| Pages:

1

2 |

Opylation

Hazard to Others

Posts: 131

Registered: 30-8-2019

Member Is Offline

|

|

Diaphragm pump + aspirator no B.P. change?

Hello everyone,

I have a serious issue that has been bugging me for a few days. So I have had this diaphragm pump that I’ve been using for about a month or so in

series with an aspirator to provide vacuum. Now, it is the exact same pump nurdrage has on his video about the same device. Just for sake of

disclosure I’ll list the specifics labeled on the front of it.

Title: micro diaphragm pump

Voltage: DC12V

Power(Max): 60W

Pressure(Max): 0.8Mpa

Flow(Max): 5L/min

The device came with the power supply wires cut and soldered so I went ahead and bought a 12V 5A power supply and a female power cable to match the

male plug on the power supply. Soldered everything up and sealed each solder joint with heat shrinking electrical tubing and have the whole pump hung

up the side of a tote with magnets.

So I’ve been using this thing to pull a vacuum on my 250ml fritted disk Büchner funnel and it usually takes 15-30 seconds to run through a filled

funnel. Now the other night I tried to distill a high boiling viscous liquid under my aspiration vacuum and noticed that the B.P. was about the same

as what it would be at atmospheric pressure. I couldn’t be 100% accurate because my thermometer only marks to 200C but leaves space for about

another 100C and it was around what it should of been at atm. Anyways, this befuddled me. I finished the run anyways, losses a decent amount to high

temp polymerization, it was a disappointment.

Well, cut to today and I decided to run some water through my setup to calculate my systems pressure using the B.P. of water. I set everything up and

lo and behold B.P. is 100C. I’m watching the aspirator, which I have hanging below the water line and I’m not seeing any air bubbles being pushed

out the exit. When the system is benign depressurized I can see the water steam leaving the aspirator is turbulent with many many bubbles. But once

under vacuum, the exit stream is flowing but void of air.

Now, to make sure everything was alright I decided to thread each joint in the aspirator with ptfe tape to make sure there was no leakage. I also

removed the back flow stopper leading to the distillation system in case for some reason there was blockage. I noticed that the port on the aspirator

that leads to the distillation setup, that takeoff adapter was super glued, including the o-ring to the aspirator. I had to break that glue when I

took it apart to remove the back flow stopper. But I have made sure to leave a healthy amount of ptfe tape to make sure once again there is no

leakage.

Lastly, my distillation system is connect via ground glass joints. Joint size is 24/40 everywhere. I secure the joints seal with 2 rings of ptfe tape.

One at the bottom, once around, and one at the top, once around. I also make sure to give each joint a good twist to make sure it’s nice and snug.

Also, when I shut off the pump, water creeps up the tube connecting my aspirator to my distillation setup decently quick like it’s flowing from high

pressure to low pressure. All in all, everything is looking like it’s functioning properly, but boiling points do not lie. I am absolutely lost as

to why I’m not seeing even a single degree off of the regular boiling points of different liquids.

If anybody could help that would be amazing. I am at a loss as to why it seems to be producing pressure but not enough to affect B.P.

[Edited on 3-6-2020 by Opylation]

|

|

|

Ubya

International Hazard

Posts: 1247

Registered: 23-11-2017

Location: Rome-Italy

Member Is Offline

Mood: I'm a maddo scientisto!!!

|

|

well, it is strange, you said that you could not see any bubbles in the aspirator outlet, so it reached its maximum vacuum, but the boiling point

doesn't change.

the boiling point is pretty sensitive to ambient pressure, if you don't see even a 1 degree difference is odd.

---------------------------------------------------------------------

feel free to correct my grammar, or any mistakes i make

---------------------------------------------------------------------

|

|

|

Opylation

Hazard to Others

Posts: 131

Registered: 30-8-2019

Member Is Offline

|

|

I’m running the system without vacuum right now and the thermometer is running at 105C so it is a little bit over submerged. With that said, I guess

I was getting ~5C off of B.P. This is disappointing though as nurdrage was able to boil water at ambient temperature using ice cold water through his

pump/aspirator

|

|

|

Ubya

International Hazard

Posts: 1247

Registered: 23-11-2017

Location: Rome-Italy

Member Is Offline

Mood: I'm a maddo scientisto!!!

|

|

Quote: Originally posted by Opylation  | | I’m running the system without vacuum right now and the thermometer is running at 105C so it is a little bit over submerged. With that said, I guess

I was getting ~5C off of B.P. This is disappointing though as nurdrage was able to boil water at ambient temperature using ice cold water through his

pump/aspirator |

i have the same pump, and i could get water to boil at 70°C, it's not a great pump, maybe nurdrage got a good one and us got a cheaper and crappier

version with the same look, or our diaphragm pumps lie about their specs

---------------------------------------------------------------------

feel free to correct my grammar, or any mistakes i make

---------------------------------------------------------------------

|

|

|

Opylation

Hazard to Others

Posts: 131

Registered: 30-8-2019

Member Is Offline

|

|

Apparently. I guess it’s only pulling ~100mmHg under ambient pressure which is, as I said disappointing. I might throw in for a 3 gpm pump. We’ll

see. Especially if I’m not even seeing a dent on the b.p. of those high boiling liquids. I was hoping there was some sort of troubleshooting I could

do before having to dish out for a new pump. I just don’t know enough about these things to know if there even is anything wrong with it

[Edited on 3-6-2020 by Opylation]

|

|

|

Ubya

International Hazard

Posts: 1247

Registered: 23-11-2017

Location: Rome-Italy

Member Is Offline

Mood: I'm a maddo scientisto!!!

|

|

can you post a picture of the setup? maybe we can figure something out

---------------------------------------------------------------------

feel free to correct my grammar, or any mistakes i make

---------------------------------------------------------------------

|

|

|

Opylation

Hazard to Others

Posts: 131

Registered: 30-8-2019

Member Is Offline

|

|

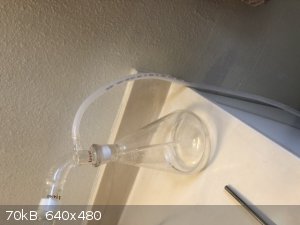

Yeah sure thing. The water is emptied hour of the aspirator system right now because it’s not in use. Just boiling some water to get a new supply of

distilled water but here are some pics of how it would look set up.

Uhh... not sure why the pictures are sideways. I hope it’s alright

Also, I went overkill with the ptfe tape to make sure it wasn’t a leakage issue

[Edited on 3-6-2020 by Opylation]

|

|

|

Ubya

International Hazard

Posts: 1247

Registered: 23-11-2017

Location: Rome-Italy

Member Is Offline

Mood: I'm a maddo scientisto!!!

|

|

mh you should connect a piece of tubing (20-30cm) to the outlet of the aspirator, and then put the end on the tubing a few cm underwater, it should

improve the system a bit

this is my setup

[Edited on 3-6-2020 by Ubya]

---------------------------------------------------------------------

feel free to correct my grammar, or any mistakes i make

---------------------------------------------------------------------

|

|

|

Opylation

Hazard to Others

Posts: 131

Registered: 30-8-2019

Member Is Offline

|

|

Normally the output is submerged below the water line so I can keep track of when the system has pulled its max vacuum. I did have a foot and a half

long rubber tube on the exit but I didn’t see a difference in the performance so I just removed it

|

|

|

beerwiz

Hazard to Others

Posts: 130

Registered: 6-2-2014

Member Is Offline

Mood: No Mood

|

|

The water in the tank needs to be cold. The problem with setups like yours is that the water heats up and the vacuum gets very weak. I've had all

kinds of rotary vanes, pump setups like yours, etc. I've spent thousands on pumps over the years. Now I just use an aspirator connected to the faucet,

it's perfect for vacuum distillations, and the cold water from the faucet runs at a constant temperature. Another benefit is that it's quiet and any

fumes get washed down the drain and you have no oil mist to deal with.

|

|

|

Ubya

International Hazard

Posts: 1247

Registered: 23-11-2017

Location: Rome-Italy

Member Is Offline

Mood: I'm a maddo scientisto!!!

|

|

Quote: Originally posted by beerwiz  | | The water in the tank needs to be cold. The problem with setups like yours is that the water heats up and the vacuum gets very weak. I've had all

kinds of rotary vanes, pump setups like yours, etc. I've spent thousands on pumps over the years. Now I just use an aspirator connected to the faucet,

it's perfect for vacuum distillations, and the cold water from the faucet runs at a constant temperature. Another benefit is that it's quiet and any

fumes get washed down the drain and you have no oil mist to deal with. |

ehhh if water was infinite and free (and i had a faucet near my hood).

even if it isn't for the money, a distillation of a few hours wastes a lot of water

---------------------------------------------------------------------

feel free to correct my grammar, or any mistakes i make

---------------------------------------------------------------------

|

|

|

Opylation

Hazard to Others

Posts: 131

Registered: 30-8-2019

Member Is Offline

|

|

The thing is I had ice in my vacuum water reservoir and it still wasn’t showing me any change on b.p. (This was when I was trying to vacuum distill

that high boiling liquid the other day) my thermometer was hitting around 250C, +-10C, right where it’s B.P. was. Even without cold water I feel

like I should at least get 30-40C off b.p., right?

|

|

|

Ubya

International Hazard

Posts: 1247

Registered: 23-11-2017

Location: Rome-Italy

Member Is Offline

Mood: I'm a maddo scientisto!!!

|

|

as a qulitative test, run the pump and put your thumb on the vacuum hose, feel the vacuum. now try with another piece of tubing, stick on end on your

mouth and start sucking while you have your thumb on the other end. with your mouth you can create more or less half a bar of negative pressure, if

your pump pulls less, you got an idea of your vacuum.

(if you can get a cheap vacuum meter is bettery, they are a few bucks on ebay)

---------------------------------------------------------------------

feel free to correct my grammar, or any mistakes i make

---------------------------------------------------------------------

|

|

|

Opylation

Hazard to Others

Posts: 131

Registered: 30-8-2019

Member Is Offline

|

|

So I tried that. I put the suction end on the top of my tongue... barely pulled anything. I felt it start pulling more and more vacuum for 10-15

seconds then, nothing, just stayed there. Honestly, wasn’t barely anything... I wonder if my pump is broken. Or, I watched a video where some vacuum

pumps have an auto feature for when they’re installed in RV’s and shit and when they meet a certain amount of resistance they turn off or turn the

flow rate down. Maybe that’s the case. I wonder if I can calibrate it

|

|

|

Opylation

Hazard to Others

Posts: 131

Registered: 30-8-2019

Member Is Offline

|

|

Now that I’m looking closer at my pump I think the whole thing is a fraudulent one. On the front facing display with all the info diaphragm is

spelled wrong...

|

|

|

monolithic

Hazard to Others

Posts: 436

Registered: 5-3-2018

Member Is Offline

Mood: No Mood

|

|

Trying orienting your aspirator so it is ejecting water straight down.

|

|

|

Opylation

Hazard to Others

Posts: 131

Registered: 30-8-2019

Member Is Offline

|

|

I’m thinking about maybe trying to get a different motor for it. Cause the pump works, it’s just only pull a very weak vacuum. The motor inside it

was a ghs-775ph-4458xx I can’t remember exactly but if I get a motor with more torque it should be able to pull more of a vacuum

|

|

|

Opylation

Hazard to Others

Posts: 131

Registered: 30-8-2019

Member Is Offline

|

|

Could it be my aspirator? Because now that I think about it I see people connect aspirators to faucets that couldn’t have a greater flow rate than

the pump I have. When i first got my aspirator, I noticed the o-ring was super glued on the vacuum take-off port and I broke the seal when unscrewing

the port. I got more super glue a little bit ago and re-glued it to make sure the seal was fine. When I took the thing apart to re-glue it I noticed

my jet nozzle was skewed, about a single radius Of the jet nozzle distance off of the exit port. Another way to say it is looking down the jet nozzle

leading to the exit nozzle only half of the jet hole lined up with the exit hole. Does this reduce the vacuum generated?

[Edited on 5-6-2020 by Opylation]

|

|

|

Sulaiman

International Hazard

Posts: 3724

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

Try connecting your aspirator to a faucet and see if it works as expected.

If yes then the pump is inadequate,

if not then the aspirator is faulty.

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

Opylation

Hazard to Others

Posts: 131

Registered: 30-8-2019

Member Is Offline

|

|

Are diaphragm pumps supposed to be loud? It’s been running at 65-70dB since I got it. I was looking at other pumps online that look the exact same

and they’re rated as quiet

|

|

|

Sulaiman

International Hazard

Posts: 3724

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

Did you make the sound level measurement at 1m from the pump ?

None of my pumps are 'quiet' (I have many types)

Have you tried the aspirator on a faucet yet ?

with and without a pipe/tube on the outlet.

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

Ubya

International Hazard

Posts: 1247

Registered: 23-11-2017

Location: Rome-Italy

Member Is Offline

Mood: I'm a maddo scientisto!!!

|

|

Quote: Originally posted by Opylation  | | Are diaphragm pumps supposed to be loud? It’s been running at 65-70dB since I got it. I was looking at other pumps online that look the exact same

and they’re rated as quiet |

no they are not quite, mine is pretty loud, and the vibrations get even amplified by my hood. i plan on mounting the whole pump/water tank on

vibration absorbing material and soft things so to muffle the sound a bit

---------------------------------------------------------------------

feel free to correct my grammar, or any mistakes i make

---------------------------------------------------------------------

|

|

|

Opylation

Hazard to Others

Posts: 131

Registered: 30-8-2019

Member Is Offline

|

|

Okay, I was just curious if my pump came damaged or something. Well, I did a test and if the flow is blocked the pump is able to build up decent

pressure. Enough pressure to break my ptfe seal to my aspirator so I’m gonna look for an adapter to connect the 18mm threading to the 3/8”

compression fitting on my aspirator. I’m not familiar at all with piping so it’s gonna be a struggle. Also, I wonder if a pressure regulator would

work. Something that prevents flow until a certain pressure is met. That way the pump can build up a working pressure and then send that pressurized

flow through the aspirator. I’m missing something though. The aspirator and the pump both look like they are working but I am just not getting any

vacuum. 100mmHg below atm at the most which is not gonna work for vacuum distillations. I don’t know if I need greater psi in my aspirator input or

greater flow overall. Also my pump has duel fitting for the hookups. 18mm thread and 10mm push connect which I’ve been using. I’m not sure if

using the smaller hookup is restricting the flow of the pump and I should just use the threaded connection. So many ifs. I think I’m gonna start

with the 18mm to 3/8” compression fem to fem adapter and see what happens. If the vacuum still is sufficient I’ll probably have to get a higher

psi pumps. I’ve been looking at a 60W 130psi pump that would work with the power supply I’ve already bought. I have a spare 5.5mm by 2.1mm cable

for the power supply

|

|

|

Ubya

International Hazard

Posts: 1247

Registered: 23-11-2017

Location: Rome-Italy

Member Is Offline

Mood: I'm a maddo scientisto!!!

|

|

Quote: Originally posted by Opylation  | | Okay, I was just curious if my pump came damaged or something. Well, I did a test and if the flow is blocked the pump is able to build up decent

pressure. Enough pressure to break my ptfe seal to my aspirator so I’m gonna look for an adapter to connect the 18mm threading to the 3/8”

compression fitting on my aspirator. I’m not familiar at all with piping so it’s gonna be a struggle. Also, I wonder if a pressure regulator would

work. Something that prevents flow until a certain pressure is met. That way the pump can build up a working pressure and then send that pressurized

flow through the aspirator. I’m missing something though. The aspirator and the pump both look like they are working but I am just not getting any

vacuum. 100mmHg below atm at the most which is not gonna work for vacuum distillations. I don’t know if I need greater psi in my aspirator input or

greater flow overall. Also my pump has duel fitting for the hookups. 18mm thread and 10mm push connect which I’ve been using. I’m not sure if

using the smaller hookup is restricting the flow of the pump and I should just use the threaded connection. So many ifs. I think I’m gonna start

with the 18mm to 3/8” compression fem to fem adapter and see what happens. If the vacuum still is sufficient I’ll probably have to get a higher

psi pumps. I’ve been looking at a 60W 130psi pump that would work with the power supply I’ve already bought. I have a spare 5.5mm by 2.1mm cable

for the power supply |

the less restrictions you can get, the better the system, as you can see the aspirator needs quite a lot of water flow to function properly

---------------------------------------------------------------------

feel free to correct my grammar, or any mistakes i make

---------------------------------------------------------------------

|

|

|

Opylation

Hazard to Others

Posts: 131

Registered: 30-8-2019

Member Is Offline

|

|

I finally splurged for a better pump. 130 psi 70w very similar design. So either things will look up or I will be a fool out more money. The thing is

the aspirator is literally the exact same one as nurdrages so I’m inclined to say it’s the pump. The issue is the pump needs to “charge up”

the water pressure But I’m not sure what to do about that. When I place my finger over the exit, I’m able to stop the flow for 5-10 second before

the pressure builds up enough to force its way through. If my new pump plays the same song and dance I’m gonna have to McGyver something. Maybe a

ball valve on the exit flow of the aspirator and wait until the pressure builds to open it.

Also, this time it’s being shipped from America so I feel more confident

[Edited on 6-6-2020 by Opylation]

|

|

|

| Pages:

1

2 |