m/s for the VoD. Compare that to 130-140% for RDX

and PETN in most brisance tests vs TNT.

Now, if that isn't from a very high detonation pressure, then what? The actual, physical test results point towards and explosive with an 8000m/s VoD

and det pressure substantially greater than 300kbar, and I will take those figures over that of an empyrical formula, no matter how well recognized it

is.

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Unfortunately, I had only very little time too experiment with spinning this weekend. I did produce another nice cone however. It is slightly tulip

shaped, going from 60 deg. at the top to 55 deg. towards the base, with a diameter of 28 mm. In the picture it is glued to a piece of 32 mm diameter

pvc tubing that acts as a standoff. (55 mm long in this case, or ~2 times CD)

A pvc adapter piece is used as the explosive container with a pvc screwcap.

As the explosive filler is used 33 grams of PETN/pib with 82% PETN. ( I made 50 grams, 41 gram PETN with 9 grams of plasticizer) This ratio results in

plastique with better cohesive properties than the 85% and is also less stiff...It may kill the VoD a little more, but with this experiment I just

want to see wether the liner functions properly.

I ended up using a little more than the 25 gram I was aiming for, but this is due to the 2 mm subcalibration between the cone and the pvc adapter that

was not taken into account. I also measured the volume of the container with water before putting the plastique in and this was 23-24 ml. So density

is somewhere between 1,38 and 1,43 which is normal for homebrew...

I will probably fire it this friday at the earliest... (evenings for myself are a rarity these days  ) )

[Edited on 26-4-2006 by nitro-genes]

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

YEA! Now we're talking! That spinning is very addictive. But mine havn't gotten to the point that I want to show the world yet as I am working with on

Al (I don't have a lot of copper right now). It is more fun than I thought.

I personally am frightened of Methyl Nitrate. During WWII I believe it was used by the Germans as a last ditch explos and slave-labour was employed in

it's mfg. due to it's "sensitivity"

However it COULD be well behaved if soaked in a filler (a la dynamite). The headache issue is another can of worms. I have heard they are not of this

world. But the explos interest I have for plastics can't be denied. The latest issue from LA Labs is the use of VersaGel C-Series MSDS PEN13392 which

is essentially a Hydrocarbon polymer! This stuff is the binder for X-9094 and is gelled parrifin oil. Which was Cooper's ideal Hydrocarbon additive.

It -=IS=- available OTC from candle mfg concerns around the world. My agenda w/ plastics is that they fulfill the compaction nesessary to make the

concepts herein work. Now I suppose that one could also make a sort of plastic w/ HMTD but the whole idea of using peroxides is a scary proposition

but what's more I actually believe that there is a lack of consistency when using peroxides due to many features that carry along with their

particular sensitivity. One COULD make a dynamite that was consistent quite easily but a peroxcide has a very short window of response & activity

that was the same as when created. I realize that the attraction is the simplicity in manufacture but I think alternitives could be found. The

Cheddites may be an interesting thing to think over. The use of double-base-smokeless powder would also be worth a try. Either of these would permit

the experimenter a margin of safety that permits the focus to be on design - the primary concern.

Nitro-Genes: what's that plastizer you are using there? What are your experiences w/ same?

[Edited on 27-4-2006 by quicksilver]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

| Quote: | Originally posted by quicksilver

Now I suppose that one could also make a sort of plastic w/ HMTD but the whole idea of using peroxides is a scary proposition. |

PLEASE don't make a plastique out of HMTD or AP, especially not with any nitric esters! The stiffer the plastique is, the more pressure sensitive it

becomes. As soon as you start to press it..... Plastique from a organic peroxide, like HMTD, is MUCH more dangerous even than the original peroxide

alone.

There are so many better alternatives, ETN, EGDN, Methyl nitrate, MHN, NM based plastiques (>4 cm diameter), ANNMSA, PETN, RDX, R-salt, PA, TNT

etc, etc and even MAN...Surely one of these must be within reach?!

Btw I just got back at home, after doing a short visit at my friends house. I did only one spin and the result was an even smaller liner. It is about

23 mm in diameter and after a 10% HCL treatment it shines like a mirror!

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

That one looks to be close to perfect as far as I am concerned. What's the thickness of the material and what mandrill did you use; the same as the

above?

I have found what seems the perfect combination of channel and angle for a linear SC. They can be readily found for repair of screen doors! A thicker

material of Channel & Angle can be found in picture-frame mfg. - However the positioning of a detonator gives one pause. If the det on a LSC is

not centralized I believe the result may not be optimum.

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

I tested the 28 mm spun liner with the 82% PETN/Pib plastique today! Notice the 2 ml culture tube as a detonator.  It was filled with 1 gram 8/2 PETN/NG and initiated with 60 milligrams of a 50/50

silverazide/PETN coprecipitation with a little silver acetylide on top. It was a great succes, but some things about the results might need some

consideration... It was filled with 1 gram 8/2 PETN/NG and initiated with 60 milligrams of a 50/50

silverazide/PETN coprecipitation with a little silver acetylide on top. It was a great succes, but some things about the results might need some

consideration...

This was the setup on location:

I also made a movie of it with my new camera (attachment). I put it on my bike as a fixed support but the strong wind made it move

anyway...Unfortunately it is badly compressed also...

This was the result on the 5 cm steel block:

Entrance hole with the carrot still inside:

Entrance hole with the carrot removed:

Exit hole with piece of the carrot on the left:

There was also a larger hole in the ground, about 10 cm deep, but in my excitement I forgot to take a picture...

The entrance hole is really weird, the first 0,5 centimeter deep is like a funnel shape. Opening at 2 cm wide, but then 0,5 cm deeper it narrows down

to about 7 mm and stays relatively constant all the way down to the exit point on the other side... Anybody an idea why this is?! Maybe lack of

confinement?

[Edited on 29-4-2006 by nitro-genes]

Attachment: 28 mm copper shaped charge small compressed 3.avi (967kB)

This file has been downloaded 2679 times

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Just wanted to say this is a really nice picture!  Makes you think twice about

possible shrapnel... Makes you think twice about

possible shrapnel...

[Edited on 28-4-2006 by nitro-genes]

|

|

|

Deceitful_Frank

Hazard to Self

Posts: 82

Registered: 5-11-2005

Member Is Offline

Mood: Pensive

|

|

BRAVO!

About to hit the sack but just had to congratulate you on an excelllent job...

|

|

|

Fulmen

International Hazard

Posts: 1726

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

Truly outstanding work, Nitro. Really impressive performance, you've really proved that spinning cones is the way to go. As for the entry hole it's

probably due to the tulip-shaped apex.

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

This has prooved to be a really excellent thread and the contribution above (Nitro's) is wonderful in the sense that it really shows the SHAPE of the

hole and line utilized for that hole. The carrot is possibly the most interesting issue presented due to it's length. There are many unknowns in this

subject and actually if empirical evidence is taken from the above work I believe that there could be a substantial issue with the cone angle. Many

have proposed that 60 degrees is optiumum but I am beginning to think that there exists variences with what explos - vs - what angle is used, exists.

If a lower angle is used, could a slower explos get better results in a given test than if a steeper angle w/ same?

The point being that perhaps one does not require an ultra fast explos to create the disired effect if angle is altered for speed of explos.

PETN is some very fast stuff especially if one is dealing w/ plastics. We know from Munroe that NC could be used (smokeless powder, etc) and that

would be a given slower testable explos for such an experiment.

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

| Quote: | Originally posted by Fulmen

As for the entry hole it's probably due to the tulip-shaped apex. |

Yes of course... Now that you mention it, the tulip shaped glass liners showed

the same funnel-like-entry-holes indeed. Strange that Axt's mini-shaped charges made from the bullet jackets don't though, maybe PETN/Pib is too slow

for a entirely good focus at the base of the cone. Could be confinement too I think or too little explosive above the cone (headheight), since only

1,5 times cone diameter from the base was used instead of the 1,7 that is optimal... Now that you mention it, the tulip shaped glass liners showed

the same funnel-like-entry-holes indeed. Strange that Axt's mini-shaped charges made from the bullet jackets don't though, maybe PETN/Pib is too slow

for a entirely good focus at the base of the cone. Could be confinement too I think or too little explosive above the cone (headheight), since only

1,5 times cone diameter from the base was used instead of the 1,7 that is optimal...

Would be nice to see how different shapes, angles and VoD's affect penetration depth and the shape of the entrance hole indeed...

[Edited on 29-4-2006 by nitro-genes]

|

|

|

| Pages:

1

..

10

11

12

13

14

..

68 |