Katie

Harmless

Posts: 35

Registered: 12-11-2019

Member Is Offline

|

|

Safety of ball milling commercial smokeless powder.

Would it be safe to run smokeless powder in a ball mill with lead media and a painted steel cylinder? I have a very fast burning double base

(nitroglycerin and nitrocellulose) pistol powder. I would of course treat the ball mill as an explosive and start/stop the mill from at least 100

yards away and behind cover, but if it’s guaranteed or likely to explode, I’d rather not destroy my ball mill! I’m doing this to see if finely

milled double base powder will detonate and how it compares to its active ingredients (nitroglycerin and nitrocellulose). If it works, I’d also like

to experiment to see if the milled powder can act as a cheap, legal, easy to make, and widely available initiator/primer.

I’m new to the forum, so I’ll mention that I have some explosives safety training and lab experience, and I’m interested in the chemistry and

engineering of energetic materials. I already went through my reckless “kewl bombz” phase when I was a kid!

|

|

|

hyfalcon

International Hazard

Posts: 1003

Registered: 29-3-2012

Member Is Offline

Mood: No Mood

|

|

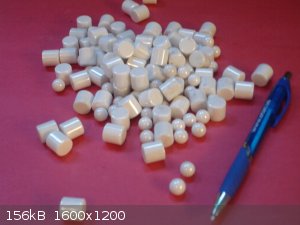

spark-less ceramic milling media. Lead media contaminates your product.

|

|

|

SWIM

National Hazard

Posts: 970

Registered: 3-9-2017

Member Is Offline

|

|

Comes in different shapes and sizes, but I like the stuff that looks like marshmallows. (yum)

It'll probably take that paint off your tumbler though. porcelain's pretty tough.

Can that stuff be ground wet?

Put it through something that functions like a quern, but mechanical?

Ha Ha, I got to use quern in a sentence.

Don't do that every day.

|

|

|

ShotBored

Hazard to Others

Posts: 124

Registered: 19-5-2017

Location: Germany

Member Is Offline

Mood: No Mood

|

|

I'd be a bit scared to ball mill NC in any way. Impact and friction sensitivity of it alone are high enough...add double base smokeless powder with

NG? I'd advise against it, tbh. Just my two cents!

|

|

|

Fulmen

International Hazard

Posts: 1716

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

@hyfalcon: Are you talking from experience or just guessing? Spark-free does not mean ignition-free, hit something hard enough and it will go off. And

ceramics are hard...

Like most people here I don't know, so all I can do is speculate.

First off: NC is fairly insensitive to ignition. If we can ball mill black powder dry, why not NC? The problem is that NC is also very strong and

flexible, quite undesirable properties for grinding. So ball milling with lead is probably going to be slow, and with heavy contamination.

Brass or copper media (also safe for BP) might work better. Ceramics would also work better, but I don't know if it's hardness can cause ignition.

A quern/grinder would probably be more efficient, but I don't know if it would be safe. The design should prevent any contact between grinding

surfaces at least.

Wet processing sounds like the obvious route for safety. As long as it's wet you can probably do whatever you like to it with no risk. The NC won't be

affected, but I 'm not sure if the NG can be washed out somehow. I don't think so, but you should at least consider the possibility and handle the

water accordingly.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

MadHatter

International Hazard

Posts: 1339

Registered: 9-7-2004

Location: Maine

Member Is Offline

Mood: Enjoying retirement

|

|

Steel drum

This would make me nervous. Formerly, smokeless

powder was listed as hazmats 1.3 and 1.4. It's now

listed as 4.1. When I had my CDL w/hazmat, transporting

any class 1s(explosives 1.1 - 1.6) required them

to be in a non-metallic or non-ferrous lined area

for transport. I don't know what the problem with

iron is. Just a cautionary note. Paint scraping off the

cylinder would expose the smokeless powder to the

steel.

Katie, check out the burn speeds for smokeless powders

as of NOVEMBER 2019. Norma R1 is the fastest and may

be an adequate solution without grinding.

Attachment: burn-rate-color.pdf (418kB)

This file has been downloaded 601 times

[Edited on 2020/4/18 by MadHatter]

From opening of NCIS New Orleans - It goes a BOOM ! BOOM ! BOOM ! MUHAHAHAHAHAHAHA !

|

|

|

hyfalcon

International Hazard

Posts: 1003

Registered: 29-3-2012

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Fulmen  | @hyfalcon: Are you talking from experience or just guessing? Spark-free does not mean ignition-free, hit something hard enough and it will go off. And

ceramics are hard...

Like most people here I don't know, so all I can do is speculate.

First off: NC is fairly insensitive to ignition. If we can ball mill black powder dry, why not NC? The problem is that NC is also very strong and

flexible, quite undesirable properties for grinding. So ball milling with lead is probably going to be slow, and with heavy contamination.

Brass or copper media (also safe for BP) might work better. Ceramics would also work better, but I don't know if it's hardness can cause ignition.

A quern/grinder would probably be more efficient, but I don't know if it would be safe. The design should prevent any contact between grinding

surfaces at least.

Wet processing sounds like the obvious route for safety. As long as it's wet you can probably do whatever you like to it with no risk. The NC won't be

affected, but I 'm not sure if the NG can be washed out somehow. I don't think so, but you should at least consider the possibility and handle the

water accordingly. |

Having done black powder in a homemade cylindrical ball mill made of pvc pipe, and milling for hours at a time. I've had no issues using ceramic

media. If you have it running the right speed, it will grind. It shouldn't be running so fast as to run up the side of the wall and drop from a

height. Fluidized bed effect is what you're shooting for.

|

|

|

MineMan

International Hazard

Posts: 1004

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Katie  | Would it be safe to run smokeless powder in a ball mill with lead media and a painted steel cylinder? I have a very fast burning double base

(nitroglycerin and nitrocellulose) pistol powder. I would of course treat the ball mill as an explosive and start/stop the mill from at least 100

yards away and behind cover, but if it’s guaranteed or likely to explode, I’d rather not destroy my ball mill! I’m doing this to see if finely

milled double base powder will detonate and how it compares to its active ingredients (nitroglycerin and nitrocellulose). If it works, I’d also like

to experiment to see if the milled powder can act as a cheap, legal, easy to make, and widely available initiator/primer.

I’m new to the forum, so I’ll mention that I have some explosives safety training and lab experience, and I’m interested in the chemistry and

engineering of energetic materials. I already went through my reckless “kewl bombz” phase when I was a kid! |

Again. I am confused as to what your goal is. Many have detonated smokeless powder with enough confinement. But it is not cheap.

How would it be an initiator? AutoStem is AN mixed with SP, FYI.

AN or AP explosives seem to make more sense.

|

|

|

Katie

Harmless

Posts: 35

Registered: 12-11-2019

Member Is Offline

|

|

Quote: Originally posted by MineMan  | Quote: Originally posted by Katie  | Would it be safe to run smokeless powder in a ball mill with lead media and a painted steel cylinder? I have a very fast burning double base

(nitroglycerin and nitrocellulose) pistol powder. I would of course treat the ball mill as an explosive and start/stop the mill from at least 100

yards away and behind cover, but if it’s guaranteed or likely to explode, I’d rather not destroy my ball mill! I’m doing this to see if finely

milled double base powder will detonate and how it compares to its active ingredients (nitroglycerin and nitrocellulose). If it works, I’d also like

to experiment to see if the milled powder can act as a cheap, legal, easy to make, and widely available initiator/primer.

I’m new to the forum, so I’ll mention that I have some explosives safety training and lab experience, and I’m interested in the chemistry and

engineering of energetic materials. I already went through my reckless “kewl bombz” phase when I was a kid! |

Again. I am confused as to what your goal is. Many have detonated smokeless powder with enough confinement. But it is not cheap.

How would it be an initiator? AutoStem is AN mixed with SP, FYI.

AN or AP explosives seem to make more sense. |

Smokeless powders are produced in large particles and have additives designed to slow their burn rate. Double base contains nitrocellulose and

nitroglycerin, so my goal is to see how finely milled smokeless powder compares to its active ingredients, as well as black powder and flash powder.

I’d also like to experiment with possible extraction techniques to extract NG and NC from smokeless powder.

I’d love to make some NG to compare it to more accurately but I don’t have a lab vacuum to distill white fuming nitric acid.

|

|

|

ShotBored

Hazard to Others

Posts: 124

Registered: 19-5-2017

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Fulmen  | @hyfalcon: Are you talking from experience or just guessing? Spark-free does not mean ignition-free, hit something hard enough and it will go off. And

ceramics are hard...

Like most people here I don't know, so all I can do is speculate.

First off: NC is fairly insensitive to ignition. If we can ball mill black powder dry, why not NC? The problem is that NC is also very strong and

flexible, quite undesirable properties for grinding. So ball milling with lead is probably going to be slow, and with heavy contamination.

Brass or copper media (also safe for BP) might work better. Ceramics would also work better, but I don't know if it's hardness can cause ignition.

A quern/grinder would probably be more efficient, but I don't know if it would be safe. The design should prevent any contact between grinding

surfaces at least.

Wet processing sounds like the obvious route for safety. As long as it's wet you can probably do whatever you like to it with no risk. The NC won't be

affected, but I 'm not sure if the NG can be washed out somehow. I don't think so, but you should at least consider the possibility and handle the

water accordingly. |

Insofar as you're talking about wet milling, then I'd likely have no qualms. But the idea of NC being fairly insensitive to ignition I very much

disagree with. It may be insensitive to ignition relative to a lot of the high explosives people mess with on here, but make no mistake, NC IS very

much impact, friction, and ESD sensitive. Not to mention the inherent instability as it decomposes over time without stabilizer.

|

|

|

Fulmen

International Hazard

Posts: 1716

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

Well, any energetic compound will display some level of sensitivity to initiation. That being said, NC is pretty darn insensitive compared to most

high explosives. I've played with "artillery powder", hollow sticks of NC appr. 6-8mm in diameter and 20cm long. You can hit those with a hammer or

tape a No8 blasting cap to the end without setting it off.

Also, if you read my post a little more carefully you'll see that I was comparing it to BP, which is a helluva lot more sensitive than NC to pretty

much anything. And that is routinely ball-milled without incident.

You are right in that NC is inherently unstable (even with stabilizers it will eventually degrade), but here we're discussing commercially produced NC

powders that should be as stable as can be.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

Deathunter88

National Hazard

Posts: 519

Registered: 20-2-2015

Location: Beijing, China

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Fulmen  | Well, any energetic compound will display some level of sensitivity to initiation. That being said, NC is pretty darn insensitive compared to most

high explosives. I've played with "artillery powder", hollow sticks of NC appr. 6-8mm in diameter and 20cm long. You can hit those with a hammer or

tape a No8 blasting cap to the end without setting it off.

Also, if you read my post a little more carefully you'll see that I was comparing it to BP, which is a helluva lot more sensitive than NC to pretty

much anything. And that is routinely ball-milled without incident.

You are right in that NC is inherently unstable (even with stabilizers it will eventually degrade), but here we're discussing commercially produced NC

powders that should be as stable as can be. |

I too would have to disagree with the sensitivity of NC. You can hit a pile of gunpowder on a steel anvil as much as you want-nothing. If you try the

same with a piece of flash paper or flash cotton you get a flash and a loud bang.

|

|

|

Fulmen

International Hazard

Posts: 1716

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

To be fair, the term "NC" is too inaccurate for this discussion. My apologies for that. My arguments have been based on "gelatinized NC-based

gunpowder",raw or untreated NC is another animal indeed.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

MineMan

International Hazard

Posts: 1004

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

I still struggle with the why of this...

|

|

|

Fulmen

International Hazard

Posts: 1716

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

What's so hard to get? He wants to test how milling changes it's properties, I think that's a completely reasonable experiment. Unless you KNOW what

the result is going to be, I don't see why you have to be so negative.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

Katie

Harmless

Posts: 35

Registered: 12-11-2019

Member Is Offline

|

|

I’m interested in this for two reasons. First, curiosity. I’d simply like to know to what degree smokeless powder additives reduce the reaction

rate of NC/NG detonation/deflagration because I have an interest in energetic materials and chemical engineering. Two, I think it’s worth doing

because if a finely milled smokeless powder is indeed somewhat comparable to pure or relatively pure NC/NG, it would be an easy and convenient OTC

source of energetic material for those times you need an energetic for some kind of task and don’t have time to synthesize something more powerful.

I’m hoping to at least see more power than black and flash powders.

|

|

|

ShotBored

Hazard to Others

Posts: 124

Registered: 19-5-2017

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Fulmen  | Well, any energetic compound will display some level of sensitivity to initiation. That being said, NC is pretty darn insensitive compared to most

high explosives. I've played with "artillery powder", hollow sticks of NC appr. 6-8mm in diameter and 20cm long. You can hit those with a hammer or

tape a No8 blasting cap to the end without setting it off.

Also, if you read my post a little more carefully you'll see that I was comparing it to BP, which is a helluva lot more sensitive than NC to pretty

much anything. And that is routinely ball-milled without incident.

You are right in that NC is inherently unstable (even with stabilizers it will eventually degrade), but here we're discussing commercially produced NC

powders that should be as stable as can be. |

I hope I'm not being considered hostile. But smokeless powder is typically using higher N-content NC (13%+) with NG. I work with NC a lot, both

lacquer grade and propellant grade and the sensitivity difference once you hit the 13%+ is night and day. Ball milling wet definitely mitigates the

risk, but if you mill it dry I give it a pretty dang good chance of going off.

That being said, @Katie, the fibrous nature of NC seems to lend itself to being more energetic. Lacquer grade NC is very powdery, whereas propellant

grade NC is typically very fibrous like wood pulp. By milling the smokeless powder, I would predict you will see an overall decrease in performance.

If you're set on testing this out, I highly recommend wet with water or ethanol. Dry is just a chance I wouldn't risk.

|

|

|