Junk_Enginerd

Hazard to Others

Posts: 251

Registered: 26-5-2019

Location: Sweden

Member Is Offline

|

|

Synthesize ethylene glycol diacetate?

I've tried looking for information on how to do this, but I can't find anything specfic enough and I don't have the skills or knowledge to figure it

out myself...

I want to make or otherwise acquire ethylene glycol diacetate, or diacetin, whichever is easiest.

The intent is to use it for self hardening/curing sodium silicate/sand mixes for making metal casting molds. If anyone knows of any other ester or

acid that can perform the same job that'd be much appreciated too.

I tried the most basic approach I could imagine and mixed about 50 ml ethylene glycol with about 50 ml 24% acetic acid. This resulted in a tiny

amount(1-2 ml perhaps) of something that is not miscible with the rest and floats on top, like an oil. I can't even track down any info on ethylene

glycol diacetate's properties to check if it should be miscible with water/glycol so I'm very much stuck.

Any and all suggestions, tips and pointers would be very appreciated!

|

|

|

Pumukli

National Hazard

Posts: 705

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

It requires more than the most basic approach. :-)

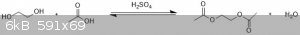

Concentrated acetic acid plus sulfuric acid.

The acetic acid should well be in molar excess, say 4 times compared to the glycol. A few milliliters sulfuric acid would be enough (at a 100 ml

scale). Requires refluxing for several hours. Then washing the water immiscible layer of the reaction mixture (ester) with dilute sodium hydrogen

carbonate solution, then with water, then drying the ester with anhydrous Na2SO4, or MgSO4, then filtering, then distillation.

Well, this is a fairly basic approach for an ester synth.

Maybe there's an easier method, I didn't check.

|

|

|

DavidJR

National Hazard

Posts: 908

Registered: 1-1-2018

Location: Scotland

Member Is Offline

Mood: Tired

|

|

24% acetic acid is definitely not going to cut it for an esterification. You need to eliminate water. Use glacial acetic acid and a strong acid

catalyst, and then reflux.

|

|

|

TheMrbunGee

Hazard to Others

Posts: 364

Registered: 13-7-2016

Location: EU

Member Is Offline

Mood: Phosphorising

|

|

Quote: Originally posted by DavidJR  | | 24% acetic acid is definitely not going to cut it for an esterification. You need to eliminate water. Use glacial acetic acid and a strong acid

catalyst, and then reflux. |

And you can concentrate yours by making acetate salt and distill with excess sulfuric acid.

|

|

|

Junk_Enginerd

Hazard to Others

Posts: 251

Registered: 26-5-2019

Location: Sweden

Member Is Offline

|

|

Quote: Originally posted by Pumukli  | It requires more than the most basic approach. :-)

Concentrated acetic acid plus sulfuric acid.

The acetic acid should well be in molar excess, say 4 times compared to the glycol. A few milliliters sulfuric acid would be enough (at a 100 ml

scale). Requires refluxing for several hours. Then washing the water immiscible layer of the reaction mixture (ester) with dilute sodium hydrogen

carbonate solution, then with water, then drying the ester with anhydrous Na2SO4, or MgSO4, then filtering, then distillation.

Well, this is a fairly basic approach for an ester synth.

Maybe there's an easier method, I didn't check. |

Nice, very thorough, thanks. But also... why?

Lol, in all seriousness, I'd be very happy if you would explain the reasoning behind these steps. I think I have all the equipment necessary with some

MacGyvering, and all the chemicals as well. I need very little of the ester, something like 2% of the final mix, so a little goes a log way.

So I gather that we're eliminating any and all water what with the glacial acetic acid and sulfuric acid.

And exactly what does refluxing entail here? I'm familiar with refluxing from alcohol distillation as a means to isolate a particular temperature

fraction, but when you say "for several hours" it doesn't sound like the goal is to actually extract anything in this stage. Is it only to keep

temperature at an absolute maximum?

And sodium carbonate washing is to remove the acids used to make it I presume, but why? If there's acid remaining, seems to me washing it with

carbonate would leave a base instead?

Is the super thorough drying necessary because of hydrolysis? I've gathered that's what makes it function in the application. It slowly hydrolyses to

acid which drops the PH of the silicate and makes it gel. Would CaCl2 suffice? I've got a 25 kg bag of that, but not MgSO4 nor Na2SO4, though I

suppose either should be super simple to make from FeSO4(which is the most readily available sulfate I possess) with either NaOH or MgCl?

I suppose my initial experiment was sort of a success after all then? The immiscible layer is ethylene glycol diacetate?

|

|

|

DavidJR

National Hazard

Posts: 908

Registered: 1-1-2018

Location: Scotland

Member Is Offline

Mood: Tired

|

|

Quote: Originally posted by Junk_Enginerd  |

So I gather that we're eliminating any and all water what with the glacial acetic acid and sulfuric acid.

And exactly what does refluxing entail here? I'm familiar with refluxing from alcohol distillation as a means to isolate a particular temperature

fraction, but when you say "for several hours" it doesn't sound like the goal is to actually extract anything in this stage. Is it only to keep

temperature at an absolute maximum?

|

Reflux = maintaining at/near boiling with the use of a condenser to avoid evaporative losses.

Usually esterifications with an alcohol and carboxylic acid don't really proceed at a noticeable rate at room temperature. The rate of reaction will

increase with temperature. So, the boiling point is as good as you can get without a pressure vessel of some kind.

Quote: Originally posted by Junk_Enginerd  |

And sodium carbonate washing is to remove the acids used to make it I presume, but why? If there's acid remaining, seems to me washing it with

carbonate would leave a base instead?

|

Yes, it's to neutralize the remaining acids and form water-soluble salts that are washed out. Acetic acid is probably pretty soluble in your target

ester, but salts will not be.

Not only would excess acid be an impurity, it would also catalyse the hydrolysis of the product meaning it would be less shelf-stable.

Quote: Originally posted by Junk_Enginerd  |

Is the super thorough drying necessary because of hydrolysis? I've gathered that's what makes it function in the application. It slowly hydrolyses to

acid which drops the PH of the silicate and makes it gel. Would CaCl2 suffice? I've got a 25 kg bag of that, but not MgSO4 nor Na2SO4, though I

suppose either should be super simple to make from FeSO4(which is the most readily available sulfate I possess) with either NaOH or MgCl?

|

Calcium chloride isn't compatible with esters.

|

|

|

Hexavalent

International Hazard

Posts: 1564

Registered: 29-12-2011

Location: Wales, UK

Member Is Offline

Mood: Pericyclic

|

|

Quote: Originally posted by Junk_Enginerd  |

So I gather that we're eliminating any and all water what with the glacial acetic acid and sulfuric acid.

And exactly what does refluxing entail here? I'm familiar with refluxing from alcohol distillation as a means to isolate a particular temperature

fraction, but when you say "for several hours" it doesn't sound like the goal is to actually extract anything in this stage. Is it only to keep

temperature at an absolute maximum?

And sodium carbonate washing is to remove the acids used to make it I presume, but why? If there's acid remaining, seems to me washing it with

carbonate would leave a base instead?

Is the super thorough drying necessary because of hydrolysis? I've gathered that's what makes it function in the application. It slowly hydrolyses to

acid which drops the PH of the silicate and makes it gel. Would CaCl2 suffice? I've got a 25 kg bag of that, but not MgSO4 nor Na2SO4, though I

suppose either should be super simple to make from FeSO4(which is the most readily available sulfate I possess) with either NaOH or MgCl?

I suppose my initial experiment was sort of a success after all then? The immiscible layer is ethylene glycol diacetate? |

The immiscible layer you saw is likely to be a small quantity of your desired di-ester.

Fischer-Speier esterifications involve an equilibrium between the reactant acid/alcohol and the product ester/water. According to Le Chatelier's

principle, an excess of water in the initial mixture promotes the reverse reaction (viz ester hydrolysis) and will severely limit your yield.

The concentrated sulfuric acid serves two purposes; firstly as a catalyst, protonating the carboxylic acid carbonyl which facilitates nucleophilic

attack of the alcohol, and secondly to sequester some of the water produced during each esterification reaction. Sadly sulfuric acid also catalyses

the reverse reaction hence the removal of water is important.

Refluxing the reaction mixture here is exactly what you suggested: maximising the temperature of the reaction without loss of any volatile components.

Washing the organic layer during workup with aqueous base deprotonates any remaining acid. The resultant charged anion is much more soluble in water

than in the organic phase and so is removed from the desired product.

The distillation of dilute acetic acid and direct preparation of glacial acetic acid has been discussed extensively on the forum.

Overall, your best bet would be to work from glacial acetic acid. Use a large excess compared to the diol, and if possible, have means of water

removal during the reaction (Dean-Stark, molecular sieves, etc.).

It goes without saying that glacial acetic acid and sulfuric acid are both corrosive. Acetic acid vapours are hazardous and unpleasant. Ethylene

glycol is metabolised to oxalic acid in the body and so has moderate oral toxicity. I don't mean to discourage you but I strongly suggest you gain

some familiarity with fundamental theoretical and experimental chemistry before attempting these processes.

[Edited on 16-9-2019 by Hexavalent]

"Success is going from failure to failure without loss of enthusiasm." Winston Churchill

|

|

|

Junk_Enginerd

Hazard to Others

Posts: 251

Registered: 26-5-2019

Location: Sweden

Member Is Offline

|

|

Quote: Originally posted by DavidJR  |

Reflux = maintaining at/near boiling with the use of a condenser to avoid evaporative losses.

Usually esterifications with an alcohol and carboxylic acid don't really proceed at a noticeable rate at room temperature. The rate of reaction will

increase with temperature. So, the boiling point is as good as you can get without a pressure vessel of some kind.

|

I see. So refluxing in this context could theoretically being as simple as boiling with a lid, or even in a pressure cooker? I mean, I'd probably use

a cooled column regardless, just trying to understand it better.

Quote: Originally posted by DavidJR  |

Yes, it's to neutralize the remaining acids and form water-soluble salts that are washed out. Acetic acid is probably pretty soluble in your target

ester, but salts will not be.

Not only would excess acid be an impurity, it would also catalyse the hydrolysis of the product meaning it would be less shelf-stable.

|

Ah, I see. Thanks.

Noted, and thank you.

Oh yay, I successfully idiot'd it!

Quote: Originally posted by Hexavalent  |

Fischer-Speier esterifications involve an equilibrium between the reactant acid/alcohol and the product ester/water. According to Le Chatelier's

principle, an excess of water in the initial mixture promotes the reverse reaction (viz ester hydrolysis) and will severely limit your yield.

|

Good lord that's a lot of names and terms I know nothing about. Though I do know the ester hydrolyses, as it is a core mechanism in the way it's

expected to work in the final silicate mix, so it makes sense of course that water in the mixture will ruin things a little. Is there some sort of

equilibrium that is reached after a while or what? The mix with a small amount of ester I have standing now seems stable enough, and it did form to

begin with, so I assume that something is currently stopping the hydrolysis?

Quote: Originally posted by Hexavalent  |

The concentrated sulfuric acid serves two purposes; firstly as a catalyst, protonating the carboxylic acid carbonyl which facilitates nucleophilic

attack of the alcohol, and secondly to sequester some of the water produced during each esterification reaction. Sadly sulfuric acid also catalyses

the reverse reaction hence the removal of water is important.

|

Ah, so in "laymans terms" I suppose one could say it acidifies my weak acetic acid using a strong acid? For this purpose then, most strong acids would

suffice? Of course it wouldn't be dehydrating like sulfuric acid which is also desired, so clearly sulfuric acid is a good candidate.

Quote: Originally posted by Hexavalent  |

Refluxing the reaction mixture here is exactly what you suggested: maximising the temperature of the reaction without loss of any volatile components.

|

So as I mentioned above then, boiling with a lid is essentially the same, and using a simple pressure cooker would be taking it one step further?

Quote: Originally posted by Hexavalent  |

Washing the organic layer during workup with aqueous base deprotonates any remaining acid. The resultant charged anion is much more soluble in water

than in the organic phase and so is removed from the desired product.

|

Ah. Makes sense. Thanks.

Quote: Originally posted by Hexavalent  |

The distillation of dilute acetic acid and direct preparation of glacial acetic acid has been discussed extensively on the forum.

Overall, your best bet would be to work from glacial acetic acid. Use a large excess compared to the diol, and if possible, have means of water

removal during the reaction (Dean-Stark, molecular sieves, etc.).

|

I've been wanting to try that anyways so it'll be an interesting step. Seems like going the acetic salt route is the most convenient route, but I

doubt that'll be an issue regardless.

Quote: Originally posted by Hexavalent  |

It goes without saying that glacial acetic acid and sulfuric acid are both corrosive. Acetic acid vapours are hazardous and unpleasant. Ethylene

glycol is metabolised to oxalic acid in the body and so has moderate oral toxicity. I don't mean to discourage you but I strongly suggest you gain

some familiarity with fundamental theoretical and experimental chemistry before attempting these processes.

[Edited on 16-9-2019 by Hexavalent] |

Of course. Not discouraged in the least, I do most of these types of things outdoors anyway. I've done quite a few processes involving NaOH, HCl,

HNO3, chlorine gas, NOx, H2S and I'm still alive and kicking, so I think a few acids will be manageable. Thanks for the heads up.

[Edited on 17-9-2019 by Junk_Enginerd]

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

If the ester is seperating from the reaction, it can be seperated in order to push the reaction to completion right? Probably not to completion but at

least to the point where the concentration of ester becomes so low it stops separating.

No need for concentrated acid in that case.

|

|

|

Pumukli

National Hazard

Posts: 705

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

Btw. ethylene glycol is an unhealthy compound. If you would touch it or its ester from time to time when dealing with the molds it might be better if

you used 1,2-propylene-glycol, which is much less of a concern.

|

|

|

Herr Haber

International Hazard

Posts: 1236

Registered: 29-1-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Pumukli  | Btw. ethylene glycol is an unhealthy compound. If you would touch it or its ester from time to time when dealing with the molds it might be better if

you used 1,2-propylene-glycol, which is much less of a concern.

|

I dont know if there is a ban in the UK but APC pure doesnt seem to be carying ethylene glycol anymore and have the diacetate instead.

The spirit of adventure was upon me. Having nitric acid and copper, I had only to learn what the words 'act upon' meant. - Ira Remsen

|

|

|

RedDwarf

Hazard to Others

Posts: 166

Registered: 16-2-2019

Location: UK (North West)

Member Is Offline

Mood: Variable

|

|

Quote: Originally posted by Pumukli  | Btw. ethylene glycol is an unhealthy compound. If you would touch it or its ester from time to time when dealing with the molds it might be better if

you used 1,2-propylene-glycol, which is much less of a concern.

|

I think you're rather overplaying the toxicity of Ethylene Glycol in normal usage. It's poisonous if taken orally and because it has a sweet taste

(allegedly - I've never knowingly tried it, although I was climbing and drinking cheap wine in Austria at the time of the wine contamination scandal),

it is seen as a risk for children or when added deliberately to other foods/drinks.

I've never seen anything about it being absorbed through the skin and based on the number of car mechanics who must have spilled the stuff over the

years I think it's unlikely to be an issue. Just don't go sucking your fingers after using it or chewing on lumps of green sand (but you probably

weren't going to do either).

|

|

|

Junk_Enginerd

Hazard to Others

Posts: 251

Registered: 26-5-2019

Location: Sweden

Member Is Offline

|

|

Quote: Originally posted by Tsjerk  | If the ester is seperating from the reaction, it can be seperated in order to push the reaction to completion right? Probably not to completion but at

least to the point where the concentration of ester becomes so low it stops separating.

No need for concentrated acid in that case. |

That's an intriguing point... Right now the layer is a little too thin to reliably separate with a syringe or similar methods. I guess a tall and

narrow container would help in that case.

Ohh, one could have a tall narrow container, and inject more liquid from the bottom to make it overflow and just keep skimming off the top...

Well, this is simple to attempt. I've got the mixture standing so I could just see if more forms upon removal.

Quote: Originally posted by Pumukli  | Btw. ethylene glycol is an unhealthy compound. If you would touch it or its ester from time to time when dealing with the molds it might be better if

you used 1,2-propylene-glycol, which is much less of a concern.

|

I've surely had worse. Besides, I don't want to touch the sodium silicate with any kind of bare skin regardless. That shit is mean on your hands.

Quote: Originally posted by Herr Haber  |

I dont know if there is a ban in the UK but APC pure doesnt seem to be carying ethylene glycol anymore and have the diacetate instead.

|

Ethylene glycol is just normal antifreeze though, right? The red kind, used in more modern engines.

[Edited on 17-9-2019 by Junk_Enginerd]

|

|

|

wg48temp9

National Hazard

Posts: 783

Registered: 30-12-2018

Location: not so United Kingdom

Member Is Offline

|

|

Quote: Originally posted by Junk_Enginerd  |

I want to make or otherwise acquire ethylene glycol diacetate, or diacetin, whichever is easiest.

The intent is to use it for self hardening/curing sodium silicate/sand mixes for making metal casting molds. If anyone knows of any other ester or

acid that can perform the same job that'd be much appreciated too.

|

Usually CO2 gas is used to harden sodium silicate/sand mixtures. More accurately it carbonic acid produced when the CO2 dissolves in the water of damp

silicate/sand mixture. I don't think the ester you want would work or if it does it would take a long time compared to the CO2 method. Why do you

think it would?

I am wg48 but not on my usual pc hence the temp handle.

Thank goodness for Fleming and the fungi.

Old codger' lives matters, wear a mask and help save them.

Be aware of demagoguery, keep your frontal lobes fully engaged.

I don't know who invented mRNA vaccines but they should get a fancy medal and I hope they made a shed load of money from it.

|

|

|

Junk_Enginerd

Hazard to Others

Posts: 251

Registered: 26-5-2019

Location: Sweden

Member Is Offline

|

|

Quote: Originally posted by wg48temp9  |

Usually CO2 gas is used to harden sodium silicate/sand mixtures. More accurately it carbonic acid produced when the CO2 dissolves in the water of damp

silicate/sand mixture. I don't think the ester you want would work or if it does it would take a long time compared to the CO2 method. Why do you

think it would? |

It is indeed. But I'm looking for alternatives. Part of the reason is that it can get a little unweildy with bigger molds, and I've had wildly varying

results for reasons I don't understand. Sometimes it hardens perfectly, sometimes it doesn't at all, and sometimes it hardens but then it starts

getting crumbly again for no apparent reason.

The other reason is I'm pretty passionate about science and engineering just for the sake of it, and I want to explore any and all possible options.

Because I can, I guess. =)

I stumbled across this patent. For a patent, it's quite easy to follow, and I think the numbers speak for themselves.

Why do you think it would not work? The logic checks out for me. The ester hydrolyses when it comes in contact with the water in the sodium silicate

solution, which should mean it releases an acid over time. A delayed release acid is the perfect thing to harden a sodium silicate mix.

According to the patent, depending on which glycol acetate is used, and the concentrations of them, the mix can be made to harden in anywhere from 10

minutes to several hours. As such, all I would need to do is mix sand, silicate solution, and some ester, make my mold, and then just put it somewhere

for a short time and it's done. It sounds super convenient to me.

I gave it some more thought and I guess there's no reason quite a few other esters would probably work too. Based on the suggestions I got here, and

due to the fact that my acetic acid ran out, I thought I'd try it with oxalic acid. It's quite closely related to acetic acid, so it should behave

similarly. It also happens to be commonly sold as a solid, so no need to bother with driving out any water.

I mixed glycol and oxalic acid powder, and added some NaHSO4 to perhaps act somewhat as the sulfuric acid recommended earlier, part strong acid and

part dehydrating. Since the glycol is very viscous without all that water in it, it's not very easy to tell how it's gone so far. Most of the ester

still is yet to sequester, and it's quite cloudy, but as far as I can tell it's produced a lot more immiscible liquid this time around.

|

|

|

wg48temp9

National Hazard

Posts: 783

Registered: 30-12-2018

Location: not so United Kingdom

Member Is Offline

|

|

Quote: Originally posted by Junk_Enginerd  |

I stumbled across this patent. For a patent, it's quite easy to follow, and I think the numbers speak for themselves.

Why do you think it would not work? The logic checks out for me. The ester hydrolyses when it comes in contact with the water in the sodium silicate

solution, which should mean it releases an acid over time. A delayed release acid is the perfect thing to harden a sodium silicate mix.

According to the patent, depending on which glycol acetate is used, and the concentrations of them, the mix can be made to harden in anywhere from 10

minutes to several hours. As such, all I would need to do is mix sand, silicate solution, and some ester, make my mold, and then just put it somewhere

for a short time and it's done. It sounds super convenient to me.

I gave it some more thought and I guess there's no reason quite a few other esters would probably work too. Based on the suggestions I got here, and

due to the fact that my acetic acid ran out, I thought I'd try it with oxalic acid. It's quite closely related to acetic acid, so it should behave

similarly. It also happens to be commonly sold as a solid, so no need to bother with driving out any water.

I mixed glycol and oxalic acid powder, and added some NaHSO4 to perhaps act somewhat as the sulfuric acid recommended earlier, part strong acid and

part dehydrating. Since the glycol is very viscous without all that water in it, it's not very easy to tell how it's gone so far. Most of the ester

still is yet to sequester, and it's quite cloudy, but as far as I can tell it's produced a lot more immiscible liquid this time around.

|

I thought it would not work because an ester would not be sufficiently acidic to convert the liquid sodium silicate to semi-solid to silica gel.

I did think that the sodium silicate might hydrolysis the ester eventually and released acid would produce the silica gel but at room temperature I

thought the hydrolysis would be very very slow.

Surprisingly that is not the case judging from your reference.

Note: Oxalic acid is frequently obtained as hydrate which would have to be dried before using it in the formation of an ester.

PS: I wounder if your ester could be used in chemical garden to gel the garden after it has formed to preserve it.

[Edited on 9/18/2019 by wg48temp9]

I am wg48 but not on my usual pc hence the temp handle.

Thank goodness for Fleming and the fungi.

Old codger' lives matters, wear a mask and help save them.

Be aware of demagoguery, keep your frontal lobes fully engaged.

I don't know who invented mRNA vaccines but they should get a fancy medal and I hope they made a shed load of money from it.

|

|

|

wg48temp9

National Hazard

Posts: 783

Registered: 30-12-2018

Location: not so United Kingdom

Member Is Offline

|

|

I searched for the hydrolysis rates of esters in the presence of alkali but was unable to find anything or find anything I could understand so I can

not give an estimate for the rate.

But I did remember that ethylene glycol reacts with silica so perhaps that reaction is part of the mechanism and or contributes to the hydrolysis of

the ester.

See https://pubs.acs.org/doi/pdf/10.1021/ja001885h

"Silica (SiO2) is found to react readily with ethylene glycol (EGH2) to form neutral glycoxysilanes in the presence of catalytic amounts of

high-boiling organic amines, such as triethylenetetramine (TETA), trishydroxymethyleneaminomethane [H2NC(CH2OH)3, THAMH3], and triethanolamine

[N(CH2CH2OH)3, TEAH3]"

That would explain the surface active agent which is also an amine.

It probably means the surface active agent (see the patent) you could use is triethanolamine which is available on ebay.

[Edited on 9/18/2019 by wg48temp9]

I am wg48 but not on my usual pc hence the temp handle.

Thank goodness for Fleming and the fungi.

Old codger' lives matters, wear a mask and help save them.

Be aware of demagoguery, keep your frontal lobes fully engaged.

I don't know who invented mRNA vaccines but they should get a fancy medal and I hope they made a shed load of money from it.

|

|

|

|