numos

Hazard to Others

Posts: 269

Registered: 22-2-2014

Location: Pasadena

Member Is Offline

Mood: No Mood

|

|

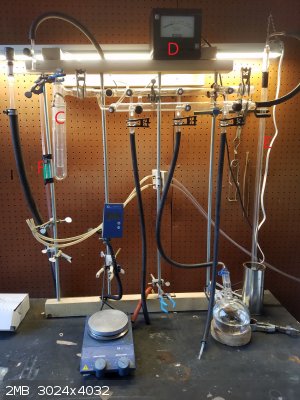

Setting up a home Schlenk system

There was some interest in doing Schlenk chemistry, and I hope this post can do it justice. Doing air-free chemistry is definitely one of the more

risky and expensive facets of home chemistry. However, for some reactions it is necessary in order to get reasonable yields, or be able to work with

some reagents safely. While my lab is equipped to handle pyrophoric reagents, a breach would still be a risky catastrophe so I tend to avoid them. I

mostly work with compounds that are sensitive to air, rather than pyrophoric, and I will suggest the same to everyone else here. My setup is

fairly polished and a big pride in my lab, and I was lucky in that I had to pay for almost nothing. I paid a few hundred dollars total for gas, oil,

and a few clamps/adapters. Keep in mind that this is a setup for doing air sensitive organometallic chemistry... this is certainly overkill for a

grigard reaction or most organic reactions.

To get right to it – Schlenk technique is not just about the equipment or the glassware, but the entire suit of actions that pertain to setting up,

running, and working up a reaction without contact to atmosphere. The line itself is a manifold that gives access to vacuum and inert gas. I’ll run

through my setup here. Part two will come a later and will go over actual techniques.

Pump (A) and Gas (B)

The pump (A)

The two options are basically direct drive pumps and the Welch pumps. Pros of a direct drive pump is that they are generally cheaper, they have a

faster pumping speed, and they are more resistant to chemicals. The pump that I have is a 1400 Welch pump. Pros are that they are very robust and they

reach a deeper vacuum. I prefer Welch pumps in all cases for Schlenk systems: the high flow rate of direct drive pumps is good for gloveboxes and

instruments but not so much for lines. The welch pumps are expensive ($2000+) but they last forever if you take care of them and maintenance is pretty

easy.

My pump was salvaged after the old owner passed away, and it had over 20 years of use before I got my hands on it. After switching out the oil, it

pulls down to 5 microns easily. To put that into perspective it can easily boil DMSO at 0 oC. Taking care of your pump is important. Replace the oil

every few months (every 6 -12 is probably good for home chemist) and NEVER pull any solvent, water, corrosive gas, etc into the pump. There are two

reasons for this:

1. The pump is cast iron, corrosives will tear it apart, THF will polymerize, gunking the mechanism, water causes rusting.

2. Even something as mundane as hexanes is a problem. The pump chamber is filled with oil, greasy solvents dissolve well in oil and despite the high

temperature, it can take days before it’s completely expelled. During that time, you have a partial pressure of solvent which kills your vacuum.

If you want to attain a vacuum far under 1 micron you have to use a diffusion pump or turbo pump. Both are unnecessary for most chemistry. I wanted to

sublime some sodium into other salts, so I’m working on getting this diffusion pump setup which can get to 0.001 micron. Also keep in mind that an

incredibly good pump is useless if your line leaks at all, but more on this later.

The inert gas (B)

Options are essentially Nitrogen or Argon. Both are available at welding suppliers and both work ok. I have a tank of Argon as it’s not too much

more expensive ($70 for Ar vs $40 for N2 for a 60cuft tank), and I use a lot less of it, making it cheaper. Ar forms a protective blanket on your

reaction, which means you generally don’t have to blast it like you would N2. Also have a high-quality regulator with low pressure control. The most

I ever set it to is 10 psi, and I never let it climb that high in the glassware either. A full tank of Ar lasts me about 50-100 reactions if I’m

being conservative, which is very affordable. Make sure to secure the tank well, if it falls it might go boom.

The Line itself has several parts: the trap (C), the gauge (D), the bubbler (E), flow control (F)/tubing/seals, and of course the Schlenk line itself.

The trap (C)

Kind of useless to home chemistry which is really sad. The idea is a dewar is placed around it and filled with liquid N2. This is great because you

can use your line to remove solvent! Just open the tap to vacuum and watch as 20 mL of water quickly disappears and gets frozen in the trap (not the

pump!!!). Since having consistent access to liquid N2 is not feasible, it means that you cannot use the pump to pull off solvent. Maybe there are some

solutions to this, because it’s very annoying to not have that functionality. (Maybe Peltier chips that go to -200C?)

The gauge (D)

I have a vacuum gauge from an old lyophilizer that I hooked up to the line. You need a gauge of some type, this one has a range of 1-5000 microns and

is pretty reliable, but I have two baratron gauges that I'm in the process of fixing. It allows you to see what your absolute deepest vacuum is, and

it allows you to see when something has (or hasn’t) reached that vacuum. For example, let’s say my readout is 5 microns. I hook up a flask and

open the vacuum. The gauge spikes and quickly drops down to 1 mmHg (1000 microns). Depending on how good the seals are and how dry the flask is, it

could take 20 seconds, hours, days, or never for it to reach the ultimate vacuum again. Generally, I wait for it to drop below 100 microns before

continuing. If it stays above that, there is probably a leak somewhere. These gauges are expensive but sometimes you can find gems on ebay. Just get

it calibrated so you have an idea if it’s accurate at all.

The bubbler (E)

They come in all shapes and sizes; I have my collection shown here. You will notice they are all small which makes them crappy to use for lines. The

best by far is a tall mercury bubbler you can see hooked up to the line. This is the bubbler I would use everywhere if I could, but unfortunately many

places have put a ban on mercury. The bubbler allows you to see when the inert gas is flowing and acts as a one way check valve to prevent air from

getting back into the line. Oil bubblers are a substitute but not a good one. If you evacuate a flask and want to refill it with Ar, the pressure in

the Ar line drops, pulling your oil/mercury up. For oil, this could mean getting a line filled with oil and your reaction ruined if you don’t go SO

SLOWLY. With a tall mercury bubbler, I could directly apply vacuum to the bubbler, and because the tube height is greater than 760mmHg, it will never

overflow. The next best thing would be the chemglass bubbler on the left, which has a little ball to prevent suck back, but I've seen those things

fail too.

flow control (F)/tubing/seals

I suggest investing in some sort of flow controller as they are cheap and allow you to set the amount of gas you are using, simple enough.

For anything that comes into contact with vacuum, don’t use latex or the crappy PVC/tygon tubing unless you want a fettuccine line. Rubber tubing is

king. For the Ar line it doesn’t matter as long as it’s air tight. The thin rubber tubing I use on the taps is about $4-5/foot, so about $50 for

everything. The thick rubber tubing on the left is important. It has ½ inch internal diameter and goes for about $20/foot (about $200 for the line to

pump connection), but I'm sure it's available cheaper elsewhere. As the pressure in your line drops, the main mechanism for molecules to travel is no

longer positive pressure based but diffusion based. As an example, if you have a sealed 10 foot pipe and hook up a pump to the left side, the pressure

(1 atm, ~15 psi) on the right side will initially force the remaining air to rapidly equilibrate and leave the pump. Assume only one molecule is left

on the right side. Now there are no other molecules to push it through, and you rely on luck that the molecule’s random motion will bring it to the

pump. So, at the pressures you are looking at in a line, if you open a flask to vacuum it takes 5 seconds to get to 1 mmHg, but it takes much longer

to get to a few microns (assuming no leak). Narrow tubing and valves will stretch this time significantly further. If you look closely at the vacuum

line, you’ll notice all paths and valves have big openings, to allow for faster gas diffusion.

That brings us to seals. Leaks, even tiny pinhole leaks, are bad and can severely degrade your pumping ability. Assuming a well-functioning line and

pump go to 1 micron. If there is a pinhole leak to atmosphere, gas rushes in and expands close to a million times as it enters! On all vacuum

seals, use hose clamps and snug fitting tubing. (I have to buy more clamps, I know) No jury rigging some Teflon tape to make a tube fit - it has to be

perfect.

The line itself

There are many different makes and models, this particular one was custom made by a glassblower as a graduation gift. A custom Schlenk line is likely

to cost around $5k-10k, but there are many affordable ones that are maybe a little less fancy but still very functional. This one has almost all

o-ring joints and Teflon stoppers, which are far superior to grease joints. Cleaner and you don’t have to worry about leaks. It is also reinforced

with thick glass supports which is a nice touch. The only grease joints are the trap and the trap-to-line connection for the vacuum. There is nothing

wrong with grease, a well-greased line is just as good as a Teflon stoppered one, just more maintenance. If you are using grease, don’t use the

Dow-corning silicone grease that comes in the little blue tubes. That stuff is great for flask joints and temporary connections, but for long term

joints like these you want something like Apiezon L grease or H grease. H is for high temperatures, and L is for ultra-high vacuums

(<2x10-8 microns). It’s a little pricier and a lot more viscous, but the silicone grease tends to “give” after a few days and

leaks appear. Also note that I’m missing a Teflon stopper - I’m working on acquiring it as it's probably why I'm getting 5 microns instead of 1.

|

|

|

Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

numos, wow, beautiful! Thank you very much for sharing such useful info with us.

|

|

|

Heptylene

Hazard to Others

Posts: 319

Registered: 22-10-2016

Member Is Offline

Mood: No Mood

|

|

Wow incredible setup, thanks a lot for sharing! Any tricky/interesting syntheses you have completed with this setup?

Also, have you considered dry ice for your trap? Would it be enough to catch the vapors at 1 micron vacuum? I've never seen dry ice used in place of

LN2 so I'm going to guess no, but who knows...

Your sodium sublimation project is most interesting too, with a diffusion pump you could probably make some really nice samples of the alkali metals

and possibly some others.

|

|

|

Metacelsus

International Hazard

Posts: 2539

Registered: 26-12-2012

Location: Boston, MA

Member Is Offline

Mood: Double, double, toil and trouble

|

|

Simply extraordinary! That's a better setup than I've seen in some university labs.

One thing I'm wondering about : how do you protect your pump if you don't have the trap? (I guess you might cover this in Part 2.)

|

|

|

numos

Hazard to Others

Posts: 269

Registered: 22-2-2014

Location: Pasadena

Member Is Offline

Mood: No Mood

|

|

Thank you all for the kind words!

Quote: Originally posted by Heptylene  | Wow incredible setup, thanks a lot for sharing! Any tricky/interesting syntheses you have completed with this setup?

Also, have you considered dry ice for your trap? Would it be enough to catch the vapors at 1 micron vacuum? I've never seen dry ice used in place of

LN2 so I'm going to guess no, but who knows...

Your sodium sublimation project is most interesting too, with a diffusion pump you could probably make some really nice samples of the alkali metals

and possibly some others.

|

Dry ice will probably work ok for water and some heavier solvents, but things like hexane, DCM, ether, I'd still be worried about. I've even seen some

setups that have two liquid N2 traps in series! At one micron and below you really start to approach territory where many things like benzene, and

even naphthalene can sublime at lower temperatures.

For the most part anything I do with this setup, you could do on a large enough scale with just a nitrogen tank and nothing else. The real benefit of

this kind of rigor is that you can do things on a smaller scale (<100 mg) without decomp, and your purification is drastically easier as many

impurities are avoided under these conditions. I guess while anyone else could make the same compounds I can using just an inert gas, it would be more

likely for my reactions to be "publication grade". Currently making some famous organometallic iron compounds (not ferrocene, don't worry) for part 2,

you might enjoy those!

I'm quite excited about the sodium project as well, but I still have to machine parts for that pump, and with everything shut down now.... It might

have to wait for quite a while.

Quote: Originally posted by Metacelsus  | Simply extraordinary! That's a better setup than I've seen in some university labs.

One thing I'm wondering about : how do you protect your pump if you don't have the trap? (I guess you might cover this in Part 2.)

|

I will cover more in part two, but the short answer is I never pull off solvent on this line, I always just use the rotovap or my little dinky 60$

direct drive pump. It's slower, and not as air free, but for now it's a much better option than ruining my nice pump

|

|

|

Copenhagen1968

Harmless

Posts: 10

Registered: 11-2-2020

Location: Denmark, Roskilde

Member Is Offline

|

|

Very cool setup. I am planning to set up similar equipment. I have had this trap made at a glass blower. It is basically a cold finger so I dont think

I should need the dewar as the cooling medium is on the inside. I plan to use dry ice. It holds 500 ml dry ice and can trap 150 ml of liquid. But that

doesnt matter much as I can draw off liquid at the bottom.

|

|

|

Copenhagen1968

Harmless

Posts: 10

Registered: 11-2-2020

Location: Denmark, Roskilde

Member Is Offline

|

|

about mercury...

I often go to second hand shops and "salvage" old thermometers. Some times I am lucky to get a barometer with a good nice bulb of mercury.

|

|

|

thalx

Harmless

Posts: 3

Registered: 12-11-2019

Location: Maryland Heartland, USA

Member Is Offline

|

|

Cold Trap

Greetings,

numos, you say the cold trap is not feasible ... do you mean because you don't have regular access to liquid nitrogen?

Here on the East Coast, I can get liquid nitrogen at the local welding supply, it's about 3-4 USD per liter. I have also had home delivery to fill my

50-liter dewar, it costs a bit more but I admit its decadent to have a truck pull up and do the fill in one's driveway.

-Thalx

|

|

|

numos

Hazard to Others

Posts: 269

Registered: 22-2-2014

Location: Pasadena

Member Is Offline

Mood: No Mood

|

|

Coppenhagen, that's a really nice design for a trap! If you can, try to get valves installed at the inlet and outlet, otherwise you won't be able to

drain while the pump is going. But maybe you won't need that, depends on what you are trying to do...

As for the nitrogen,

Regular access to liquid N2 is a problem. $3-4 per liter is quite expensive, considering I need to 1-2 liters to bring the trap to temperature, and

about a liter of liquid N2 every few hours to keep it cold. Sure, for one important reaction it's definitely feasible, but if you calculate losses

between transferring and the fact that you lose it over time and can't really store it, it becomes difficult.

Consider that I work during the week so can only run reactions on the weekends. This means I would have to fill a small 20L dewer for each weekend,

about $60-80 per week, and it would likely be gone by next weekend. That's really expensive. Compare that to the price we buy liquid N2 at in lab,

about $0.12 per liter. So about a dollar or two for a complete fill - definitely don't care if I end up wasting some of it. I currently spend about

100$ a month for chemistry and trying to not increase that number by too much

|

|

|

monolithic

Hazard to Others

Posts: 436

Registered: 5-3-2018

Member Is Offline

Mood: No Mood

|

|

Stirling cryocooler can make liquid air quite easily, if you can find a used one at auction. Check YouTube for operation videos.

|

|

|

|