| Pages:

1

2

3 |

UnintentionalChaos

International Hazard

Posts: 1454

Registered: 9-12-2006

Location: Mars

Member Is Offline

Mood: Nucleophilic

|

|

Quote: Originally posted by CuReUS  | DJF90

so nitration on sulphonated ring is possible .but while sulphonating wont the sulpho group go to ortho as well as para position because the methyl

group is not such a bulky molecule? |

o-toluenesulfonic acid is unfavorable due to sterics. Importantly, though, is that the reaction is readily reversible and at the high temps used for

sulfonation of toluene with concentrated sulfuric acid, the less stable ortho-product desulfonates/resulfonates into the more stable p-isomer readily.

Nitration is not, to my knowledge, readily reversible.

You might see considerable o-toluenesulfonic acid if you used oleum at low temperatures where the reaction is not so readily reversible and the much

greater sulfonating power of oleum makes up for the lack of heat.

The nitration of the p-toluenesulfonic acid would require moderate conditions, because it is possible for a nitro group to displace the sulfonic acid

moiety on the ring. This is the case for TNT, where some preps specify treatment of dinitrotoluene with oleum before adding the final amount of nitric

acid.

[Edited on 11-5-14 by UnintentionalChaos]

Department of Redundancy Department - Now with paperwork!

'In organic synthesis, we call decomposition products "crap", however this is not a IUPAC approved nomenclature.' -Nicodem

|

|

|

CuReUS

National Hazard

Posts: 928

Registered: 9-9-2014

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by UnintentionalChaos  |

o-toluenesulfonic acid is unfavorable due to sterics. Importantly, though, is that the reaction is readily reversible and at the high temps used for

sulfonation of toluene with concentrated sulfuric acid, the less stable ortho-product desulfonates/resulfonates into the more stable p-isomer readily.

Nitration is not, to my knowledge, readily reversible.

|

that's great ,if even a small group like methyl can cause the sulpho group to go to para ,think of how many reaction could be controlled by this

method

| Quote: | | The nitration of the p-toluenesulfonic acid would require moderate conditions, because it is possible for a nitro group to displace the sulfonic acid

moiety on the ring. This is the case for TNT, where some preps specify treatment of dinitrotoluene with oleum before adding the final amount of nitric

acid |

iirc ,moderate conditions of nitration is conc nitric acid/sulphuric acid at 100'c but then you say that the nitro group will replace the sulpho group

at high temp(that's also the method to make picric acid ) .so what should we do. ) .so what should we do.

|

|

|

Hellafunt

Hazard to Self

Posts: 65

Registered: 2-12-2014

Member Is Offline

Mood: No Mood

|

|

so, I attempted this procedure a while ago and it went pretty well. During the nitration process, which I did by following a friend's advice by adding

the toluene to the mixed acids, after each addition, the toluene turned dark, and then turned yellowish in a minute or two. I had to take water out of

the ice bath a few times and add fresh ice to maintain a cold enough temp. It turned out well.

Recently, I tried this again. This time, anticipating having to keep adding ice to the water bath, the night before I froze a few inches of water

in the bottom of the water bath vessel. When I added the reaction flask and some water, it maintained a cold (18C) temp easily. It seemed like maybe

it was too cold, I would add toluene to the reaction, and it never turned dark at all, and it didnt heat up at all. I was able to add all the toluene

without it ever really heating up.

I figured it was all done, so I stepped away for less than 10 minutes. When I returned, there was brown gas evolving from the reaction, I put in

a thermometer and it was still climbing at 60C when I yanked it out, and put a whole lot of ice and cold water around the RBF this was happening in. I

was prepared to run, but it cooled down. Later, I thought it was done but when I poured it into a sep funnel, there was still nitrogen dioxide coming

off it, so I put it back in the RBF and let it react another hour. In the end, the finished product looked ok, maybe a little darker than the first

time. I thought perhaps there was some NO2 dissolved in it causing the darker color, like the way it does in Nitric acid.

Now, a few days later, the nitrotoluene has separated in the storage bottle, with the top third appearing as the normal , yellow, thick liquid

and the bottom two thirds being a darker, thinner liquid. Whats the deal? Id like to make o-toluidine from this. Is it usable?

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Quote: Originally posted by S.C. Wack  | | ...maybe no dinitrotoluene is formed using excess nitric acid if the temperature is low enough and there is enough sulfuric acid to compensate for the

water...maybe that isn't how it goes. AFAIK it isn't recommended. |

Surprised that no one mentioned COPAE:

A mixture of 294 grams of concentrated sulfuric acid {d. 1.84) and 147 grams of nitric acid (d. 1.42) is added slowly from a dropping funnel to 100

grams of toluene in a tall 600-cc. beaker, while the liquid is stirred vigorously with an electric stirrer and its temperature is maintained at 30°

to 40° by running cold water in the vessel in which the beaker is standing. The addition of acid will require from an hour to an hour and a half. The

stirring is then continued for half an hour longer without cooling; the mixture is allowed to stand over night in a separatory funnel...

|

|

|

Tabun

Harmless

Posts: 38

Registered: 17-4-2015

Member Is Offline

Mood: No Mood

|

|

Did you see the procedure in Science and Technology of Explosives-Urbanski?They say that this procedure gives o- and p- free of m-.The nitrating

composition is 68% acetic anhydride and 32% nitric acid with an exces of 10% acid,made at 10 degrees Celsius over a period of 2 hours.It also says

that you can reduce the m- quantity by adding sodium nitrite....Here's a SS:

http://i.imgur.com/yP6gxT2.jpg

|

|

|

Texium

Administrator

Posts: 4580

Registered: 11-1-2014

Location: Salt Lake City

Member Is Offline

Mood: PhD candidate!

|

|

I'm planning on attempting this synthesis soon, but I just wanted to clarify- what concentrations are the nitric and sulfuric acids that you used? I'd

guess ~63% and 98% respectively, but I wanted to make sure before I go throwing stuff together so I'll know to do stoichiometric corrections as

needed.

Sorry if I missed something, but I didn't see exact concentrations mentioned anywhere in the thread.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

There are many contributions to this thread, but I'm assuming you are asking me.

My con H2SO4 is whatever Rooto supplies: probably about 96%.

My con nitric acid is the azeotrope which IIRC is about 68%.

Good luck.

edit: I see that in my procedure I specify nitric acid of density 1.44, which corresponds to a 77wt% acid. I likely took this from

Cumming. Normally I don't have this so likely used an equivalent amount of 68%. Unfortunately I didn't say anything about this in my notebook.

[Edited on 18-11-2015 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Texium

Administrator

Posts: 4580

Registered: 11-1-2014

Location: Salt Lake City

Member Is Offline

Mood: PhD candidate!

|

|

Alright, thank you! I may try this synthesis today if I have time.

|

|

|

Aromatik

Harmless

Posts: 2

Registered: 6-2-2020

Location: Buenos Aires, Argentina

Member Is Offline

Mood: information is all I need

|

|

Nitrotoluenes

Dear Colleague,

Reviewing your procedure for toluene mononitration, kindly let me ask you if reverse addition has been experienced.

See attached ref. frm Urbanski about it.

Rgds,

Rod

Attachment: Addition_Urbanski.pdf (60kB)

This file has been downloaded 699 times

|

|

|

Aromatik

Harmless

Posts: 2

Registered: 6-2-2020

Location: Buenos Aires, Argentina

Member Is Offline

Mood: information is all I need

|

|

Quote: Originally posted by Tabun  | Did you see the procedure in Science and Technology of Explosives-Urbanski?They say that this procedure gives o- and p- free of m-.The nitrating

composition is 68% acetic anhydride and 32% nitric acid with an exces of 10% acid,made at 10 degrees Celsius over a period of 2 hours.It also says

that you can reduce the m- quantity by adding sodium nitrite....Here's a SS:

http://i.imgur.com/yP6gxT2.jpg

|

Has anybody checked the 88% o-NT distrubution informed in references cited by Urbanski?

Rod

|

|

|

basement

Harmless

Posts: 9

Registered: 7-7-2018

Member Is Offline

|

|

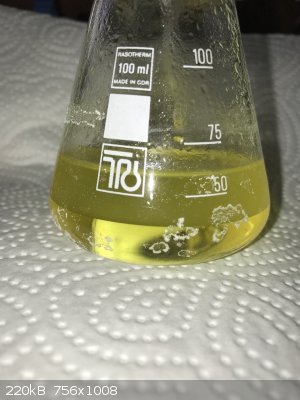

Solidified nitrotoluene while washing?!

I hope to find some help from the wise people of sciencemadness.

I performed the nitration of toluene largely based on the procedure described here by magpie. Along the way I took the following notes:

| Quote: |

A 100-mL Erlenmeyer flask was equipped with a stir bar, a thermometer and a dropping funnel, sitting on a magnetic stirrer, surrounded by an ice-salt

bath. Toluene (23.04 g, 27 mL, 0.25 mol) was placed in the flask and a previously chilled mixture of sulfuric acid (35.76 g, 20 mL, 96%, 0.35 mol) and

nitric acid (25 g, 18 mL, 75%, 0.30 mol) was placed in the dropping funnel. With vigorous stirring, the mixed acid solution was dropped in very slowly

(about one drop every 3 seconds), keeping the internal temperature below 20 °C during addition (around 0 °C most of the times). The color faded from

an initial dark red color to an orange yellow color during addition. After complete addition (about 60 minutes), the ice bath was removed and an

air-cooled reflux column was attached to contain splashes. The reaction mixture was stirred vigorously for further 3 hours (2 hours is enough, it

stirred longer because I wasn’t around) without heating or cooling (the reaction is still exothermic on its own). After 3 hours, the reaction

mixture was at room temperature and the color was still brightly yellow. The yellow-colored turbid upper layer, containing the product, was separated

and washed with water (50 mL). |

The first deviation I encountered was the color of the post-reaction mixture. Mine was yellow and magpies was red. I supposed this is a good thing and

that I've rendered less side products. The major deviation and reason for this post is an odd phenomenon. After addition of water as described above,

the whole lower layer solidified (containing the nitrotoluene). I let everything stand over night and the next day, the separated acid layer also

partly solidified i.e. nitrotoluene precipitated from it. This was heavily diluted with dH2O and filtered through a coffee filter.

The fear of polynitration came in mind. Technically it makes no sense as temperature was controlled carefully.

I attached some pictures which hopefully help you to understand and solve my confusion.

The apparatus (missing a stirbar in the picture):

The flask after complete acid addition:

The flask after further 2 hours of vigorous stirring (the white crust is at the outside, presumably sodium chloride):

The sep funnel after removal of the lower aqueous acid layer and the addition of 50 mL dH2O:

The filtered precipitate from the separated aqueous acid layer:

TLDR; The questions:

1) What happened? I really am puzzled.

2) How could I differentiate between mono-, di- and trinitrated products? AFAIK they behave very similar in mp, color and solubility. Is there a

noticeable odor difference e.g. polynitrated toluol doesn't smell sweet?

3) How would you further proceed? Until now, everything rests as described. I isolated the precipitated product from the acid layer to test its

'properties'. I'd like to further dry it at room temperature, place a few mg in a test tube and heat it. In case it's trinitrotoluene, it should

explode shouldn't it? Are dinitrotoluenes explosives?

Regarding the primary workup I thought of two ways: Heating the sep funnel with a heating gun in order to melt the solidified phase and continue as

described by magpie OR transfer the contents of the sep funnel to a beaker and simply wash the solids. In theory the washings should separate in two

layers, one contaning the liquid ortho-nitrotoluene?

I'm interested in any kind of feedback, constructive criticism and help!

Ty, basement

[Edited on 28-3-2020 by basement]

[Edited on 28-3-2020 by basement]

|

|

|

mackolol

Hazard to Others

Posts: 459

Registered: 26-10-2017

Member Is Offline

Mood: Funky

|

|

I think it's just p nitrotoluene that may solidify, as it has really high melting point. Maybe your water was very cold or you performed the

separation in cold room.

I have performed this reaction a few times and never had situation like this.

Just freeze out the rest of p toluene and enjoy your products.

|

|

|

sulfuric acid is the king

Hazard to Self

Posts: 94

Registered: 11-1-2017

Member Is Offline

|

|

If we use freezing method, why do we have (in liquid phase) o- mixed with m-, when m- melts at 16C,and we are lowering below -10C in the freezer?

Colligative properties?

How far we can go with freezing?My fridge is -20

Is there any way to remove unreacted toluene in the nitration process?

Something better than boiling?

Of course my goal is o- .

|

|

|

fdnjj6

Banned by request

Posts: 114

Registered: 20-2-2019

Member Is Offline

Mood: Pissed

|

|

Quote: Originally posted by sulfuric acid is the king  | If we use freezing method, why do we have (in liquid phase) o- mixed with m-, when m- melts at 16C,and we are lowering below -10C in the freezer?

Colligative properties?

How far we can go with freezing?My fridge is -20

Is there any way to remove unreacted toluene in the nitration process?

Something better than boiling?

Of course my goal is o- . |

If I were you I'd look into the DCM nitration of toluene. It favors the ortho product highly and you would have a lot less impurities.

|

|

|

fdnjj6

Banned by request

Posts: 114

Registered: 20-2-2019

Member Is Offline

Mood: Pissed

|

|

I also tried this nitration. It's a success so far, I'll be crystallizing the para product tonight. I used 75mL of toluene I extracted from a carb

cleaner can and distilled.

I also had to titrate the dilute nitric acid I made. ~58%. I decided to pretend as if it was 50-55%. I did the math and used a slight molar excess of

nitric acid. I needed 1.5 hours for the additions and kept the temps below 15C the entire time. I swapped the ice bath for water at 20 ish C and began

very light heating. It was kept at 35C (+-5C) for about 1 hour and 15 minutes. Then I let the layers separate, and decanted the top layer. Washed with

multiple water washes and sodium bicarbonate solutions. The mix of isomers is a nasty fucking mess. Oily, likes to spill (probably my fault), is

volatile, toxic, and carcinogenic. Even after washing glassware with water and acetone a few times, the smell was still there. I just let it sit

outside for a day or two and the smell is gone. I still hate working with it though. It also likes to stain stuff. The gloves were put in a trash bag

and thrown away and it made the whole trash can smell of it if you opened the lid. I just dried the isomer mix and it has become much clearer.

Beforehand it was very wet. I used Damp Rid calcium chloride to dry it.

To separate the isomers, I'll make a regular ice bath and cool the mix to around 0C. Two days ago I put a saturated salt water solution into the

freezer and it's at -20C now. After the isomers are at ice bath temps, I'll swap the ice bath for the salt water solution and let it chill to as cold

as I can get it. I'll set up a gravity filtration (despite it being oily, it filters very quickly, at least with my filters) and filter off the

crystals. I have around 50-55mL of the isomer mix which should theoretically weigh about 55 grams, so I can expect an absolute maximum of about 22

grams of para product. I highly doubt I'll get that much but I'll be more than happy with 10 grams of para product.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Quote: Originally posted by sulfuric acid is the king  | If we use freezing method, why do we have (in liquid phase) o- mixed with m-, when m- melts at 16C,and we are lowering below -10C in the freezer?

Colligative properties?

How far we can go with freezing?My fridge is -20

Is there any way to remove unreacted toluene in the nitration process?

Something better than boiling? |

Rotary evaporation with vacuum? I assume there is still an azeotrope with vacuum and this will dry the product too. The m is in the p.

I like the smell of o-nitrotoluene.

The picture is not quite the curdy milkshake like product mentioned in the main thread, that was thought to be due to oxidation and/or dinitration,

but could it actually be the result of bad toluene that needs purification?

[Edited on 12-8-2020 by S.C. Wack]

|

|

|

fdnjj6

Banned by request

Posts: 114

Registered: 20-2-2019

Member Is Offline

Mood: Pissed

|

|

Me too haha. It smells like cherries to me. Too bad it's so toxic. Every time I smell it I right away stop smelling it by exhaling all the way, moving

away, putting on the respirator, etc. This usually only happens when I don't expect the MNT to still be present. Like some will have spilled onto the

wood plate I'm working on and then when I go to pick up one last thing and I go near it, I smell it and right away stop haha. During the reaction and

most of the cleanup I have a fan and respirator and even then smell sometimes leaks in from a non perfect seal that is made if I move my mouth or

something. Right away exhale and reseal. If it weren't carcinogenic and toxic, I'd huff that stuff all dayyyy. I'd make it one of those car scent

thingies haha. Although I haven't smelled a really large dose or deeply inhaled some but the very slight exposure I get through inhalation smells

soooo good. I'd like to keep exposure to that level or less haha.

[Edited on 12-8-2020 by fdnjj6]

|

|

|

fdnjj6

Banned by request

Posts: 114

Registered: 20-2-2019

Member Is Offline

Mood: Pissed

|

|

Also for people like me who don't have a dedicated lab freezer and don't want to put a carcinogenic and toxic liquid into their food freezer, use

compressed air turned upside down and get a nice liquid bath going. Only do this for lab glass. I tried using the method of salt water in the freezer

but it just didn't work very well and was a hassle. I only managed to get like half of a gram of para product out. I should be expecting 10-22 grams

not 500mg haha. So I'll be using compressed air bath tomorrow. It boils at around 20 ish Celsius so it's perfect for this application. I don't want to

use my vacuum filter for this, any recommendations for how to keep the filter and liquid cold during gravity filtration?

I'll be doing multiple rounds of crystallizing and filtering to get the max amount out. Hopefully I don't overshoot and begin crystallizing out the

ortho product. I guess once I feel like I got around 10 grams, I'll store that separately from what comes over next. If at some point it doesn't

crystallize anymore due to the mixture having a much lower melting point or something, I'll collect as much as I can. The absolute maximum I should be

able to get is 22 grams. It'd be perfect if I got 15-20 grams but I'm not sure how much para product is actually able to come out before either

staying as a liquid mix or having the ortho product crystallize out.

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

You don't have to worry about crystallizing the ortho isomers, the para and or meta impurities drop the melting point so far I wasn't able to

crystallize the ortho isomer after several days at - 20 degrees.

|

|

|

CouchHatter

Hazard to Others

Posts: 152

Registered: 28-10-2017

Location: Oklahoma

Member Is Offline

Mood: 76 elements taken!

|

|

By tweaking this reactions conditions, it is very easy to get a very different isomer makeup. Sounds like you used a higher concentration of nitric

acid than Magpie, that's all I can see. Maybe it's simply the subtleties in temp control vs time.

I'm not sure of any shortcuts for isomer separation. I'd be curious as to how much of each isomer you got though, basement. Could you be more specific

about your reactants?

I used 96-98% Rooto sulfuric, 52% dist. nitric, and tech-grade toluene. My results never meaningfully deviated from OP.

I let several people smell it, and they likened it to those bubble-straw kids toy from the early 2000s. Not unpleasant.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Attached here is part of the uncredited reference of COPAE and quite likely also Cheapskate for nitrotoluene. Both halve the amounts, but Cheapskate "doubles" the beginning temperature given from 9 to 18C...who cools anything

just to 18C?

Cheapskate does use the procedure recommended (even though it takes longer than the normal way!) by the author for mononitrotoluene...if you're making

TNT, as it's not really MNT at all, being 37% DNT and a Bureau of Mines document not produced for the unsavory likes of those here to make

methaqualone. Cheapskate glosses over that bit; people are surprised to get a milkshake on workup.

Some postwar Germans follow different nitration directions (e.g. 5-10C) than everyone else, probably reflecting a fear of runaway nitrations in

student hands rather than optimization. Compare the directions for nitration of benzene and naphthalene in the Organikum to Vogel; it's not just

nitrotoluene. Perhaps there was An Incident. The Organikum's Vigreux usage is wise; the o cpd. being distinctly more volatile, and the distillation

hardly needs to be perfect and long.

At a certain point, there's no further reason to use a column, unless one wants to use a good one later for a final step. And no requirement for fear.

One may expect to launch any parts of the apparatus not firmly clamped down only if they're spacing off while running too hot and too long and too

dark and too dry. One may just decide to wash and extract the last once the pot temp gets uncomfortably warm.

There's a sensitive test for dinitrotoluene not made from m-nitrotoluene. The 2,4 cpd. in acetone (or ketamine, rohypnol in alcohol etc.) turns blue

with aq. alkali.

Attachment: hoffman1916.pdf (405kB)

This file has been downloaded 569 times

[Edited on 4-3-2021 by S.C. Wack]

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

JCS (Transactions) 121, 270 (1922) deals with freezing points for nitrotoluene mixtures. Increasing the amount of the m isomer lowers freezing points

considerably, which could hardly happen if it all crystallized out first.

So it depends on how one goes about collecting and cooling and warming and all. Partial crystallization is partially meaningless if one doesn't know

when one thing has crystallized as much as it will and whether the next thing has already started or finished coming out too. They do not bother to

mention the composition or temperature (probably around -17C) of this eutectic:

When commercial nitrotoluene is cooled, the initial crystallisation point is rather difficult to determine, as it is not very far removed from the

eutectic and there is a great risk of overcooling. The second crystallisation point is well defined, however, as the eutectic represents about 85 per

cent. of the mixture.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

It looks like most of the MNT preparations over 110 years old use just nitric acid, sometimes quite a lot, heated up to 60C. No one worries about

excess acid causing dinitration, with just azeotropic HNO3. Which leads me to wonder if sulfuric acid is needed outside of industrial batches, when

fractionating the water from waste acid isn't a big deal.

BTW dark brown waste acid is magically converted to clear colorless waste acid after adding water to it...or the reverse (you know what I mean

dammit)...precipitates a fair bit of purish p-NT...best to reuse the acid for the next run as is...but some nifty long needles (after a milky phase)

can be obtained by dilution.

It's interesting how the "usual" (BTW Cumming et al. appear to have ripped The Manufacture of Intermediate Products for Dyes) process gives no DNT

(BTW IPA also gives a nice blue with DNT, which soon darkens...these color reactions happen because the m-dinitro group is particularly activating) at

all, none, but using the same weight of nitric acid of 60% conc. <30C (instead of d1.44 acid under warmer conditions) gives some DNT and much

unreacted toluene. Small changes can be big here.

[Edited on 17-4-2021 by S.C. Wack]

|

|

|

Fery

International Hazard

Posts: 1015

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Here they suggest HNO3+H2SO4 at very low temp, -10 to +5 C:

https://www.oc-praktikum.de/nop/en/instructions/pdf/1001_en....

they still use excess of HNO3 and the DNT is obtained by vacuum distillation as a remainder in distillation flask after distilling out mononitro.

I did the same and the dinitro recrystallized from ethanol few times, I got quite pure 2,4-DNT with nice m.p.

https://www.sciencemadness.org/whisper/viewthread.php?tid=15...

the MNT is still waiting for vacuum distillation through column (I got yet a little of para by crystallization after cooling to -15 C).

[Edited on 17-4-2021 by Fery]

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Not a big fan of overcautious modern German directions that give DNT or 60% yield. Temperatures over 30C might lead to a darker color of the raw

product, and over 40C there can be some nitrous vapor in the system, but even so the industrial method (or large excesses of azeotropic HNO3,

apparently) does not dinitrate, with proper stirring. Everything is as Cumming says except where they didn't notice that the distillation in Cain's

text is with vacuum.

BTW n-propanol is good at separating dirty, mixed NT crystals; 91% IPA might be better.

|

|

|

| Pages:

1

2

3 |